Acid making process and device adopting SO2 pre-reforming

A SO2, pre-conversion technology, used in sulfur dioxide/sulfurous acid, inorganic chemistry, sulfur compounds, etc., can solve problems such as catalyst over-temperature burning, and achieve the effect of good operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

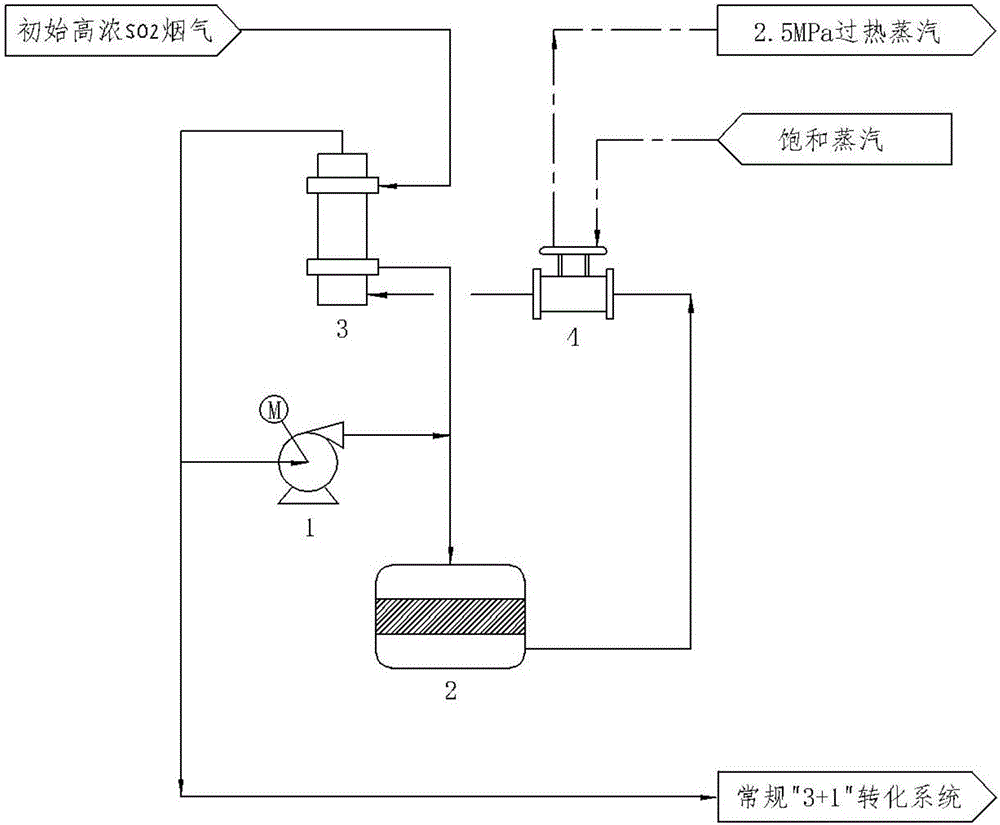

[0056] Embodiment 1 (without preabsorption device, such as figure 1 ):

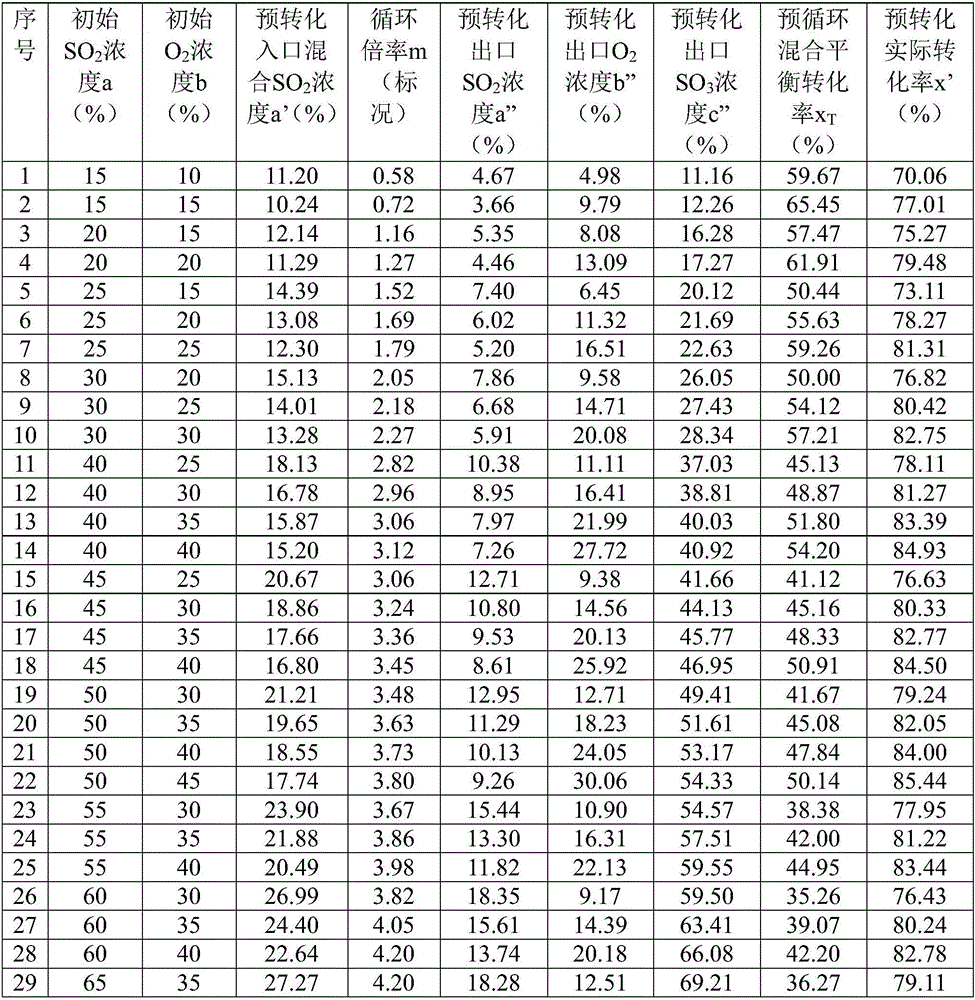

[0057] initial SO 2 The concentration is 65%, O 2 The flue gas with a concentration of 35% enters the pre-circulation heat exchanger, is heated by the high-temperature flue gas at about 500°C after passing through the steam superheater, and then combines with the SO2 sent by the pre-circulation fan. 3 The flue gas is mixed to about 400°C and enters the inlet of the pre-reformer together. SO of mixed flue gas 2 The concentration was reduced to 27.26%, SO 3 Concentration 55.9%, O 2 The concentration is 16.83%, and it enters the pre-reformer for equilibrium conversion reaction. The gas temperature at the outlet of the pre-reformer reaches about 610°C, the equilibrium conversion rate is 36.27%, and the SO in the flue gas 2 The concentration is 18.28%, SO 3 Concentration is 69.21%, O 2 The concentration is 12.5%. The pre-reformed high-temperature flue gas first enters the steam superheater to produce...

Embodiment 2

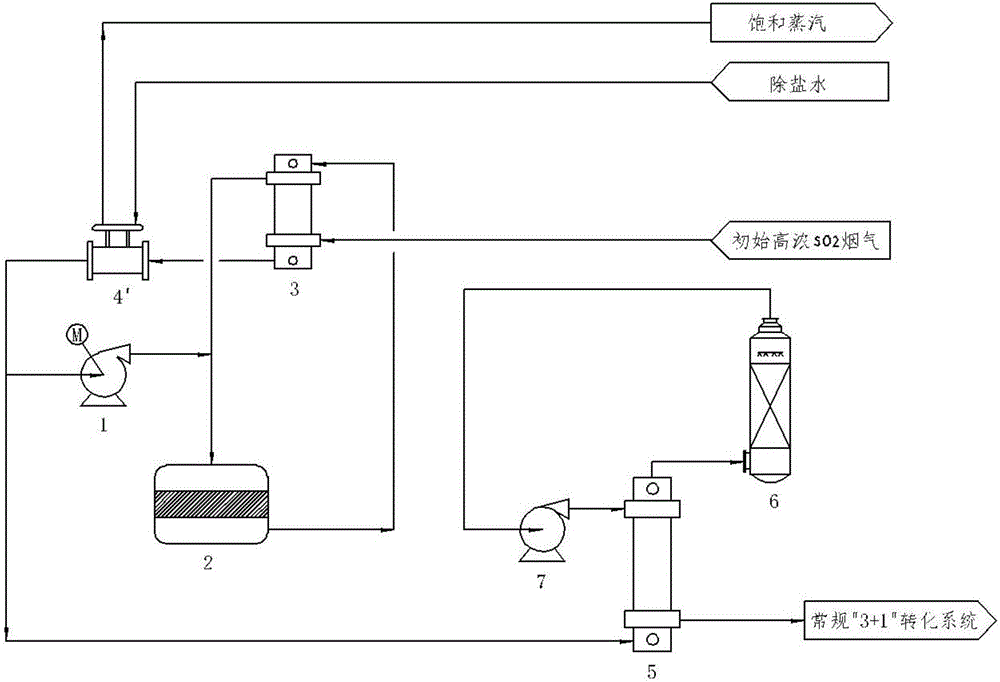

[0058] Embodiment 2 (has pre-absorption device, as figure 2 ):

[0059] initial SO 2 The concentration is 35%, O 2 The flue gas with a concentration of 35% enters the pre-circulation heat exchanger, is heated to 400°C by the high-temperature flue gas after pre-transformation, and then sends 400°C SO with the pre-circulation fan. 3 The flue gas is mixed and enters the pre-reformer together, and the mixed SO 2 The concentration was reduced to 14.24%, O 2 The concentration is 26.82%, SO 3 The concentration is 25.16%, the equilibrium conversion occurs when entering the pre-reformer, the temperature of the gas exiting the pre-reformer is 610°C, and the equilibrium conversion rate is 55.55%. Pre-reformed export SO 2 The concentration is 6.6%, O 2 Concentration is 23.8%, SO 3 The concentration is 34.43%. The converted high-temperature flue gas first enters the pre-circulation heat exchanger to heat the high-concentration SO 2 The gas reaches 400°C, and then enters the wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com