Variable timing system of engine valve

A technology of engine valves and timing systems, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of complex engine structure and high cost of use, and achieve simple structure, cost saving and good operation stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

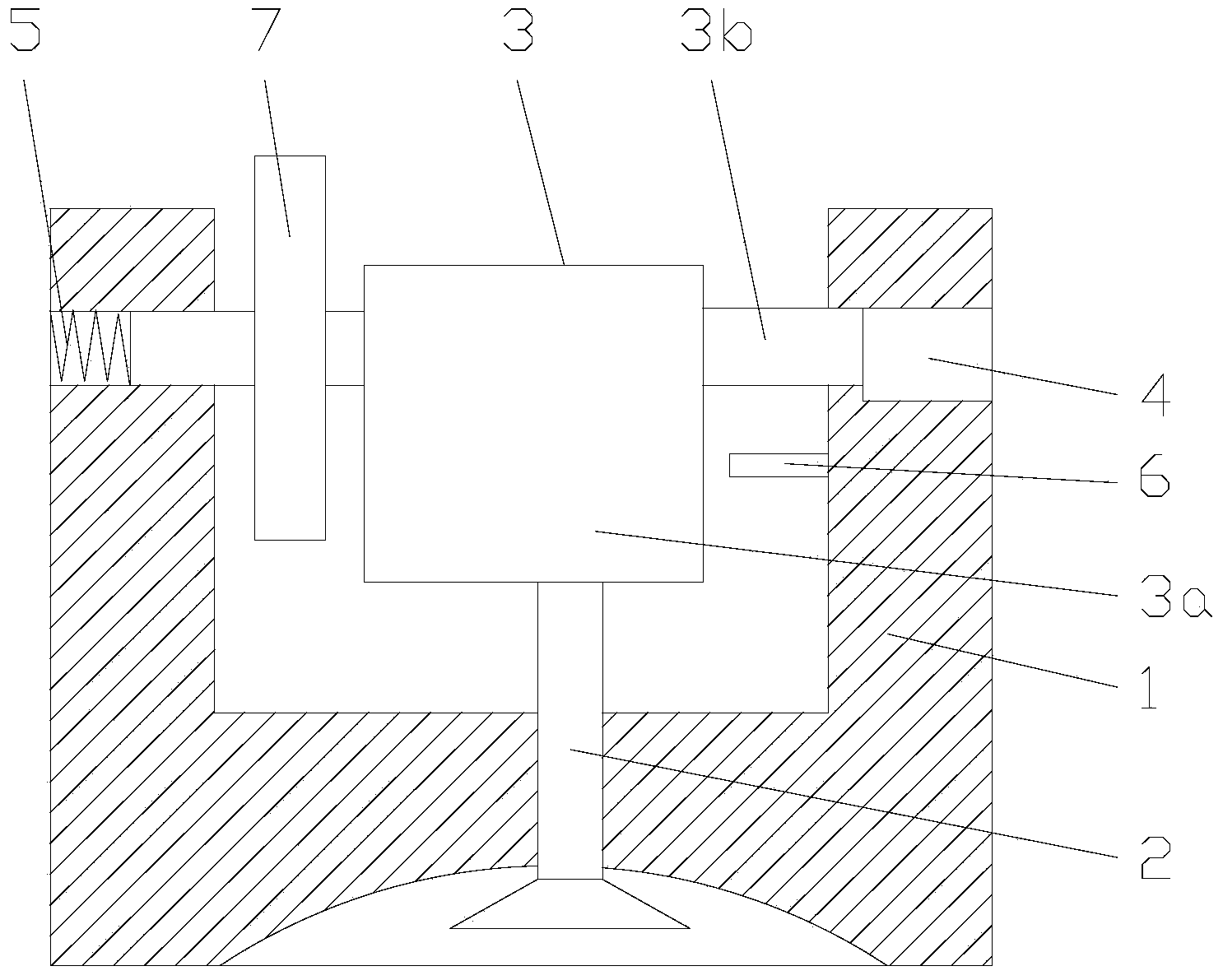

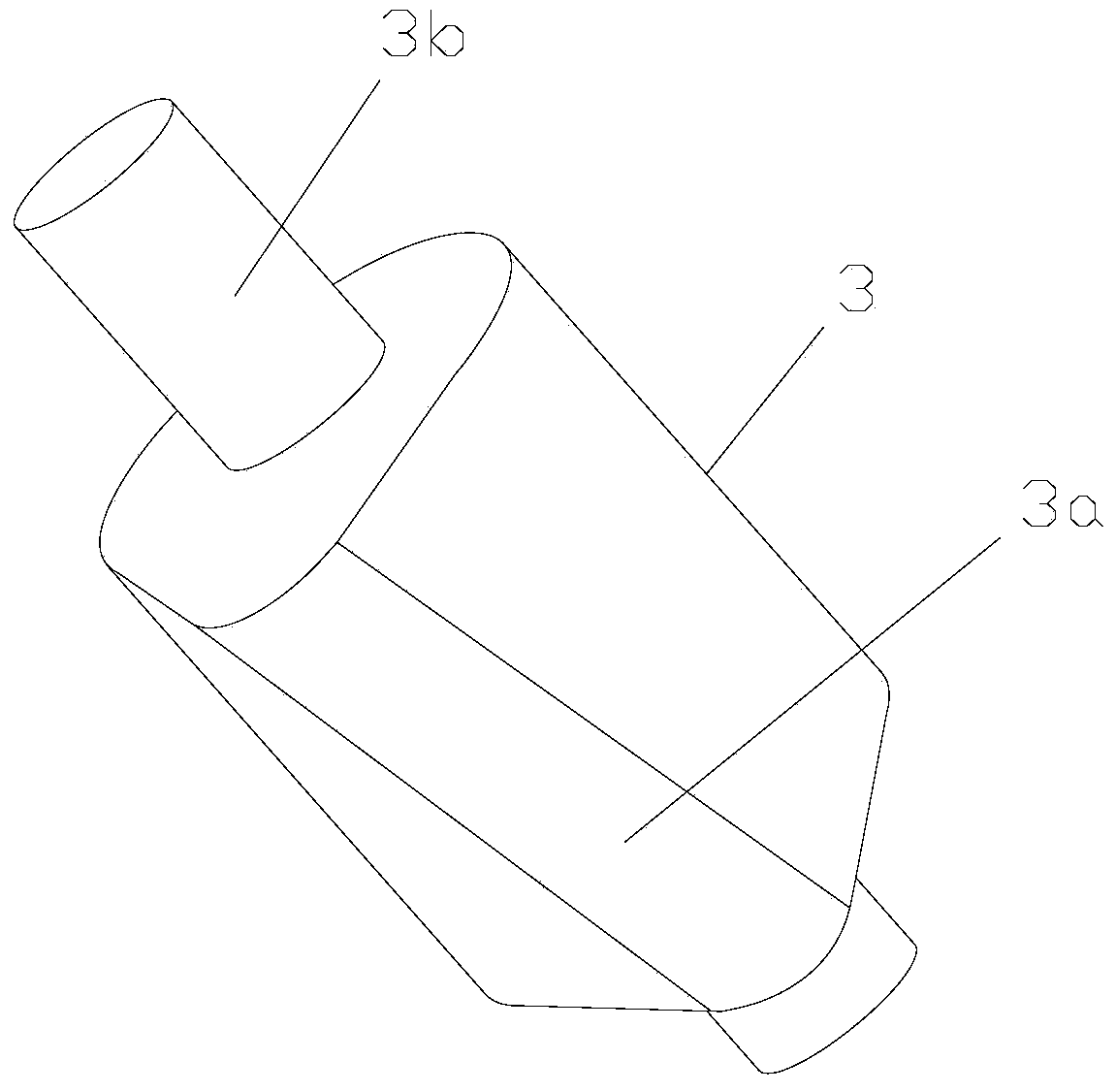

[0012] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the cam structure, as shown in the figure: the engine valve variable timing system of this embodiment includes a cylinder head 1, a valve 2, a cam 3 and a control mechanism; the valve 2 is arranged on the cylinder head 1 and controlled by the cam 3 driving movement; the cam 3 is rotatably connected to the cylinder head 1 in an axially slidable manner, and the projection of the convex portion 3a of the cam 3 along the axial direction of the cam 3 does not completely overlap; the control mechanism is connected to the cam 3 and the cylinder The cover 1 is used to drive the cam 3 to slide axially and to axially position the cam 3; the cam 3 is connected to the cylinder head 1 through its wheel shaft 3b in rotation and connected to the engine crankshaft through the timing chain and the sprocket 7, and then by The crankshaft drives the rotation, and the sprocket 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com