H-shaped steel robot submerged arc welding method

A technology of submerged arc welding and H-shaped steel, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of poor operation stability, insufficient efficiency, poor use effect, etc., achieve high welding efficiency, improve welding quality, and run good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

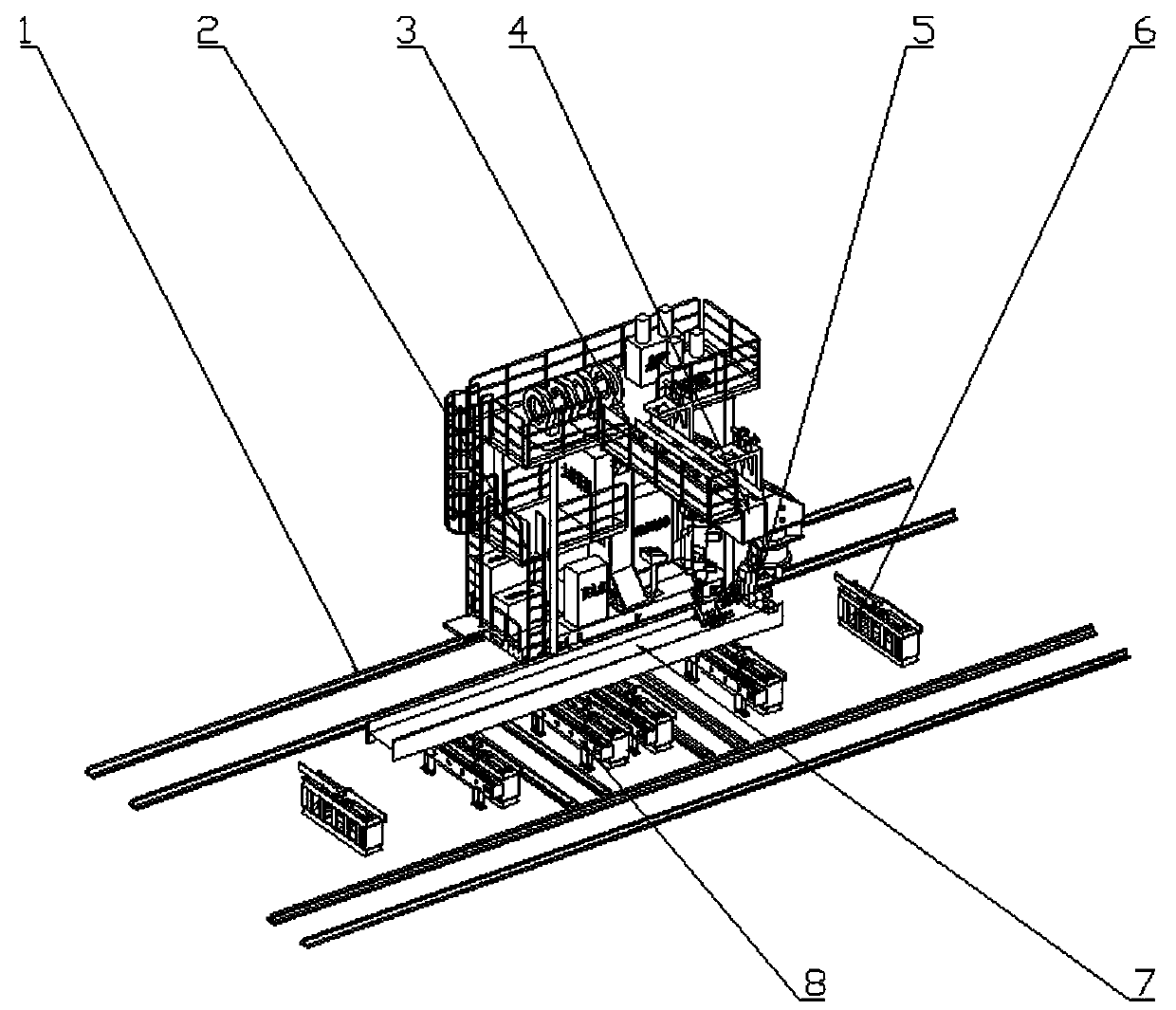

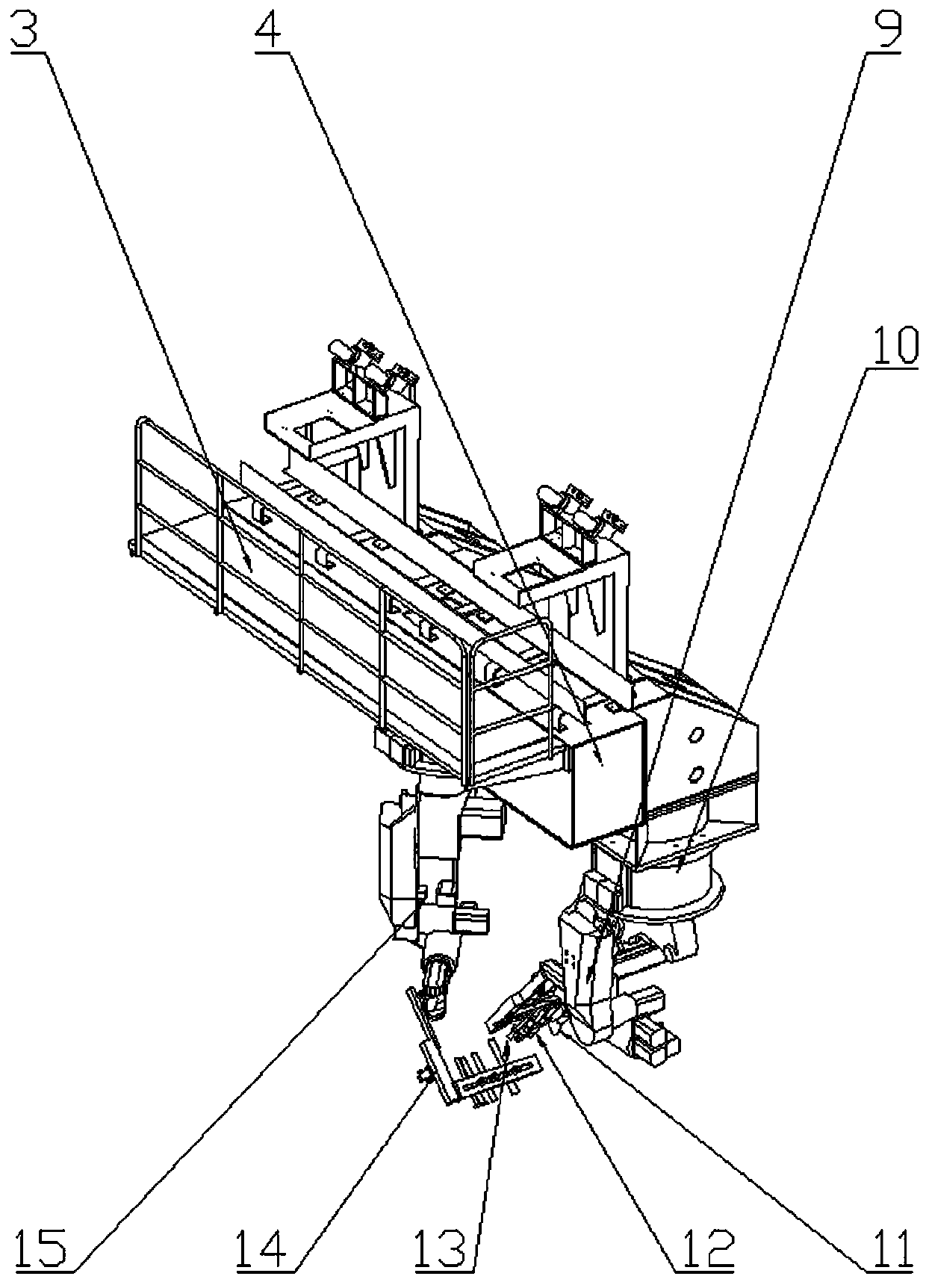

[0025] Example: such as Figure 1-4 Shown, a kind of H-beam robot submerged arc welding method comprises the following steps:

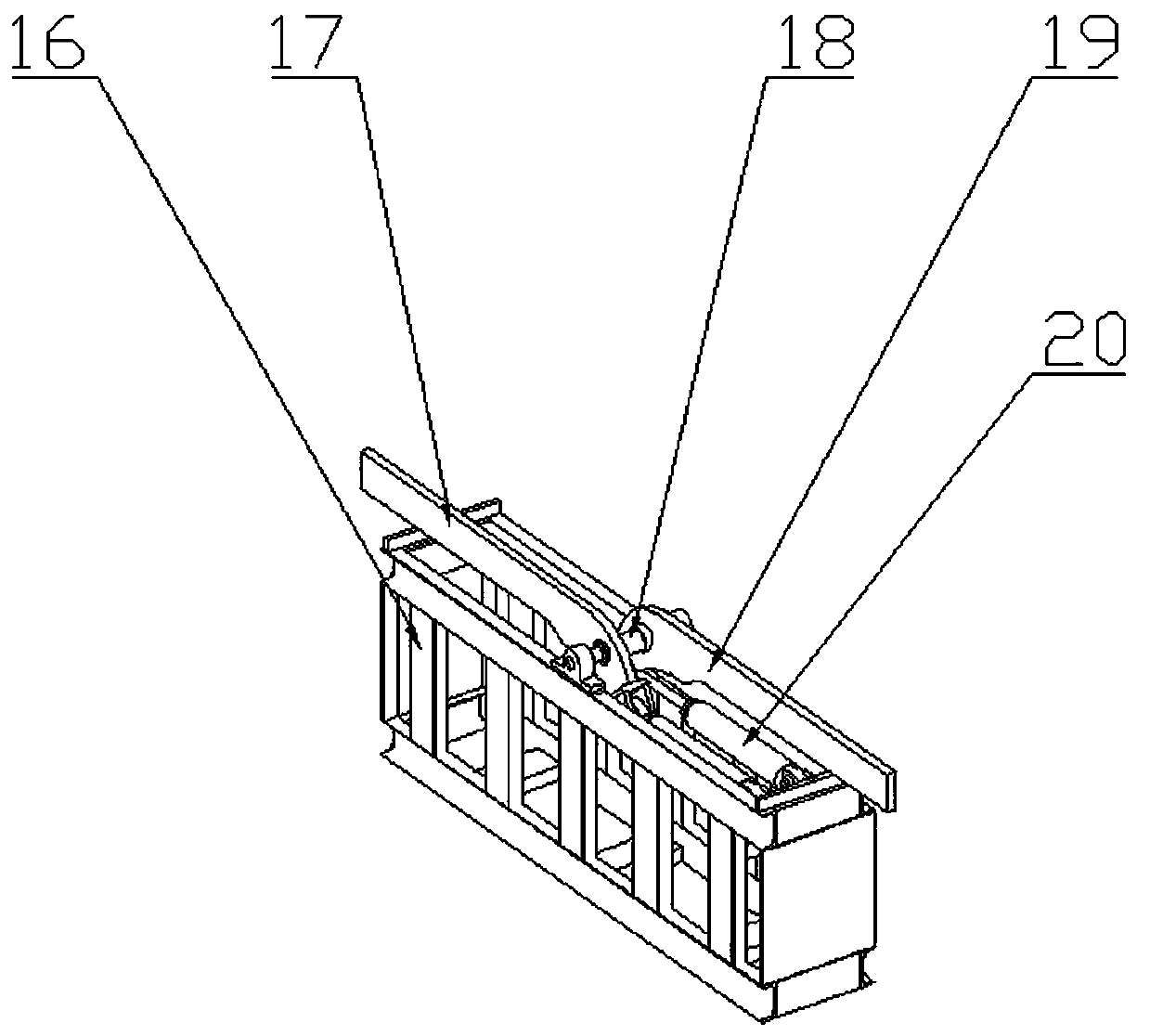

[0026] The first step: the assembled pre-welded H-shaped steel 7 is placed on the bidirectional turning assembly 6 by the RGV conveying trolley. When the main weld of the pre-welded H-shaped steel 7 is a groove weld, the bidirectional turning assembly 6 will pre-weld the H-shaped steel 7 Flip 45°. When the main weld seam of the pre-welded H-shaped steel 7 is non-groove welding, the pre-welded H-shaped steel 7 is placed flat on the bidirectional turning assembly 6 .

[0027] Step 2: After placing the pre-welded H-beam 7, the traveling gantry 2 moves along the traversing track 1 to the side of the pre-welded H-beam 7, and then welds the welder cross arm 4 on the extension platform 3 to drive the submerged arc welding robot 5 To the top of the pre-welded H-shaped steel 7.

[0028] Step 3: After completing the operation preparation process of the subme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com