Belt conveyor hopper with multiple built-in sweepers

A belt conveyor and sweeper technology, applied in the field of conveyors, can solve the problem of difficult cleaning of sticky materials, and achieve the effects of protecting health, preventing waste and increasing operating load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

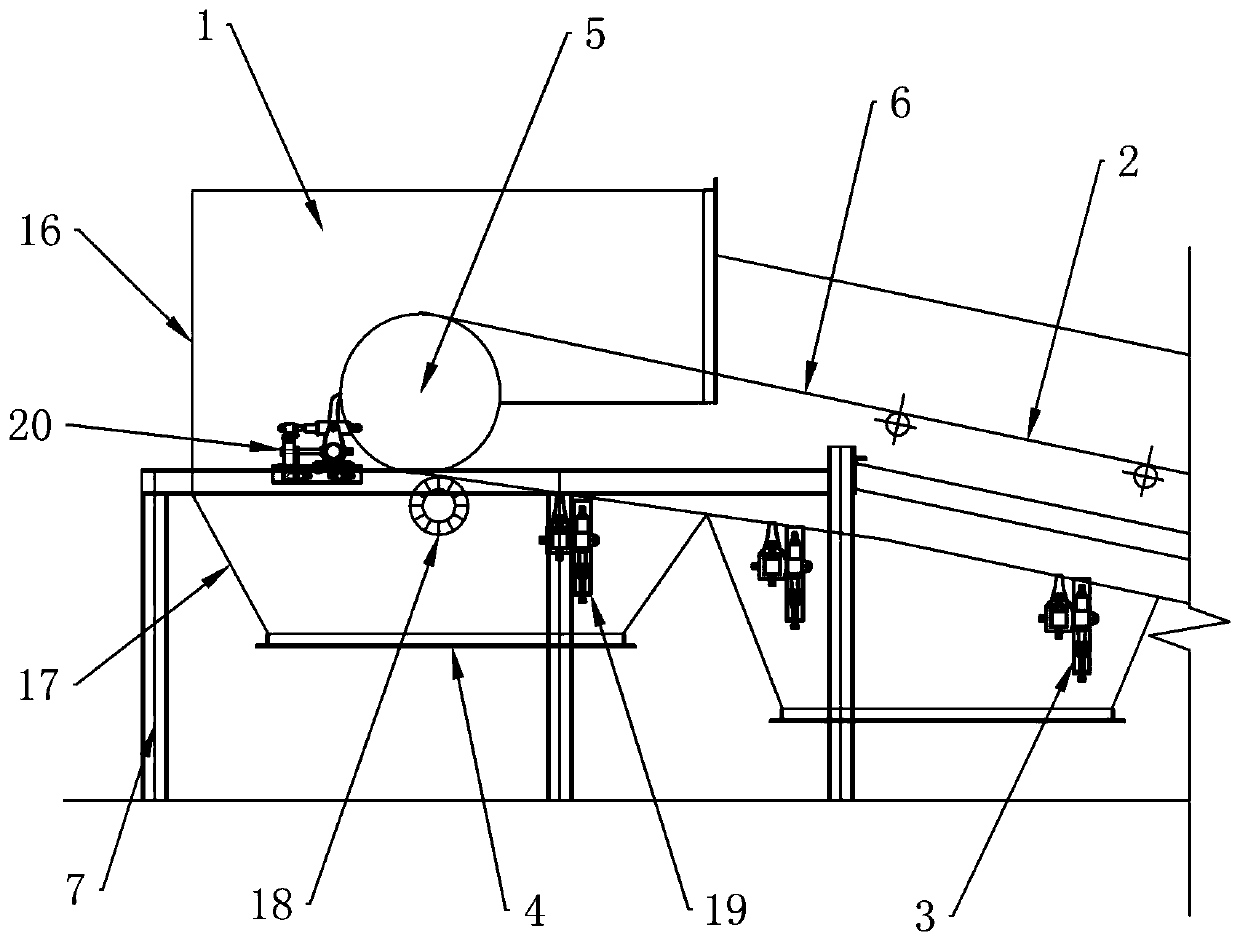

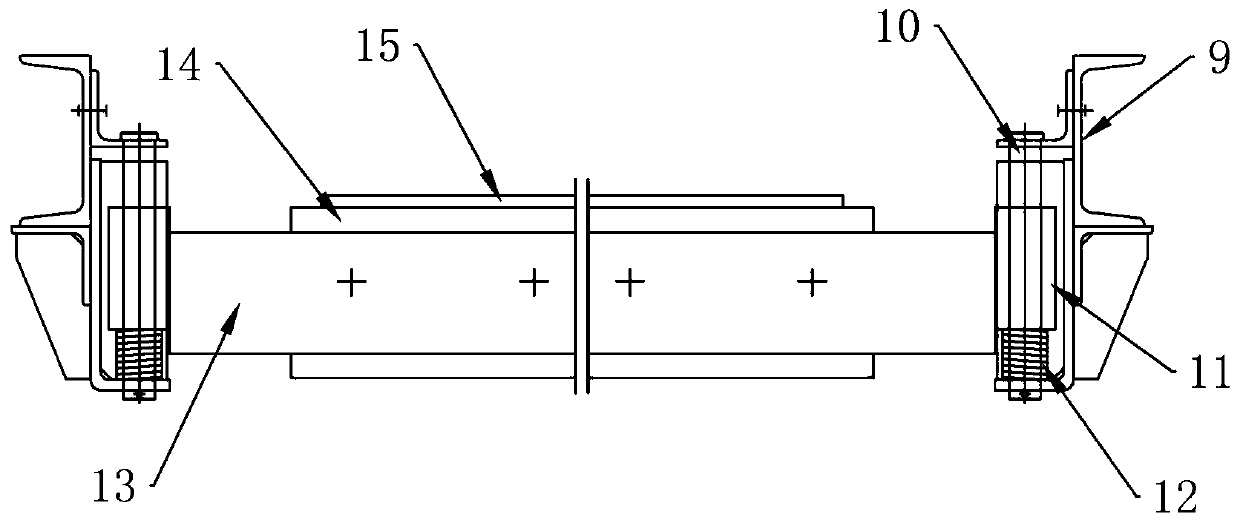

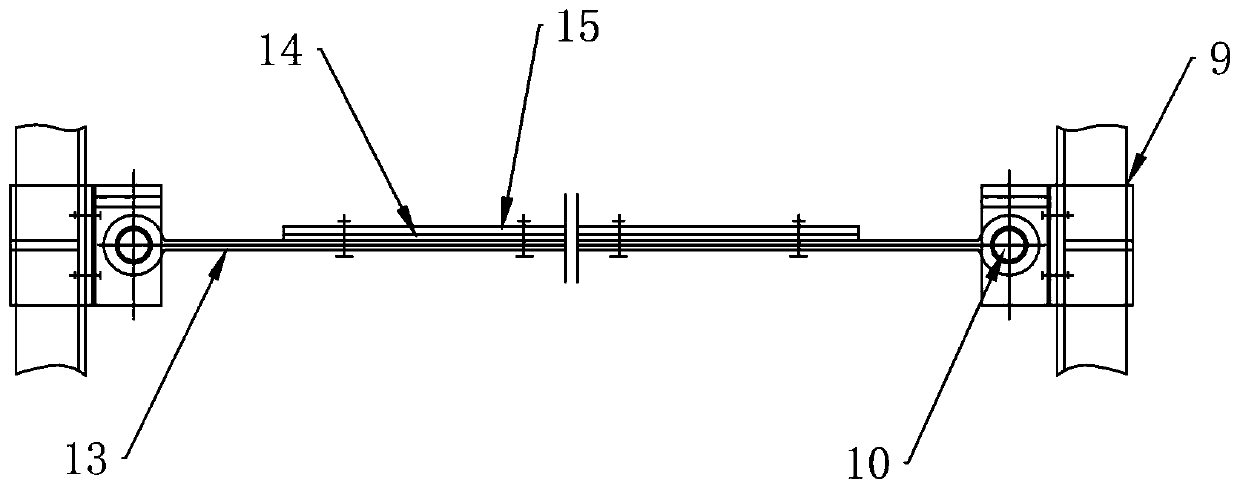

[0048] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 4 As shown, the belt conveyor funnel with a built-in multi-channel cleaner also includes: a reduction motor, which is connected to the head wheel 5 in transmission. Preferably, the reduction motor is arranged outside the funnel 1 .

[0049] In a further embodiment of the present invention, the funnel 1 includes a feed part 16 and a discharge part 17 connected to each other, the feed part 16 is arranged in a cuboid shape, and the discharge part 17 is arranged in an inverted cone shape.

[0050] In a further embodiment of the present invention, several funnels 1 are connected in turn, and belt conveyor 2 is arranged in several funnels 1, and the lower end of each funnel 1 is all provided with outlet 4, and head wheel 5 is positioned at a funnel 1, and this The side wall of a funnel 1 is provided with feed inlet. Preferably, the number of hoppers 1 can be set to one or more, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com