Wastewater treatment process based on combination of super magnetic separation and SBR (Styrene Butadiene Rubber) technique

A wastewater treatment and magnetic separation technology, which is applied in processing wastewater treatment, magnetic/electric field water/sewage treatment, water/sewage treatment, etc., can solve the problem of unsatisfactory COD treatment effect, substandard sewage treatment, large amount of chemical agents, etc. problem, to achieve good sensory effect of water discharge, good water discharge effect, and the effect of reducing microbial indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

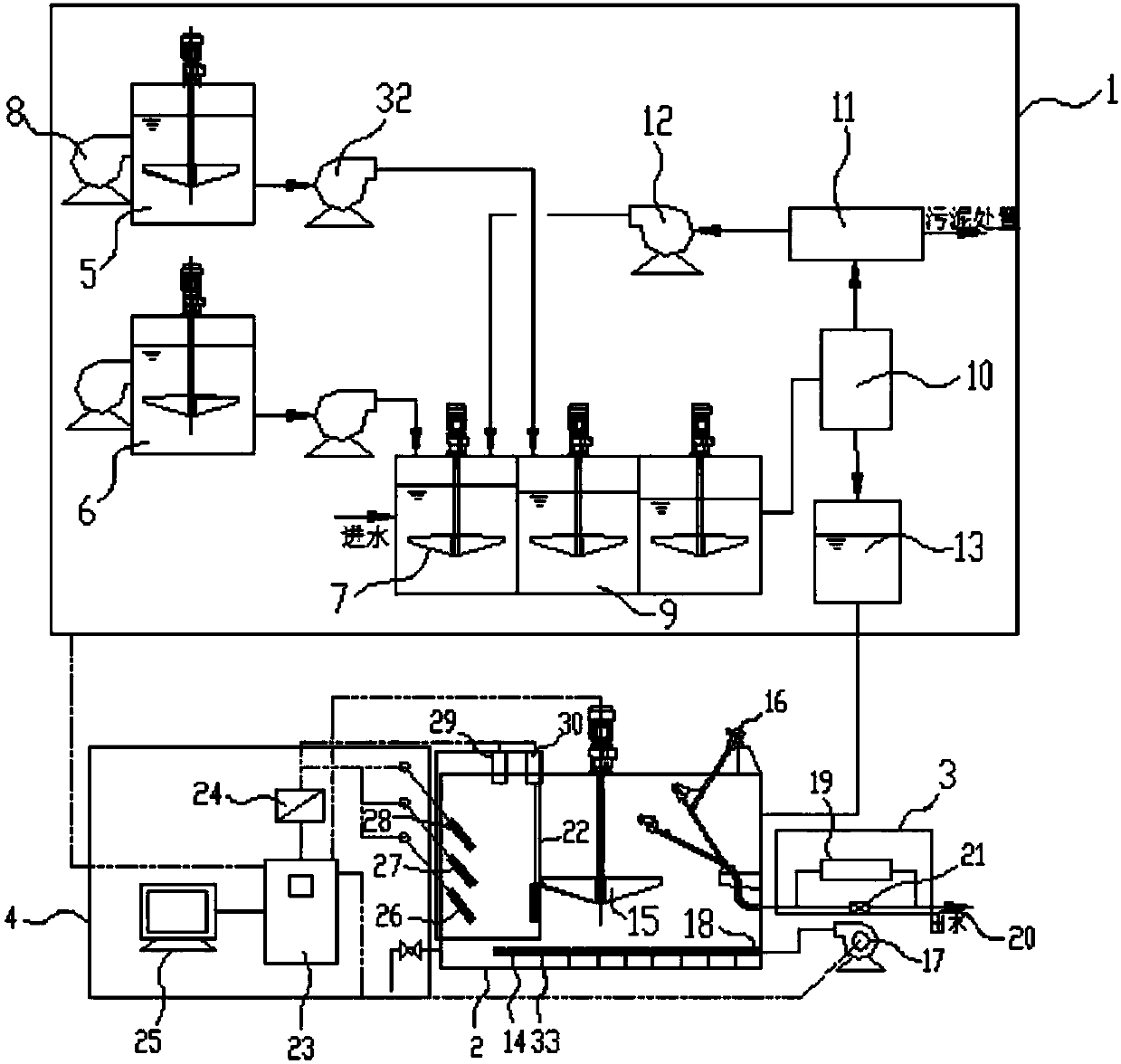

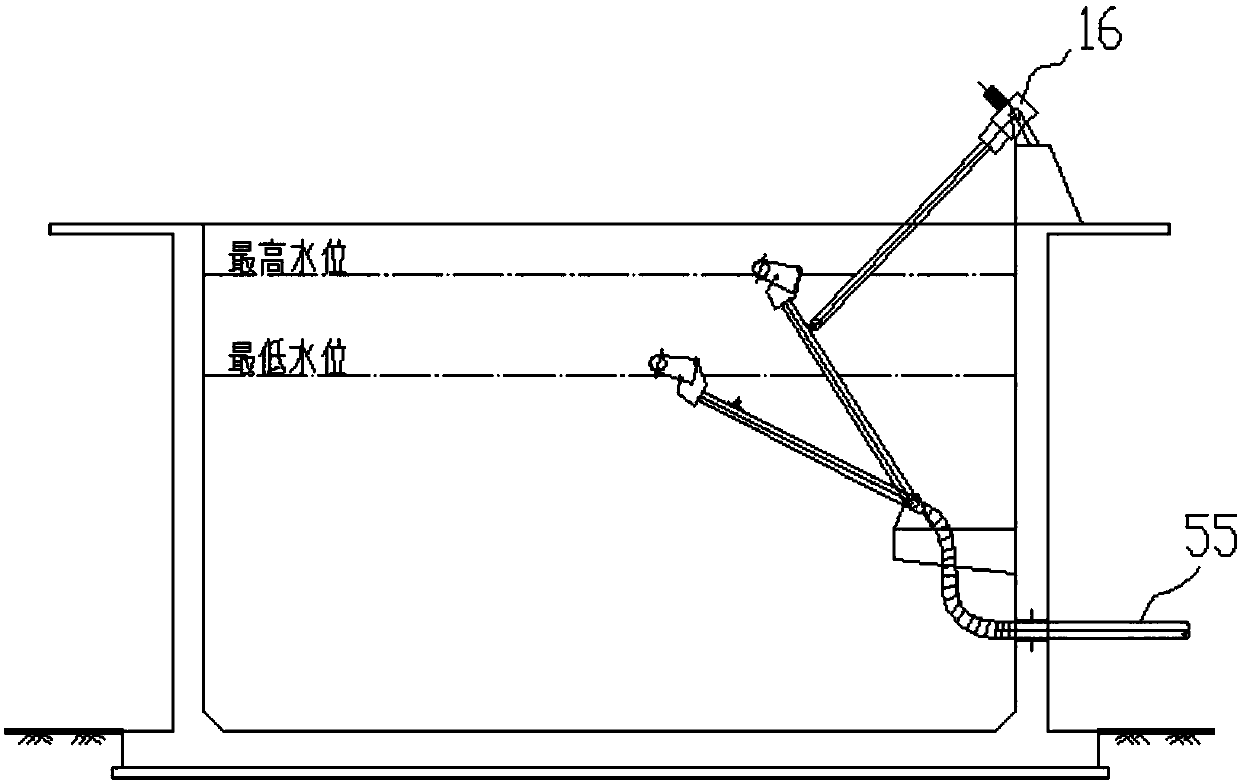

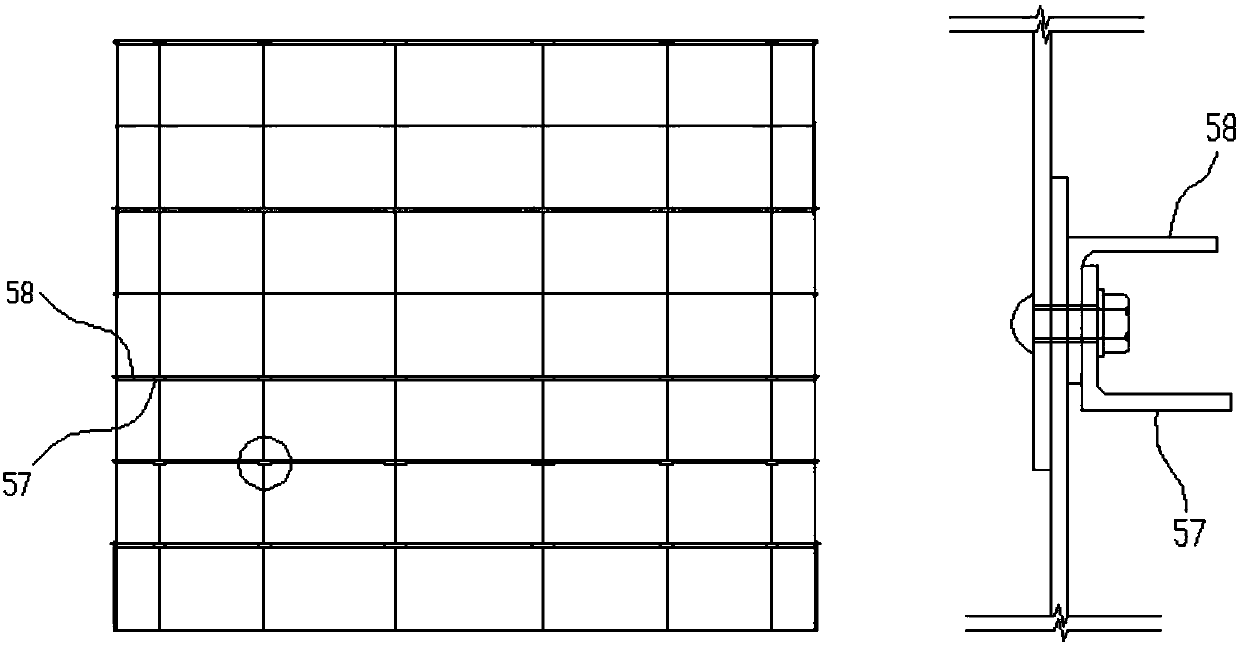

[0032] Such as Figure 1-9 As shown, the present invention provides a wastewater treatment process based on the combination of supermagnetic separation and SBR technology, including supermagnetic separation system 1, SBR system 2, ultraviolet disinfection system 3 and automatic control system 4, and automatic control system 4 is connected with supermagnetic separation system 1 , SBR system 2 and ultraviolet disinfection system 3, waste water is lifted to supermagnetic separation system 1 through pipeline pump, supermagnetic separation system 1 includes coagulation dosing tank 5, flocculation dosing tank 6, first mixer 7, dosing pump 8 , coagulation reactor 9, supermagnetic separator 10, magnetic seed recovery system 11, magnetic seed pump 12 and water outlet pool 13, PAC, magnetic seed and PAM are added in sequence in the coagulation reactor 9, and the PAC drug dissolving device includes The first drug-dissolving body 33, the top of the first drug-dissolving body 33 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com