Marine tubular-type biofilm colonization filling material

A bio-filming, tubular technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Wall flow time and other issues, to achieve the effect of reducing PVC instability, strong shock load resistance, and short hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

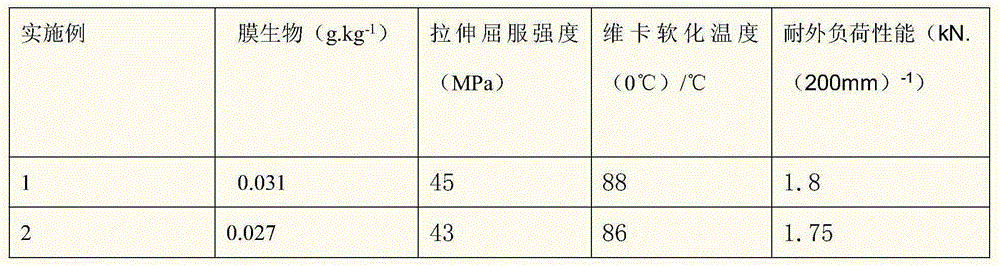

Embodiment 1

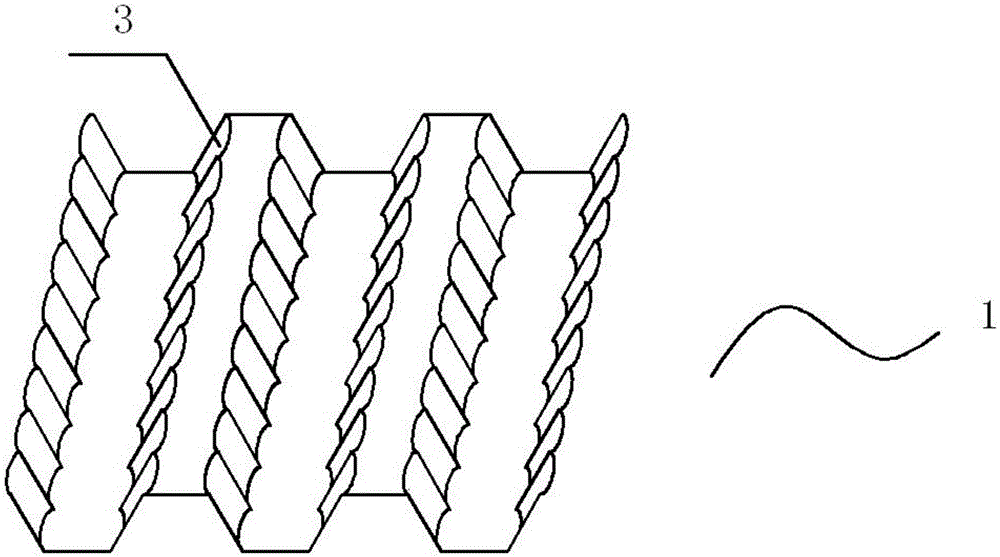

[0018] The above-mentioned preparation method of the trapezoidal wave-bent PVC board of the present invention is a conventional technology in the industry, which is roughly as follows: fully mix the raw materials according to the formula ratio, then put them into the feeding hopper of the injection molding machine, and extrude them through the filler mold. Then, the injection-molded biological filler is magnetized on a magnetizer to obtain the above-mentioned board of the present invention.

[0019] The formula is: 98 parts of PVC, 0.5 part of salt mud (SM), 1 part of polyvinyl alcohol, 0.5 part of polyacrylamide, and 1 part of activated carbon.

Embodiment 2

[0021] The above-mentioned preparation method of the trapezoidal wave-bent PVC board of the present invention is a conventional technology in the industry, which is roughly as follows: fully mix the raw materials according to the formula ratio, then put them into the feeding hopper of the injection molding machine, and extrude them through the filler mold. Then, the injection-molded biological filler is magnetized on a magnetizer to obtain the above-mentioned board of the present invention.

[0022] The formula is: 95 parts of PVC, 1 part of salt mud (SM), 3 parts of polyvinyl alcohol, 0.5 part of polyacrylamide, and 0.5 part of activated carbon.

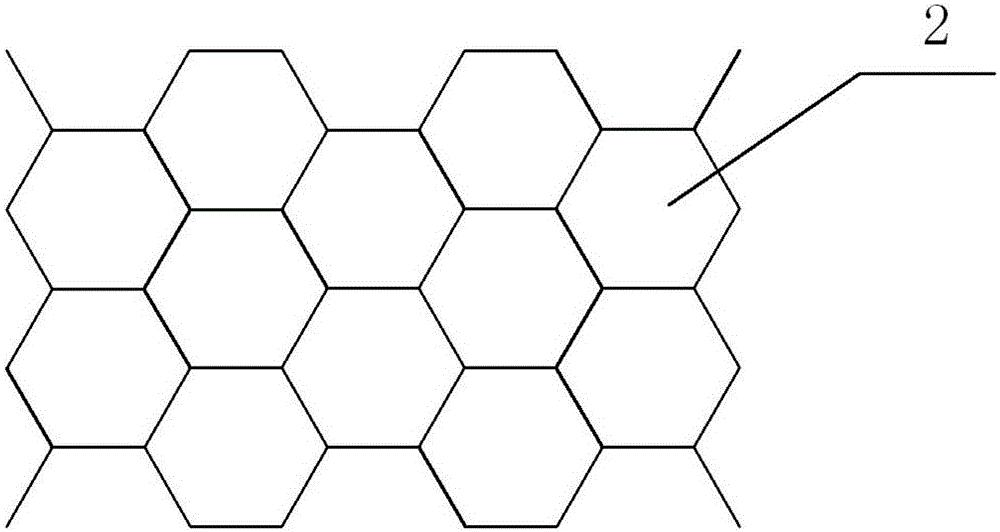

[0023] The boards prepared by the embodiments of the present invention are bonded to each other to form an attached figure 1 The shown packing, due to the frosted protrusions on the surface, has a specific surface area more than 10 times larger than that of the traditional smooth structure.

[0024] For specific application, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com