Energy-saving control system of vehicle engine, method, device and engineering vehicle

An energy-saving control system and control device technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of low engine load rate, high production cost, and low adjustment and control accuracy, so as to increase load rate and reduce power consumption. The effect of improving the oil volume and improving the accuracy of regulation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

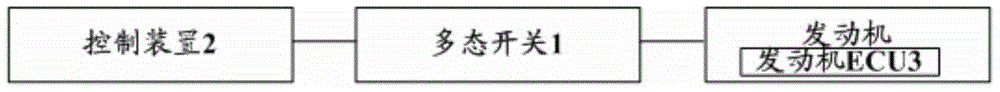

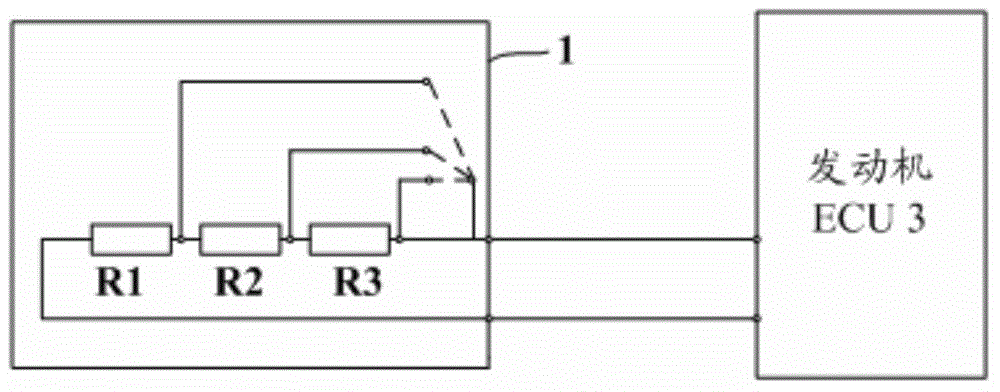

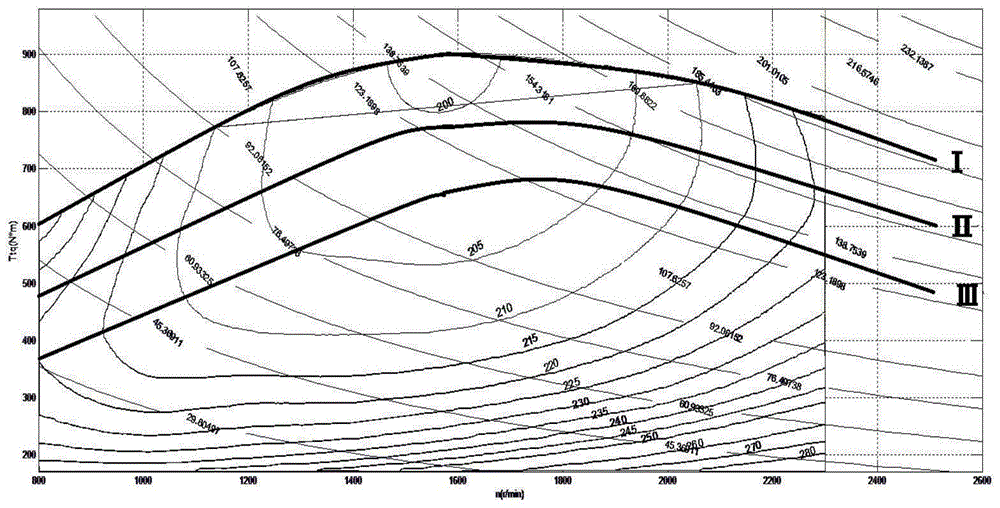

[0049] In order to effectively increase the load rate of the engine by adjusting the load-bearing gear of the multi-state switch, and further reduce the fuel consumption of the engine during the transportation operation of the engineering vehicle, the embodiment of the present invention provides an energy-saving control system for the vehicle engine, Method, device and engineering vehicle. In this technical solution, the control device can adaptively adjust the current load working gear of the multi-state switch according to the load working conditions in real time, and then make the engine run in different states to reduce fuel consumption and improve the adjustment and control accuracy, thus effectively By adjusting the load-bearing gear of the multi-state switch, the load rate of the engine can be increased, and the fuel consumption of the engine of the engineering vehicle in the transportation operation can be further reduced.

[0050] The present invention will be describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com