Pre-combustion mechanical grate decoupling combustion furnace and combustion method for same

A technology of mechanical furnace and combustion furnace, which is applied in the field of pre-combustion mechanical grate decoupling combustion furnace and its combustion, which can solve the problems of interruption of combustion, difficulty in greatly increasing the combustion load of pre-combustion chamber, and slow pre-combustion speed. Ensure stable and continuous operation, reduce the effect of decoupling combustion, and avoid the effect of combustion interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the present invention will be further described in conjunction with the accompanying drawings and embodiments.

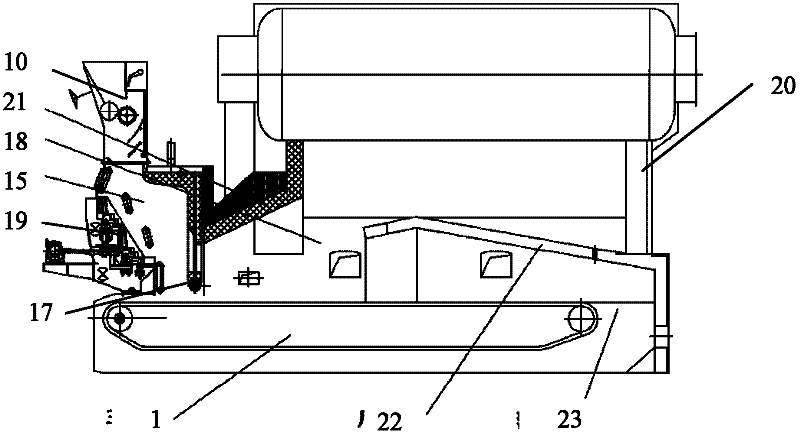

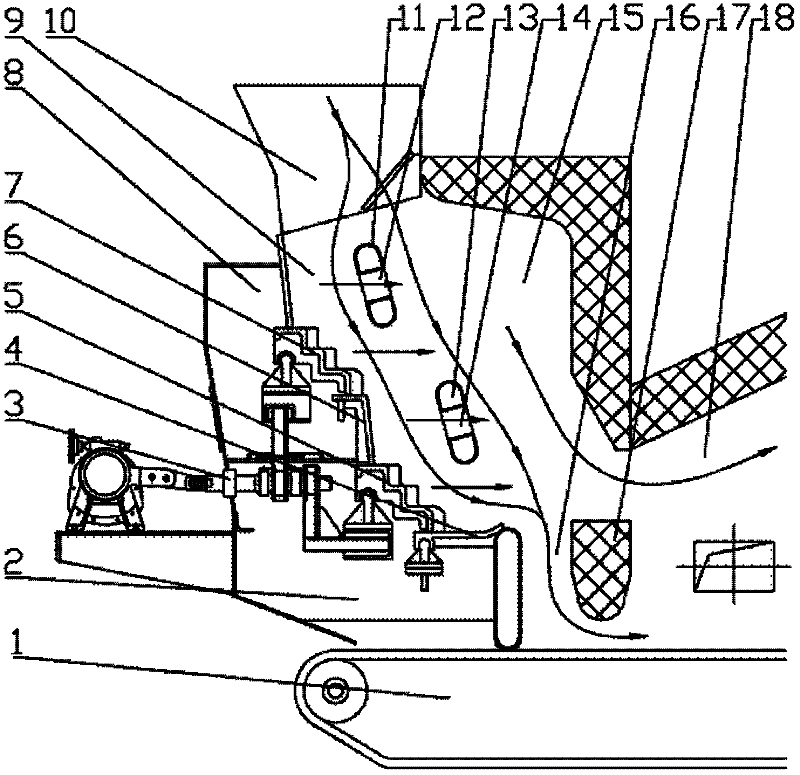

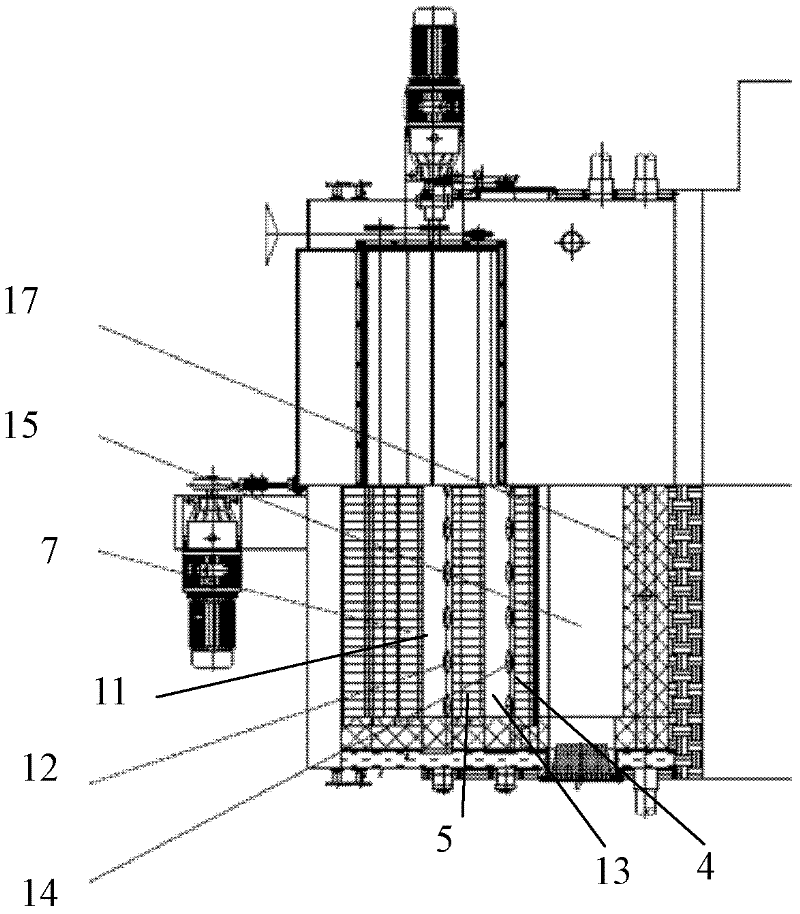

[0036] According to one embodiment of the present invention, a pre-combustion mechanical grate decoupling combustion furnace is provided, such as figure 1 As shown, the decoupled combustion furnace includes: a layered coal feeding device 10 , a furnace body 20 , a combustion chamber partition wall 17 , a main grate 1 and a pre-combustion grate 19 . In the present invention, the furnace body can directly adopt various specific structures of industrial boilers in the prior art, for example, the furnace body can include a front arch 21 and a rear arch 22, and the specific structure of the furnace body will not be repeated here. The inside of the furnace body is provided with a combustion chamber partition wall 17 , which generally divides the inner space of the furnace body into an upstream pre-combustion chamber 15 and a downstream main combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com