Integral sludge incineration system for circulating fluidized bed

A circulating fluidized bed and sludge incineration technology, which is applied in the direction of fluidized bed combustion equipment, fuel burned in a molten state, incinerators, etc., can solve the problems of high processing cost, large energy consumption, and many equipment, and achieve production cost Low, increase the operating load, the effect of a large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

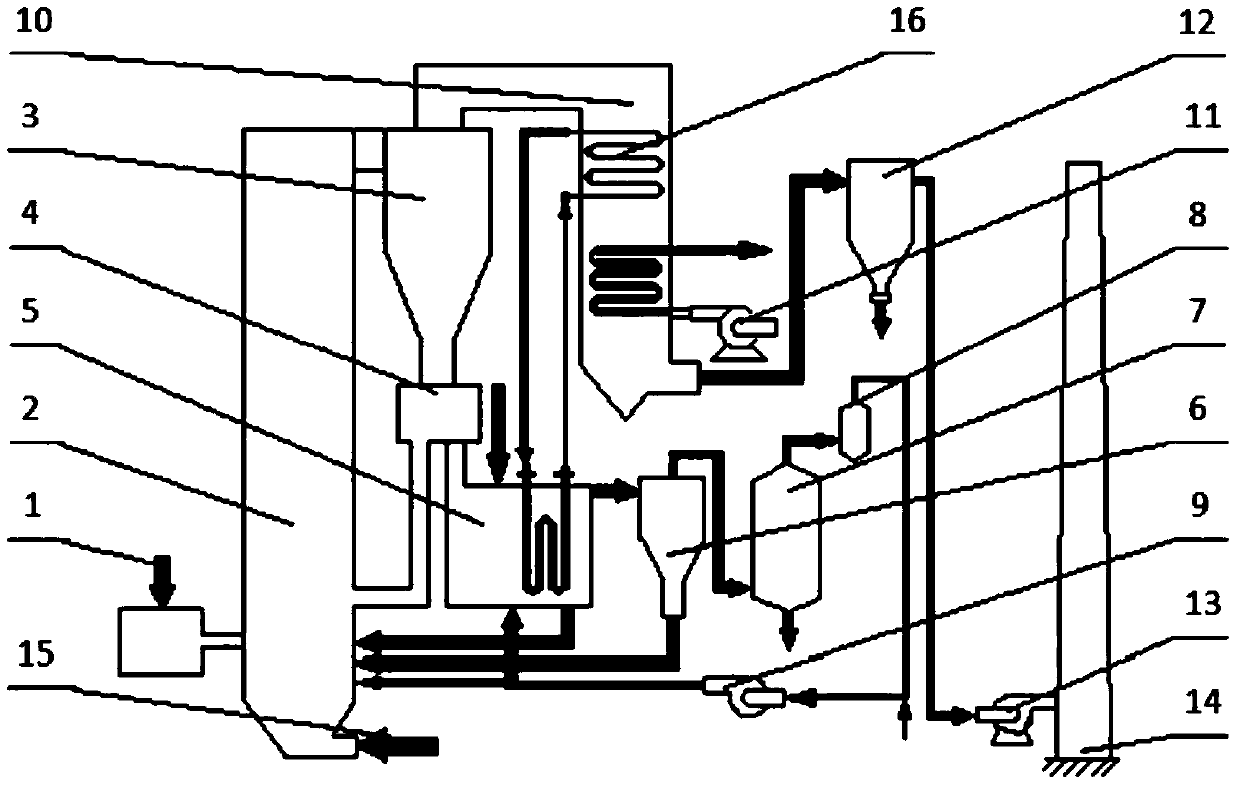

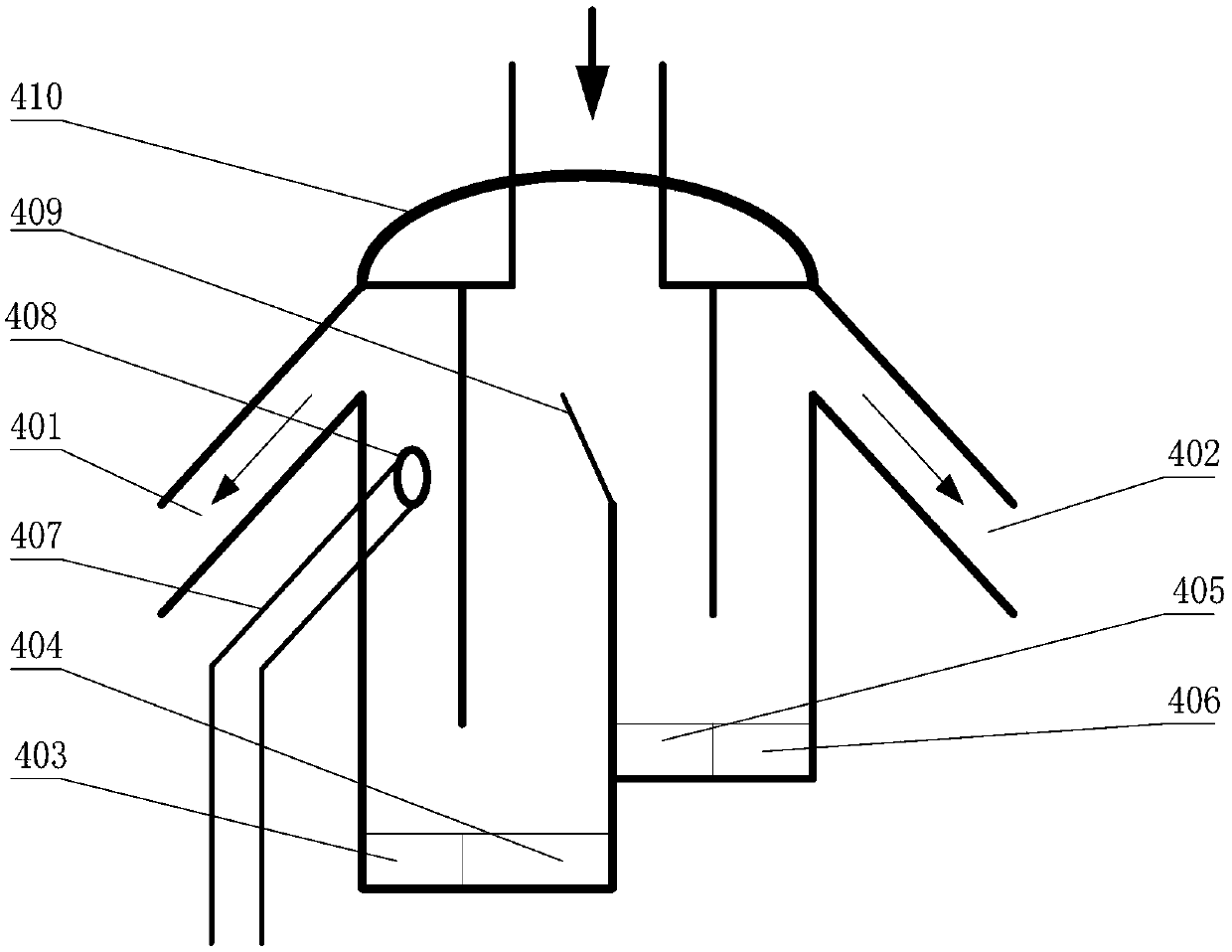

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] combine figure 1 , a circulating fluidized bed integrated sludge incineration system, including auxiliary fuel 1, incinerator 2, separator 3, pneumatic distribution valve 4, dryer 5, fine ash separator 6, condenser 7, steam-water separator 8. The first blower 9, the rear heating surface 10, the second blower 11, the dust collector 12, the induced draft fan 13, the chimney 14, and the heat transfer oil 16.

[0025] The upper part of the incinerator 2 is respectively connected with the separator 3 and the tail heating surface 10; the lower part of the separator 3 is respectively connected with the incinerator 2 and the dryer 5 through the pneumatic distribution valve 4, and the dried sludge in the dryer 5 is sequentially Through the fine ash separator 6, condenser 7, and steam-water separator 8, it is sent to the inciner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com