Plastic piece punching and cutting die

A technology of plastic parts and dies, which is applied in the field of stamping dies, can solve the problems of glue overflow, poor processing accuracy, and high cutting pressure, and achieve the effects of high surface finish, long service life, and reduced punching force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

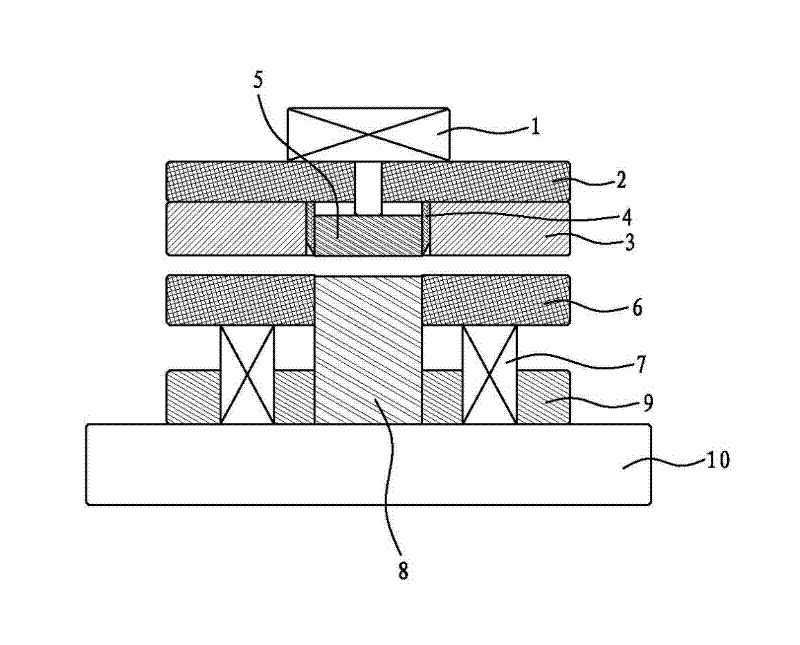

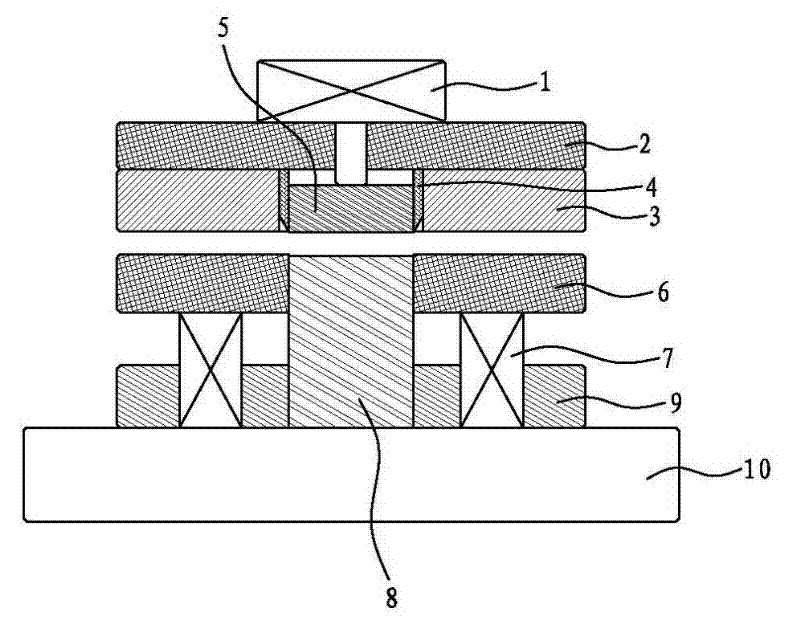

[0010] like figure 1 As shown, the present invention is a stamping and cutting die for plastic parts, which includes a cylinder 1, a upper die base plate 2, a upper die 3, a cutting die 4, a binder plate 5, a stripping plate 6, a stripping spring 7, a punch 8, lower mold 9, lower mold bottom plate 10.

[0011] The cylinder body of the cylinder 1 is installed on the outside of the upper die base plate 2, and the upper die 3 is fixed on the inner side of the upper die base plate 2; The surface of the die at the other end of the die 4 obliquely forms a cutting edge 41 inwardly, and the cutting edge is beveled.

[0012] The clamping plate 5 is movably nested in the cutting die 4; the piston rod of the cylinder 1 passes through the upper die bottom plate 2 through the connecting rod and presses on the clamping plate 5; the lower die 9 is fixed on the lower die. On the mold bottom plate 10. The stripping plate 6 is sleeved on the punch 8 at a gap, and the stripping spring 7 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com