Once fine blanking forming method for thick plate disc

A disc and fine blanking technology, applied in the field of one-time fine blanking of thick plate and disc, can solve the problems of unstable quality, poor part accuracy and high production cost, to ensure dimensional accuracy and section quality, save resources, and improve strength. and longevity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

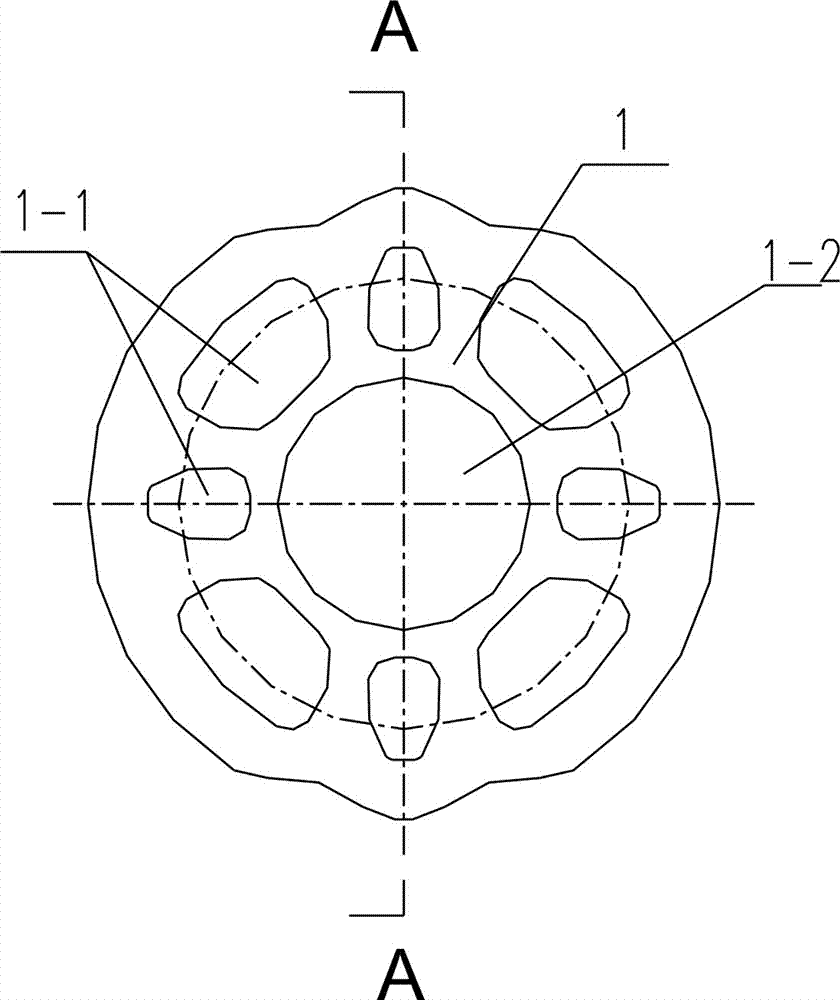

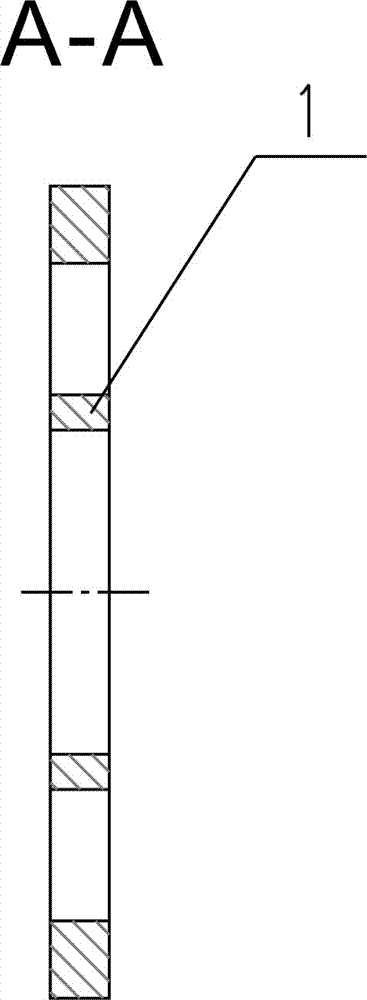

[0040] figure 1 It is a schematic diagram of the structure of a commonly used thick plate disc, figure 2 for figure 1 The A-A sectional view of the thick plate disc part 1 is provided with a round hole 1-2 in the middle, and a symmetrical special-shaped hole 1-1 is arranged around the round hole 1-2. The bottom surface of the thick plate disc part 1 has the same shape as the top surface. Among them, the material of disk 1 is SS400, the thickness is 9mm, the outer diameter is 123.5mm, and the wall between the holes is 60% of the material thickness. Parts have high requirements on cross-section quality, bright band > 75%, and no tearing is allowed in special-shaped holes and outer contours, non-perpendicularity 0.025mm, and flatness 0.3mm.

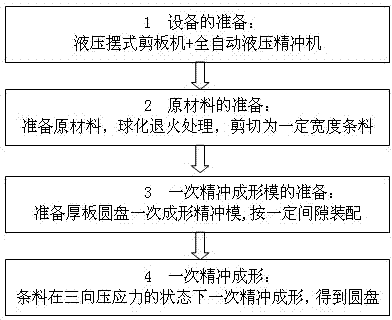

[0041] image 3 A flow chart of the forming process for a thick plate disc, which includes the following steps:

[0042] 1) Preparation:

[0043] Preparation of equipment: Prepare hydraulic pendulum shearing machine, fully automatic hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com