Stamping device of ventilation plate

A technology of stamping device and ventilation plate, which is applied in the field of mechanical equipment, can solve the problems of high mold production cost, large stamping mold area, and high pressure, and achieve the effects of reducing production cost, improving stamping precision, and reducing stamping pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

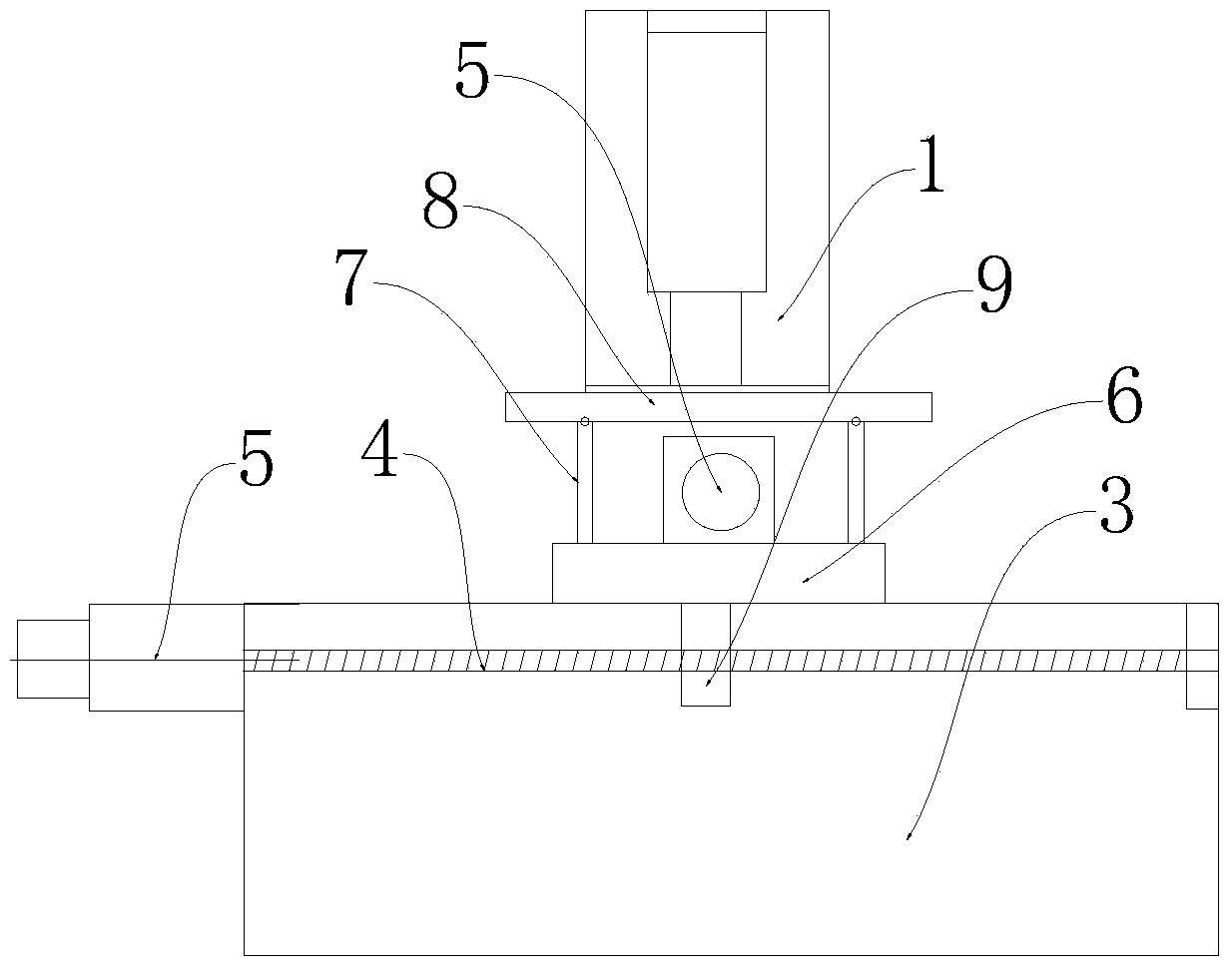

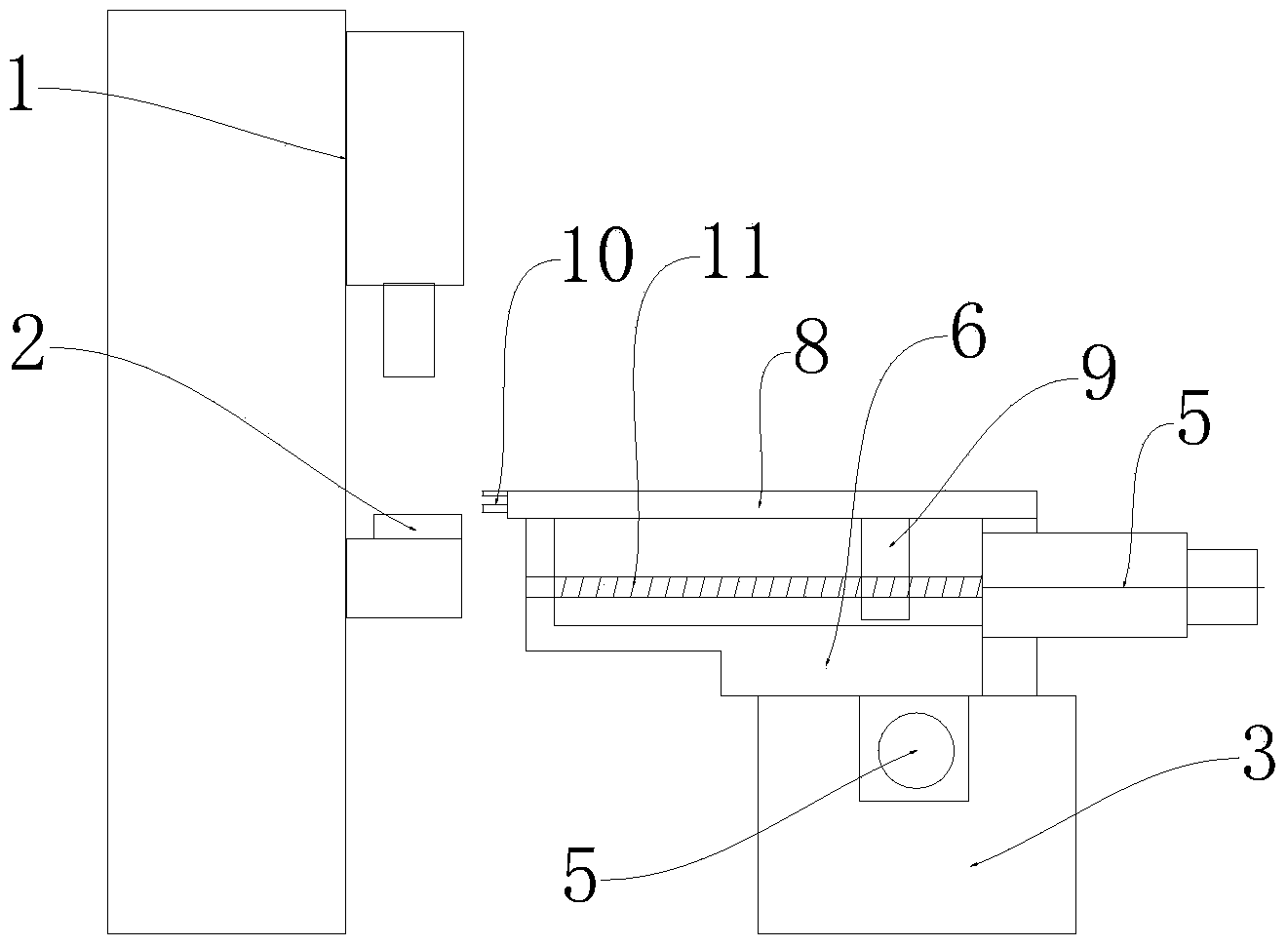

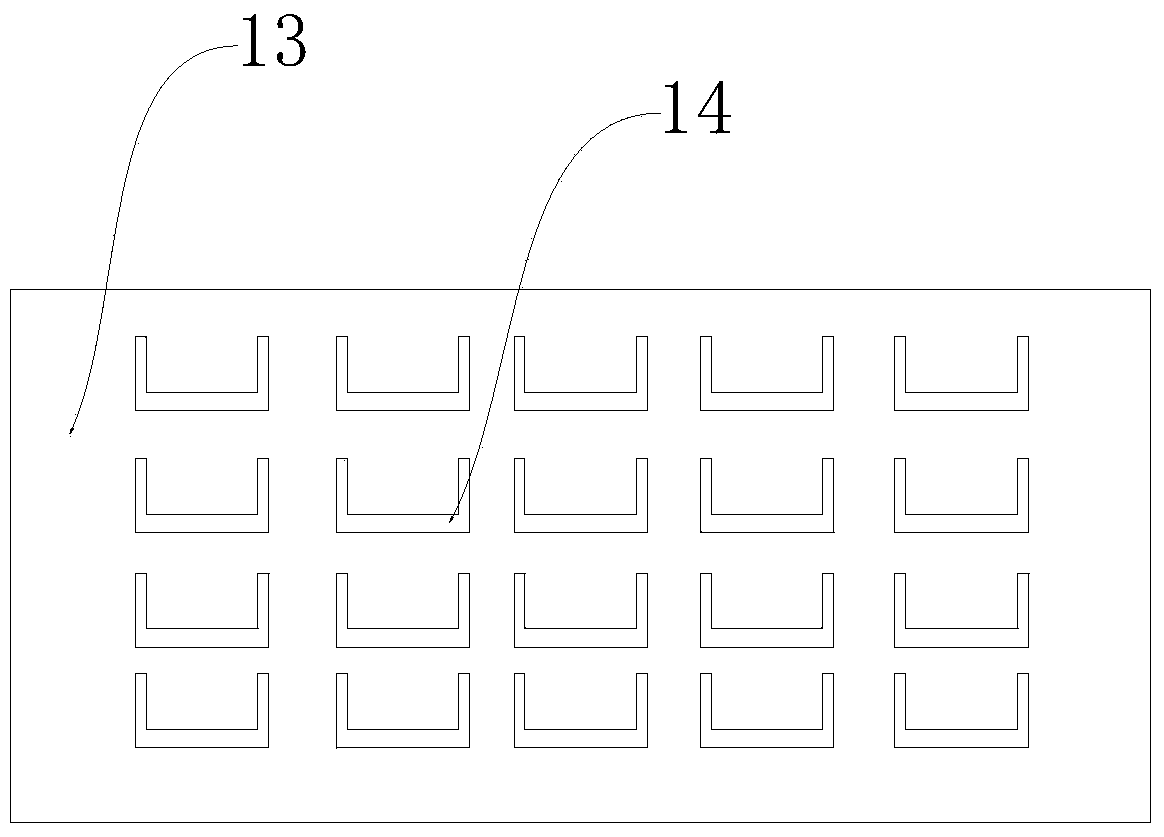

[0015] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the stamping device of the ventilation plate described in this embodiment includes a punch press 1 and a moving fixture, and the stamping die 2 includes an upper mold and a lower mold, and the number and position of the depressions 12 on the lower mold are consistent with the positions of a row of openings 14 on the ventilation plate. The quantity corresponds to the position; a moving fixture is provided directly opposite the punch press 1 . The structure of the mobile fixture includes a base 3, a transverse screw 4 is arranged inside the base 3, a motor 5 is provided at one end of the transverse screw 4, a base 6 is arranged on the base 3, the base 6 can slide laterally on the base 3, and the base 6 The bottom is fixed with a nut 9, the nut 9 is sleeved on the horizontal screw 4, a longitudinal slide rail 7 is provided on the base 6, a connecting arm 8 is provided on the longitudinal slide rail 7, and a long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com