Adjustable press

A press and adjustable technology, applied in the field of presses, can solve the problems of adjustment of metal parts that cannot be stamped, low stamping quality, and small scope of application, and achieve the effects of easy operation, improved quality, and improved scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

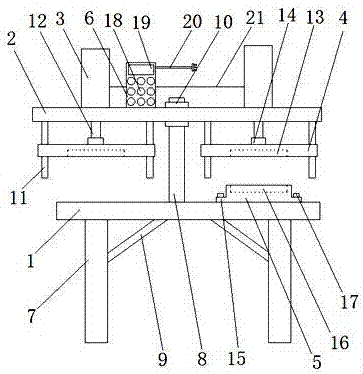

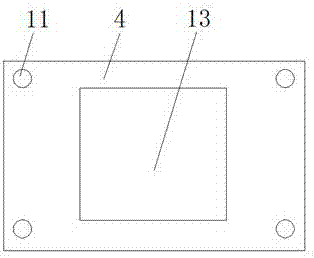

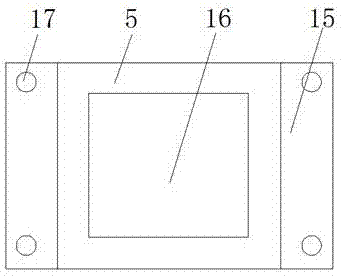

[0020] as attached Figure 1-3 As shown, an adjustable press machine includes an operation table 1, an adjustment plate 2, a cylinder 3, an upper pressure block 4, a lower cushion block 5 and a controller 6, and it is characterized in that: the operation table 1 is set on the bracket 7, and a column 8 is set on the console 1, the adjustment plate 2 is set on the column 8 through the connecting ring 10, and a limit rod 11 is set on the adjustment plate 2, and the cylinder 3 is set on the adjustment plate 2, and a piston rod 12 is provided on the cylinder 3, the upper pressing block 4 is arranged on the limit rod 11, the upper pressing block 4 is connected with the piston rod 12, and the upper pressing block 4 is provided with Pressure groove 13, said lower cushion block 5 is provided with installation block 15, carrying groove 16, and installation block 15 is arranged on the console 1 through installation bolt 17, and described controller 6 is arranged on the adjusting plate 2 ...

Embodiment 2

[0028] as attached Figure 4 As shown, an adjustable press machine includes an operation table 1, an adjustment plate 2, a cylinder 3, an upper pressure block 4, a lower cushion block 5 and a controller 6, and it is characterized in that: the operation table 1 is set on the bracket 7, and a column 8 is set on the console 1, the adjustment plate 2 is set on the column 8 through the connecting ring 10, and a limit rod 11 is set on the adjustment plate 2, and the cylinder 3 is set on the adjustment plate 2, and a piston rod 12 is provided on the cylinder 3, the upper pressing block 4 is arranged on the limit rod 11, the upper pressing block 4 is connected with the piston rod 12, and the upper pressing block 4 is provided with Pressure groove 13, said lower cushion block 5 is provided with installation block 15, carrying groove 16, and installation block 15 is arranged on the console 1 through installation bolt 17, and described controller 6 is arranged on the adjusting plate 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com