Flattener

A technology of leveling machine and supporting platform, applied in the field of leveling machine, can solve the problems of inability to achieve fine-tuning and precise stamping, inability to achieve fine-tuning, and low structural precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

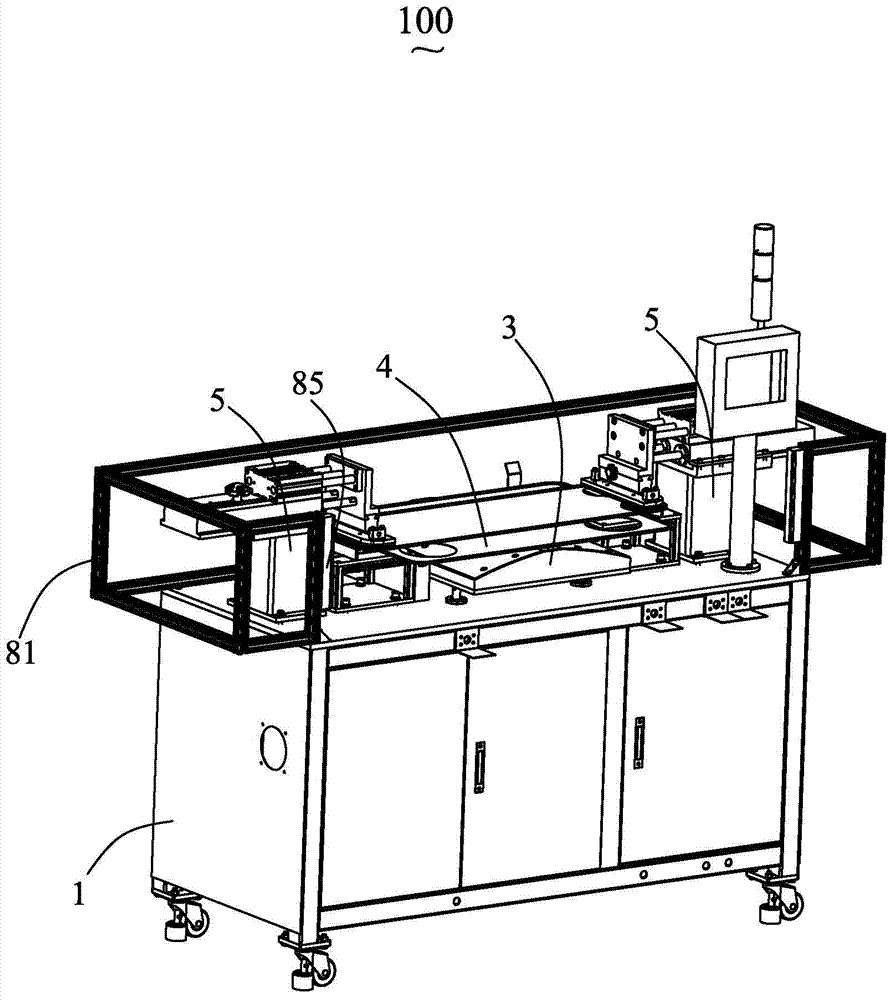

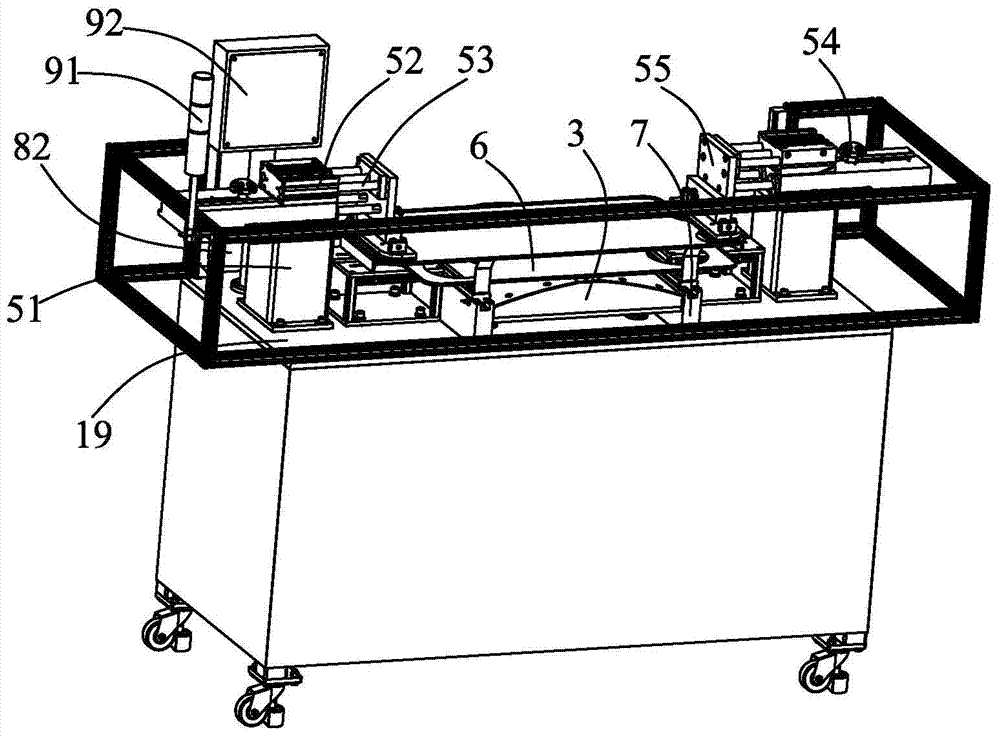

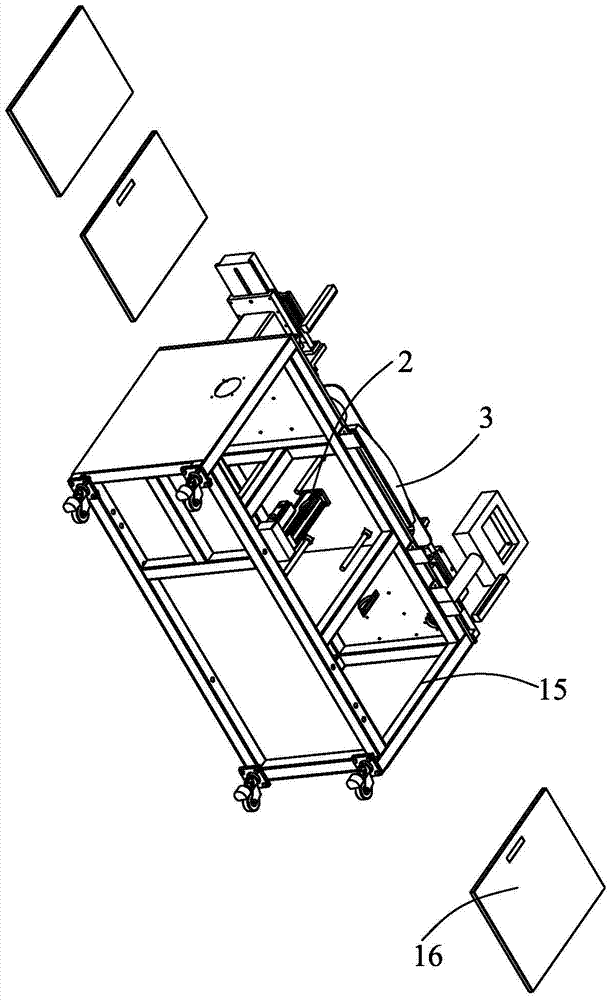

[0047] like Figure 1 to Figure 3 As shown, a leveling machine 100 includes a cabinet body 1 , a support platform 19 installed above the cabinet body 1 , a servo electric cylinder 2 , and a stamping head 3 located above the servo electric cylinder 2 .

[0048] like figure 1 and Figure 4 As shown, the cabinet body 1 is made of metal material and paint is sprayed on the outside of the metal material. The cabinet body 1 is roughly in the shape of a cuboid, and the cabinet body 1 has two side walls 11 , a bottom wall 12 , a rear wall 13 , and a receiving chamber 14 surrounded by these walls. The cabinet body 1 is also provided with an inlet and outlet 15 and some cabinet doors 16 installed at the inlet and outlet 15 places, and these cabinet doors 16 are parallel to the rear wall 13 . The cabinet door 16 is provided with a handle 161 that facilitates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com