Inclined slider mechanism

A technology of inclined sliding block and limit mechanism, applied in metal processing equipment, perforating tools, manufacturing tools, etc., can solve the problems of reduced work efficiency, large punching force of punches, increased processing costs, etc., and achieves extended service life, Low punching force, improved strength and height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

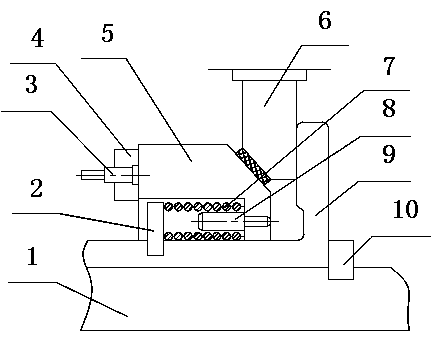

[0011] As an embodiment of the present invention, such as figure 1 As shown, a kind of oblique slider mechanism, comprises upper mold base, lower mold base 1 and punch 3, is fixedly connected with wedge base 9 on the lower mold base, and described wedge base 9 is L-shaped, and wedge base 9 An oblique slider 5 is arranged on it, a chute is provided on the oblique wedge seat 9, the oblique slider 5 can slide along the chute, and a resetting mechanism and a limit mechanism are arranged in the oblique slider 5. In this embodiment, as a preferred , the bottom surface of the oblique slider 5 has a half-through groove, the opening of the half-through groove is located on the side of the oblique slider 5 away from the wedge 6, the half-through groove is provided with a reset screw 8 along the horizontal direction, and the reset screw 8 is sleeved with Back-moving spring 7, on the wedge seat 9 near the opening of the half-pass groove and the position corresponding to the reset screw 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com