Preparation method of hydrofining catalyst with high mechanical strength

A technology of hydrofining and mechanical strength, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of lower production efficiency, complicated preparation procedures, and impact on Carrier physical and chemical properties and other issues, to optimize the formation and distribution, overcome the preparation process, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

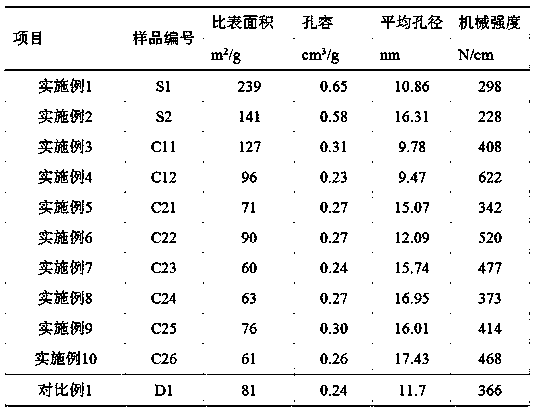

Examples

Embodiment 1

[0035] Weigh 204 parts of pseudo-boehmite (purchased from South Korea Chemical Co., Ltd., the same below), add 4.5 parts of safflower powder, and knead for 5 minutes to ensure uniform mixing, with a rotation speed of 50 r / min. Weigh 11.0 g of concentrated nitric acid with a concentration of 68 wt%, and add it into 210 g of deionized water to prepare a dilute solution. Slowly add it dropwise to the well-mixed pseudo-boehmite dry powder within 3 minutes (control the water-powder ratio to 1:1), continue kneading for 10 minutes to ensure that the wet mixing is uniform, and use 50 r / min, 130 W in the extruder Extrude strips under high power to obtain four-leaf clover-shaped wet strips with a specification of Φ1.45×1.59, dry them at room temperature for 2 hours, dry them in an oven at 120 °C for 2 hours, cool to room temperature, and shape them at a speed of 400 r / min It is a four-leaf clover strip of 3-10 mm, sieved with a 20-mesh standard sieve, placed in a muffle furnace, and rai...

Embodiment 2

[0037] Weigh 204 parts of pseudo-boehmite and 47 g of PURAL SB powder (manufactured by Sasol, Germany), add 4.5 parts of celadon powder, and knead for 5 min to ensure uniform mixing at a speed of 50 r / min. Weigh 11.0 g of concentrated nitric acid with a concentration of 68 wt%, and add it into 210 g of deionized water to prepare a dilute solution. Slowly add it dropwise to the mixed dry powder within 5 minutes (control the water-powder ratio to 1:1), continue to knead for 15 minutes to ensure that the wet mixing is uniform, and extrude in the extruder at 50 r / min and 150 W power Molding, the four-leaf clover-shaped wet strip with the specification of Φ1.45×1.59 is obtained. Dry at room temperature for 2 hours, dry in an oven at 120°C for 2 hours, cool to room temperature and shape into four-leaf clover strips with a length of about 3-10 mm at a speed of 450 r / min, and sieve through a 20-mesh standard sieve After sieving, put it in a muffle furnace, raise the temperature from ...

Embodiment 3

[0039] Dissolve 18 parts of phosphoric acid with a concentration of 85 wt% and 30 parts of ethylene glycol in 50 parts of deionized water, and add the solution to 34 parts of molybdenum oxide and 12 parts of basic nickel carbonate. Raise the temperature to 85 °C, stir and heat to reflux under the condition of 300 r / min until the solid components are completely dissolved, and the active component impregnation solution is obtained. Weigh 100 parts of the alumina carrier S1 and measure its water absorption in advance, and impregnate an equal volume of the active component impregnating solution onto the carrier. After rotary impregnation for 6 h, the temperature was programmed to dry in a muffle furnace under an air atmosphere. The temperature was raised from room temperature to 55 °C at a rate of 1 °C / min, kept at a constant temperature for 10 min, and then raised to 120 °C at a rate of 0.3 °C / min for 4 h. , and then heated up to 200 °C at a rate of 1.2 °C / min, then kept at a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com