Method for directly preparing activated carbon in waste acid

An activated carbon, direct technology, applied in the field of comprehensive utilization of resources, can solve the problem of high cost, achieve the effect of low cost, excellent fertilizer retention, and improved air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

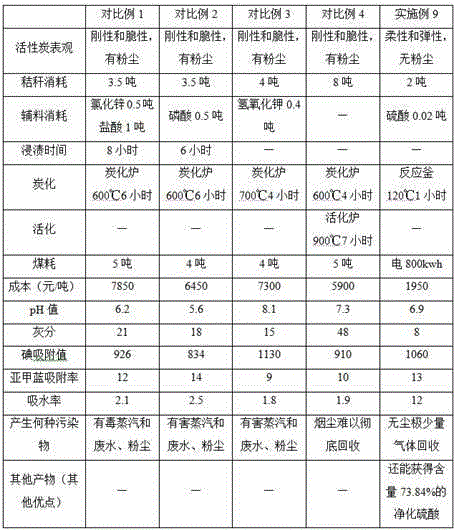

Examples

Embodiment 1

[0037] (1) Crush the peanut shells to 5 meshes to obtain 10g of peanut shell powder, and spray 20g of water for wetting;

[0038] (2) According to step (1) the weight ratio of peanut shell powder and sulfuric acid with a concentration of 98wt% is 1:20, the peanut shell powder obtained in step (1) is mixed with sulfuric acid with a concentration of 98wt%, and heated at 20°C The oscillation frequency is 50 times / min, and the oscillation reaction is carried out for 24 hours to obtain the reactant;

[0039] (3) The reactant obtained in step (2) is separated into solid and liquid to obtain a solid product and a filtrate, and the solid product is repeatedly washed with water until it is neutral and free of sulfate ions, and then dried by suction filtration to obtain activated carbon.

[0040] The filtrate is purified industrial sulfuric acid; the washing water produced by repeated washing is industrial dilute sulfuric acid, which can be used for acid absorption in sulfuric acid work...

Embodiment 2

[0043] (1) Crush the straw to 200 mesh to get 100g of straw powder;

[0044] (2) According to step (1) the weight ratio of rice straw powder and sulfuric acid with a concentration of 93wt% is 1:2, mix the rice straw powder obtained in step (1) with sulfuric acid, and stir once every hour at 22°C, react 36 hour, the reactants were obtained;

[0045] (3) The reactant obtained in step (2) is separated into solid and liquid to obtain a solid product and a filtrate, and the solid product is repeatedly washed with water until it is neutral and free of sulfate ions, and then dried by suction filtration to obtain activated carbon.

[0046] The filtrate is purified industrial sulfuric acid; the washing water produced by repeated washing is industrial dilute sulfuric acid, which can be used for acid absorption in sulfuric acid workshops in conventional production.

[0047] After testing, the water content of rice straw powder is 13.95%, the weight of activated carbon product is 352g, t...

Embodiment 3

[0049] (1) Crush the sawdust to 80 mesh to obtain 40g of sawdust powder; spray 100g of water on the obtained sawdust powder for wetting;

[0050] (2) According to step (1) the weight ratio of wood powder and alkylation waste sulfuric acid with a concentration of 92wt% is 1:100, mix the wood powder obtained in step (1) with alkylation waste sulfuric acid, and place in a microwave oven to 700W, 2450MHz (about 120°C) heating reaction for 15 minutes, take it out and stir it, then place it in a microwave oven and heat it for 15 minutes to obtain the reactant;

[0051] (3) The reactant obtained in step (2) was separated by suction filtration with a Buchner funnel to obtain a solid product and a filtrate, and the solid product was moved into an ultrasonic cleaning machine with a temperature of 80°C for 10 minutes until it was neutral and free of sulfate ions. And then dried by suction filtration to obtain activated carbon.

[0052] The filtrate is purified industrial sulfuric acid; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine value | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com