Textile and production process thereof

A technology for textile fabrics and processes, applied in the field of textile fabrics and their production processes, can solve the problems of allergies, fabric and environmental pollution, and unsatisfactory service life, and achieve the effect of reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

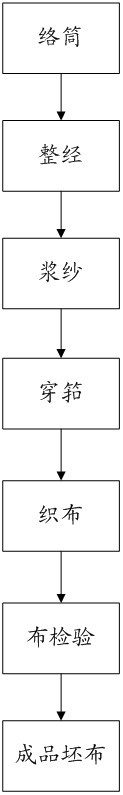

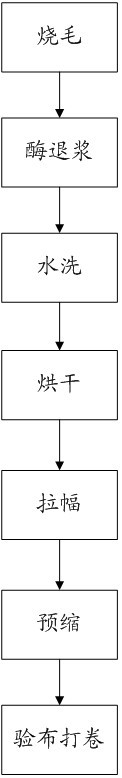

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0031] The invention provides a textile fabric, the textile fabric is interwoven with warp threads and weft threads to form plain weave or twill weave organizational units. Among them, the warp thread is colored cotton, the weft thread is natural colored hemp, and the organization unit of plain weave or twill weave is the upper and lower layers of warp thread and weft thread, and the ratio of warp thread and weft thread is 5:3. The density of the warp and weft in the textile fabric of the present invention is 300T-500T, the width of the textile fabric is 44 inches, and the shrinkage rate is ±4%.

[0032] Due to the limitations of natural colors, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com