Method for removing lead, antimony, bismuth, selenium, tellurium and arsenic from copper anode slime by vacuum reduction

A technology for copper anode slime and lead, antimony and bismuth, which is applied in the field of metal smelting, can solve the problems of complex metal recovery process, numerous and complicated process steps, low equipment utilization rate, etc. of Dole alloy, and achieves easy industrial automation, short process flow and high production efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

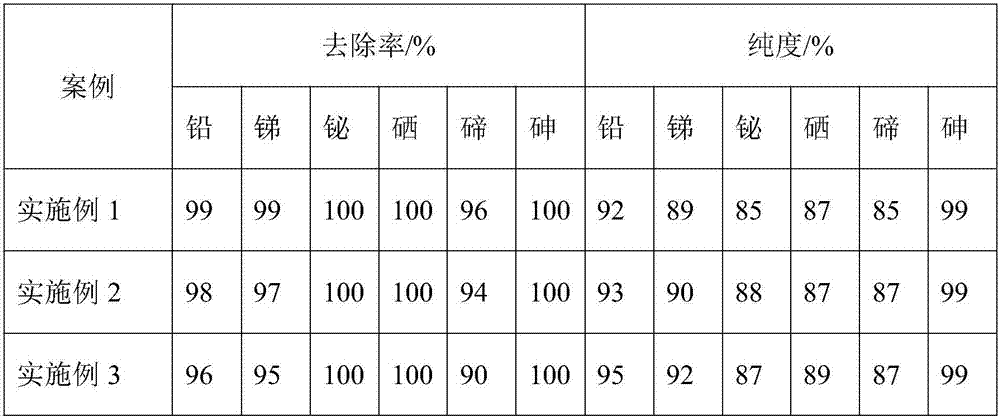

Embodiment 1

[0027] A method for vacuum reduction of copper anode slime to delead antimony bismuth selenium tellurium arsenic comprises the following steps:

[0028] S1. After drying and dispersing the copper anode slime, take 1000kg of copper anode slime and mix them evenly with 5kg of solid reductant coal, and then electrically heat and reduce in a vacuum furnace to distill lead, antimony, bismuth, selenium, tellurium, and arsenic vapors. Residues containing gold, silver and copper remain. Wherein, the vacuum degree of the vacuum furnace is 2 Pa, the temperature in the vacuum furnace is 1400° C., and the electric heating reduction distillation time in the vacuum furnace is 5 hours.

[0029] S2. Pass the vapors into the multi-stage condenser group, and the vapors are directly passed into the multi-stage condenser group from the vacuum furnace, and control the temperature gradient of the multi-stage condenser group, so that the lead, antimony, bismuth, selenium, and tellurium in the smoke ...

Embodiment 2

[0032] A method for vacuum reduction of copper anode slime to delead antimony bismuth selenium tellurium arsenic comprises the following steps:

[0033] S1. After drying and dispersing the copper anode slime, take 1000kg of copper anode slime and mix evenly with 10kg of solid reductant coal, and then electrically heat and reduce in a vacuum furnace to distill lead, antimony, bismuth, selenium, tellurium, and arsenic vapors. Residues containing gold, silver and copper remain. Wherein, the vacuum degree of the vacuum furnace is 8 Pa, the temperature in the vacuum furnace is 1350° C., and the electric heating reduction distillation time in the vacuum furnace is 6 hours.

[0034] S2. Pass the vapors into the multi-stage condenser group, and the vapors are directly passed into the multi-stage condenser group from the vacuum furnace, and control the temperature gradient of the multi-stage condenser group, so that the lead, antimony, bismuth, selenium, and tellurium in the smoke and ...

Embodiment 3

[0037] A method for vacuum reduction of copper anode slime to delead antimony bismuth selenium tellurium arsenic comprises the following steps:

[0038] S1. After drying and dispersing the copper anode slime, take 1000kg of copper anode slime and mix evenly with 15kg of solid reductant charcoal, and then electrically heat and reduce in a vacuum furnace to distill lead, antimony, bismuth, selenium, tellurium, and arsenic vapors. Residues containing gold, silver and copper remain. Wherein, the vacuum degree of the vacuum furnace is 10 Pa, the temperature in the vacuum furnace is 1300° C., and the electric heating reduction distillation time in the vacuum furnace is 7 hours.

[0039] S2. Pass the vapors into the multi-stage condenser group, and the vapors are directly passed into the multi-stage condenser group from the vacuum furnace, and control the temperature gradient of the multi-stage condenser group, so that the lead, antimony, bismuth, selenium, and tellurium in the smoke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com