Vanadium-doped nickel-manganese composite hydroxide and preparation method thereof

A composite hydroxide and manufacturing method technology, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of uneven doping of vanadium, easy broken particles, etc., achieve uniform distribution of elements, increase specific capacity, Overcome the effect of uneven doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

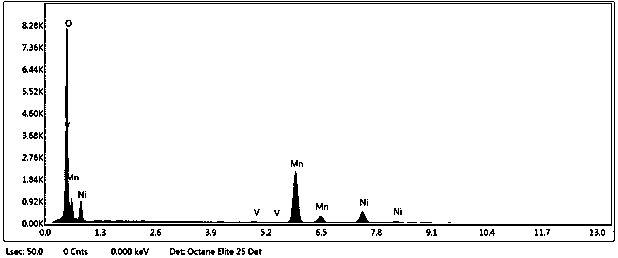

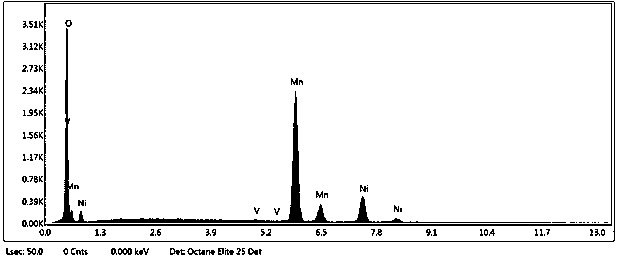

Image

Examples

Embodiment 1

[0046] The chemical formula is Ni 0.25 mn 0.75 V 0.01 (OH) 2.05 The preparation method of the nickel-manganese composite hydroxide doped with vanadium in the particle size:

[0047] Step 1, select nickel sulfate, manganese sulfate, ammonium metavanadate as raw material, prepare according to nickel, manganese, vanadium molar ratio as 25:75:1;

[0048] Step 2, nickel sulfate, manganese sulfate and pure water selected in step 1 are mixed with a mixed salt solution whose total concentration is 2.0mol / L;

[0049] Step 3, select sodium hydroxide and ammoniacal liquor, be mixed with the ammonia-alkali mixed solution that sodium hydroxide concentration is 10mol / L, ammonia concentration is 1.5mol / L;

[0050] Step 4, dissolving the ammonium metavanadate selected in step 1 into the ammonia-alkali mixed solution prepared in step 3 until the mixed solution is clear without precipitation, and obtaining a vanadium concentration of 0.01mol / L vanadium-containing ammonia-alkali mixed soluti...

Embodiment 2

[0058] The chemical formula is Ni 0.3 mn 0.7 V 0.01 (OH) 2.05 The preparation method of the nickel-manganese composite hydroxide doped with vanadium in the particle size:

[0059] Step 1, select nickel sulfate, manganese sulfate, ammonium metavanadate as raw material, prepare according to nickel, manganese, vanadium molar ratio as 30:70:1;

[0060] Step 2, nickel sulfate, manganese sulfate and pure water selected in step 1 are mixed with a mixed salt solution whose total concentration is 2.0mol / L;

[0061] Step 3, select sodium hydroxide and ammoniacal liquor, be mixed with the ammonia-alkali mixed solution that sodium hydroxide concentration is 10mol / L, ammonia concentration is 1.5mol / L;

[0062] Step 4, dissolving the ammonium metavanadate selected in step 1 into the ammonia-alkali mixed solution prepared in step 3 until the mixed solution is clear without precipitation, and obtaining a vanadium concentration of 0.01mol / L vanadium-containing ammonia-alkali mixed solution...

Embodiment 3

[0070] The chemical formula is Ni 0.2 mn 0.8 V 0.01 (OH) 2.05 The preparation method of the nickel-manganese composite hydroxide doped with vanadium in the particle size:

[0071] Step 1, select nickel sulfate, manganese sulfate, ammonium metavanadate as raw material, prepare according to nickel, manganese, vanadium molar ratio as 20:80:1;

[0072] Step 2, nickel sulfate, manganese sulfate and pure water selected in step 1 are mixed with a mixed salt solution whose total concentration is 2.0mol / L;

[0073] Step 3, select sodium hydroxide and ammoniacal liquor, be mixed with the ammonia-alkali mixed solution that sodium hydroxide concentration is 10mol / L, ammonia concentration is 1.5mol / L;

[0074] Step 4, dissolving the ammonium metavanadate selected in step 1 into the ammonia-alkali mixed solution prepared in step 3 until the mixed solution is clear without precipitation, and obtaining a vanadium concentration of 0.01mol / L vanadium-containing ammonia-alkali mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com