Slag system for smelting GH984G nickel base alloys and application method thereof

A GH984G, nickel-based alloy technology, applied in the field of smelting alloys, can solve the problems of poor surface quality of ingots, uneven distribution of easily oxidized elements, etc. The effect of even distribution of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

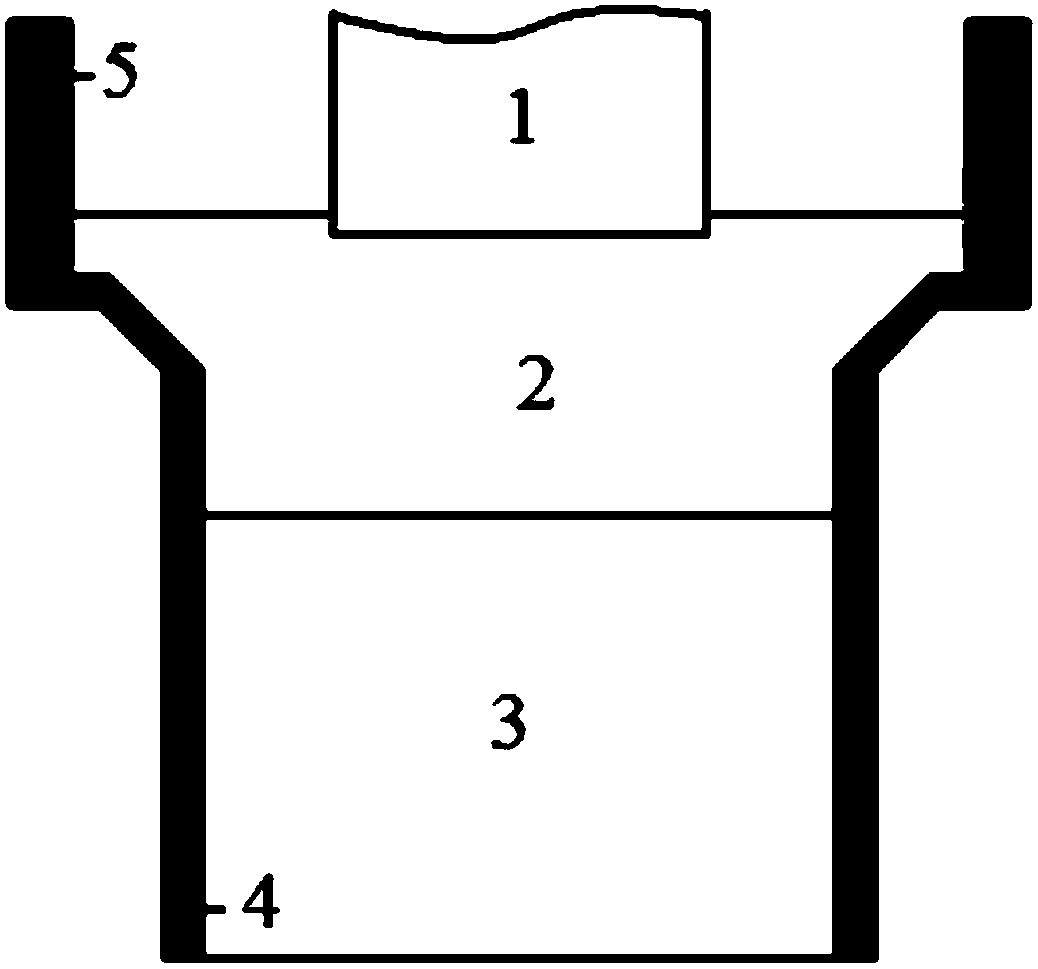

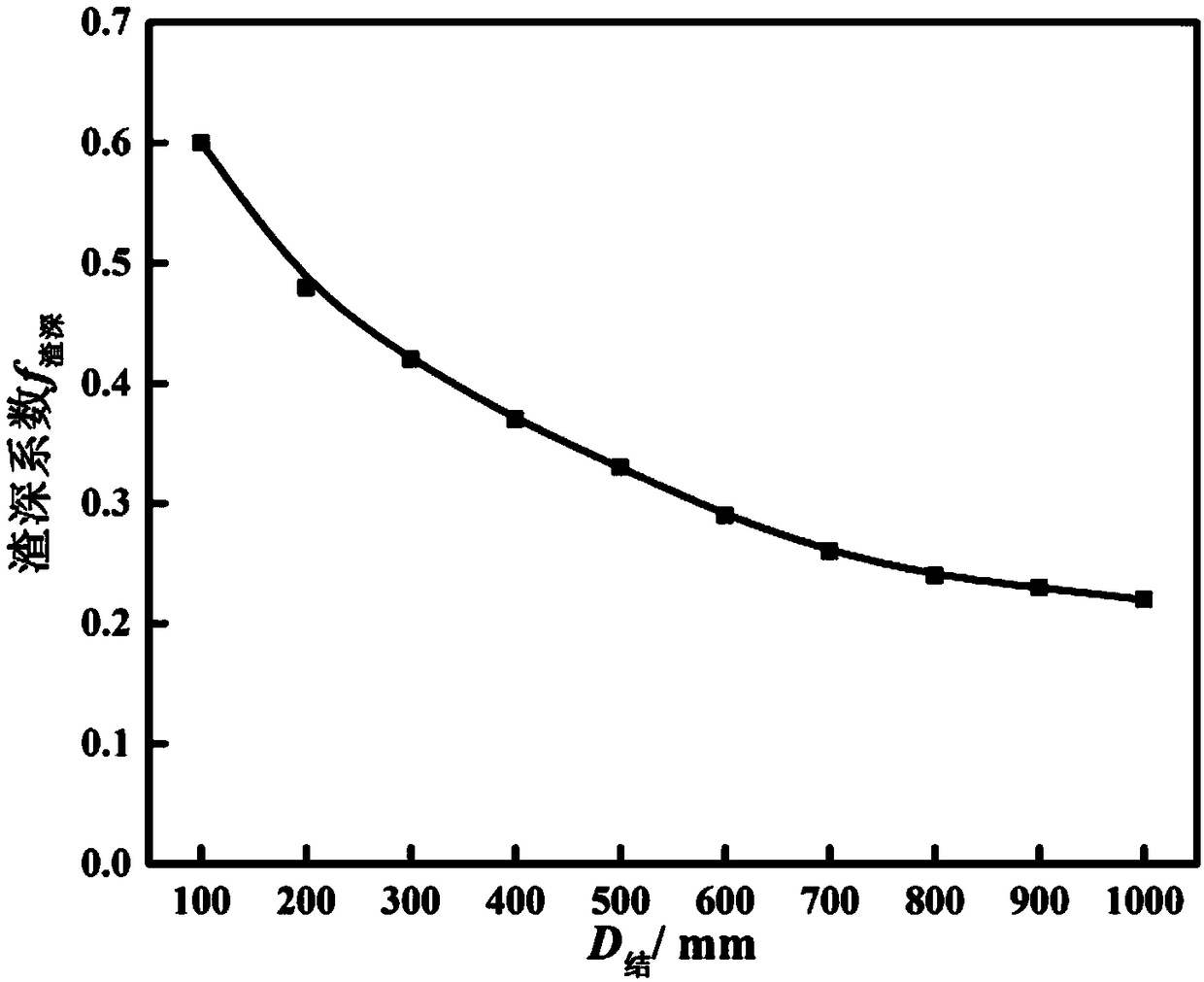

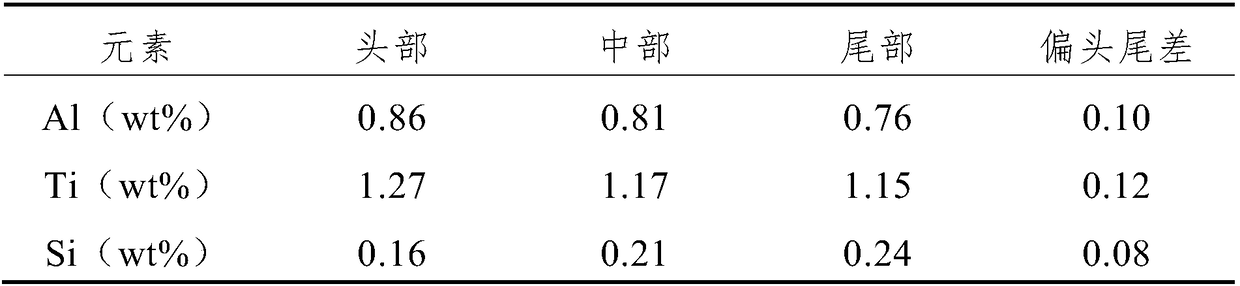

[0044] In this embodiment, as figure 1 The T-shaped crystallizer shown includes consumable electrode 1 , slag pool 2 , ingot 3 , crystallizer 4 , and atmosphere protection device 5 . The relationship between the slag depth coefficient and the crystallizer diameter is as follows: figure 2 shown.

[0045] In this embodiment, the smelting crystallizer has a diameter of 260 mm, and the chemical composition of the nickel-based superalloy slag system for electroslag remelting and smelting of ingots is configured according to the following mass percentages: CaF 2 : 41%, CaO: 30%; Al 2 o 3 : 20%; MgO: 3%; TiO 2 : 5%; SiO 2 :1%. The melting point of the slag system is 1221°C, and at a temperature of 1600°C, the density of the ingot slag system is 2.64g·cm -3 , the resistivity is 0.46Ω·cm.

[0046] Weigh 20kg of the above-mentioned slag material, put it into a muffle furnace and bake at 800°C for 3 hours before smelting the superalloy, and then cool down with the furnace.

[004...

Embodiment 2

[0056] This example is the same as Example 1, except that the chemical composition mass percentage of the nickel-based superalloy slag system used for electroslag remelting and smelting of ingots is: CaF 2 : 42%, CaO: 25%; Al 2 o 3 : 22%; MgO: 3%; TiO 2 : 6%; SiO 2 :2%. The melting point of the slag system is 1263°C, and at a temperature of 1600°C, the density of the ingot-drawing slag system is 2.60 g·cm -3 , the resistivity is 0.51Ω·cm.

[0057] In this embodiment, first weigh 20 kg of prepared slag. Before smelting superalloys, put the configured slag into a muffle furnace and bake at 800°C for 4 hours, then cool down slowly to room temperature with the furnace cooling down.

[0058] A protective atmosphere device is used at the furnace mouth, and argon gas is introduced; in order to facilitate the arc ignition operation, 25g of fluorite powder (calcium fluoride) and 100g of baked pre-melted slag are placed around the arc ignition agent of the T-shaped crystallizer m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com