Nickel/cobalt-rich high-entropy ceramic positive electrode material for lithium ion battery and preparation method thereof

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effect of improving performance and uniform distribution of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

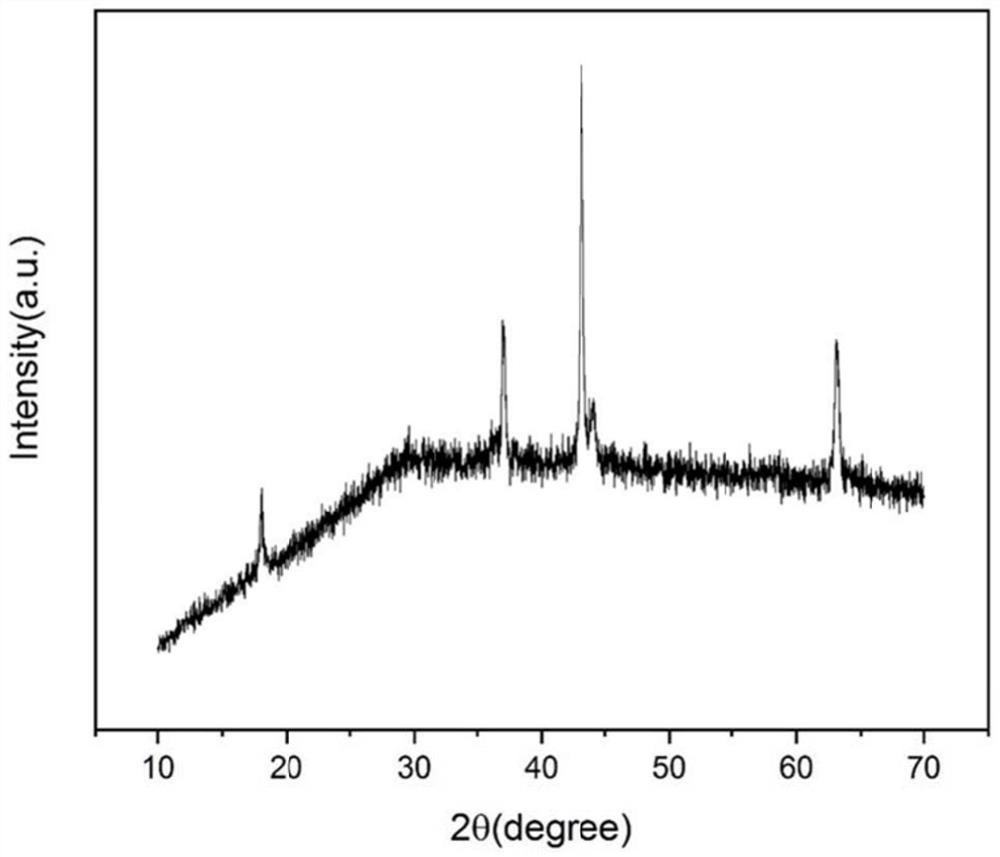

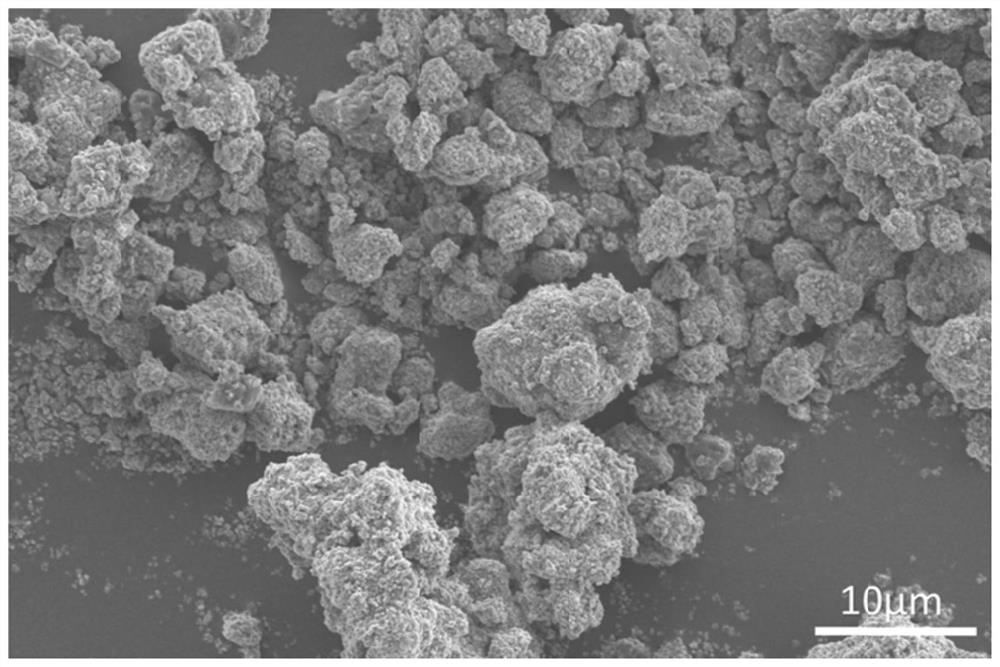

Embodiment 1

[0028] Configure nickel sulfate, cobalt sulfate, manganese sulfate, zinc sulfate, magnesium sulfate, and sodium aluminate into an aqueous solution according to the ratio of substances 12:4:1:1:1:1, wherein nickel sulfate, cobalt sulfate, manganese sulfate, sulfuric acid Zinc and magnesium sulfate are mixed together, the total metal salt concentration is 1.5M, sodium aluminate is prepared separately, the concentration is about 0.1M, the amount of ammonia water is 0.2 times that of metal ions (including sodium aluminate), sodium hydroxide The concentration is 3M. Control the reaction temperature at 58°C, add the solution dropwise under stirring, and pass nitrogen gas to prevent oxidation, keep the pH of the solution at about 10.8, obtain a precipitate, wash the precipitate with deionized water continuously, and then dry it at 100°C , to obtain the precursor of the cathode material.

[0029] Mix the precursor and lithium carbonate uniformly in proportion, the mixing ratio is 1.0...

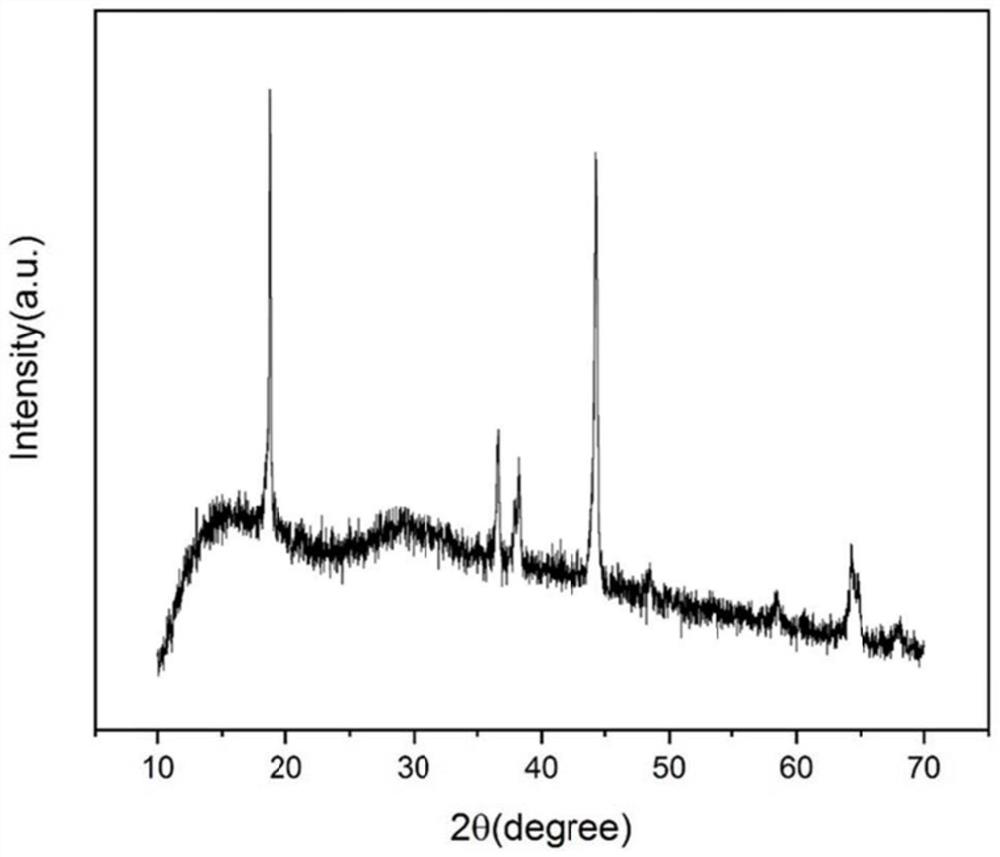

Embodiment 2

[0031] Nickel sulfate, cobalt sulfate, manganese sulfate, magnesium sulfate, and sodium aluminate are configured into an aqueous solution according to the mass ratio of 9:3:1:1:1, wherein nickel sulfate, cobalt sulfate, manganese sulfate, and magnesium sulfate are mixed together, The total metal salt concentration is 1.5M, sodium aluminate is prepared separately, the concentration is about 0.1M, the amount of ammonia water is 0.2 times that of metal ions (containing sodium aluminate), and the concentration of sodium hydroxide is 3M. Control the reaction temperature at 58°C, add the solution dropwise under stirring, and pass nitrogen gas to prevent oxidation, keep the pH of the solution at about 10.8, obtain a precipitate, wash the precipitate with deionized water continuously, and then dry it at 100°C , to obtain the precursor of the cathode material.

[0032] Mix the precursor and lithium carbonate uniformly in proportion, the mixing ratio is 1.05:1 between lithium and other ...

Embodiment 3

[0034] Configure nickel sulfate, cobalt sulfate, manganese sulfate, zinc sulfate, magnesium sulfate, and sodium aluminate into an aqueous solution according to the ratio of substances 32:4:1:1:1:1, and mix with lithium carbonate at a temperature of 780°C. The conditions are the same as in Example 2, and the temperature is lowered to obtain the high-entropy oxide ceramic cathode material LiNi 0.8 co0.1 mn 0.025 Mg 0.025 Al 0.025 Zn 0.025 o 2 . According to the 0.2C test, the discharge capacity of the electrode material is 183mAh g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com