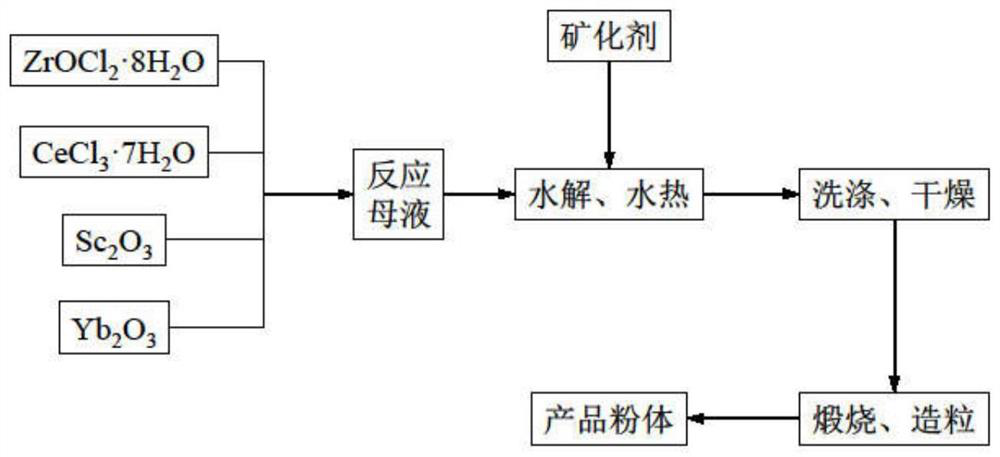

Hydrolysis-hydrothermal method for preparing scandium-cerium-ytterbium-doped zirconium oxide ultrafine powder

A technology of ultrafine powder, zirconium oxychloride octahydrate, which is applied in the field of hydrolysis-hydrothermal preparation of scandium, cerium and ytterbium doped zirconia ultrafine powder, which can solve the problem of low sintering activity and avoid precipitation agglomeration, physical The effect of uniform and stable chemical properties and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

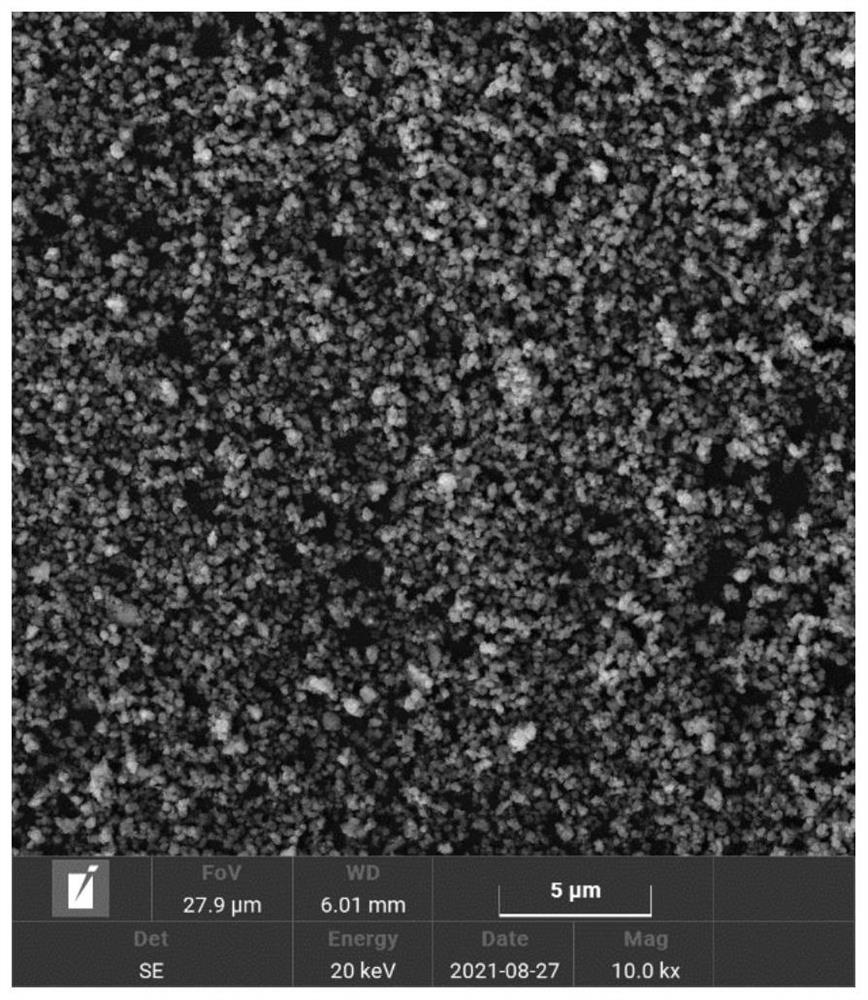

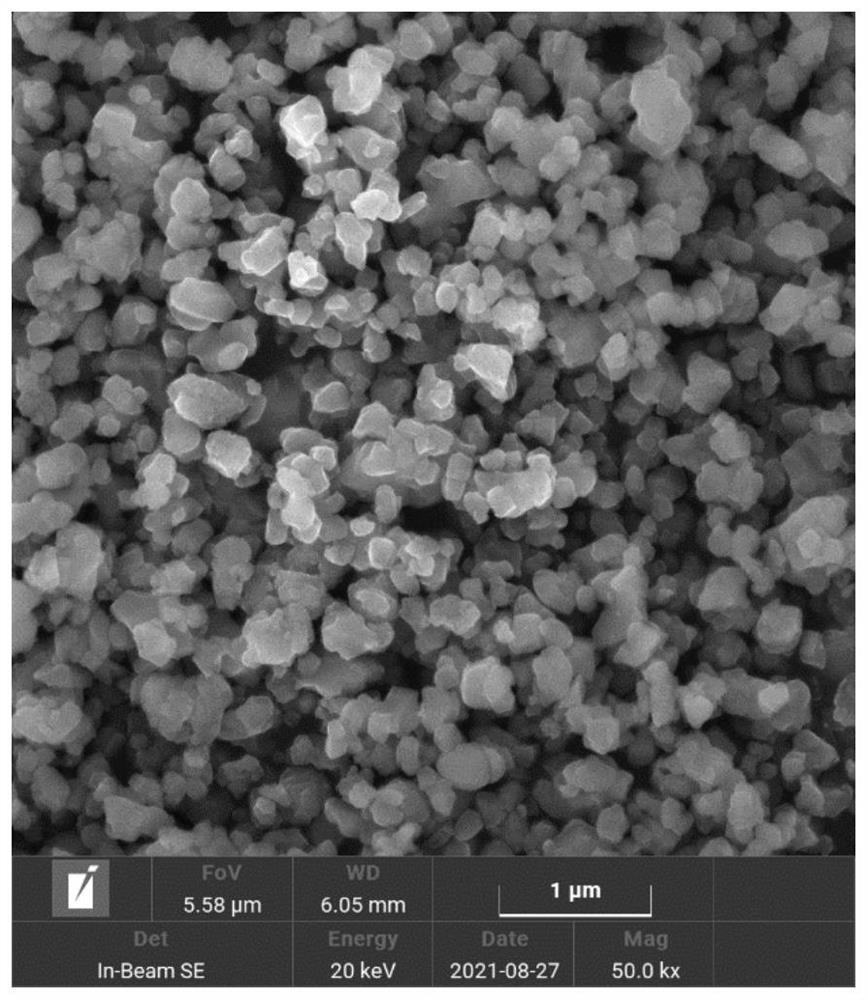

Examples

Embodiment 1

[0047] Step 1. Dissolution: Weigh zirconium oxychloride octahydrate, cerium chloride heptahydrate, scandium oxide, and ytterbium oxide, and put them in a flask, add water and mix well, then heat in an electric heating mantle to make scandium oxide and ytterbium oxide Dissolve to obtain the reaction mother liquor. The concentration of zirconium oxychloride octahydrate in the reaction mother liquor is 2.5mol / L. The ratio of zirconium oxychloride octahydrate, cerium chloride heptahydrate, scandium oxide and ytterbium oxide is ZrO according to the powder composition 2 84wt.%, Sc 2 o 3 11wt.%, Yb 2 o 3 3wt.%, CeO 2 2wt.%.

[0048] Step 2, hydrolysis: transfer the reaction mother liquid to the reaction kettle, and add water to dilute the Zr concentration in the solution to 50g / L to obtain the reaction stock solution; then turn on the heating hydrolysis, use a steam heat exchanger to heat, and raise the temperature of the reaction stock solution to 100 ~104°C, keep warm at ...

Embodiment 2

[0053] Step 1. Dissolution: Weigh zirconium oxychloride octahydrate, cerium chloride heptahydrate, scandium oxide, and ytterbium oxide, and put them in a flask, add water and mix well, then heat in an electric heating mantle to make scandium oxide and ytterbium oxide Dissolving to obtain a reaction mother liquor; the concentration of zirconium oxychloride octahydrate in the reaction mother liquor is 2.2mol / L. The ratio of zirconium oxychloride octahydrate, cerium chloride heptahydrate, scandium oxide and ytterbium oxide is ZrO according to the powder composition 2 82wt.%, Sc 2 o 3 12wt.%, Yb 2 o 3 4wt.%, CeO 2 2wt.%.

[0054] Step 2, hydrolysis: transfer the reaction mother liquid to the reaction kettle, and add water to dilute the Zr concentration in the solution to 50g / L to obtain the reaction stock solution; then turn on the heating hydrolysis, use a steam heat exchanger to heat, and raise the temperature of the reaction stock solution to 100 ~104°C, keep warm at ...

Embodiment 3

[0059] Step 1. Dissolution: Weigh zirconium oxychloride octahydrate, cerium chloride heptahydrate, scandium oxide, and ytterbium oxide, and put them in a flask, add water and mix well, then heat in an electric heating mantle to make scandium oxide and ytterbium oxide Dissolving to obtain a reaction mother liquor; the concentration of zirconium oxychloride octahydrate in the reaction mother liquor is 2.8mol / L. The ratio of zirconium oxychloride octahydrate, cerium chloride heptahydrate, scandium oxide and ytterbium oxide is ZrO according to the powder composition 2 86wt.%, Sc 2 o 3 10wt.%, Yb 2 o 3 3wt.%, CeO 2 1 wt.%.

[0060] Step 2, hydrolysis: transfer the reaction mother liquid to the reaction kettle, and add water to dilute the Zr concentration in the solution to 50g / L to obtain the reaction stock solution; then turn on the heating hydrolysis, use a steam heat exchanger to heat, and raise the temperature of the reaction stock solution to 100 ~104°C, keep warm at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com