Slag system for smelting GH3625 nickel-base alloy containing rare earth Ce and electroslag remelting smelting method thereof

A nickel-based alloy and slag system technology, applied in the field of metallurgy, can solve problems such as burning of Ce elements, achieve the effects of good composition quality, solve burning loss of easily oxidizable elements, and uniform distribution of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the present embodiment, the crystallizer diameter is 150mm, and the chemical composition of the slag system used is configured according to the following mass percentages: CaF 2 : 38%, CaO: 24%; Al 2 o 3 : 20%; NaF: 6%; MgO: 4%; TiO 2 : 2%; CeO 2 : 5%; SiO 2 :1%.

[0038] During the smelting process using the above slag system, smelting is carried out according to the smelting method of the present invention. During the smelting process, aluminum particles are added to the slag pool in an amount of 1 g per kilogram of alloy.

[0039] At the same time, another group of notoginseng slag is smelted, and the chemical composition of notoginseng slag is configured according to the following mass percentage: CaF 2 : 70%; Al 2 o 3 : 30%.

[0040] In the smelting process using notoginseng slag, no aluminum particles are added.

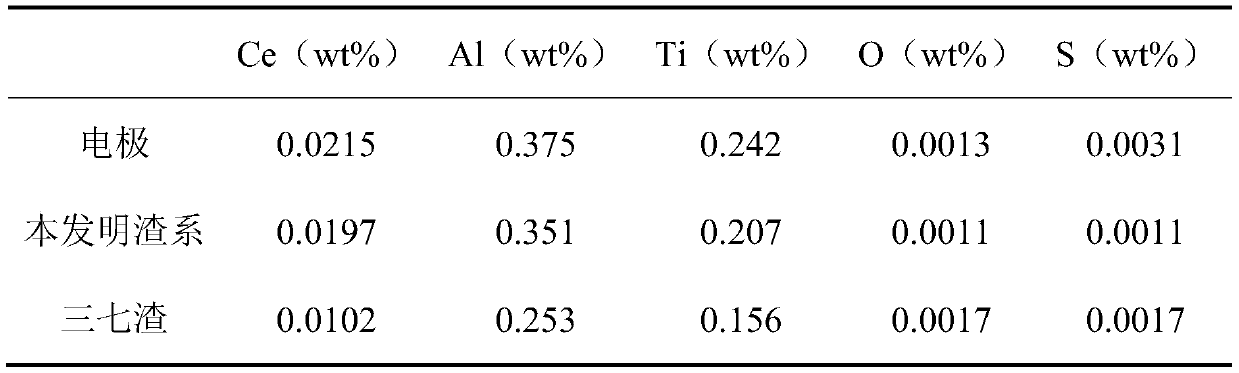

[0041] After smelting, the ingots were detected by ICP and nitrogen and oxygen analyzers, and the chemical analysis results are shown in Tab...

Embodiment 2

[0046] In the present embodiment, the crystallizer diameter is 260mm, and the chemical composition of the slag system used is configured according to the following mass percentages: CaF 2 : 38%, CaO: 24%; Al 2 o 3 : 20%; NaF: 6%; MgO: 4%; TiO 2: 2%; CeO 2 : 5%; SiO 2 :1%.

[0047] In this example, three GH3625 alloys with different Ce contents were used for electroslag remelting.

[0048] During the smelting process using the above slag system, smelting is carried out according to the smelting method of the present invention. During the smelting process, aluminum particles are added to the slag pool in an amount of 1 g per kilogram of alloy.

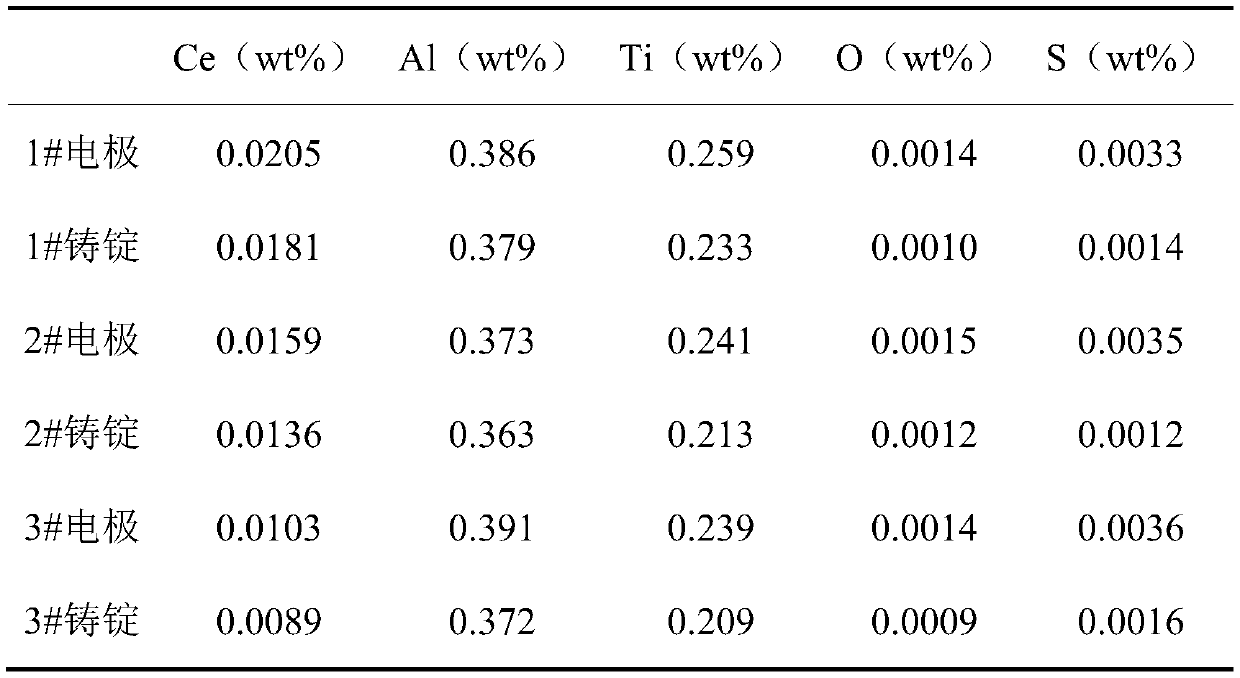

[0049] The composition of the cast ingot after smelting was detected by ICP and nitrogen and oxygen analyzer, and the chemical analysis results are shown in Table 2.

[0050] Table 2 GH3625 alloy components content

[0051]

[0052] The smelting results show that the slag system and smelting method of the present invention effe...

Embodiment 3

[0054] In this embodiment, the diameter of the crystallizer is 260 mm, and the chemical components of the three slag systems used are configured according to the following mass percentages: S1: CaF 2 : 42%, CaO: 24%; Al 2 o 3 : 20%; NaF: 7%; MgO: 4%; TiO 2 : 2%; SiO 2 : 1%; S2: CaF 2 : 39%, CaO: 24%; Al 2 o 3 : 20%; NaF: 7%; MgO: 4%; TiO 2 : 2%; CeO 2 : 3%; SiO 2 : 1%; S3: CaF 2 : 36%, CaO: 24%; Al 2 o 3 : 20%; NaF: 7%; MgO: 4%; TiO 2 : 2%; CeO 2 : 6%; SiO 2 :1%.

[0055] In this embodiment, the GH3625 alloy with the same composition is used for electroslag remelting.

[0056] During the smelting process using the above slag system, smelting is carried out according to the smelting method of the present invention. During the smelting process, aluminum particles are added to the slag pool in an amount of 1 g per kilogram of alloy.

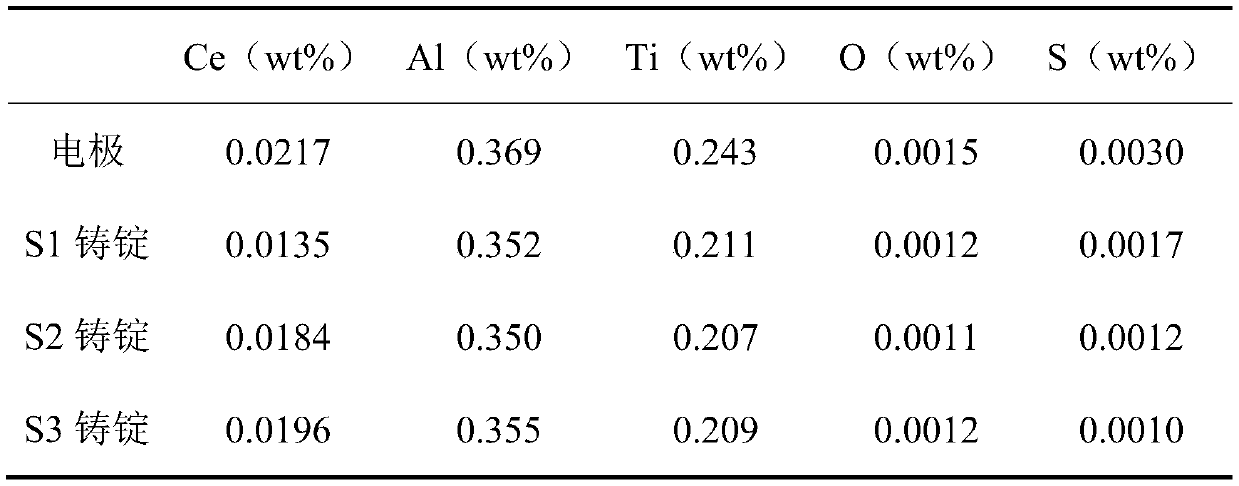

[0057] After smelting, the ingots were detected by ICP and nitrogen and oxygen analyzers, and the chemical analysis results are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com