Manganese ferrous phosphate as well as preparation method and application thereof

A technology of ferrous manganese phosphate and ferrous phosphate, which is applied in the preparation of ferrous manganese phosphate, application of ferrous manganese phosphate in lithium iron manganese phosphate battery, in the field of ferrous manganese phosphate, can solve the problem that the proportion of ferrous manganese phosphate is different Stability and other issues, to achieve the effect of stable ratio, low impurity content, and uniform distribution of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

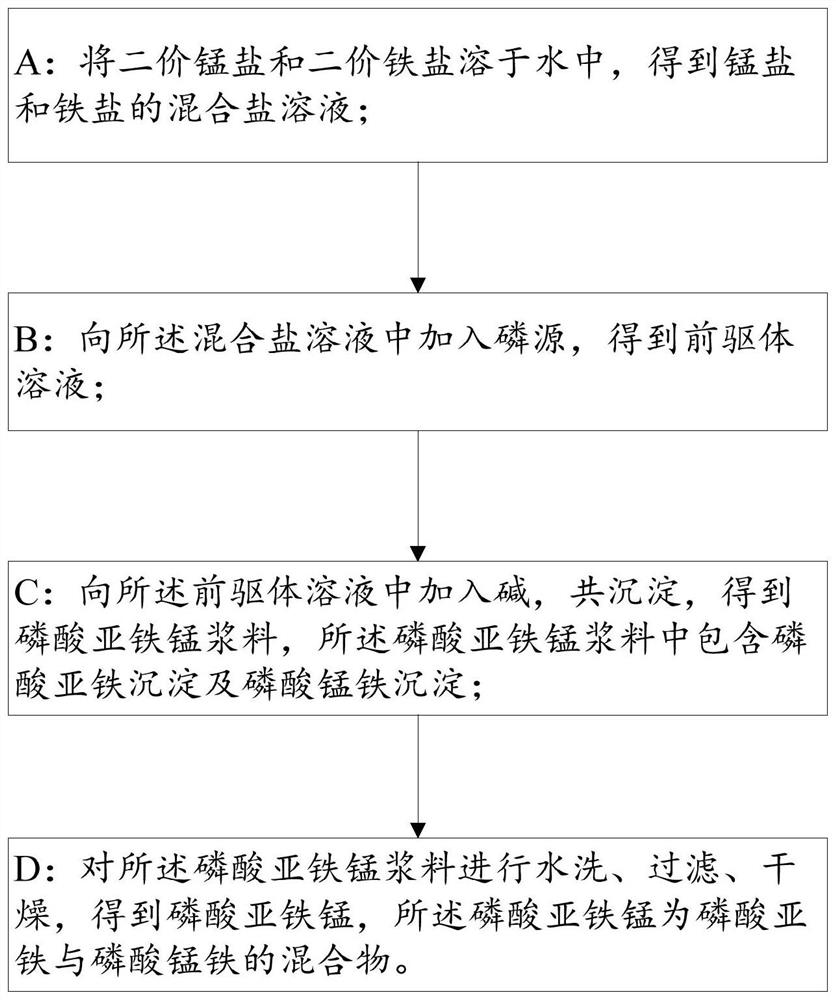

[0033] see figure 1 , the embodiment of the present application provides a method for preparing battery-grade manganese ferrous phosphate, comprising the following steps:

[0034] A: dissolving divalent manganese salt and ferrous salt in water to obtain a mixed salt solution of manganese salt and iron salt;

[0035] B: adding a phosphorus source to the mixed salt solution to obtain a precursor solution;

[0036] C: adding alkali to the precursor solution, and co-precipitating to obtain ferrous manganese phosphate slurry, which contains ferrous phosphate precipitation and ferromanganese phosphate precipitation;

[0037] D: Washing, filtering and drying the ferrous manganese phosphate slurry to obtain ferrous manganese phosphate, and the ferrous manganese phosphate is a mixture of ferrous phosphate and ferromanganese phosphate.

[0038] In the step A:

[0039] The divalent manganese salt is a water-soluble divalent manganese salt. The water-soluble divalent manganese salt may ...

Embodiment 1

[0062] 120.000g of ferrous sulfate heptahydrate (0.432mol) and 110.466g of battery grade manganese sulfate (0.648mol) were dissolved in 300g of water to obtain a mixed salt solution;

[0063] 225.583g of trisodium phosphate (0.582mol) was dissolved in 700g of water to obtain trisodium phosphate solution, and 24g of phosphoric acid solution (0.209mol) with a concentration of 85.4% was added dropwise to the mixed salt solution while stirring, and then added dropwise The trisodium phosphate solution;

[0064] Use sodium hydroxide to adjust the pH value of the system to 7, and then continue to stir at room temperature for 2 hours to obtain ferrous manganese phosphate slurry;

[0065] The ferrous manganese phosphate slurry is washed with water, filtered and dried to obtain ferrous manganese phosphate.

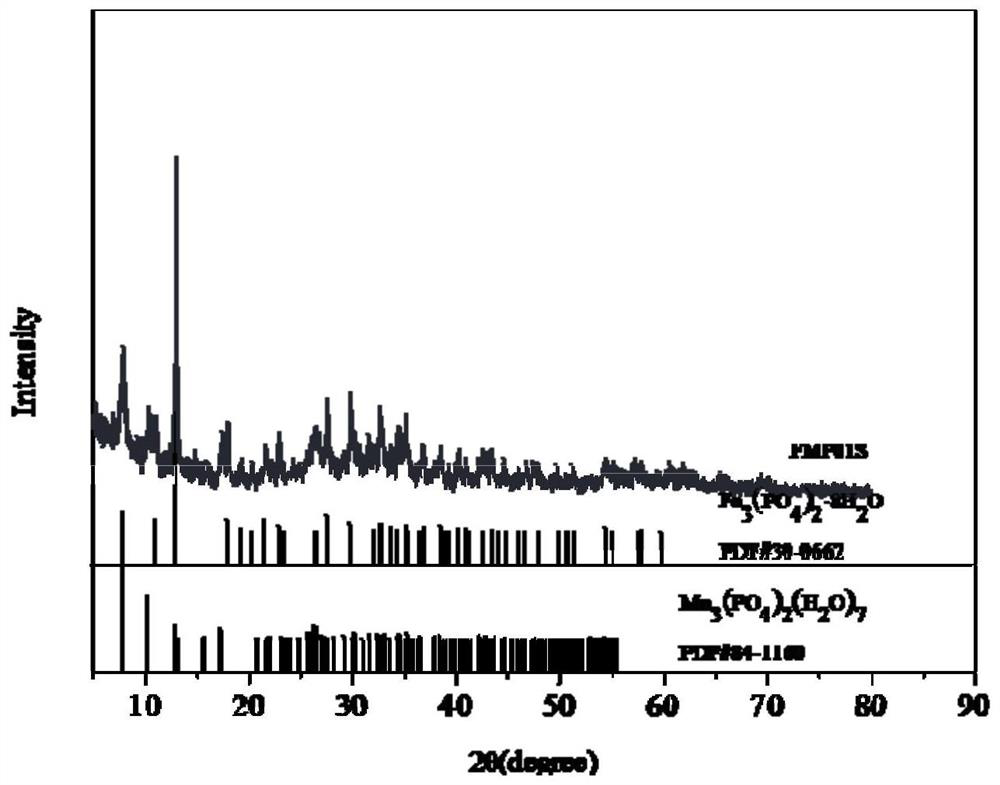

[0066] The ferrous manganese phosphate of the present embodiment is (Mn 0.6 Fe 0.4 ) 3 (PO 4 ) 2 ·yH 2 O.

Embodiment 2

[0068] Dissolve 120.000g of ferrous sulfate heptahydrate (0.432mol) and 110.466g of battery grade manganese sulfate (0.647mol) in 300g of water to obtain a mixed salt solution;

[0069] 225.583g of trisodium phosphate (0.582mol) was dissolved in 700g of water to obtain trisodium phosphate solution, and 24g of phosphoric acid solution (0.209mol) with a concentration of 85.4% was added dropwise to the mixed salt solution while stirring, and then added dropwise The trisodium phosphate solution;

[0070] Adjust the pH value of the system to 6.5 with sodium hydroxide, and then continue to stir at room temperature for 2 hours to obtain ferrous manganese phosphate slurry;

[0071] The ferrous manganese phosphate slurry is washed with water, filtered and dried to obtain ferrous manganese phosphate.

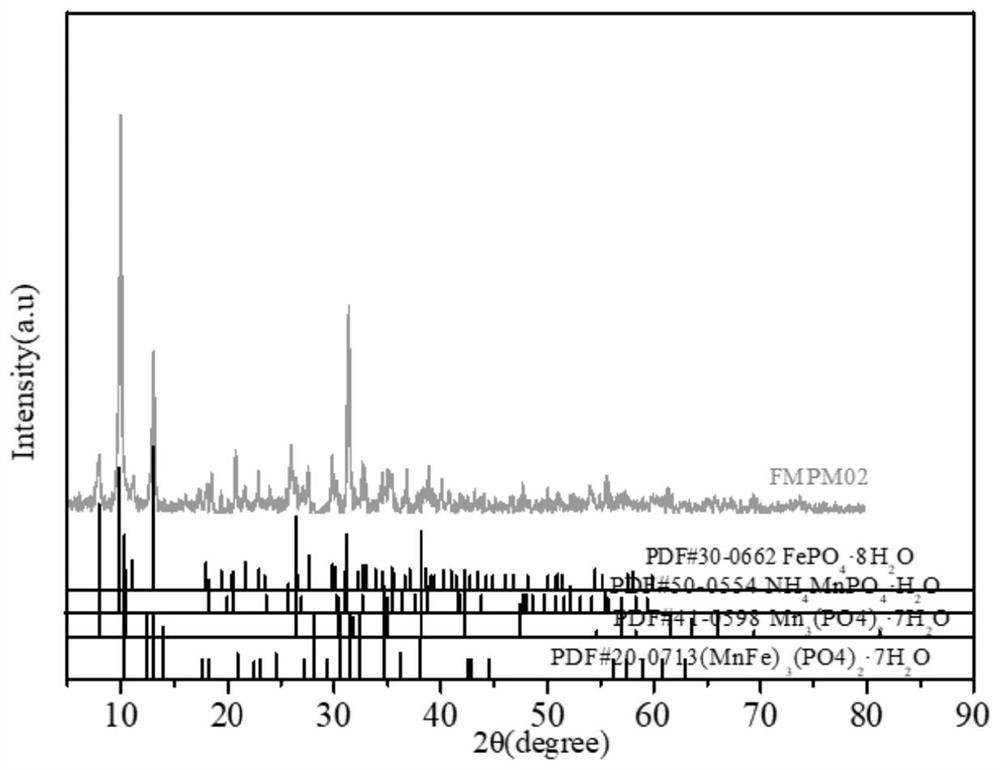

[0072] The ferrous manganese phosphate of the present embodiment is (Mn 0.6 Fe 0.4 ) 3 (PO 4 ) 2 ·yH 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com