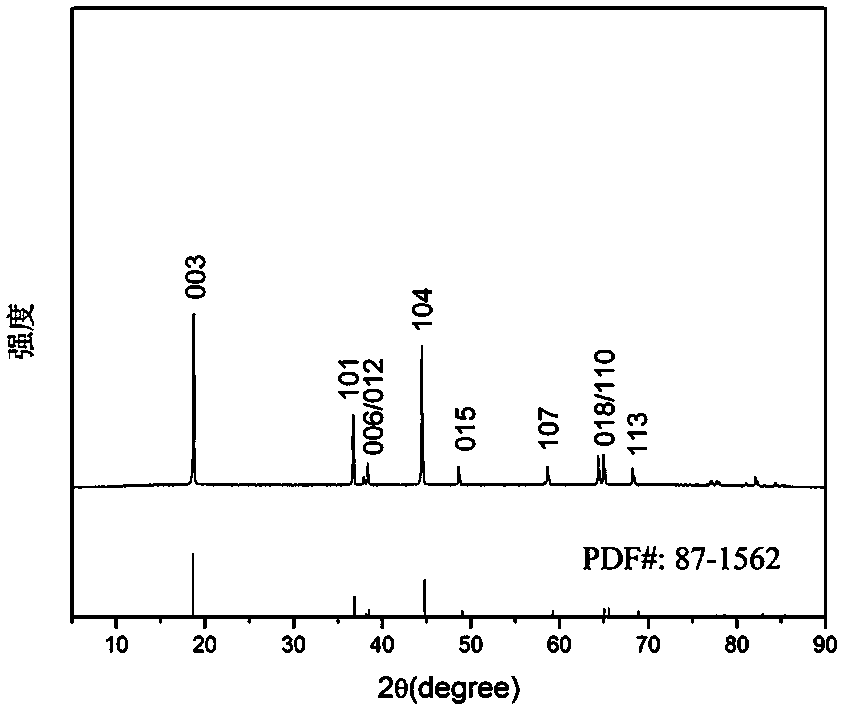

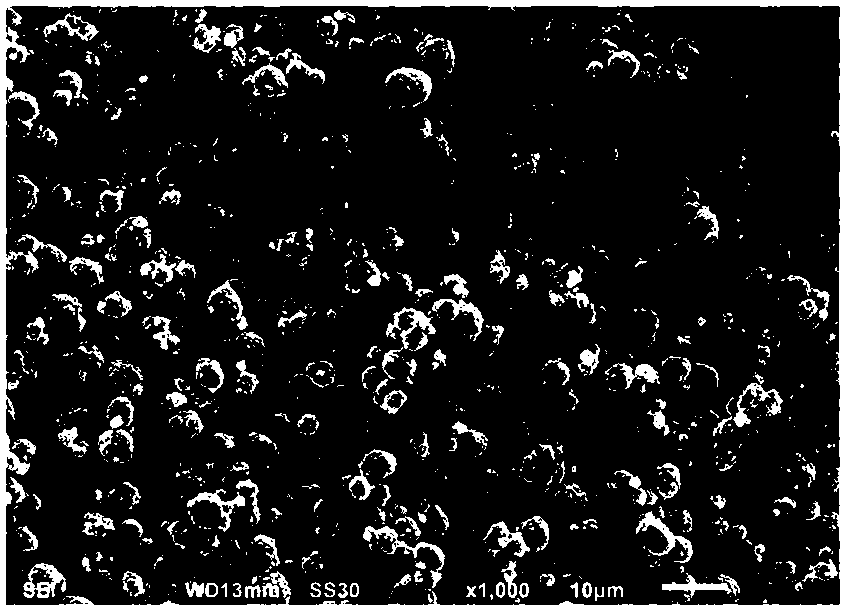

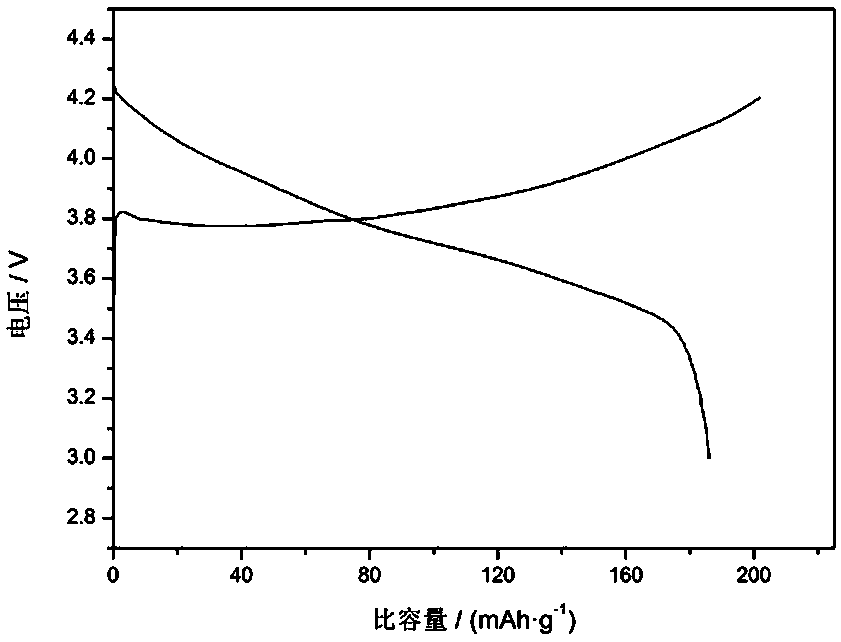

Negative and positive ion co-doped monocrystal-like ternary positive electrode material and preparation method thereof

A cathode material, anion and cation technology, applied in the field of single-crystal ternary cathode materials, can solve the problems of low packing density, collapse of secondary spherical particle structure, and degradation of electrochemical performance, so as to achieve uniform distribution of elements and reduce cation mixing degree, the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of precursors: The precursors of ternary cathode materials doped with Zn cations were prepared by sol-gel method. According to the molar ratio Ni:Co:Al:Zn=0.78:0.15:0.05:0.02, weigh the acetate of nickel, cobalt, aluminum, and zinc and dissolve it in the methanol / ethanol mixed solution, and the mixed solution is continuously carried out at 50°C. Stir and slowly add complexing agent citric acid. After reacting for 12 hours, the mixed solution was placed at 80° C. and stirred continuously until the solution completely turned into a xerogel. Dry the obtained xerogel in a vacuum oven at 100°C for 24 hours, then place the dried powder in a tube furnace at 750°C for 12 hours in an air atmosphere, and then grind and sieve the obtained powder to prepare it precursors.

[0024] (2) Preparation of single-crystal-like ternary cathode materials co-doped with anions and cations. Weigh lithium hydroxide, precursor, and lithium fluoride according to the molar ratio ...

Embodiment 2

[0027] (1) Preparation of precursors: The precursors of ternary cathode materials doped with Mg cations were prepared by sol-gel method. According to the molar ratio Ni:Co:Al:Mg= 0.77:0.15:0.05:0.03, weigh the acetate of nickel, cobalt, aluminum, magnesium and dissolve it in the methanol / ethanol mixed solution, and the mixed solution is continuously carried out at 50°C Stir and slowly add complexing agent citric acid. After reacting for 12 hours, the mixed solution was placed at 80° C. and stirred continuously until the solution completely turned into a xerogel. Dry the obtained xerogel in a vacuum oven at 100°C for 24 hours, then place the dried powder in a tube furnace at 750°C for 12 hours in an air atmosphere, and then grind and sieve the obtained powder to prepare it precursors.

[0028] (2) Preparation of single-crystal-like ternary cathode materials co-doped with anions and cations. Weigh lithium hydroxide, precursor, and lithium fluoride according to the molar ratio...

Embodiment 3

[0030] (1) Preparation of precursors: The precursors of ternary cathode materials doped with Zn cations were prepared by sol-gel method. According to the molar ratio Ni:Co:Al:Zn=0.79:0.15:0.05:0.01, weigh the acetate of nickel, cobalt, aluminum, and zinc and dissolve it in the methanol / ethylene glycol mixed solution, and keep the mixed solution at 50°C. Stir and slowly add complexing agent glycolic acid. After reacting for 12 hours, the mixed solution was placed at 80° C. and stirred continuously until the solution completely turned into a xerogel. Dry the obtained xerogel in a vacuum oven at 100°C for 24 hours, then place the dried powder in a tube furnace at 750°C for 12 hours in an air atmosphere, and then grind and sieve the obtained powder to prepare it precursors.

[0031] (2) Preparation of single-crystal-like ternary cathode materials co-doped with anions and cations. Weigh lithium hydroxide, precursor, and lithium chloride according to the molar ratio of 1.04:1:0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com