Method for preparing ternary cathode material NCA of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied to battery electrodes, positive electrodes, electrical components, etc., can solve the problems of large loss of cycle capacity and poor structural stability, and achieve good product quality, less waste of raw materials, and better process control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

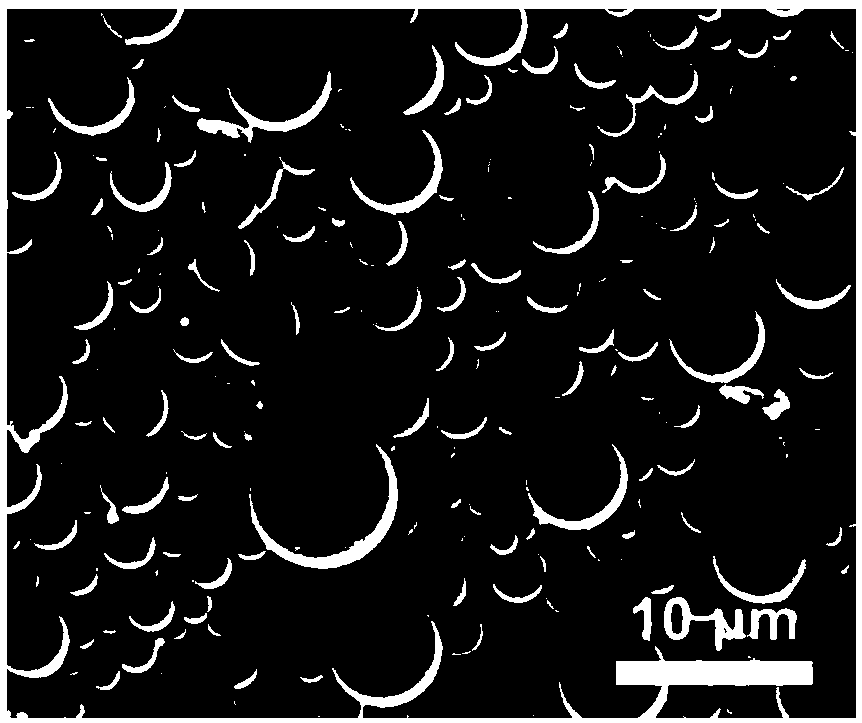

Embodiment 1

[0026] Prepare 800 mL of 1mol / L nickel sulfate, 150 mL of 1mol / L cobalt sulfate, and 50 mL of 1mol / L aluminum sulfate solution, mix the cobalt sulfate and aluminum sulfate solutions evenly, and then add the template agent spherical activated carbon to the mixed solution , the template agent is spherical activated carbon, wherein the specific surface area of activated carbon and high specific surface is greater than 1000m 2 / g, the added template mass is 0.15% of the mass fraction of the prepared precursor, fully stirred for 2 hours, then added nickel sulfate solution to the mixed solution, and finally mixed 1L of precipitant solution 2mol / L sodium hydroxide solution with The mixed solution is put into the reaction kettle together to carry out reaction and precipitation, and after the full reaction, it is allowed to stand for aging. After the aging treatment, the solid material is washed and vacuum-dried to obtain the NCA precursor of the ternary positive electrode material; ...

Embodiment 2

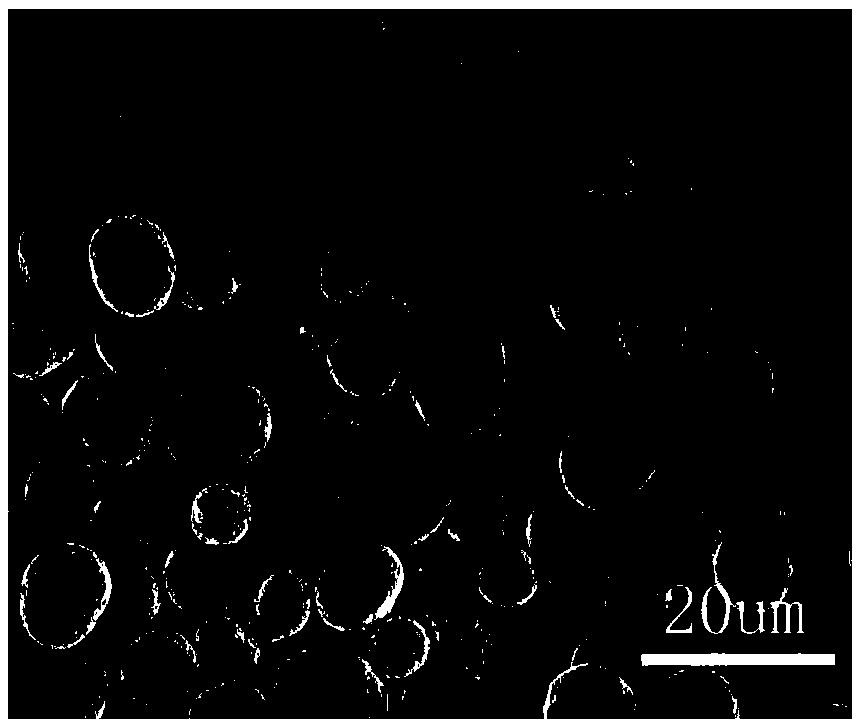

[0029] Prepare 800 mL of 1mol / L nickel chloride, 130 mL of 1mol / L cobalt chloride, and 70 mL of 1mol / L aluminum chloride solution, mix the cobalt chloride and aluminum chloride solutions evenly, and then add the template agent spherical activated carbon Added to the mixed solution, the template agent is a high specific surface adsorption resin with a specific surface area greater than 1000m 2 / g, the added template mass is 1% of the mass fraction of the prepared precursor, fully stirred for 8 hours, then added the nickel chloride solution to the mixed solution, and finally the precipitant solution 2.3mol / L sodium hydroxide solution 1L and the mixed solution flow together into the reaction kettle for reaction and precipitation. After full reaction, let it stand for aging. After the aging treatment, the solid material is washed and vacuum-dried to obtain the NCA precursor of the ternary cathode material;

[0030] The NCA precursor of the obtained ternary positive electrode mater...

Embodiment 3

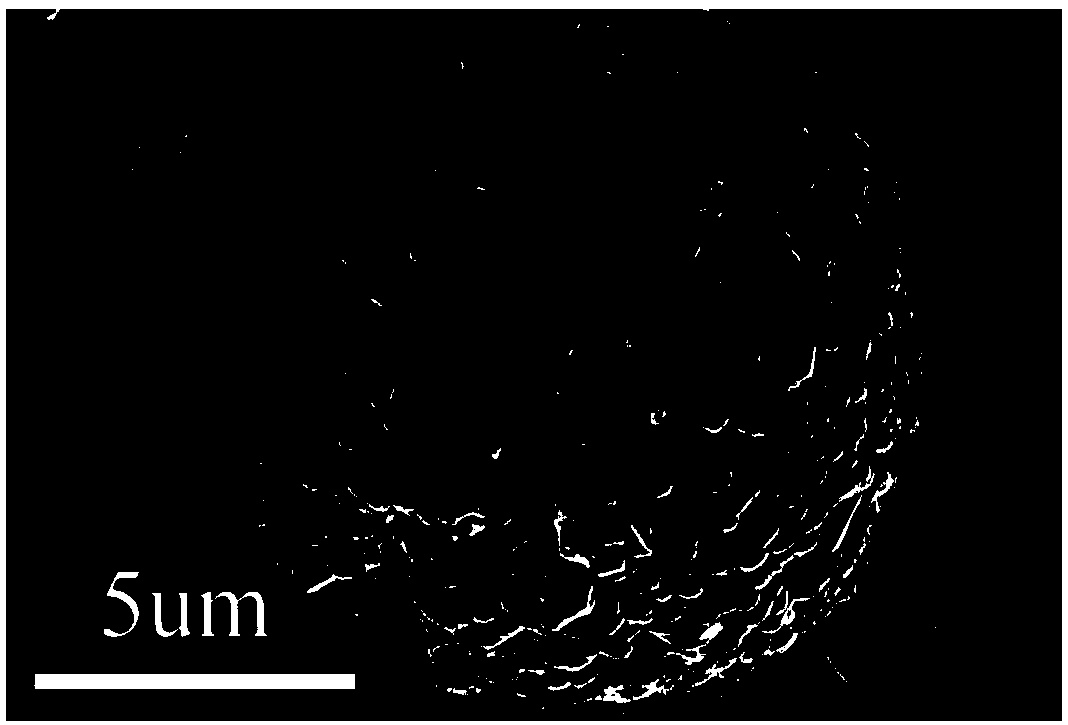

[0032] Prepare 800 mL of 1mol / L nickel carbonate, 160 mL of 1mol / L cobalt carbonate, and 40 mL of 1mol / L aluminum carbonate solution, mix the cobalt carbonate and aluminum carbonate solutions evenly, and then add the template agent spherical activated carbon to the mixed solution , the template agent is spherical activated carbon, wherein the specific surface area of activated carbon and high specific surface is greater than 1000m 2 / g, the added template quality is 5% of the mass fraction of the prepared precursor, fully stirred for 3 hours, then the nickel carbonate solution was added to the mixed solution, and finally the precipitant solution 1.5mol / L sodium hydroxide solution 1L and the mixed solution flow together into the reaction kettle for reaction and precipitation. After full reaction, let it stand for aging. After the aging treatment, the solid material is washed and vacuum-dried to obtain the NCA precursor of the ternary cathode material;

[0033] The NCA precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com