Composite cathode material for lithium ion battery and preparation method thereof

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as failure to meet the life requirements of new energy vehicles, poor battery cycle life and high temperature performance, and electrolyte deterioration reactions. Achieve the effects of easy control of manufacturing process, low production cost and tight cladding layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

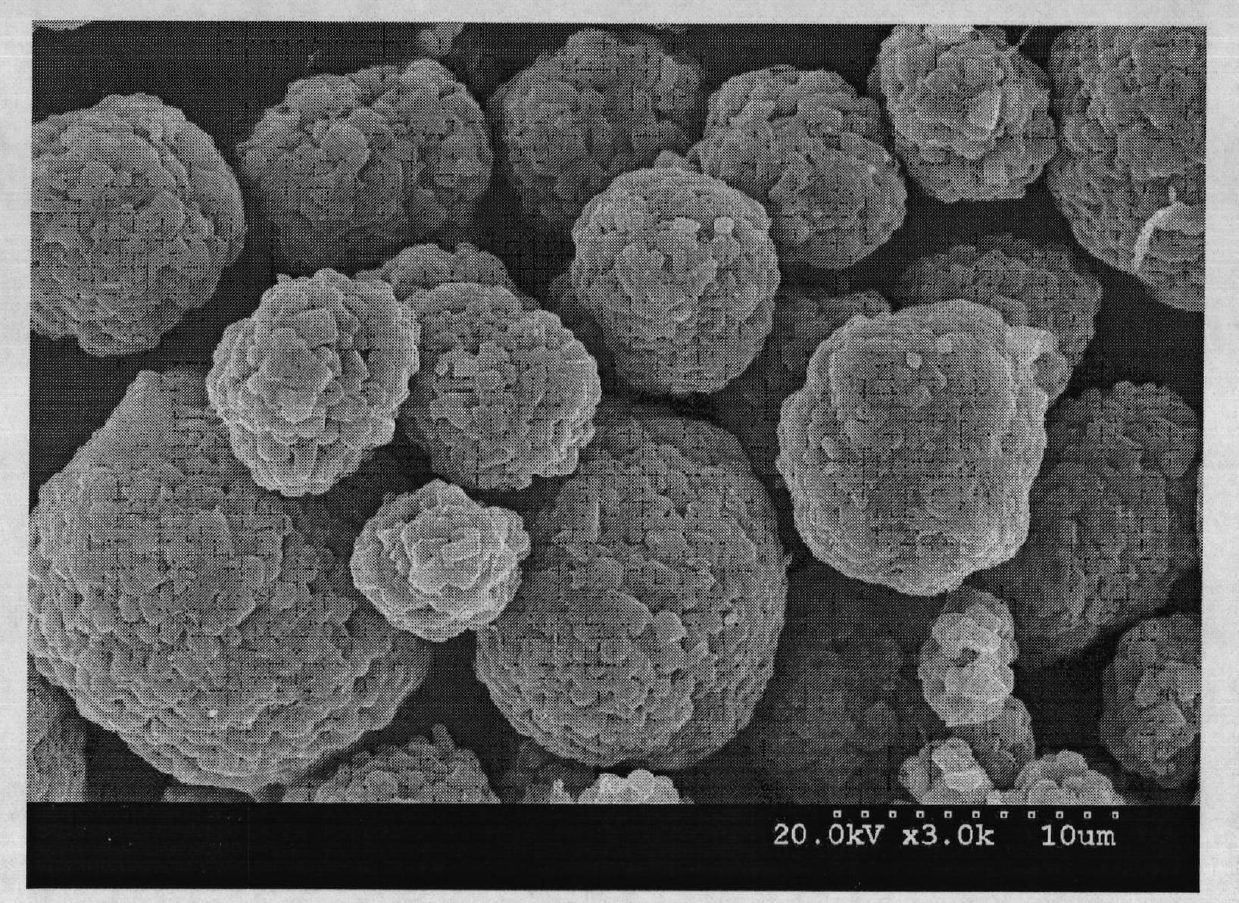

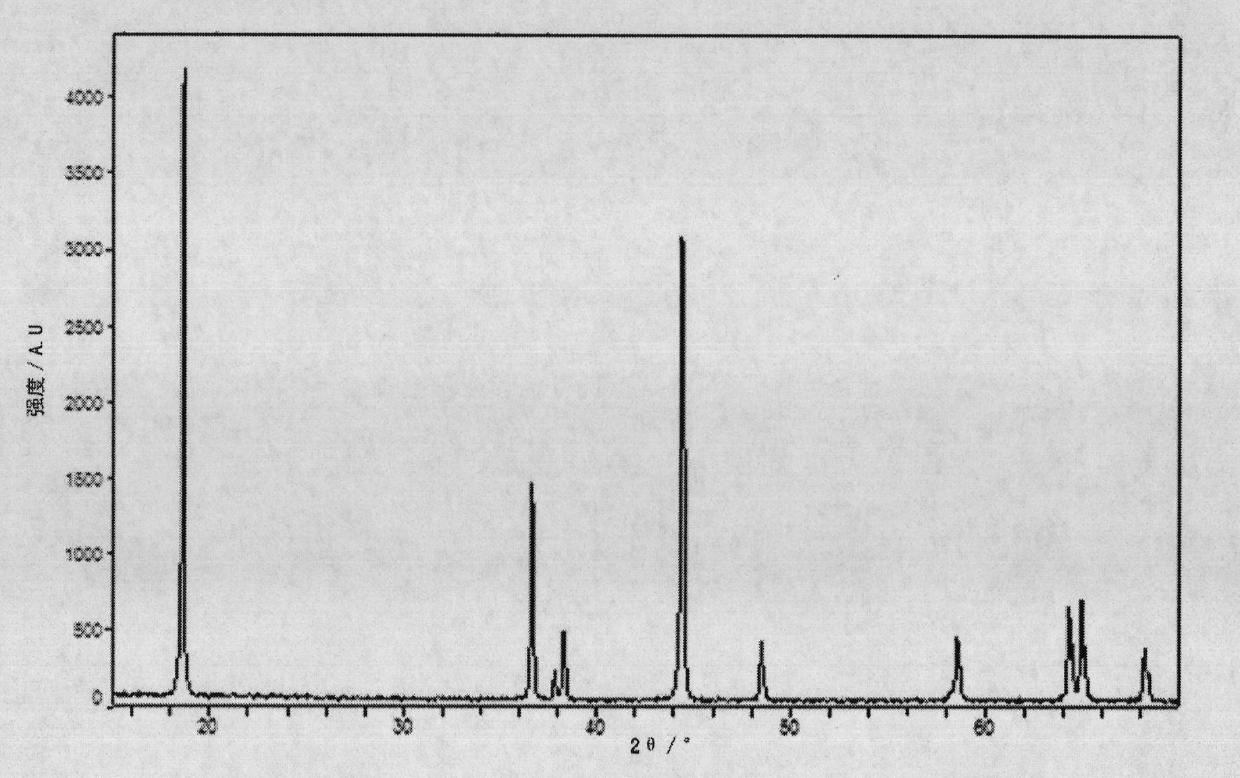

[0021] Embodiment one: with synthetic chemical formula LiNi 0.5 co 0.2 mn 0.3 o 2 0.005Al 2 o 3 As an example, the LiNi 0.5 co 0.2 mn 0.3 o 2 Add deionized water 5 times its weight into the reactor, and then prepare aluminum chloride solution with a rate of 0.25mol / L, and 3.5mol / L ammonia solution and 2mol / L NaOH solution; use an electronic metering pump to press 10L / min, 6L / min, 1.25L / min into the reactor, keep the reaction temperature at 80°C, pH value 11.5, react in the reactor at 500r / min for 6h, wash, filter and dry , and then placed in a high-temperature furnace, sintered at 350 ° C for 4 hours, the composite cathode material LiNi 0.5 co 0.2 mn 0.3 o 2 .0.005Al 2 o 3 . Its SEM picture is attached figure 1 , see attached XRD chart figure 2 .

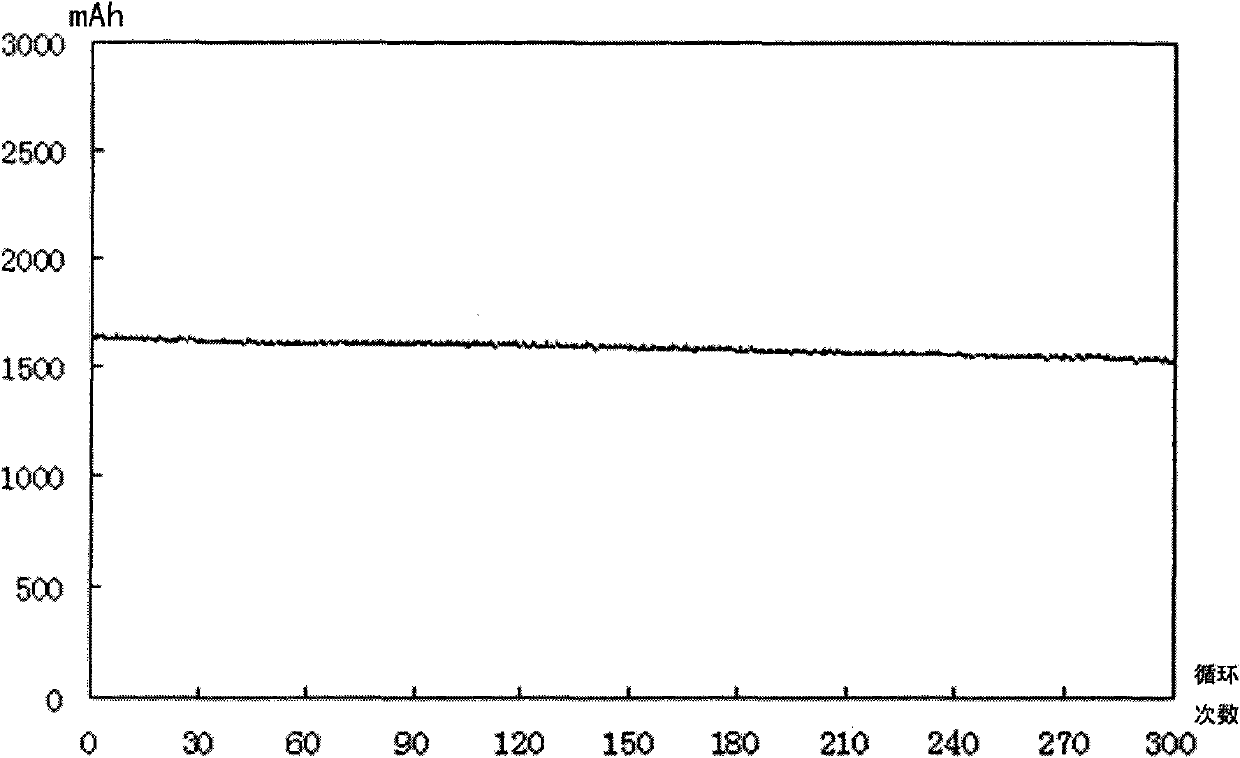

[0022] This material is used as the positive electrode material of the lithium ion battery, acetylene black is used as the conductive agent, and the polytetrafluoroethylene is used as the binder. The weight ratio...

Embodiment 2

[0023] Embodiment two: with synthetic chemical formula LiN i0.5 co 0.2 mn 0.3 o 2 0.01Al 2 o 3 As an example, the LiNi 0.5 co 0.2 mn 0.3 o 2 Add deionized water 6 times its weight into the reactor, and then prepare aluminum chloride solution with a rate of 0.3mol / L, and 3.5mol / L ammonia solution and 2mol / L NaOH solution; use an electronic metering pump to press 10L / min, 6L / min, 1.5L / min flow into the reactor, keep the reaction temperature at 85°C, pH value 11.8, react in the reactor at 550r / min for 6h, wash, filter and dry , and then placed in a high-temperature furnace, sintered at 350 ° C for 4 hours, the composite cathode material LiNi 0.5 co 0.2 mn 0.3 o 2 0.01Al 2 o 3 .

[0024] The 0.2C capacity and 1C cycle life of the composite material were tested by the same method as in Example 1. The first discharge capacity at 0.2C reached 157mAh / g, and the 300-cycle capacity retention rate at 1C rate reached 97.4%.

Embodiment 3

[0025] Embodiment three: with synthetic chemical formula LiNi 0.5 co 0.2 mn 0.3 o 2 .0.01TiO 2 As an example, the LiNi 0.5 co 0.2 mn 0.3 o 2Add deionized water 5 times its weight into the reactor, and then prepare titanium chloride solution with a rate of 0.5mol / L, and 3.5mol / L ammonia solution and 2mol / L NaOH solution; / min, 6L / min, 0.25L / min flow into the reactor, keep the reaction temperature at 90°C, pH value 11.0, react in the reactor at 800r / min for 6h, wash, filter and dry , put it into a high-temperature furnace, and sinter at 450°C for 6 hours to obtain the composite cathode material LiNi 0.5 co 0.2 mn 0.3 o 2 .0.01TiO 2 .

[0026] The 0.2C capacity and 1C cycle life of the composite material were tested by the same method as in Example 1. The first discharge capacity at 0.2C reached 162mAh / g, and the 300-cycle capacity retention rate at 1C rate reached 93.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com