Novel Cd-Te based thermoelectric material and preparation method thereof

A thermoelectric material and matrix technology, which is applied in the direction of the lead wire material of the thermoelectric device junction to achieve the effects of uniform distribution of elements, short preparation time and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the thermoelectric material of the present invention comprises the following steps:

[0046] (a) Provide tellurium, cadmium, and provide doping raw materials and / or composite raw materials;

[0047] (b) heating the tellurium, cadmium, and the doping raw material and / or composite raw material for 1-50 hours under vacuum and high temperature conditions to obtain a mixture, and the high temperature refers to 800-1500°C;

[0048] (c) grinding the mixture obtained in step b) into powder after cooling;

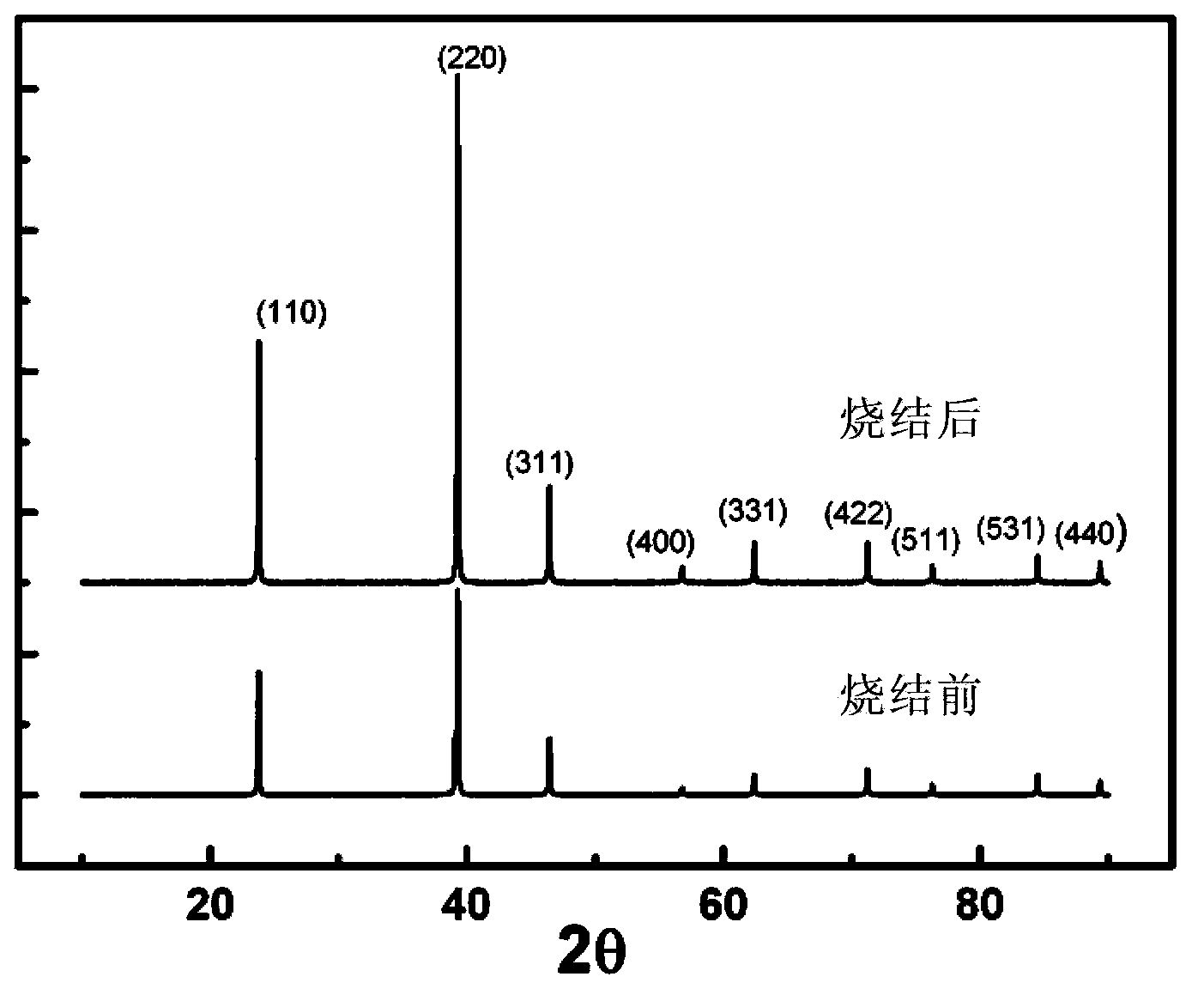

[0049] (d) Sintering the powder obtained in step c) to obtain the thermoelectric material, wherein

[0050] The doping raw material is CdX 2 Or A, where X is a halogen element, and A is a metal element with a valence of +3;

[0051] The composite raw material is a conductive element or a conductive compound;

[0052] The sintering is hot press sintering, spark plasma sintering or microwave sintering.

[0053] In a preferred embodiment, the prepa...

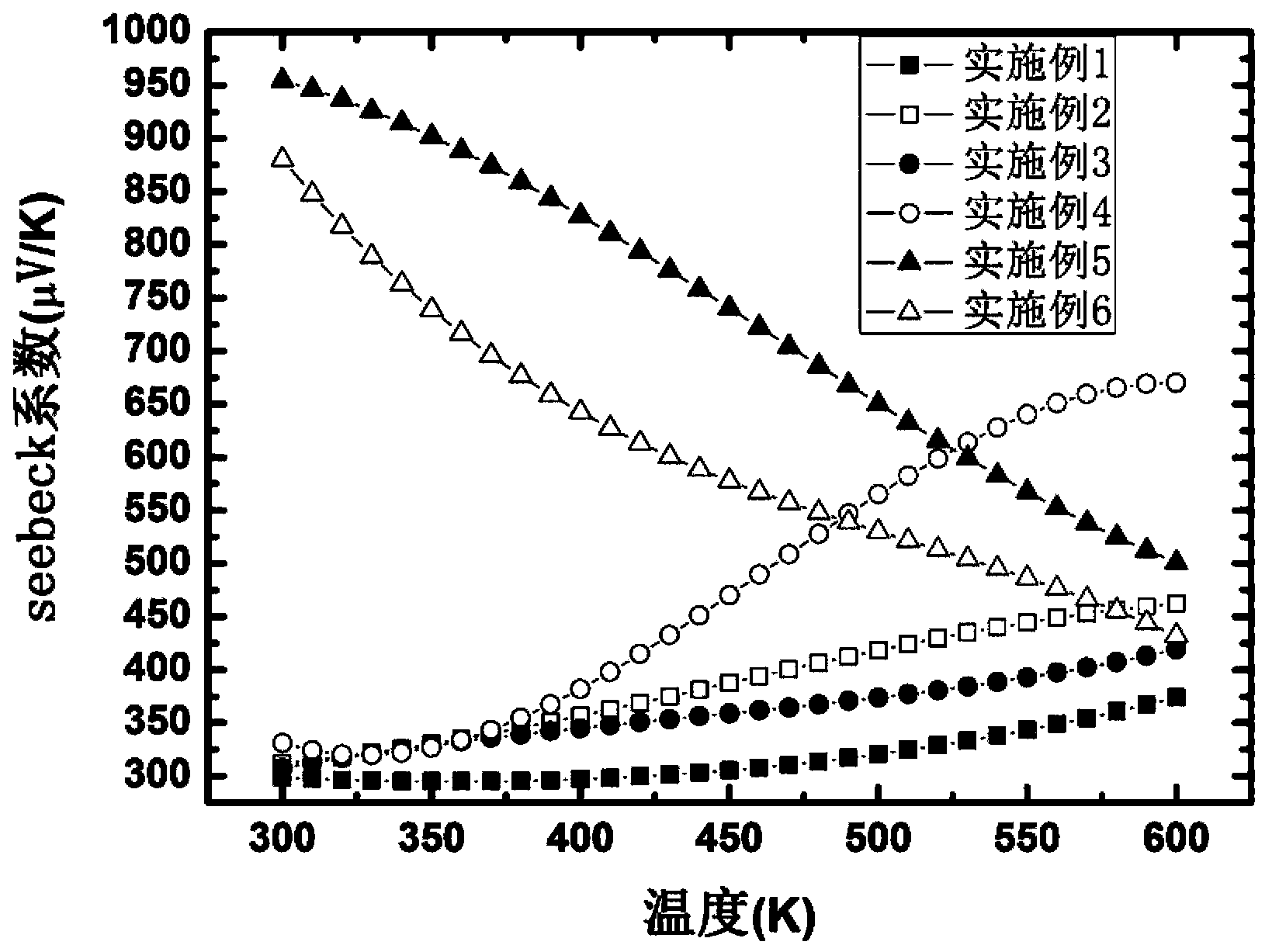

Embodiment 1

[0067] Weigh the bulk cadmium (Cd) and bulk tellurium (Te) according to the mass ratio of 0.5:1, and then add 1% (molar percentage) of cadmium chloride (CdCl 2 ), put it into a quartz tube whose inner wall has been coated with carbon, and then vacuumize the quartz tube (to 10 -3 torr) and encapsulate the quartz tube with an acetylene flame. Put the vacuum-packed quartz tube in a high-temperature furnace, raise it to 850°C at 5°C / min, and keep it for 5 hours, then raise it to 1200°C at 3°C / min, keep it for 8 hours, and then lower it to room temperature at 10°C / min taken out, thus obtaining chlorine-doped cadmium telluride polycrystalline material.

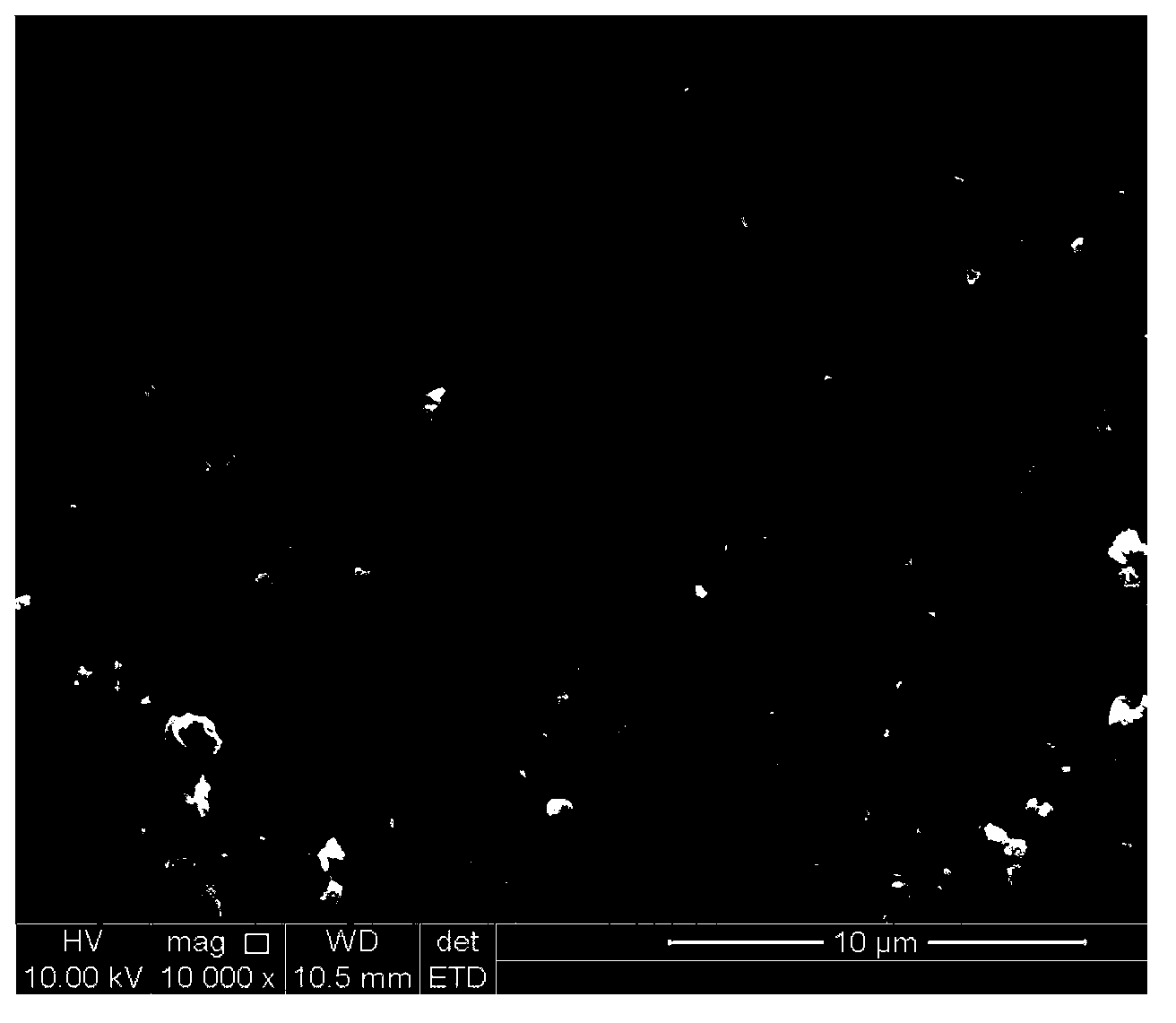

[0068] The quartz tube cooled to room temperature was crushed, and the chlorine-doped cadmium telluride polycrystalline material was taken out for grinding, and the powder with a particle size of 60 μm-180 μm was subjected to spark plasma sintering (SPS). The sintering temperature was 850°C. The sintering pressure used is 50MPa, t...

Embodiment 2

[0070] Weigh the bulk cadmium (Cd) and bulk tellurium (Te) according to the mass ratio of 1.0:1, and then add 1% (molar percentage) of cadmium bromide (CdBr 2 ), put it into a quartz tube whose inner wall has been coated with carbon, and then vacuumize the quartz tube (to 10 -3 torr) and encapsulate the quartz tube with an acetylene flame. Place the vacuum-encapsulated quartz tube in a high-temperature furnace, raise it to 1100°C at a rate of 20°C / min, keep it warm for 12 days, and then cool it down to room temperature naturally to obtain a chlorine-doped cadmium telluride polycrystalline material. The quartz tube cooled to room temperature is crushed, and the chlorine-doped cadmium telluride polycrystalline material is taken out and ground to a powder with a particle size of 60 μm-180 μm. The above-mentioned powders were hot-pressed and sintered, the sintering temperature was selected as 880°C, the sintering pressure was 60MPa, the heating rate was 50°C / min, and the holding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com