Mechanical alloying preparation method of Ti-22Al-25Nb (at.%) solid solution

A ti-22al-25nb, mechanical alloying technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of Al element burning, long production cycle, high cost, etc., to improve efficiency, avoid component segregation, prevent pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

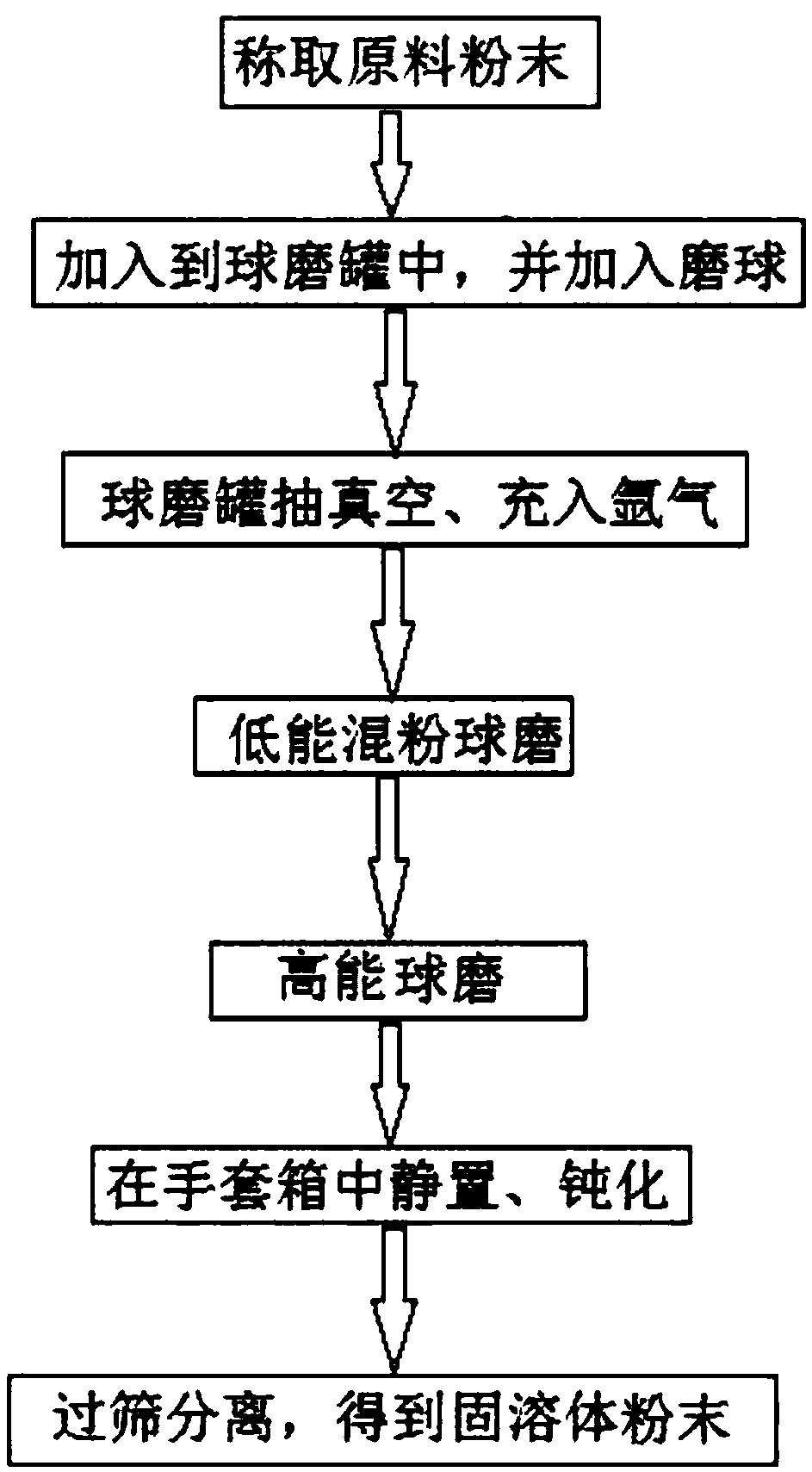

Method used

Image

Examples

Embodiment 1

[0043] S1. Weigh 20.8g of Ti powder, 5g of Al powder, and 19.2g of Nb powder, totaling 45g of elemental element powder;

[0044] S2, adding the weighed elemental element powder into a stainless steel ball milling tank, putting stainless steel grinding balls with a diameter of 5 mm, 10 mm and 20 mm in the ball grinding tank, and the quality of the grinding balls is 147.3 g, 98.2 g, 24.6 g respectively;

[0045] S3. The stainless steel ball mill tank is evacuated and filled with argon, and then evacuated and filled with argon, repeating 3 times;

[0046] S4. Place the stainless steel ball mill tank on the planetary ball mill to perform low-energy powder mixing ball milling at a speed of 150r / min. The mixing time is 8 hours, and the machine is stopped for 10 minutes after mixing for 1 hour;

[0047] S5. The stainless steel ball milling tank is subjected to high-energy ball milling on a planetary ball mill at a speed of 390r / min for 50 hours, and the ball mill is stopped for 20 mi...

Embodiment 2

[0052] S1. Weigh 20.8g of Ti powder, 5g of Al powder, and 19.2g of Nb powder, totaling 45g of elemental element powder;

[0053] S2. Add the weighed elemental element powder into the stainless steel ball mill tank, and add a total of 360g of stainless steel grinding balls at a ratio of 8:1. The diameters of the stainless steel grinding balls are 5mm, 10mm and 20mm, and the masses are 196.4g respectively. , 130.9g, 32.7g;

[0054] S3. The stainless steel ball mill tank is evacuated and filled with argon, and then evacuated and filled with argon, repeating 3 times;

[0055] S4. Place the stainless steel ball mill jar on the planetary ball mill to perform low-energy powder mixing ball milling at a speed of 180r / min for 8 hours, and stop for 10 minutes every time the powder is mixed for 1 hour;

[0056] S5. The stainless steel ball milling tank is subjected to high-energy ball milling on a planetary ball mill at a speed of 390r / min for 50 hours, and the ball mill is stopped for 2...

Embodiment 3

[0061] S1. Weigh 20.8g of Ti powder, 5g of Al powder, and 19.2g of Nb powder, totaling 45g of elemental element powder;

[0062] S2. Add the weighed elemental element powder into a stainless steel ball mill tank, and add a total of 405g of stainless steel grinding balls at a ratio of 8:1. The diameters of the stainless steel grinding balls are 5mm, 10mm, and 20mm, and their masses are 220.9g. , 147.3g, 36.8g;

[0063] S3. The stainless steel ball mill tank is evacuated and filled with argon, and then evacuated and filled with argon, repeating 3 times;

[0064] S4. Place the stainless steel ball milling tank on a planetary ball mill and perform low-energy powder mixing ball milling at a speed of 150r / min for 8 hours, stop and rest for 10 minutes every 1 hour of powder mixing;

[0065] S5. The stainless steel ball milling tank is subjected to high-energy ball milling on a planetary ball mill at a speed of 390r / min for 70 hours, and the ball mill is stopped for 20 minutes every ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com