Method for synthesizing lithium ion battery negative electrode material according to mechanochemical method

A technology of lithium ion battery and mechanochemical method, which is applied in the field of graphene-metal oxide nanocomposite materials, can solve the problems of unfavorable industrial application, complex synthesis process, and high condition requirements, and achieve good electrochemical performance, uniform distribution of elements, The effect of low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

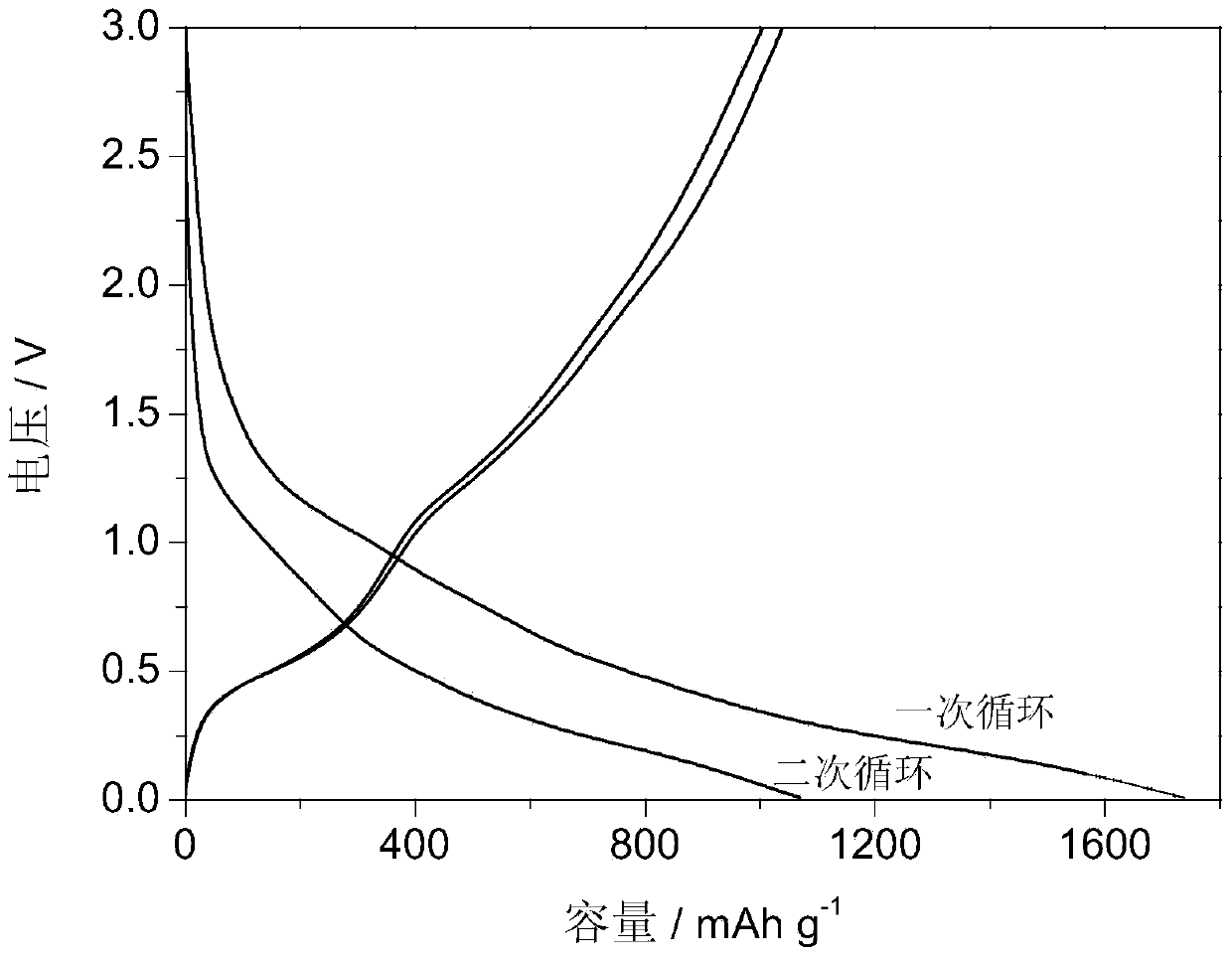

[0021] Implementation Case 1: SnO 2 / Graphene synthesis, structural stability test and electrochemical performance test of simulated battery assembled with Li.

[0022] Add Sn powder and graphite oxide powder (prepared by Hammers method) into an 80ml stainless steel ball mill tank filled with zirconia balls at a mass ratio of 1:1, use deionized water as the grinding medium, and argon as the protective gas, at 400rpm Ball milling at a rotating speed for 8 hours, after which, the sample was dried naturally and baked at 300°C for 1 hour under the protection of argon at a rate of 5°C / min to obtain the desired SnO 2 / graphene composites.

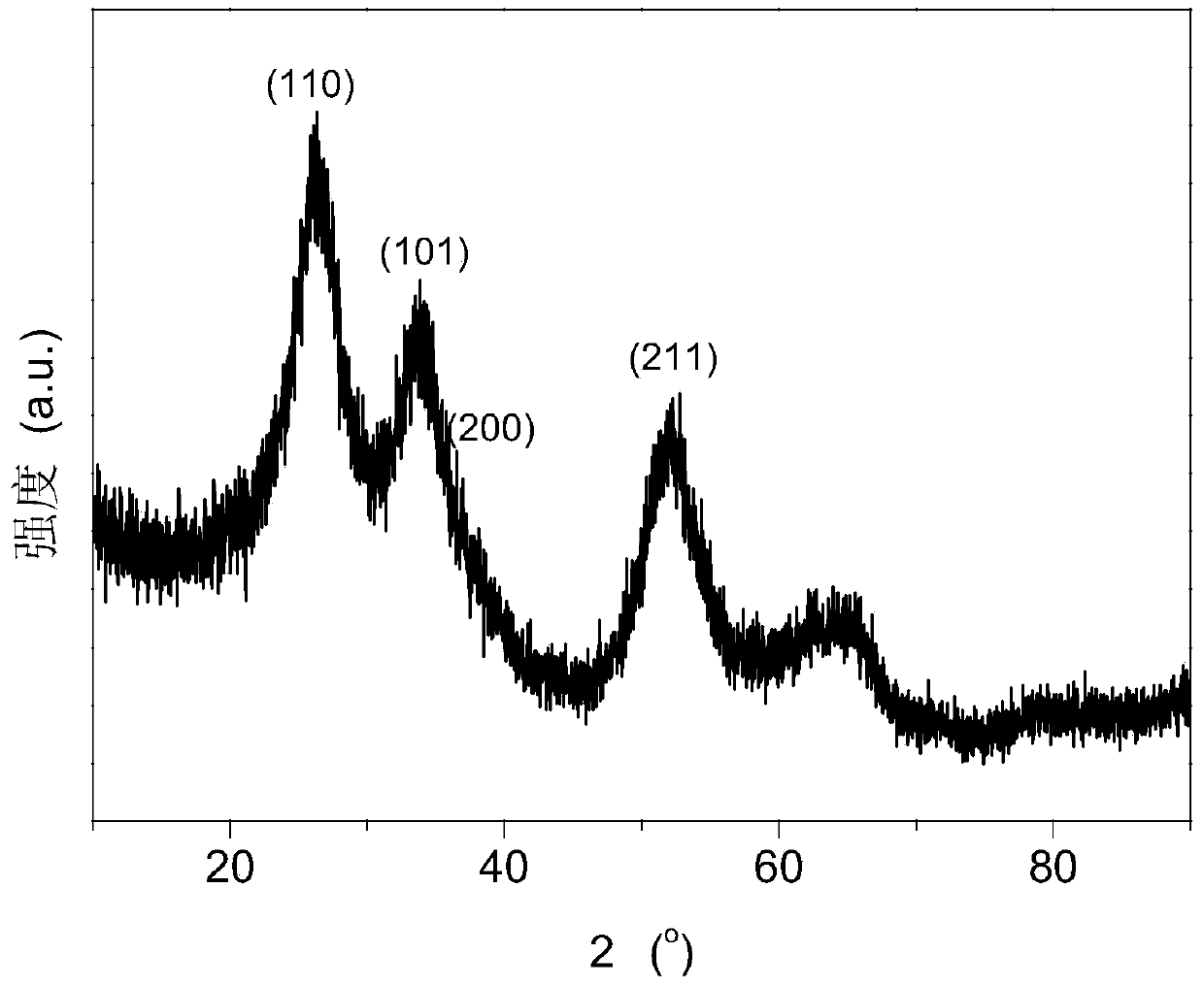

[0023] The XRD powder diffraction method showed that SnO was generated 2 ,like figure 1 Shown is SnO 2 / XRD phase structure of graphene, from figure 1 It can be seen that the position of each diffraction peak in the XRD pattern of the synthesized product is related to that of the SnO 2 The standard JCPDS card (41-1445) agrees with that, in...

Embodiment example 2

[0025] Implementation Case 2: Fe 3 o 4 / Graphene synthesis, structural stability test and electrochemical performance test of simulated battery assembled with Li.

[0026] Fe powder and graphite oxide powder (prepared by Hammers method) were added to an 80ml stainless steel ball mill tank filled with zirconia balls at a mass ratio of 1:1, with deionized water as the grinding medium and argon as the protective gas, at 200rpm After ball milling at a rotational speed for 6 hours, the sample was naturally dried and calcined at 450°C for 2 hours under an argon atmosphere at a rate of 10°C / min to obtain the desired composite material. Figure 5 The XRD powder diffraction method measurement shown shows that the prepared composite material Fe 3 o 4 structure.

[0027] The prepared sample was evenly mixed with superconducting carbon black (Super P) and PVDF according to the ratio of 8:1:1, and NMP was used as the solvent. After mixing evenly, it was coated on a copper foil with a t...

Embodiment example 3

[0028] Implementation Case 3: Cu 2 Synthesis of O / graphene, structural stability test and electrochemical performance test of simulated battery assembled with Li.

[0029] Add Cu powder and graphite oxide powder (prepared by Hammers method) into an 80ml stainless steel ball mill jar filled with zirconia balls at a mass ratio of 2:1, use absolute ethanol as the grinding medium, and nitrogen gas as the protective gas, at 300rpm Ball milled at a rotating speed for 4 hours. Afterwards, the sample was dried naturally and baked at 350°C for 3 hours under the protection of nitrogen gas at a rate of 10°C / min to obtain the desired Cu 2 O / graphene composites. Figure 7 The XRD powder diffraction method measurement shown shows that the prepared composite material Cu 2 O structure.

[0030] The prepared sample was evenly mixed with superconducting carbon black (Super P) and PVDF according to the ratio of 8:1:1, and NMP was used as the solvent. After mixing evenly, it was coated on a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com