Sulfide target cosputtering preparation method of CZTSSe film and product thereof

A technology of co-sputtering and sulfide, which is applied in the direction of sputtering coating, final product manufacturing, metal material coating process, etc., can solve the problems of low repeatability of film preparation process and uneven distribution of various elements of film, and achieve film Thickness is easy to control, solving the effect of poor sample quality and few pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0059] (1) On the soda-lime glass substrate, Cu-Zn-Sn-S precursor prefabricated film was prepared by co-sputtering:

[0060] Ⅰ. Clean the glass substrate with ionized water;

[0061] Ⅱ. Wash the glass substrate with dilute hydrochloric acid, then shake it with deionized water for 5 minutes;

[0062] Ⅲ. After cleaning the glass substrate with carbon tetrachloride, then ultrasonically oscillate with carbon tetrachloride for 10 minutes;

[0063] Ⅳ. After cleaning the glass substrate with acetone, then ultrasonically oscillate with acetone for 10 minutes;

[0064] Ⅴ. After cleaning the glass substrate with absolute ethanol, then ultrasonically oscillate with absolute ethanol for 10 minutes;

[0065] Ⅵ. Store the glass substrate in absolute ethanol for later use;

[0066] VII. Take out the glass substrate from absolute ethanol, put it into the sputtering chamber of the magnetron co-sputtering instrument after drying.

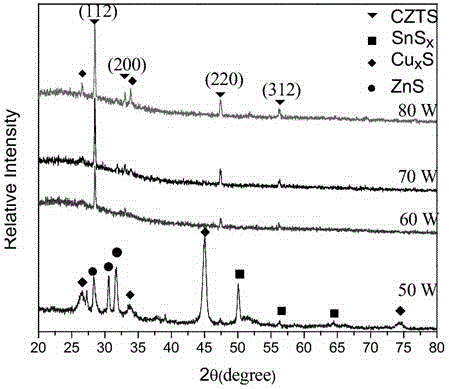

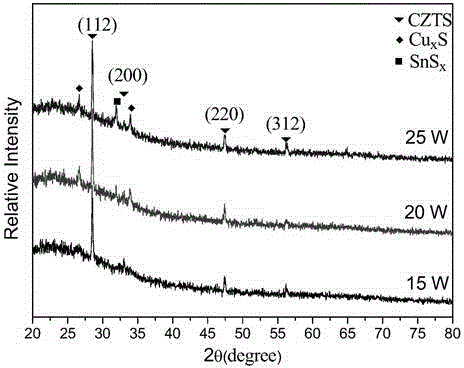

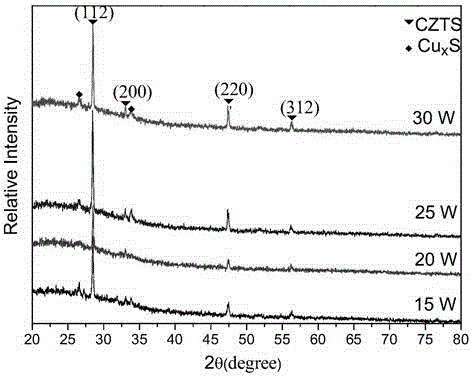

[0067] Ⅷ. Co-sputtering to prepare Cu-Zn-Sn-S precursor pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com