Non-layered two-dimensional PbSe crystal material and preparation method thereof

A crystalline material, non-layered technology, applied in the field of non-layered two-dimensional PbSe crystal material and its preparation, can solve the problems of low yield, weak interlayer bonding force, difficult integration of silicon-based substrates, etc. Evaporation time, avoidance of insufficient reaction, effect of slowing down the evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

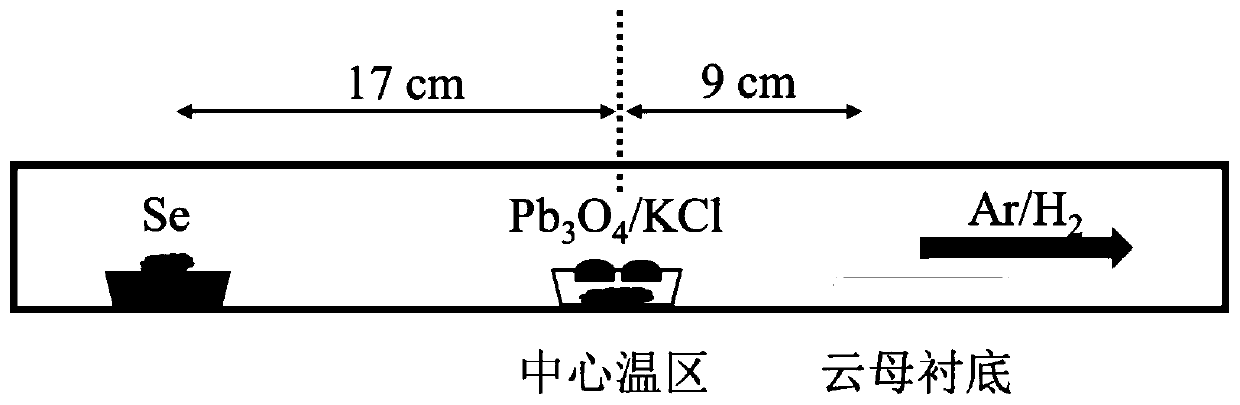

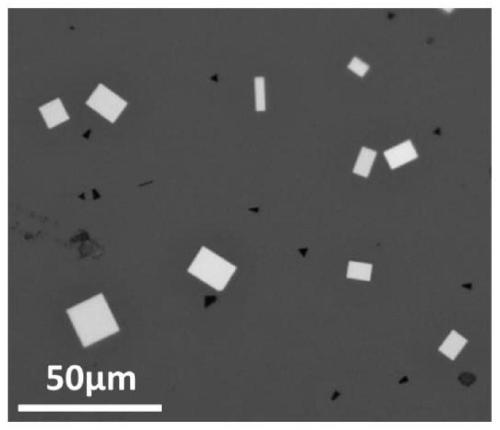

Embodiment 1

[0041] A horizontal tube furnace with a single temperature zone is used as the reactor. The tube length of the horizontal tube furnace is 90cm, the outer diameter is 25mm, the tube wall thickness is 2mm, the range of the constant temperature zone is 10cm, the temperature in the central temperature zone is set to 650°C, and the heating rate is 30°C / min. Use Se powder (purity>99.99%) as the selenium source to place in the upstream area; Pb 3 o 4Powder (purity>99.99%) is used as the lead source, KCl is added to obtain the precursor, and molecular sieves are placed on the precursor at the same time, and placed in the central temperature zone; the mica substrate is placed in the downstream area to collect the product. Before the reaction, pre-evacuate to about 10Pa, then fill with 600sccm of Ar to atmospheric pressure, and repeatedly wash the gas 3 times to eliminate residual oxygen; 2 As the reaction gas, the pressure is maintained at one atmospheric pressure, the reaction time...

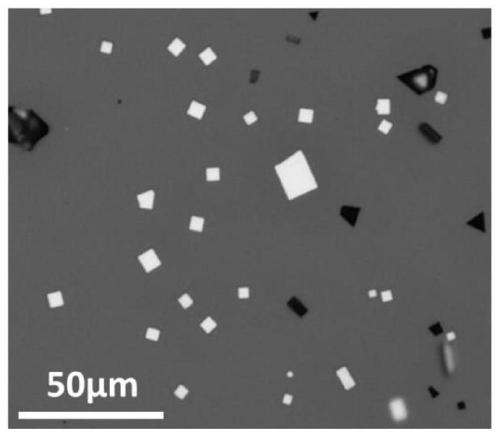

Embodiment 2

[0043] A horizontal tube furnace with a single temperature zone is used as the reactor. The tube length of the horizontal tube furnace is 90cm, the outer diameter is 25mm, the tube wall thickness is 2mm, the range of the constant temperature zone is 10cm, the temperature in the central temperature zone is set to 700°C, and the heating rate is 30°C / min. Use Se powder (purity>99.99%) as the selenium source to place in the upstream area; Pb 3 o 4 Powder (purity>99.99%) is used as the lead source, KCl is added to obtain the precursor, and molecular sieves are placed on the precursor at the same time, and placed in the central temperature zone; the mica substrate is placed in the downstream area to collect the product. Before the reaction, pre-evacuate to about 10Pa, then fill it with 600sccm Ar to atmospheric pressure, and repeatedly wash the gas 3 times to eliminate residual oxygen; 2 As the reaction gas, the pressure is maintained at one atmospheric pressure, the reaction tim...

Embodiment 3

[0045] A horizontal tube furnace with a single temperature zone is used as the reactor. The tube length of the horizontal tube furnace is 90cm, the outer diameter is 25mm, the tube wall thickness is 2mm, the range of the constant temperature zone is 10cm, the temperature in the central temperature zone is set to 650°C, and the heating rate is 30°C / min. Use Se powder (purity>99.99%) as the selenium source to place in the upstream area; Pb 3 o 4 Powder (purity>99.99%) is used as the lead source, KCl is added to obtain the precursor, and molecular sieves are placed on the precursor at the same time, and placed in the central temperature zone; the mica substrate is placed in the downstream area to collect the product. Before the reaction, pre-evacuate to about 10Pa, then fill with 600sccm of Ar to atmospheric pressure, and repeatedly wash the gas 3 times to eliminate residual oxygen; 2 As a reaction gas, the pressure is maintained at one atmospheric pressure, the reaction time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com