Patents

Literature

32results about How to "Control evaporation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

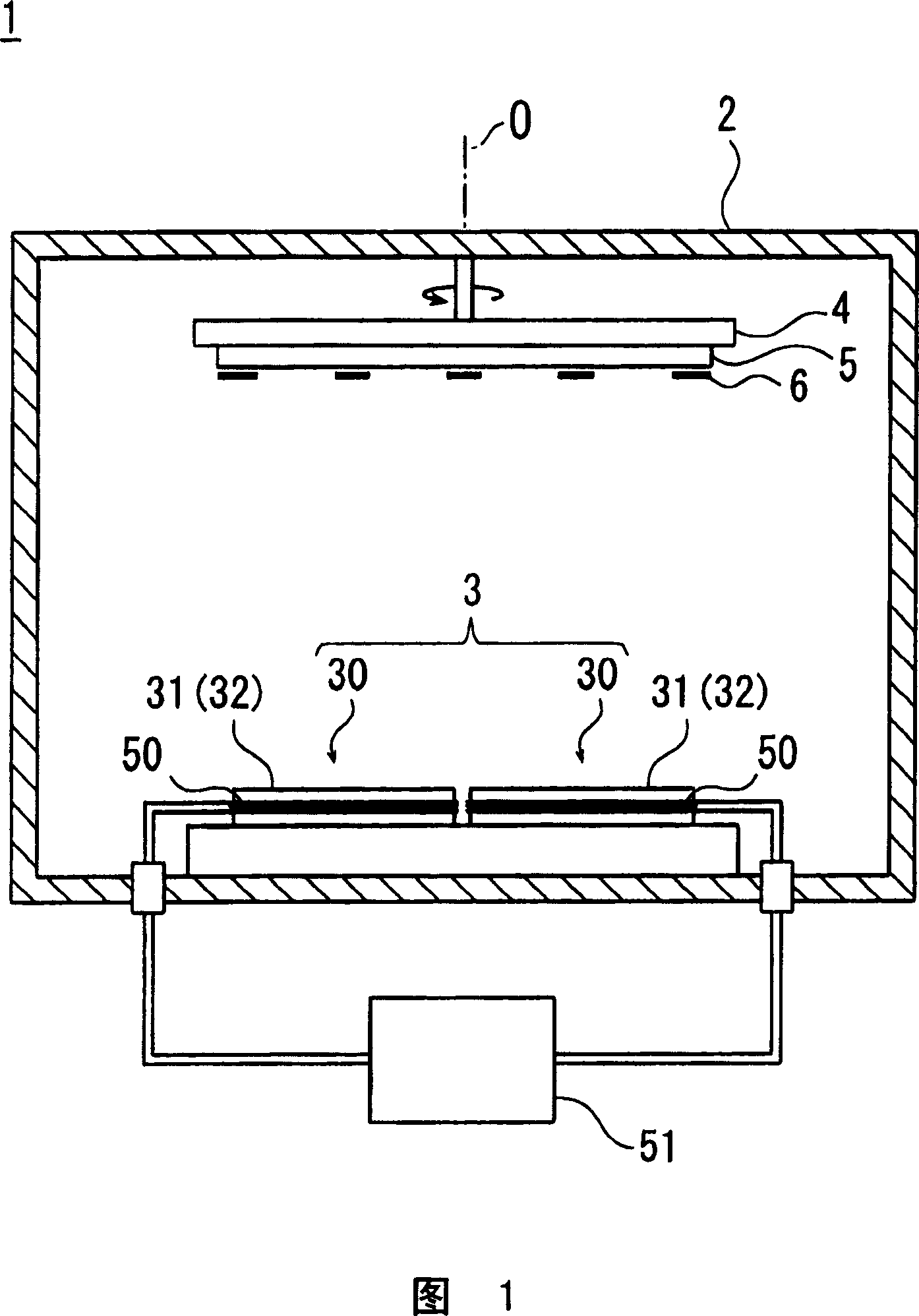

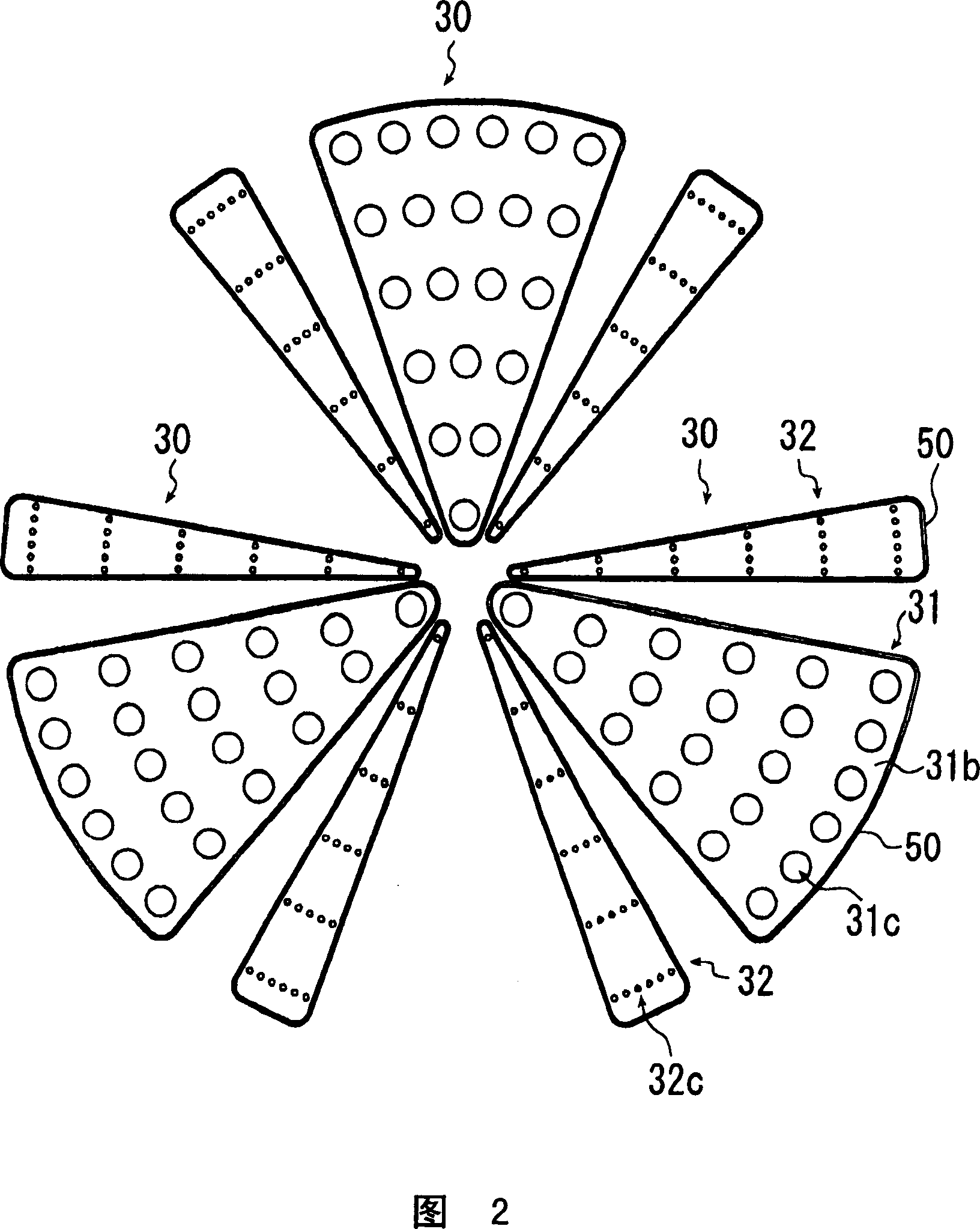

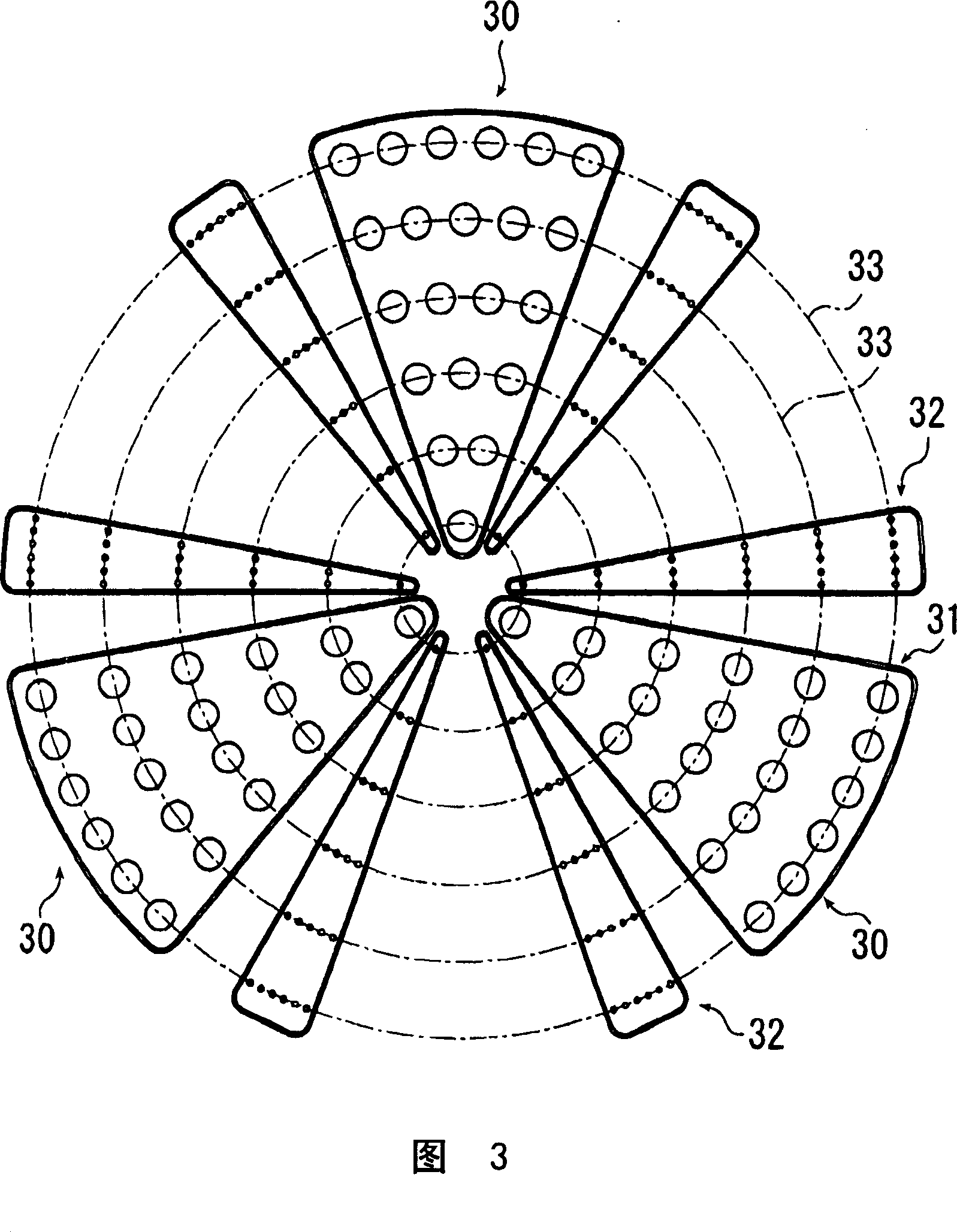

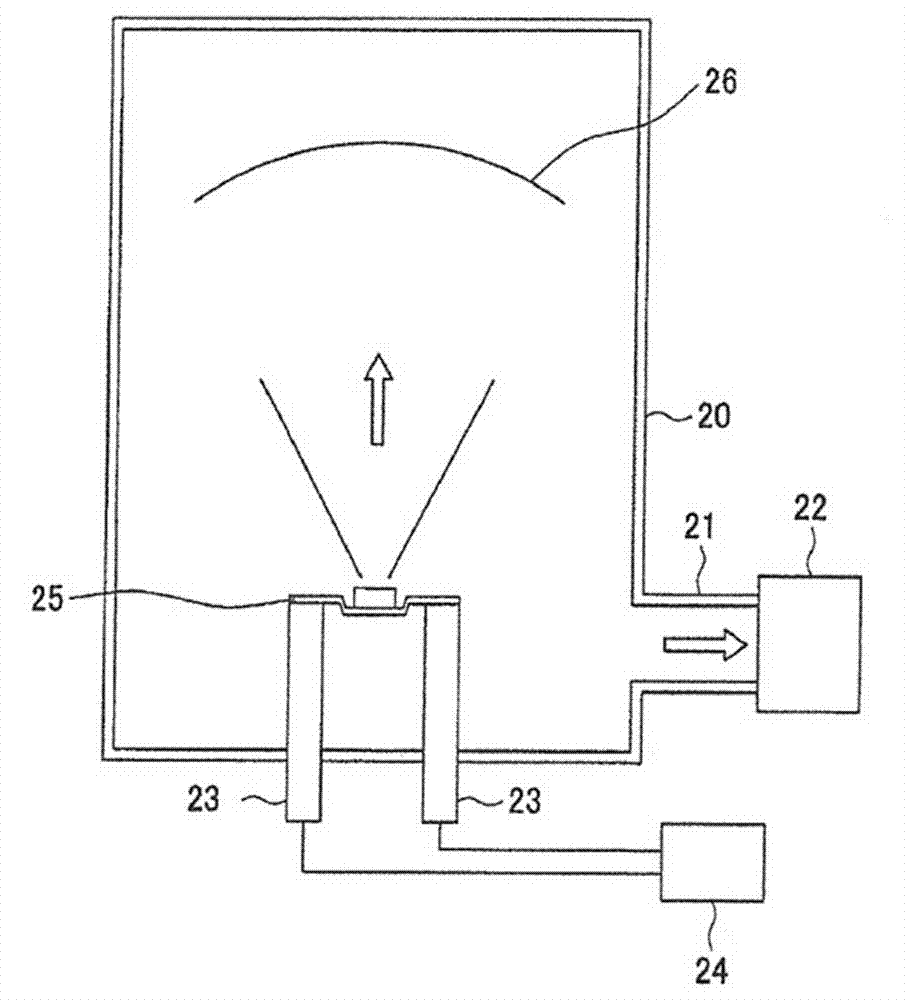

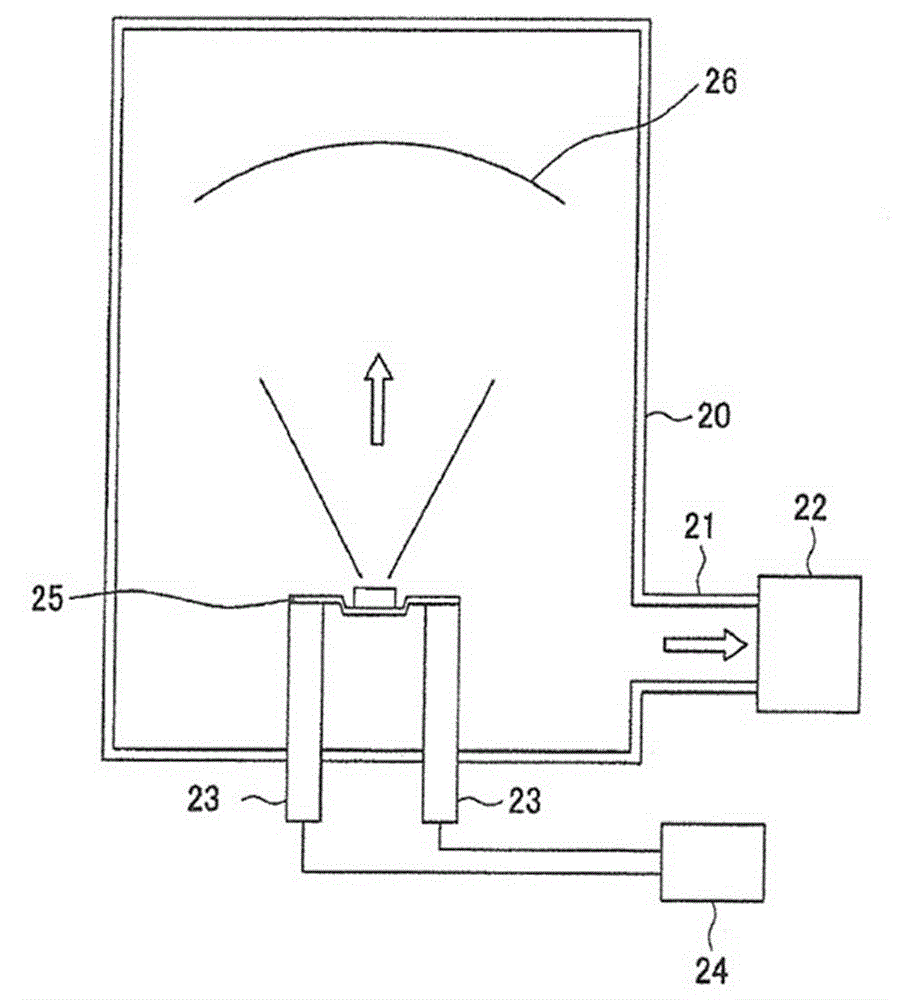

Organic material evaporation source and organic vapor deposition device

InactiveCN1950536AUniform film thickness distributionControl heating temperatureElectroluminescent light sourcesSolid-state devicesVaporizationMembrane thickness

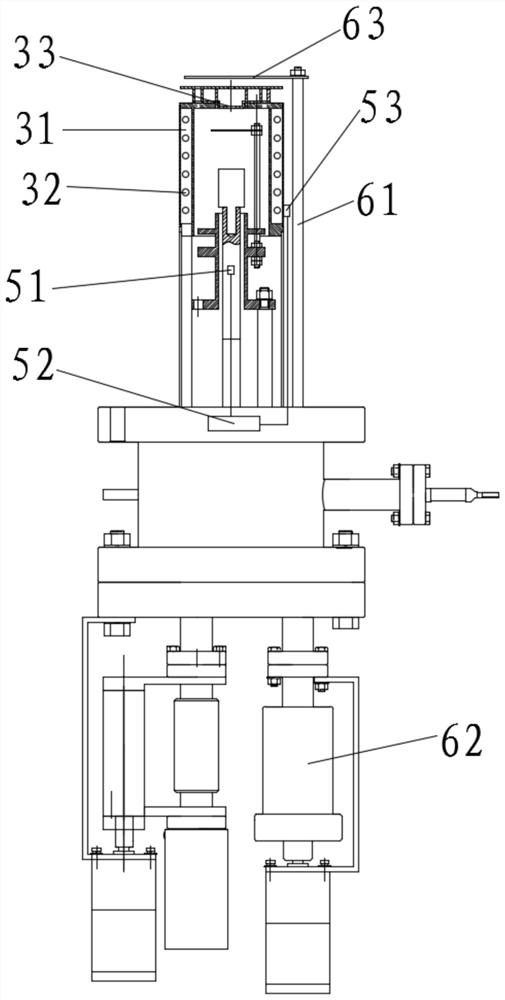

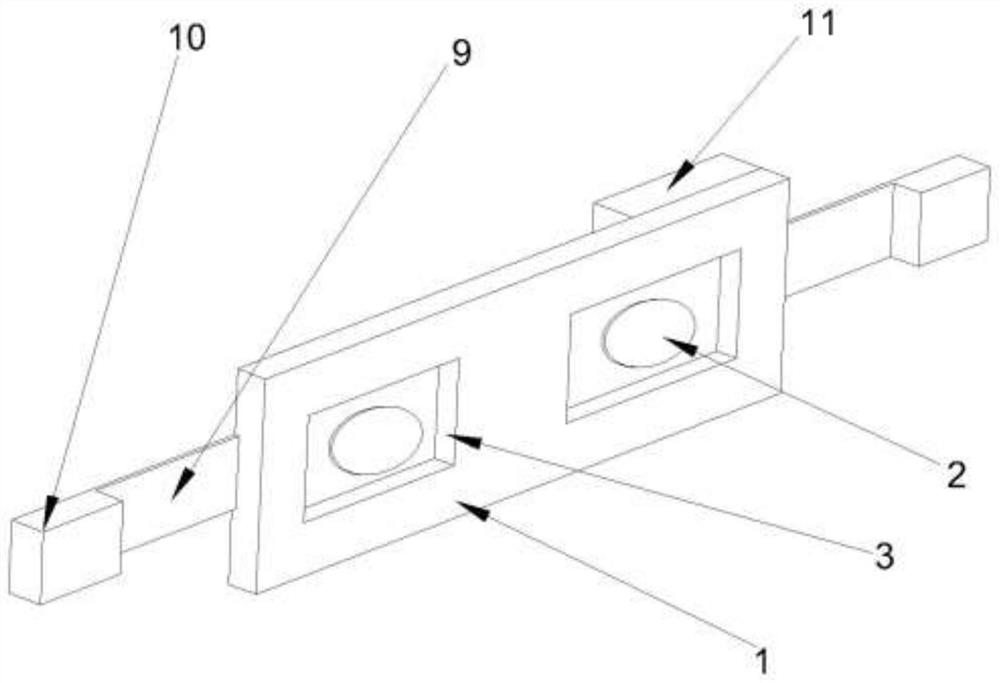

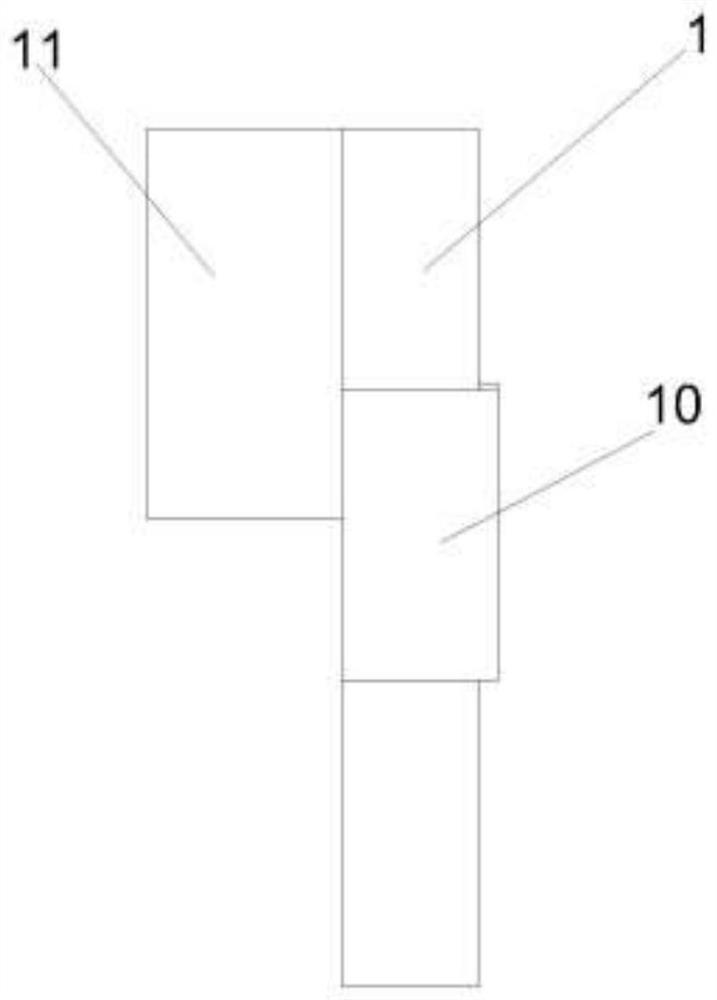

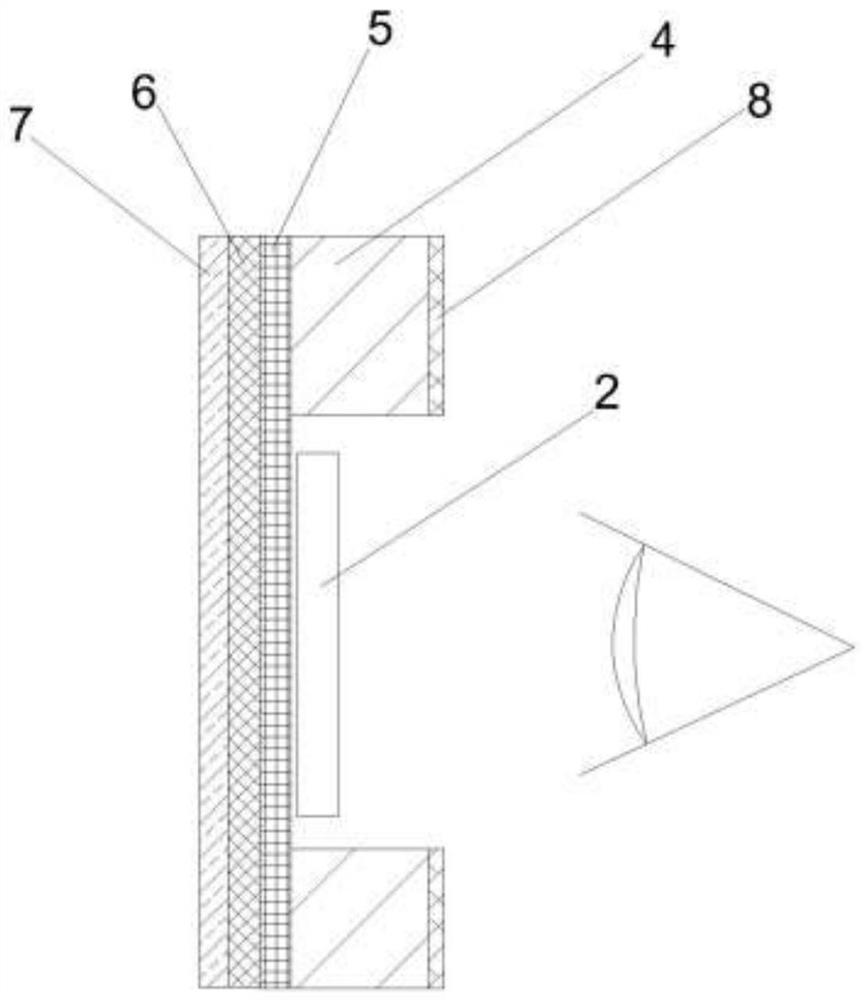

An organic material evaporation source capable of forming a membrane having a uniform membrane thickness distribution with respect to a large-sized substrate and capable of controlling heating temperature and evaporation rate during vapor deposition accurately and with good responsiveness; and an organic vapor deposition device using the source. A vaporization source comprises a vessel main body (31a) having a heating section consisting of a high frequency induction coil (50) and receiving a predetermined organic material, and a lid (31b) having a vaporization port (31c) for the vapor of the organic material to pass therethrough. The arrangement is such that the amount of vapor of the organic material discharged from the vaporization port (31c) in the lid (31b) steadily increases with respect to a two-dimensional position with a predetermined reference position used as a basis.

Owner:ULVAC INC

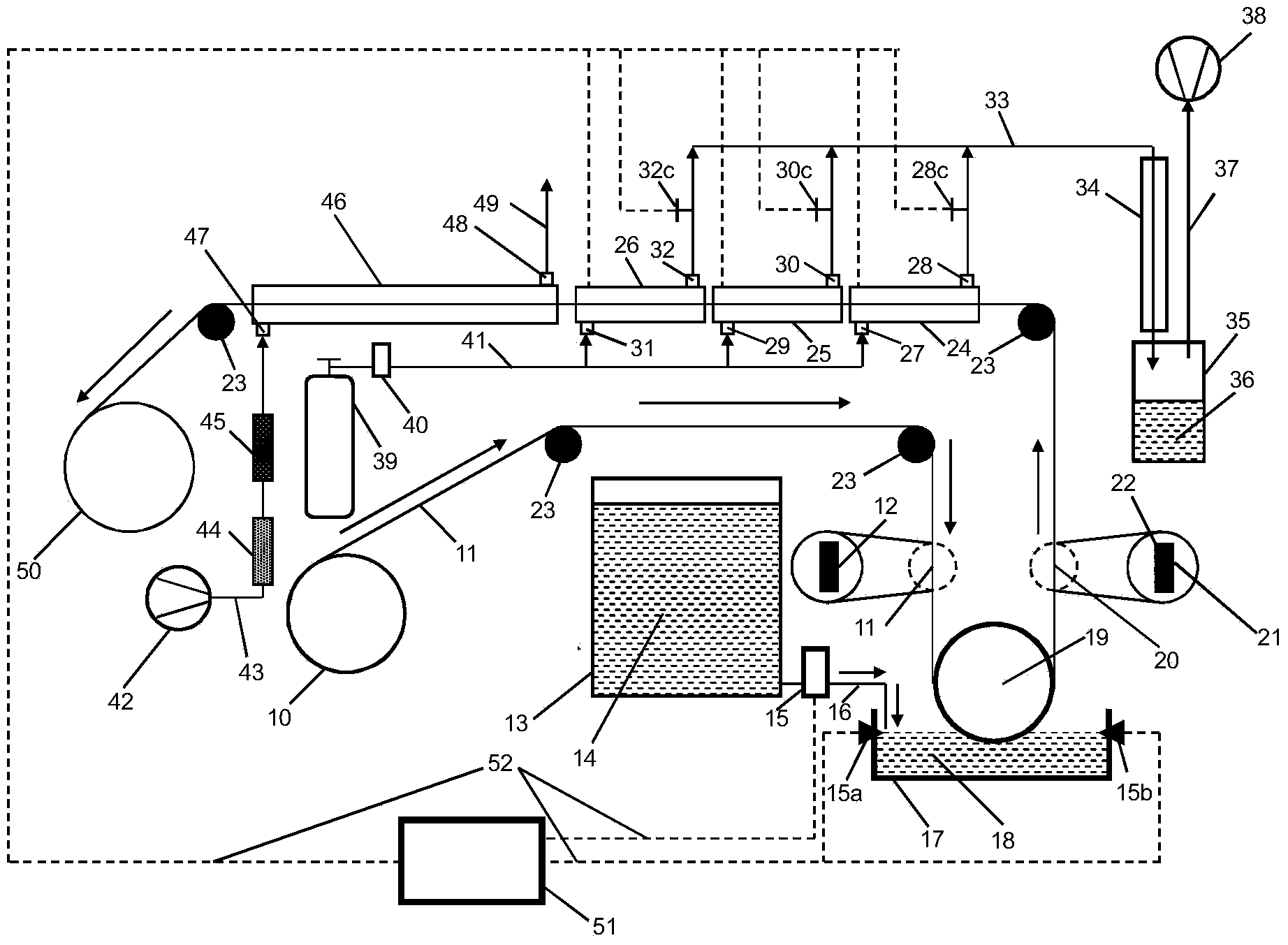

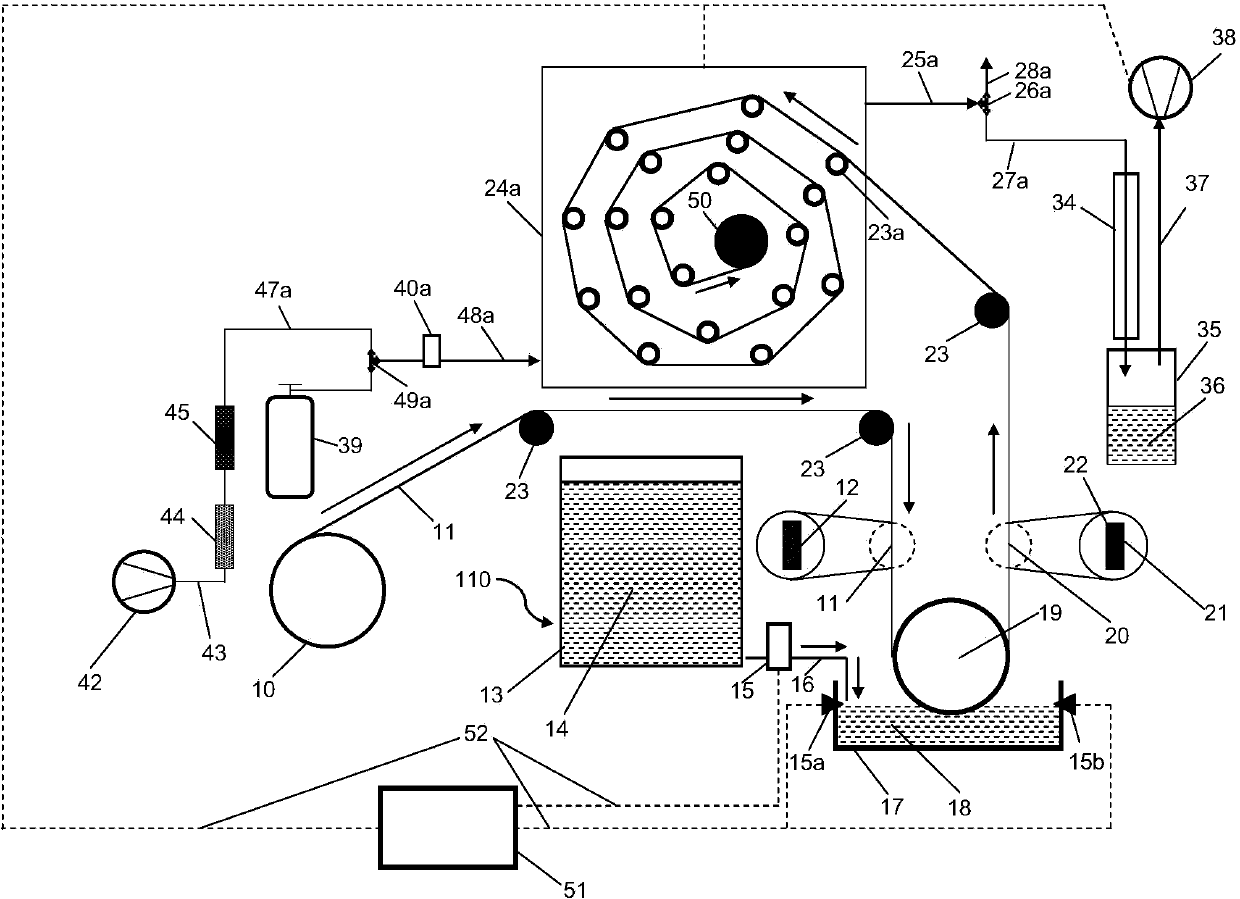

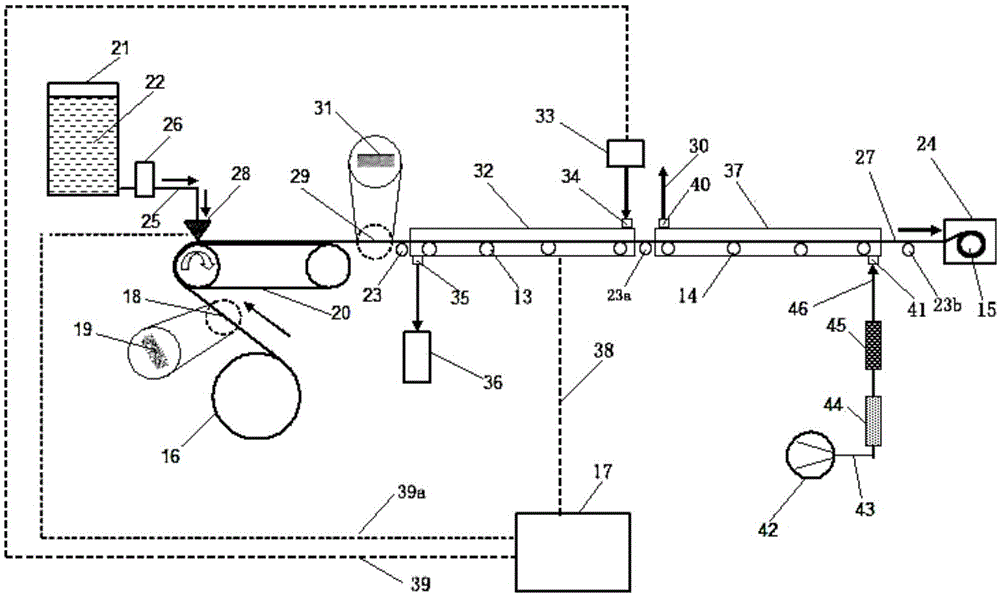

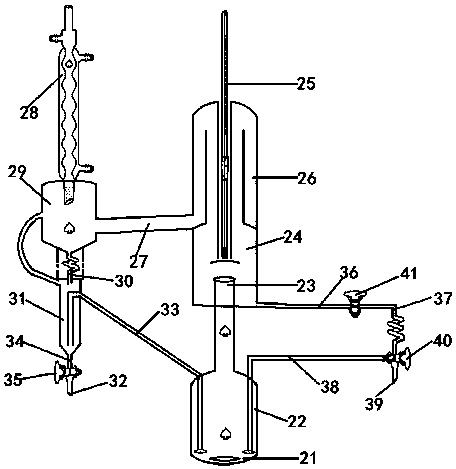

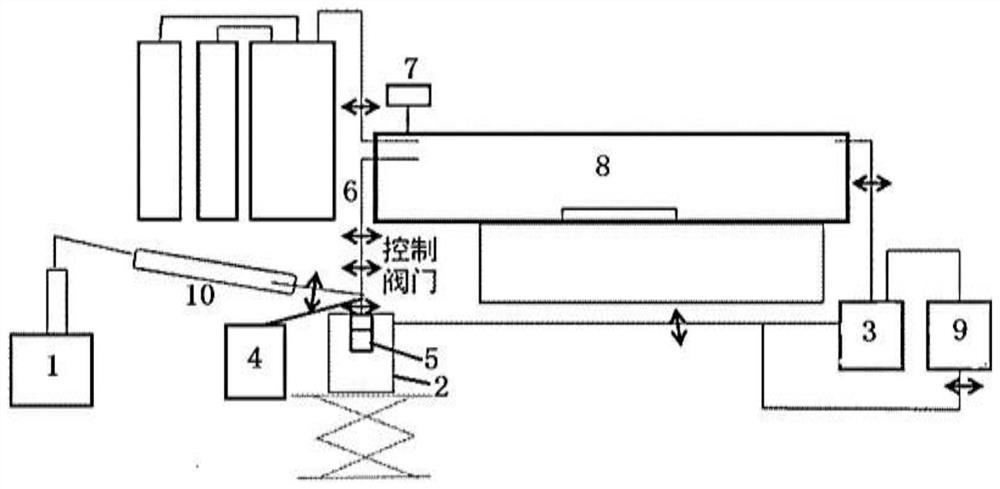

Curtain coating micro dip coating continuous production equipment and method of ultrathin membrane polymer complex film

InactiveCN103446895AIncrease productivityGood quality finished productSemi-permeable membranesSolventChemistry

The invention discloses curtain coating micro dip coating continuous production equipment and a method of an ultrathin membrane polymer complex film, belonging to the technical field of chemical equipment and process. The technical scheme I is that the production equipment provided by the invention comprises a transmission system, a computer control system, a micro dip coating system, a drying system and a solvent recovery system; The technical scheme II is the curtain coating micro dip coating continuous production method of the ultrathin membrane polymer complex film provided by the invention. The equipment and the method provided by the invention have the advantages that the complex film is continuously automatically produced, the production efficiency is high, and the end product quality is good; the uniform and flawless complex film is produced, the temperature, resistance time and vacuum degree and the like of a vacuum drying oven are controlled, and the quality of the complex film is guaranteed; a solvent is recovered, the manufacturing cost is saved, meanwhile, the environmental pollution is stopped, and when output achieves a certain scale, the costs of the continuous production equipment and the method are lower than the batch processing costs.

Owner:HUBEI LONGFEIXIANG IND GRP CO LTD +1

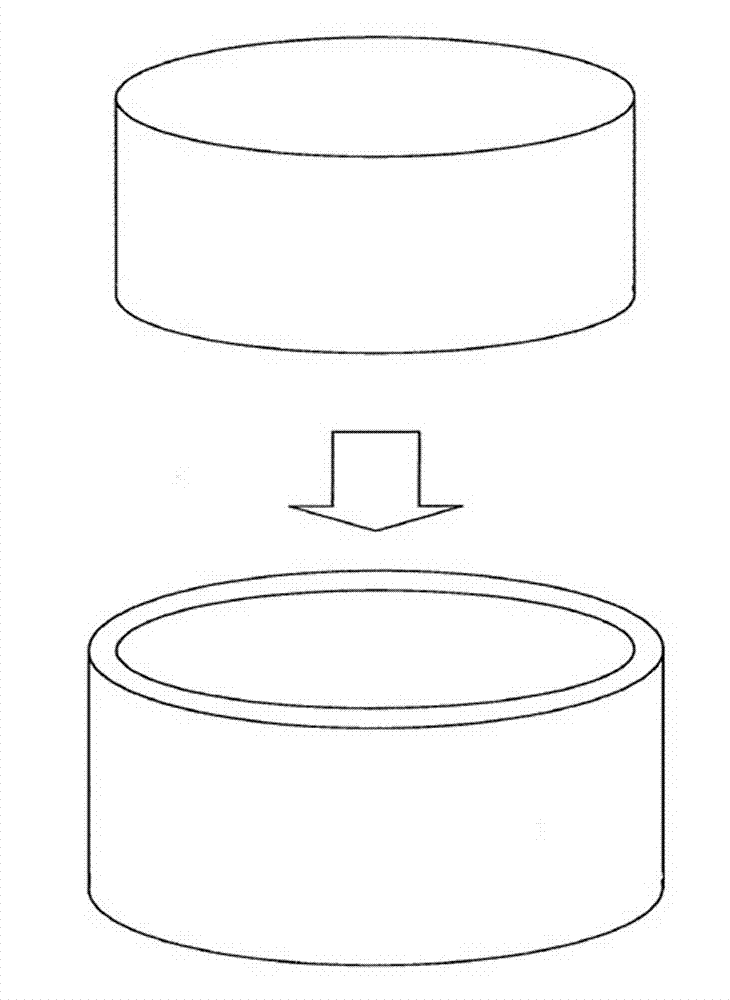

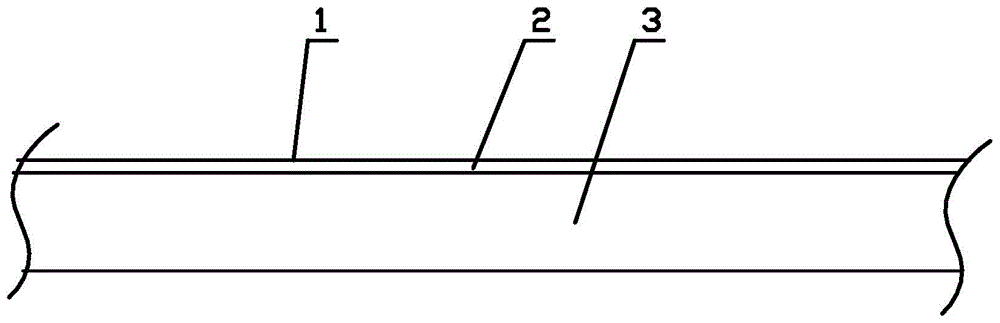

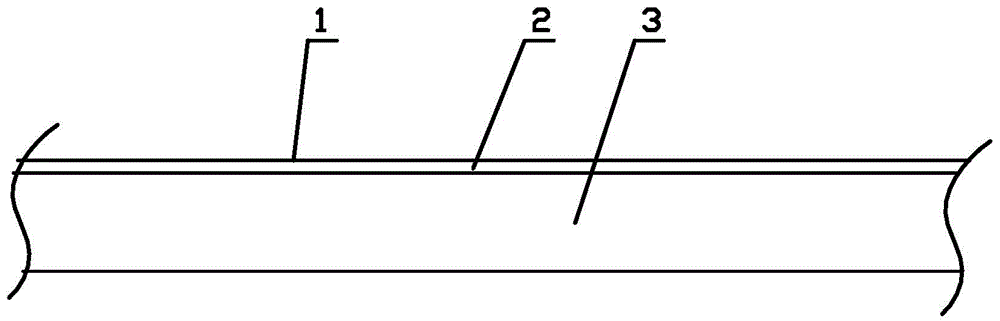

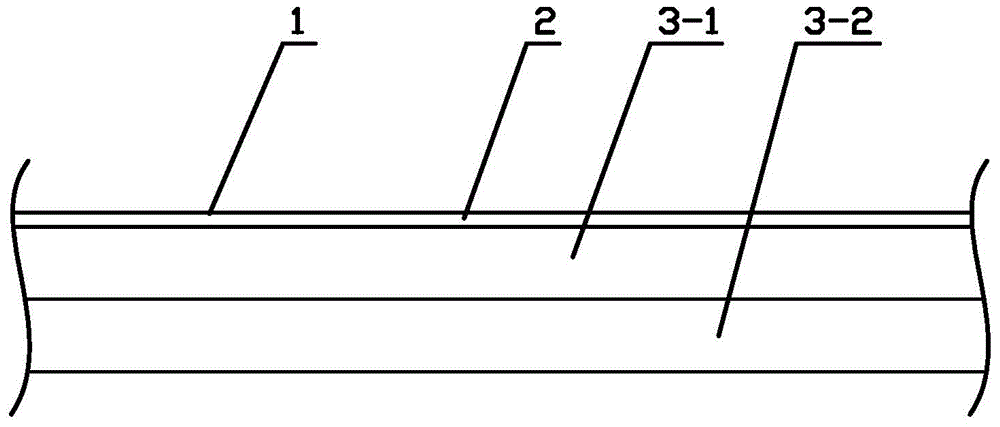

Adsorption carrier for evaporation material for evaporation of anti-fouling film

ActiveCN103205716AGuaranteed uniformityImprove friction resistanceVacuum evaporation coatingSputtering coatingChemistryAluminium

The invention provides an adsorption carrier for an evaporation material for evaporation of an anti-fouling film. The adsorption carrier is a sintered body of metal powder, and the metal powder is one or a metal mixture of at least two selected from iron, stainless steel, copper and aluminum. The adsorption carrier provided by the invention has the advantages that the adsorption carrier does not contain impurities and can ensure that the impurities can not be produced by melting during the film plating process under high-vacuum and high-temperature conditions, and the adsorption carrier can not perform chemical reaction with the evaporation material which is adsorbed and carried by the adsorption carrier; a sintering raw material with appropriate heat conductivity can be selected according to the demands of film plating equipment, so that the uniformity of film plating is ensured; and the anti-fouling film which is obtained by using the adsorption carrier provided by the invention to perform vacuum evaporation can greatly improve the wear resistance and is better than the anti-fouling film which is obtained by evaporation by using the adsorption carrier in the prior art.

Owner:OPTORUN SHANGHAI CO LTD

Lutein microcapsule and preparation method thereof

InactiveCN103565778AMask special odorHigh activitySenses disorderHydroxy compound active ingredientsLuteinGranularity

The invention relates to a lutein microcapsule and a preparation method thereof, wherein the lutein microcapsule consists of a core containing a lutein crystal and an oil soluble emulsifying agent, a shell covering the core, and starch grains stuck outside the shell; the shell includes a capsule material, a water soluble emulsifying agent and a stabilizing agent, wherein dosage ratio of the lutein crystal to the oil soluble emulsifying agent to the capsule material to the water soluble emulsifying agent to the stabilizing agent is (1-30): (0.5-5): (60-95): (1-8): (0.5-5) in parts by weight. The lutein microcapsule is regular in shape, relatively uniform in granularity, good in fluidity, and excellent in both stability and activity.

Owner:中国中化股份有限公司 +1

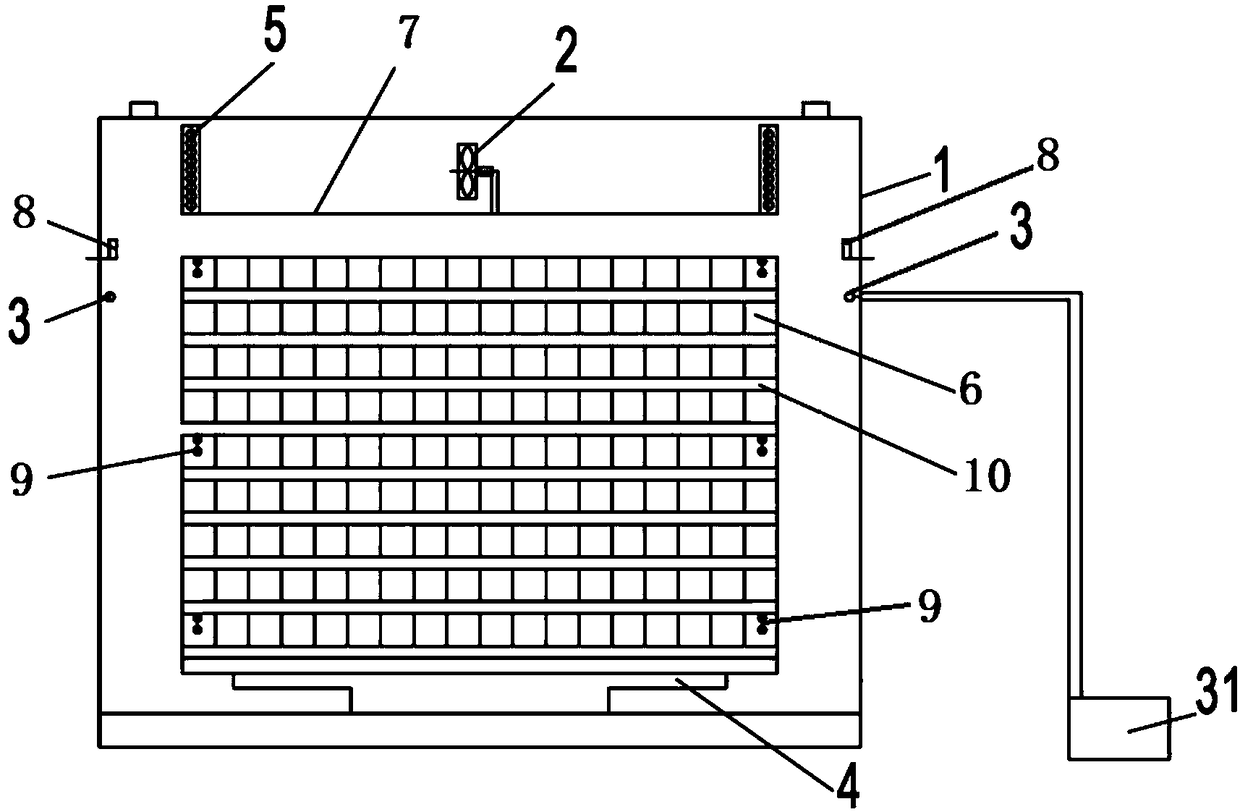

Wood drying method

ActiveCN109405441ASlow down the internal and external temperature gradientReduce drying defectsDrying gas arrangementsDrying solid materialsTemperature differencePre treatment

The invention discloses a fast-growing wood drying method. The method comprises the steps that after to-be-dried wood is pretreated to obtain pretreated wood, the pretreated wood is dried according toordinary benchmark programs for wood drying, wherein the water content of the pretreated wood is 30-90%. The central temperature and surface temperature difference of wood in a wood stack is precisely controlled, the wet bulb depression in a drying room is adjusted, and the wood is dried according to the ordinary benchmark programs for wood drying after the wood is pretreated, so that high-quality dried wood is obtained. By means of the method, the water content gradient in the fast-growing wood drying process is reduced, and thus the treatment quality of the wood in the pretreatment processis guaranteed; then conventional drying is adopted, and compared with direct adoption of conventional drying, the wood drying method greatly improves wood drying efficiency, reduces drying stress, reduces drying defects and improves drying efficiency.

Owner:BEIJING FORESTRY UNIVERSITY

Evaporation source evaporation rate control equipment, method and device and storage medium

PendingCN108342712AControl evaporation rateVacuum evaporation coatingSputtering coatingControl equipmentHeating power

The embodiment of the invention discloses evaporation source evaporation rate control equipment, method and device and a storage medium. The equipment comprises a controller and an on-line collectioninstrument which are connected; the on-line collection instrument is used for collecting film plating parameters of a base plate and sending the film plating parameters to the controller; and the controller is used for generating the heating power adjusting quantity according to the received film plating parameters and controlling the evaporation source evaporation rate based on the heating poweradjusting quantity. The equipment provided in the embodiment can control the evaporation source evaporation rate.

Owner:上海祖强能源有限公司

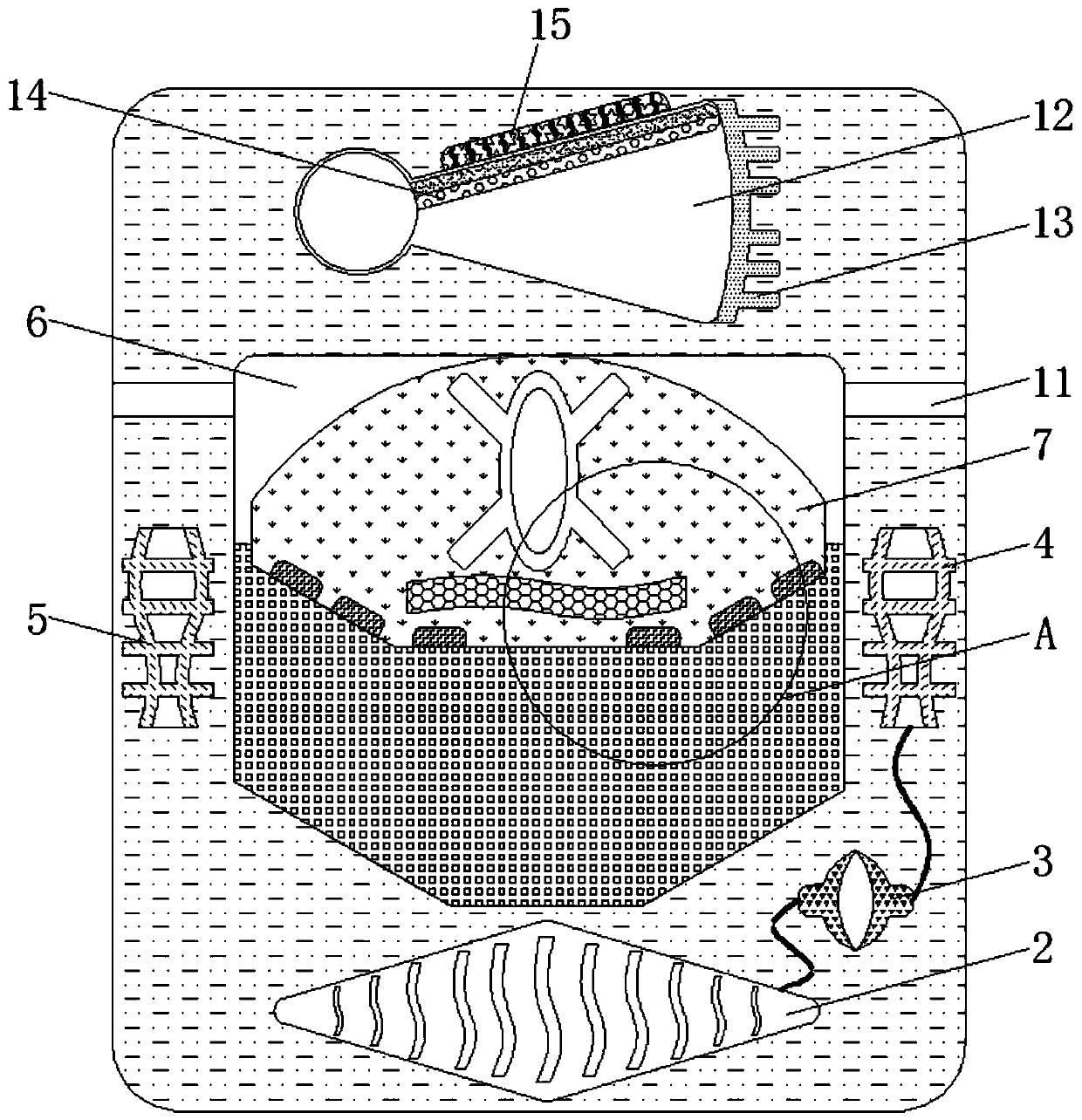

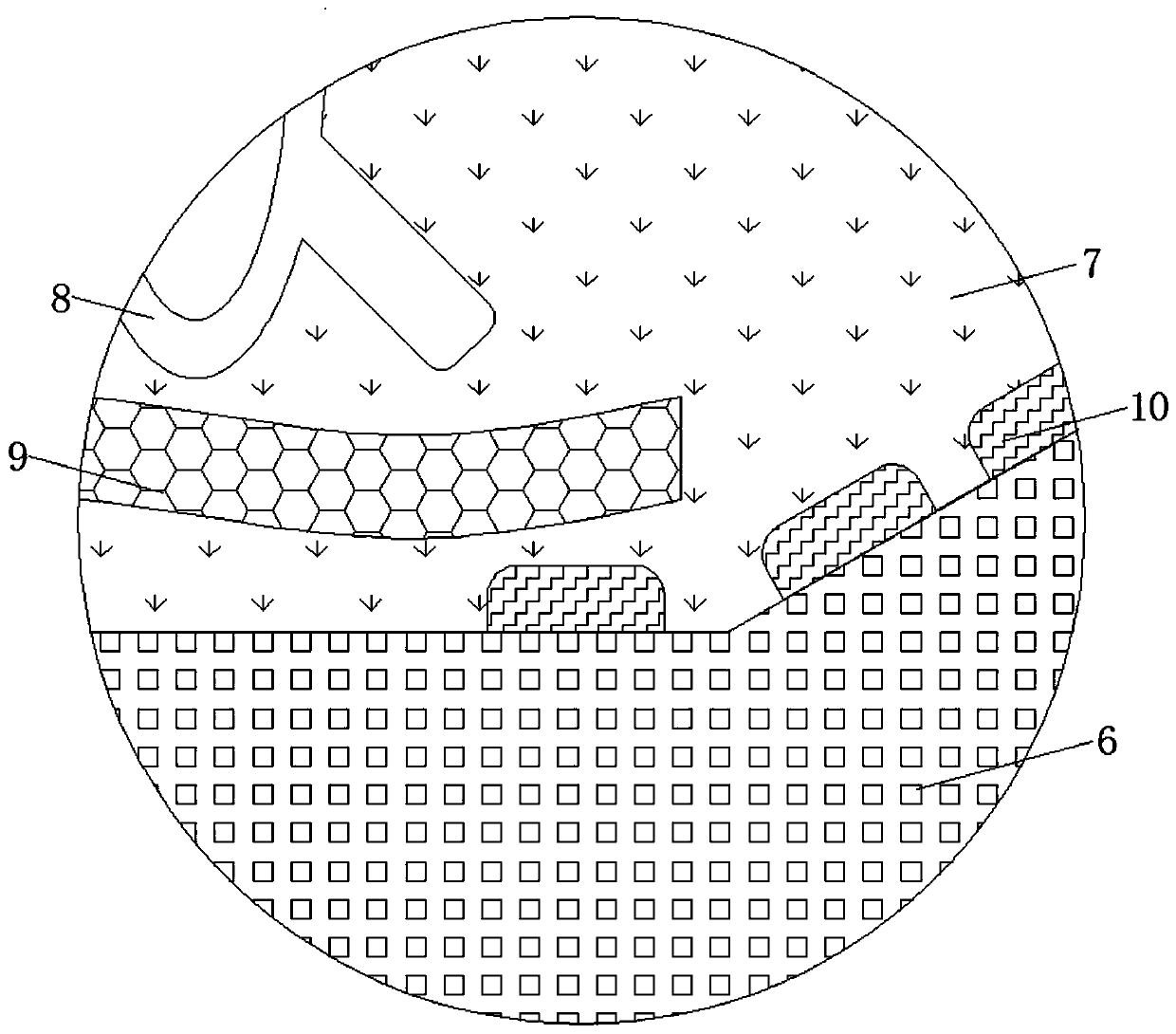

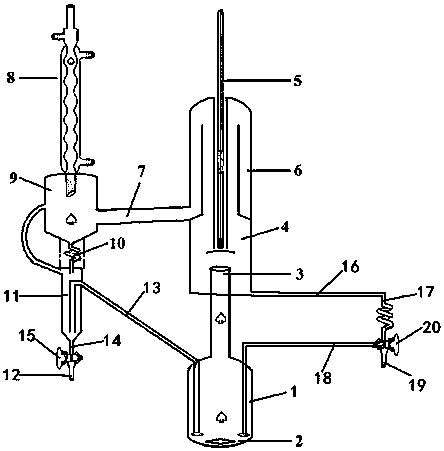

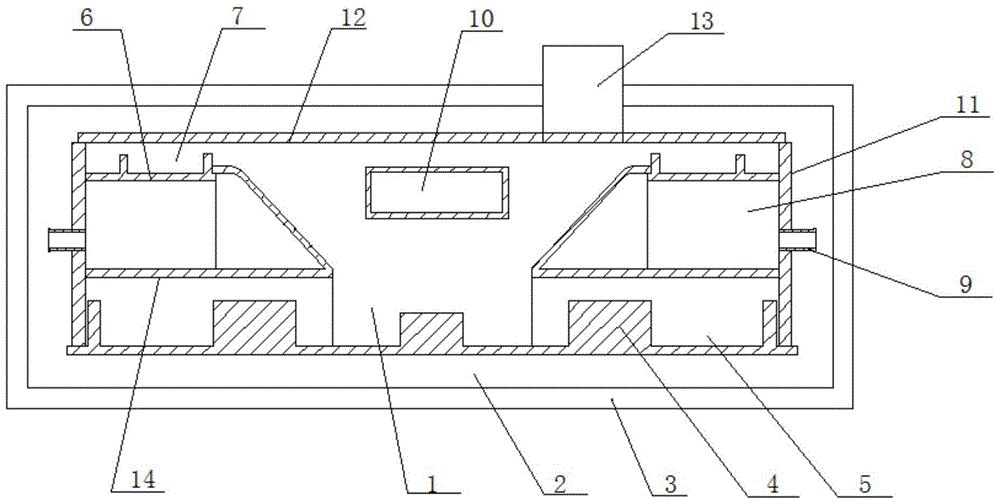

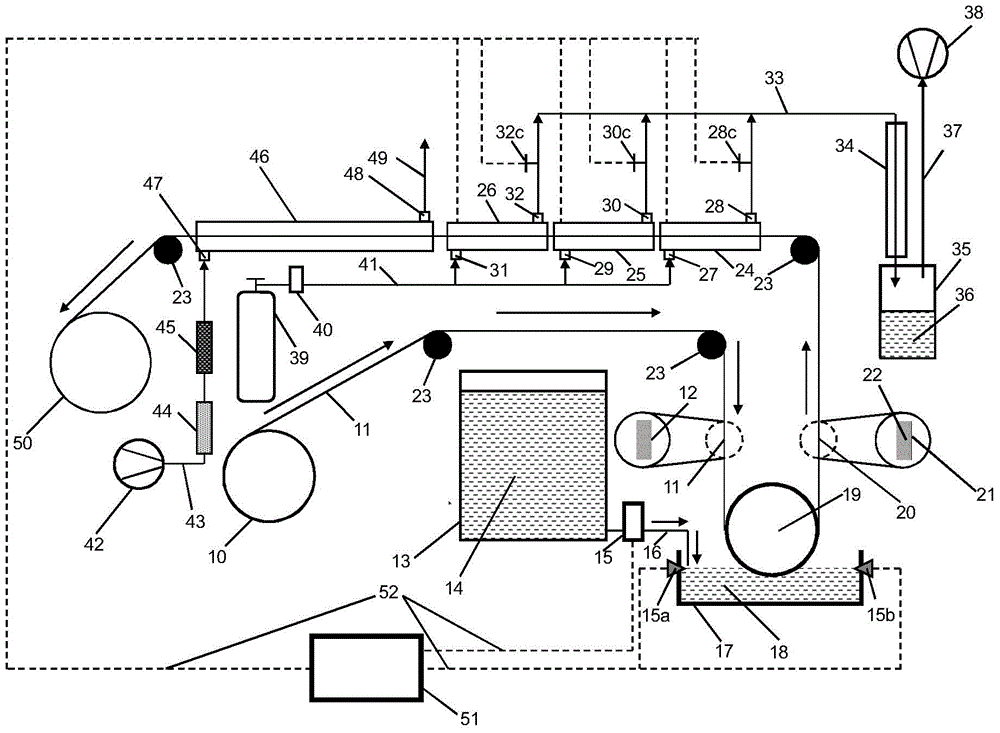

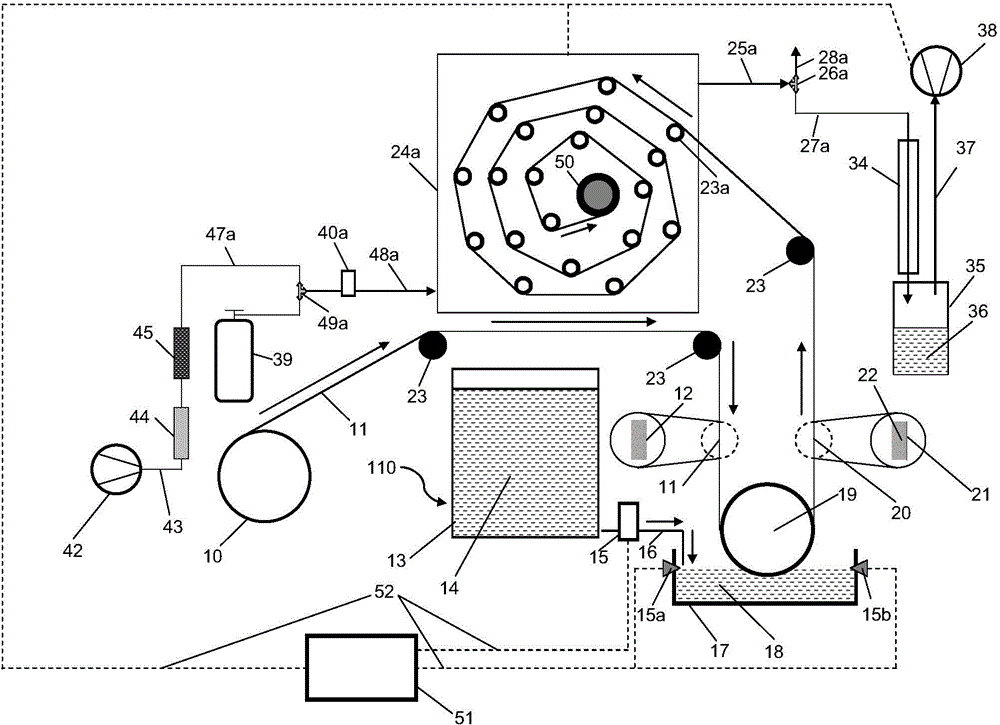

Production equipment and method for batch casting and micro-dipping of ultrathin polymer composite film

InactiveCN103418251AQuality assuranceControl evaporation rateSemi-permeable membranesComputer control systemTransport system

The invention discloses production equipment and a method for batch casting and micro-dipping of ultrathin polymer composite film and belongs to the technical field of chemical equipment and process. The production equipment comprises a conveying system, a computer control system, a micro-dipping system, a drying system and a solvent recovery system. The equipment and the method are for intermittent production. The composite film produced by the equipment and the method is high in production efficiency, and the finished film is high in quality. In order to produce even and flawless composite film, evaporating speed of solvents in the polymer solution coating is controlled. Retention time and vacuity of wet film in a vacuum drier are controlled especially; the evaporating speed of the solvents in the polymer solution coating is controlled effectively; accordingly, the quality of the composite film is guaranteed. The equipment and the method also allow for recovery of the solvents, so that production cost is saved; meanwhile, environmental pollution is avoided.

Owner:HUBEI LONGFEIXIANG IND GRP CO LTD

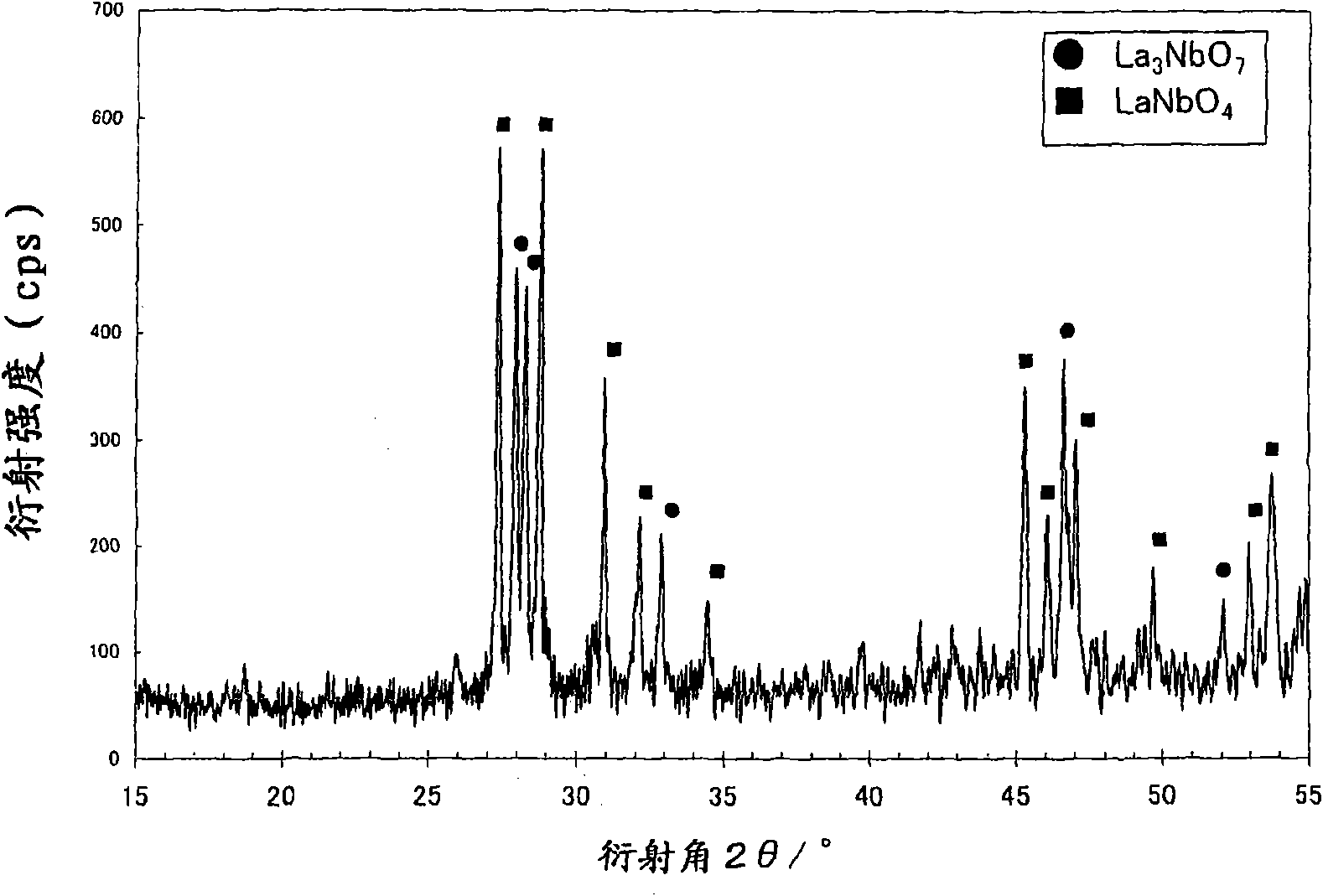

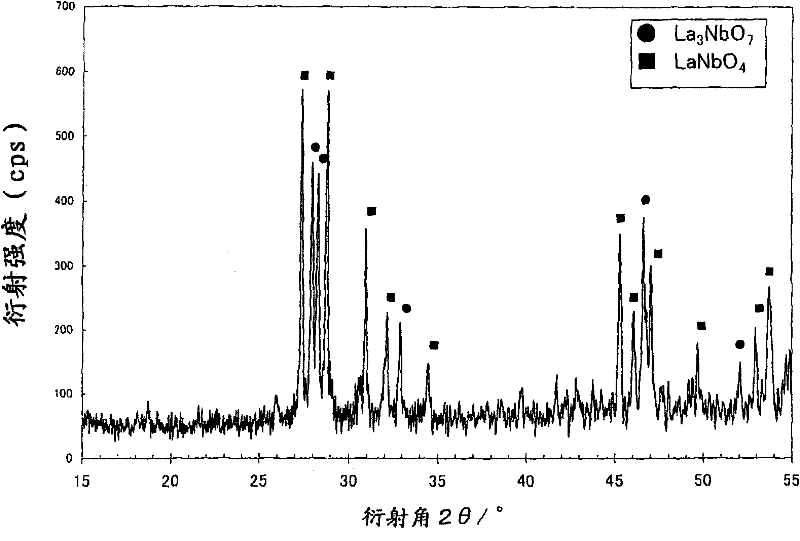

Vapor deposition material and optical thin film obtained from the same

ActiveCN101636518AControl evaporation rateRealize continuous evaporationVacuum evaporation coatingSputtering coatingNiobiumOptical thin film

The invention relates to a vapor deposition material composed of a two-component oxide of niobium and lanthanum, or a vapor deposition material composed of the two-component oxide and niobium metal and / or lanthanum metal. This vapor deposition material is characterized in that the molar ratio between niobium and lanthanum is from 25:75 to 90:10.

Owner:FUJI TITANIUM IND

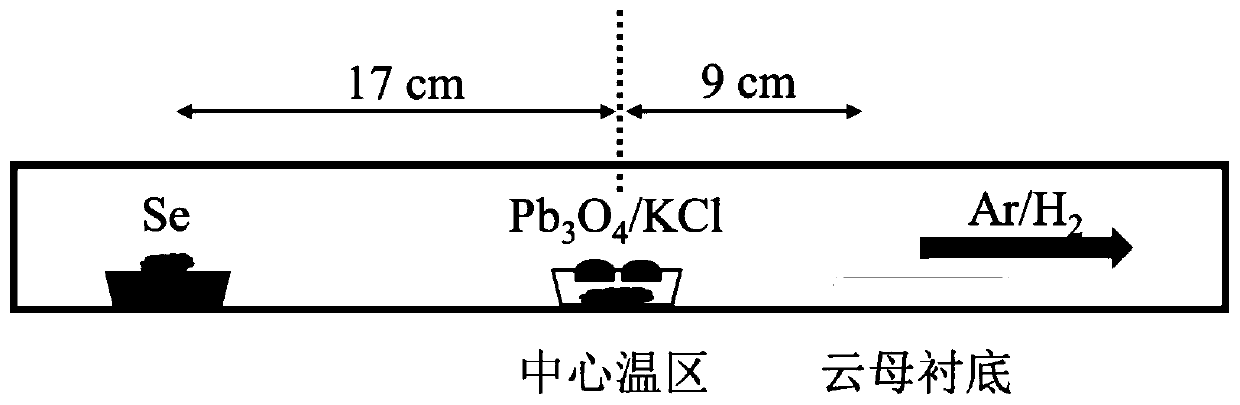

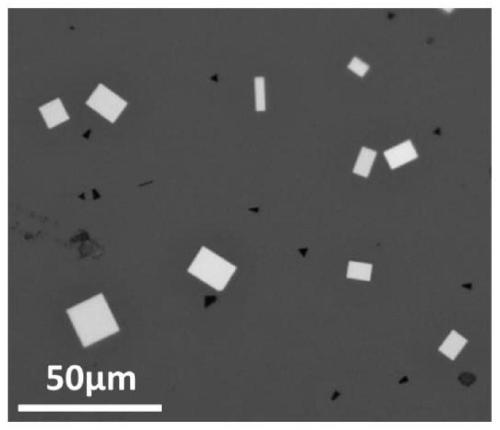

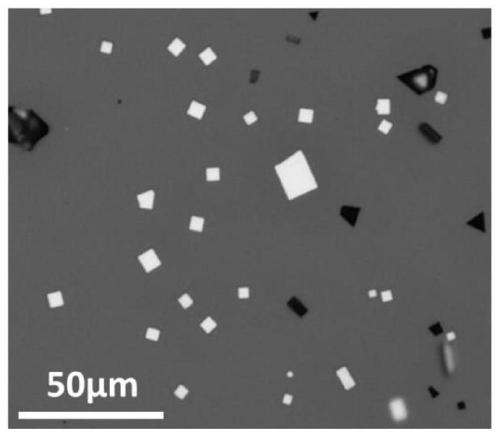

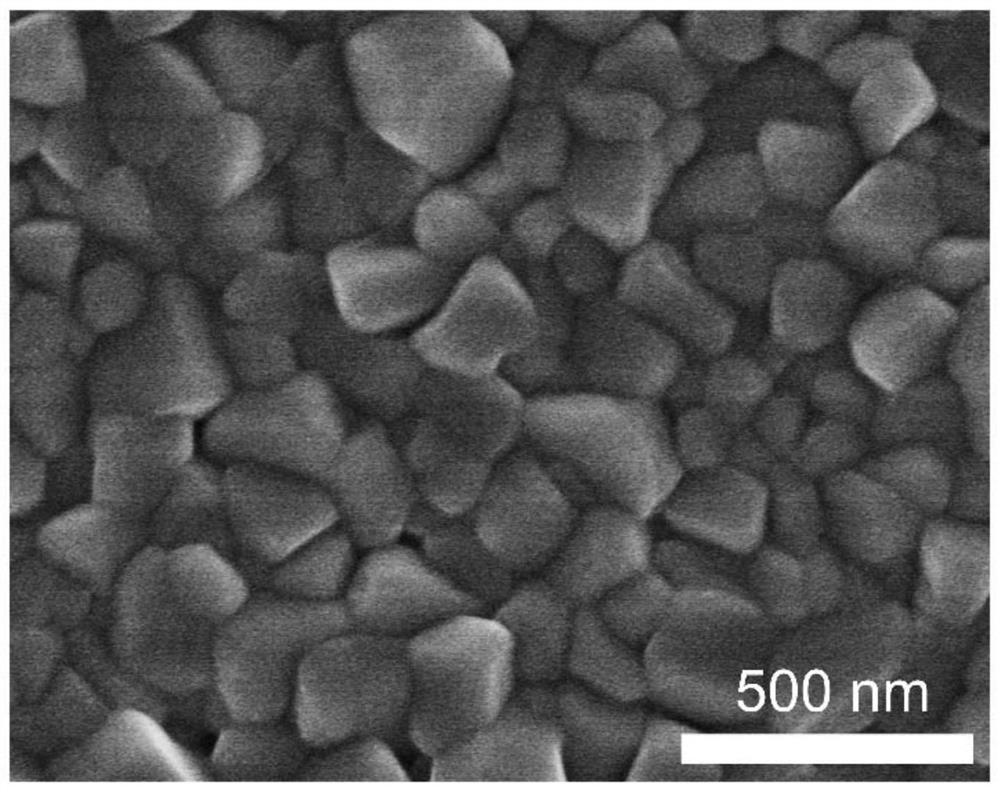

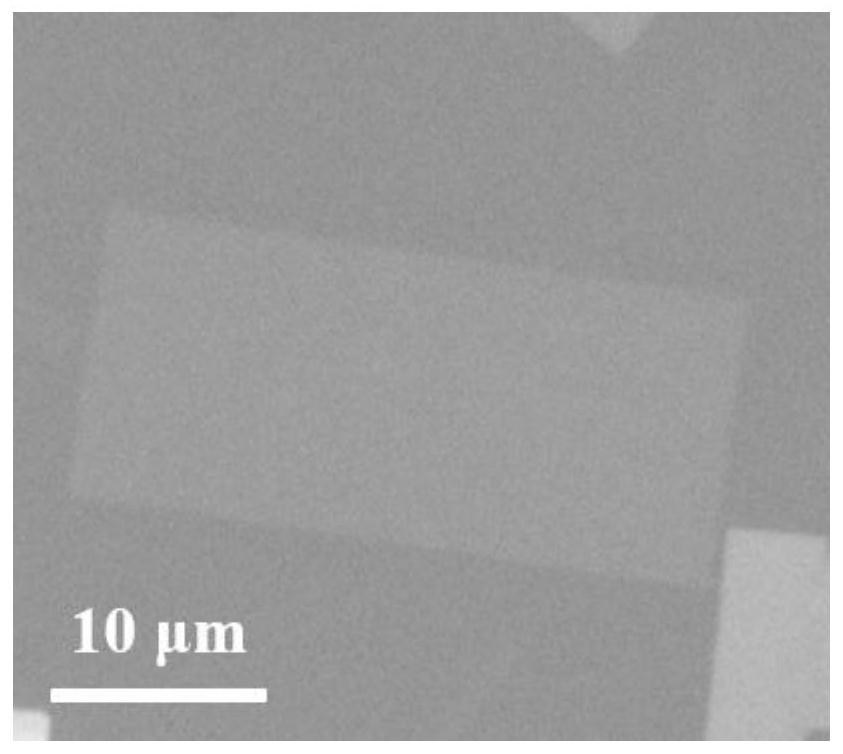

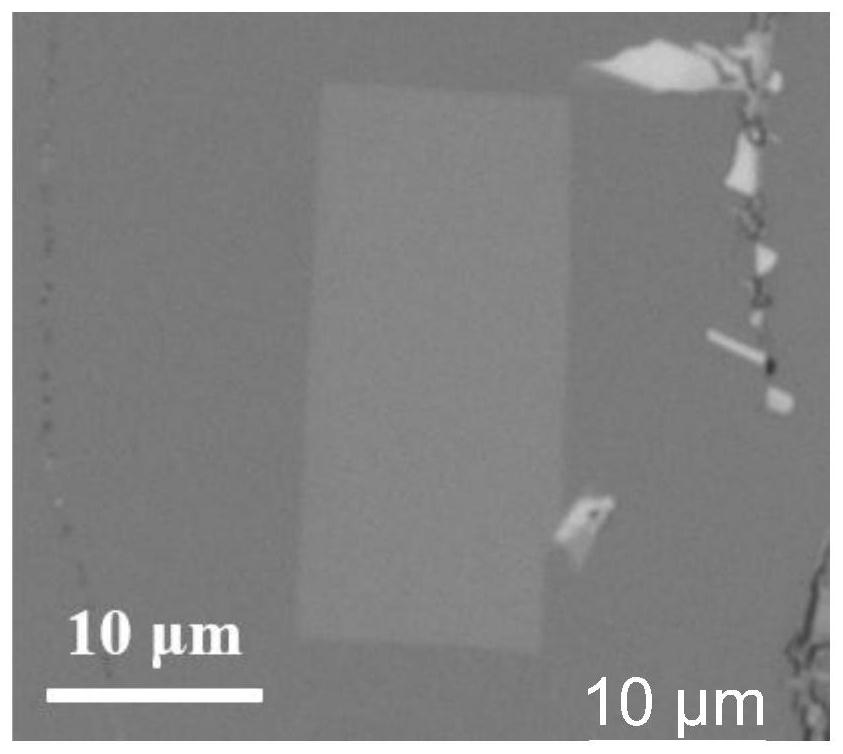

Non-layered two-dimensional PbSe crystal material and preparation method thereof

ActiveCN111304747ALow reaction temperatureUniform responsePolycrystalline material growthFrom chemically reactive gasesSemiconductor materialsPhysical chemistry

The invention belongs to the field of nanometer semiconductor materials, and discloses a non-layered two-dimensional PbSe crystal material and a preparation method thereof. The preparation method comprises the following steps: (a) selecting a reaction container, marking the reaction container as an upstream region, a central region and a downstream region, selecting Se powder as a selenium source,and placing the Se powder in the upstream region; (b) selecting Pb3O4 as a lead source, mixing the Pb3O4 with potassium chloride so as to obtain a precursor, then placing the precursor in the centralregion, and selecting mica as a growth substrate to be placed in the downstream region; and (c) introducing argon into the reaction container as carrier gas, introducing hydrogen as reaction gas, andcarrying out a reaction under heating so as to obtain the non-layered two-dimensional PbSe crystal material on the mica substrate. The invention also discloses a product prepared by using the method.The method provided by the invention meets the preparation requirements of large-batch two-dimensional nanometer PbSe crystal materials; a product crystal has the advantages of smooth and clean surface, uniform morphology, uniform element distribution, rich and cheap raw materials, simple preparation, and convenience in popularization and large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

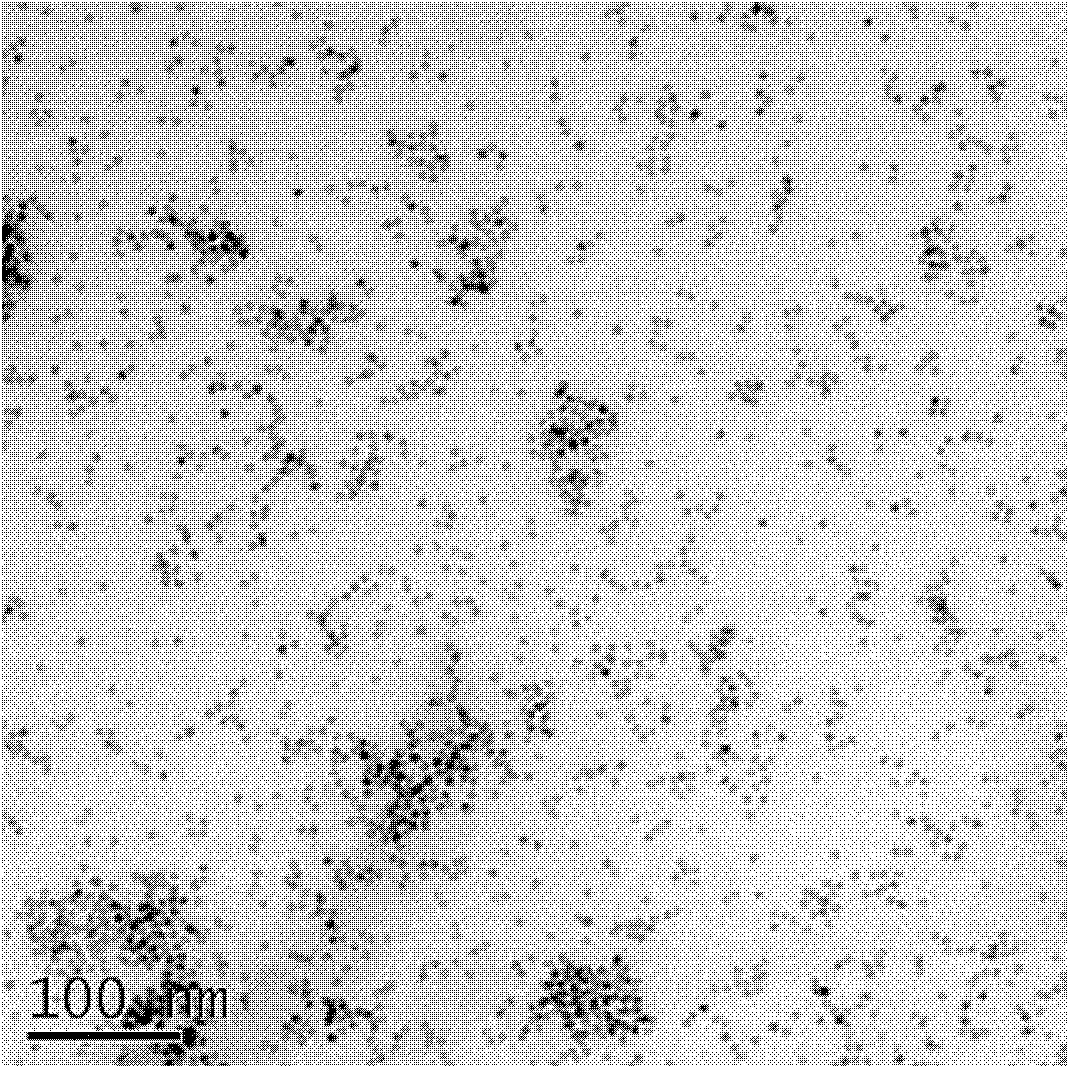

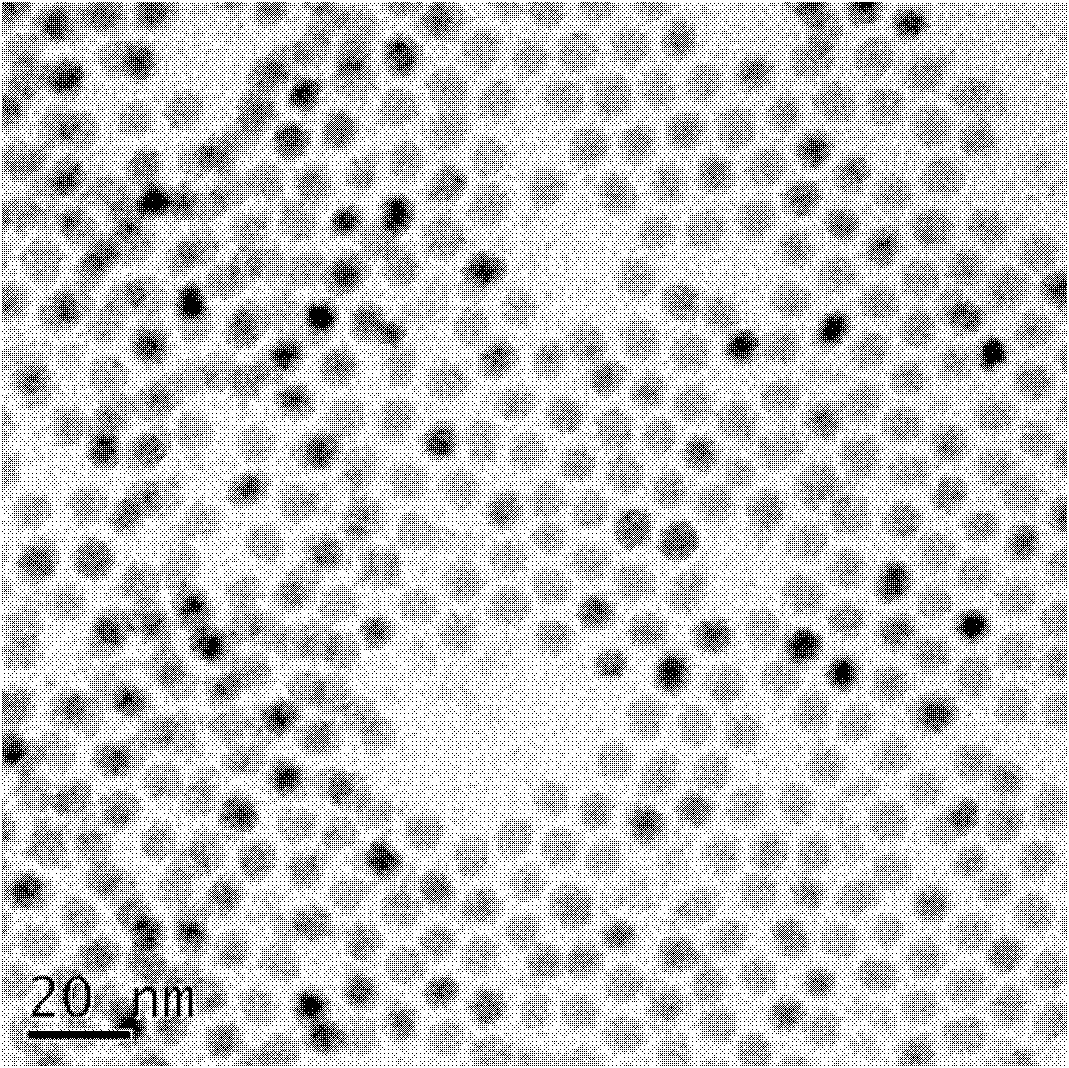

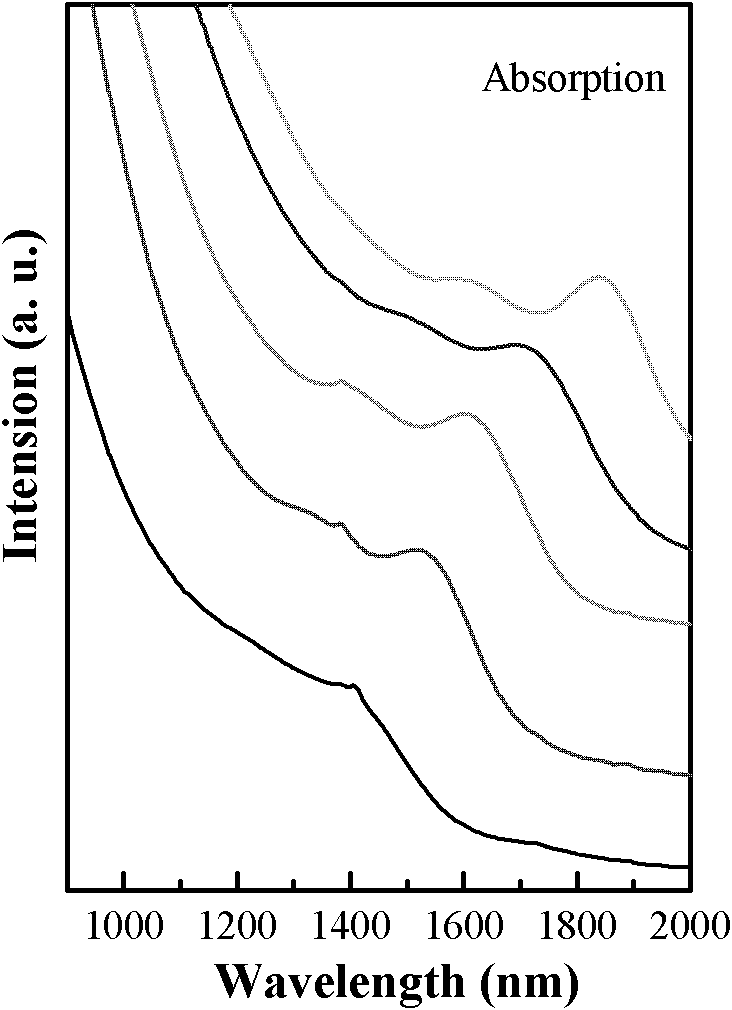

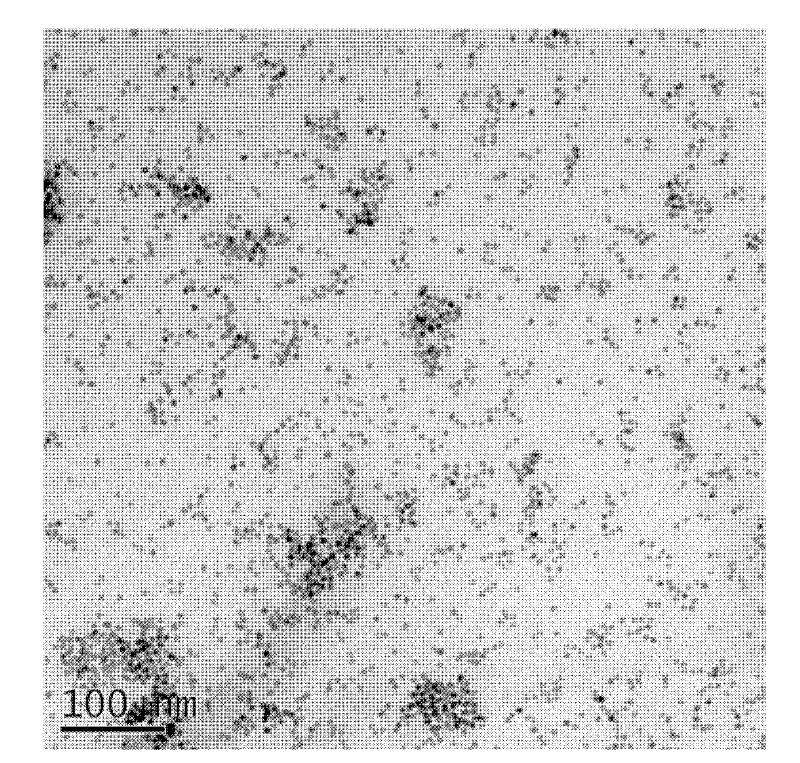

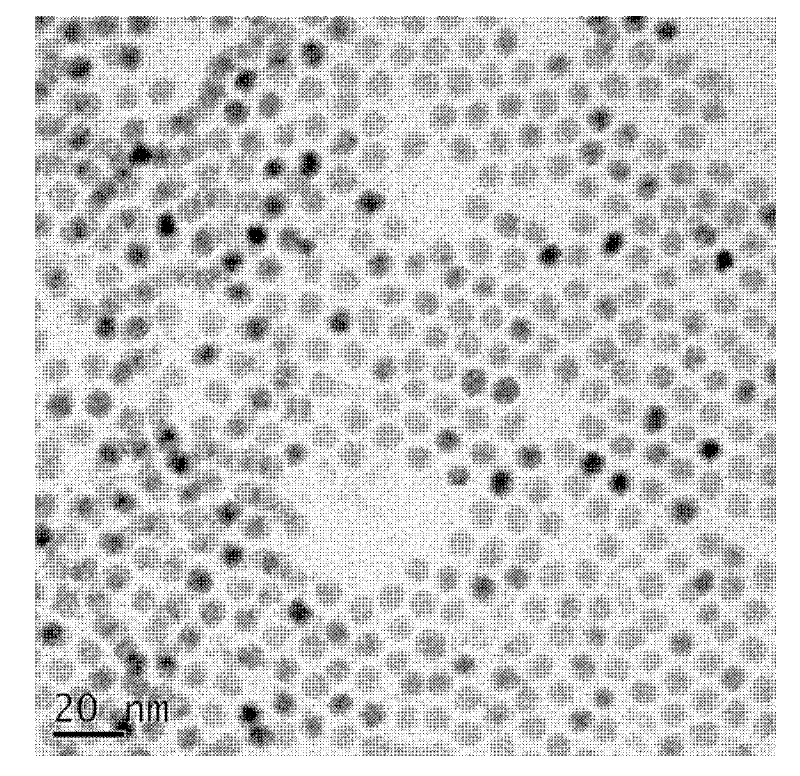

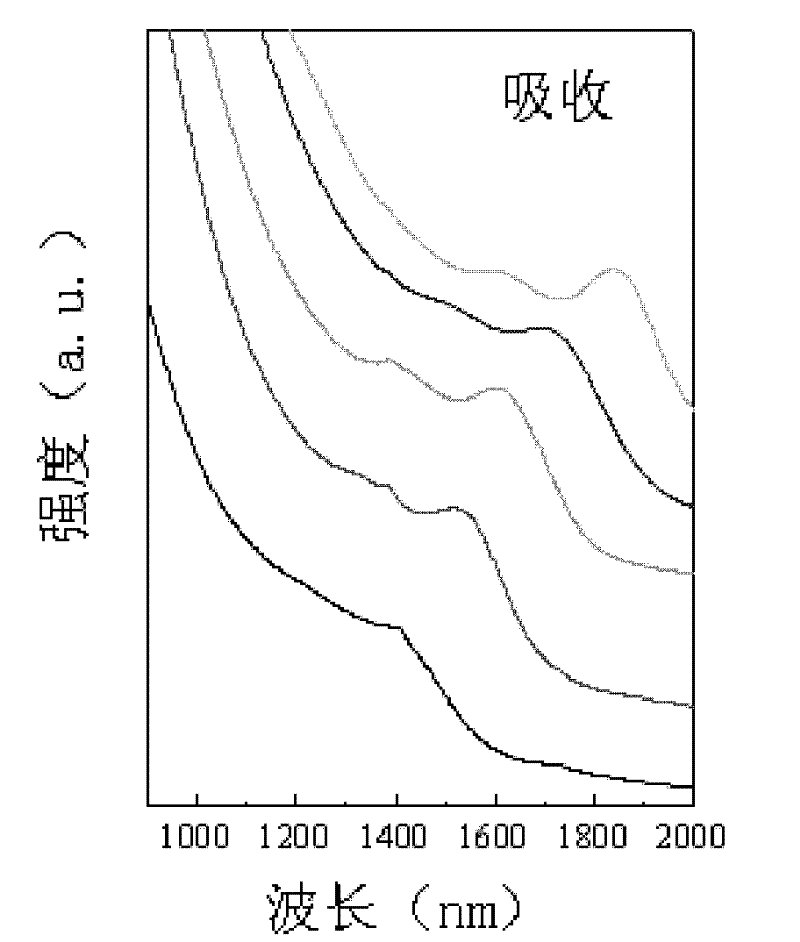

Preparation method of PbTe colloid nanocrystalline self-assembly film

InactiveCN101830446APrevent oxidationHighly ordered assemblyLiquid surface applicatorsCoatingsWater bathsEvaporation

The invention relates to a preparation method of a PbTe colloid nanocrystalline self-assembly film driven by constant temperature, constant pressure and constant load air flow, belonging to the field of preparation of ordered nano films by using rheotaxy, and the ordered nano film material is an important material for the development of new technologies of electronics, information, biology, and the like. The method comprises the following steps of: dispersing colloid nanocrystalline in a constant temperature, constant pressure and constant load air flow deposition device filled with a mixed solvent, wherein the colloid nanocrystalline is monodisperse PbTe colloid nanocrystalline prepared by adopting a colloid chemical method; driving the colloid nanocrystalline to carry out self-assembly by utilizing bath temperature and carrier air flow; assembling the colloid nanocrystalline on a Si wafer substrate to form a PbTe nanocrystalline film layer; and then clearing away residual liquid on the surface of the film by utilizing a high-speed film throwing technology. The thickness of the film layer can be effectively controlled through controlling the deposition time, and the prepared PbTe colloid nanocrystalline self-assembly film has uniform and consistent surface and is highly ordered. A tool in the invention for controlling solution evaporation has simple structure, low cost, simple and convenient operation and effective method.

Owner:XI AN JIAOTONG UNIV

Greenhouse irrigation device capable of simulating vegetable water loss

InactiveCN111527949AControl heating temperatureControl evaporation rateClimate change adaptationGreenhouse cultivationAgricultural scienceGreenhouse

The invention provides a greenhouse irrigation device capable of simulating vegetable water loss, and relates to the technical field of Internet of things equipment. The device comprises a fixed seat,wherein an electromagnet is fixedly connected to the inner wall of the bottom of the fixed seat; a resistor electrically connected with the electromagnet is fixedly connected to the inner wall of thebottom of the fixed seat; and a negative plate is fixedly connected to the inner wall of the right side of the fixed seat. According to the greenhouse irrigation device capable of simulating vegetable water loss, through the cooperative use of a variable resistance block and an electric heating block, when the device is used, a heat conduction block can conduct the temperature in a greenhouse toa bimetallic plate, so that the bimetallic plate is heated and bent downwards, the bending degree of the bimetallic plate can be adjusted according to the temperature, and as a result, the bimetallicplate points to different positions of the variable resistance block, the heating temperature of the electric heating block is controlled, the evaporation speed of water in a water tank is controlled,the water loss speed of plants at different temperatures is simulated, the speed of simulating the water loss of the plants is achieved, the irrigation efficiency of greenhouse planting is improved,and the yield of greenhouse planting is increased.

Owner:郑晓龙

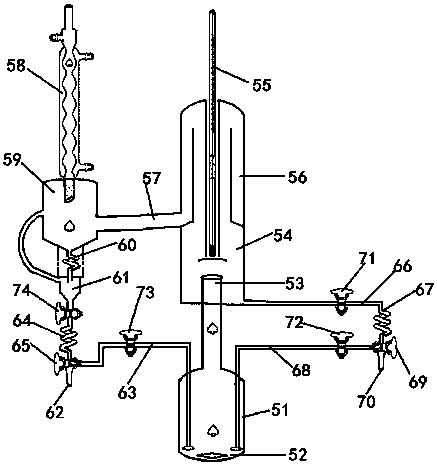

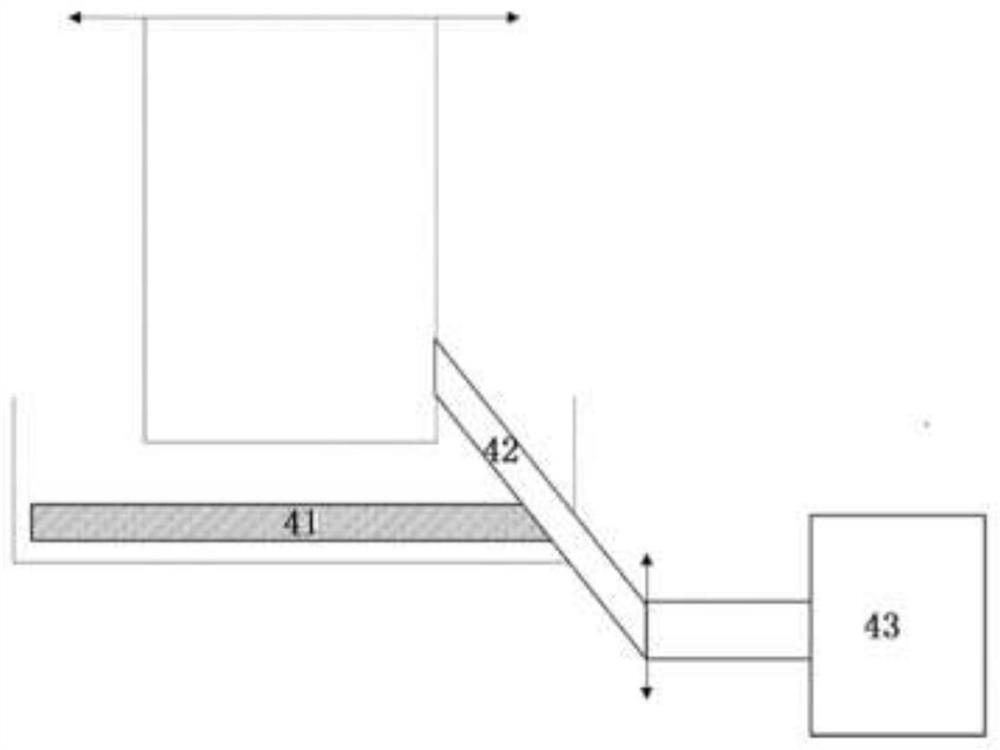

Solution coating continuous production equipment and method for polymer ultra-thin sub-nanofiltration composite membrane filter element

ActiveCN104056494BImprove breathabilityControlled evaporationFiltration separationAgricultural engineeringNitrogen gas

The invention provides a device and a method for continuously producing a solution coating of a polymer ultrathin sub-nanofiltration composite membrane filter cartridge. The device comprises a transmission system, a computer-controlled system, a solution spraying system and a drying system, wherein the transmission system consists of a material roller, a support coating conveyer belt and transmission rollers in a plurality of drying boxes; the material roller is connected with the support coating conveyer belt through a porous carrier layer raw material sheet; the support coating conveyer belt is connected with the transmission rollers in the drying boxes through a wet high-breathability polymer ultrathin sub-nanofiltration composite membrane sheet coated with the coating solution; a coating opening of a coating solution spraying device of the solution spraying system is arranged by facing to the upper surface of the support coating conveyer belt; the drying system comprises drying boxes with controllable temperature gradients and a preheated nitrogen purging system; a nitrogen output pipe of the preheated nitrogen purging system is communicated with nitrogen inlets of the drying boxes with controllable temperature gradients. The device and the method have the advantages of simple and convenient process, low equipment investment cost, high production efficiency and good quality of finished products.

Owner:岳阳万泓化工有限公司

Dynamic vapor-liquid balance measuring device

PendingCN108627535AControl evaporation rateEasy to control temperatureInvestigating phase/state changeVapor liquidReflux

The invention provides a dynamic vapor-liquid balance measuring device, which comprises an equilibrium still, a vapor-liquid separation bottle, a vapor phase condensing device and a plurality of flowtubes, wherein a stirring magneton is disposed in the equilibrium still; a liquid phase outlet is arranged at one side of the horizontal bottom of the vapor-liquid separation bottle; the top end of the first liquid phase flow tube is connected to the liquid phase outlet with an included angle of 0.5 to 10 degrees; a liquid phase sampling opening is formed in the top end of the second liquid phaseflow tube, and the portion, close to the liquid phase sampling opening, of the second liquid phase flow tube is communicated with the interior of the top end of the third liquid phase flow tube through a third liquid phase reflux shutoff valve. The dynamic vapor-liquid balance measuring device is additionally provided with the stirring magneton, and the stirring magneton is driven to rotate by oilbath heating, so as to avoid liquid flooding. The first liquid phase flow tube and the vapor-liquid separation bottle are designed to eliminate a liquid phase dead angle in an existing device. The spiral return tube is designed to eliminate the problem of volatilization loss caused by the too high temperature of liquid phase and vapor phase samples in the using process of existing device.

Owner:泰州学院

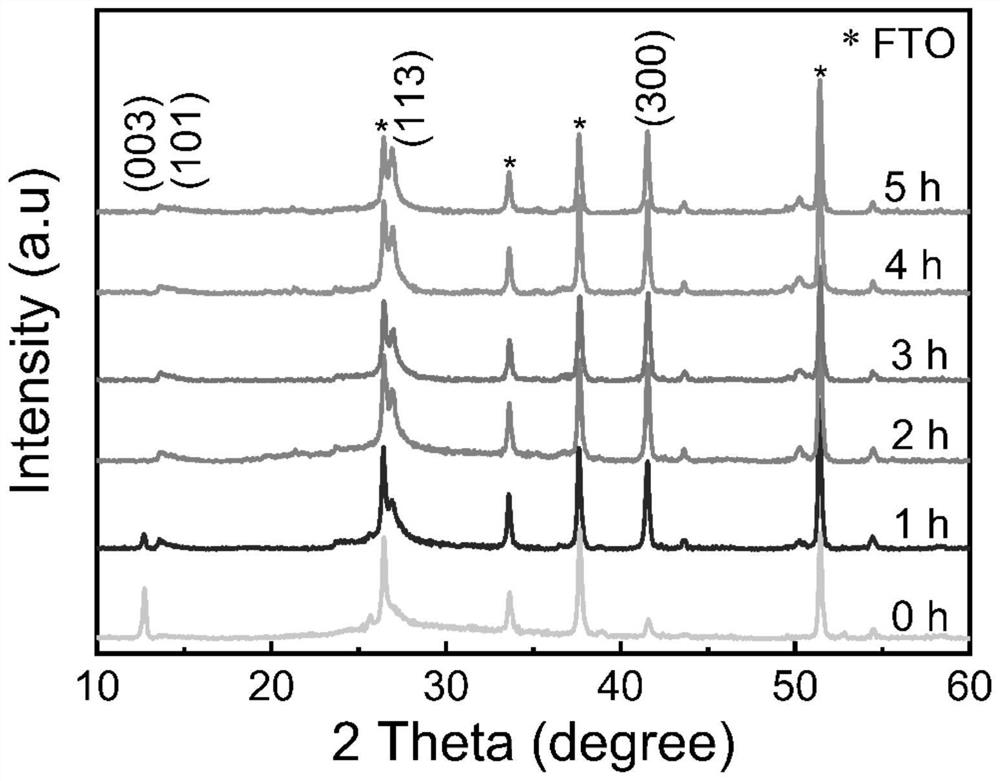

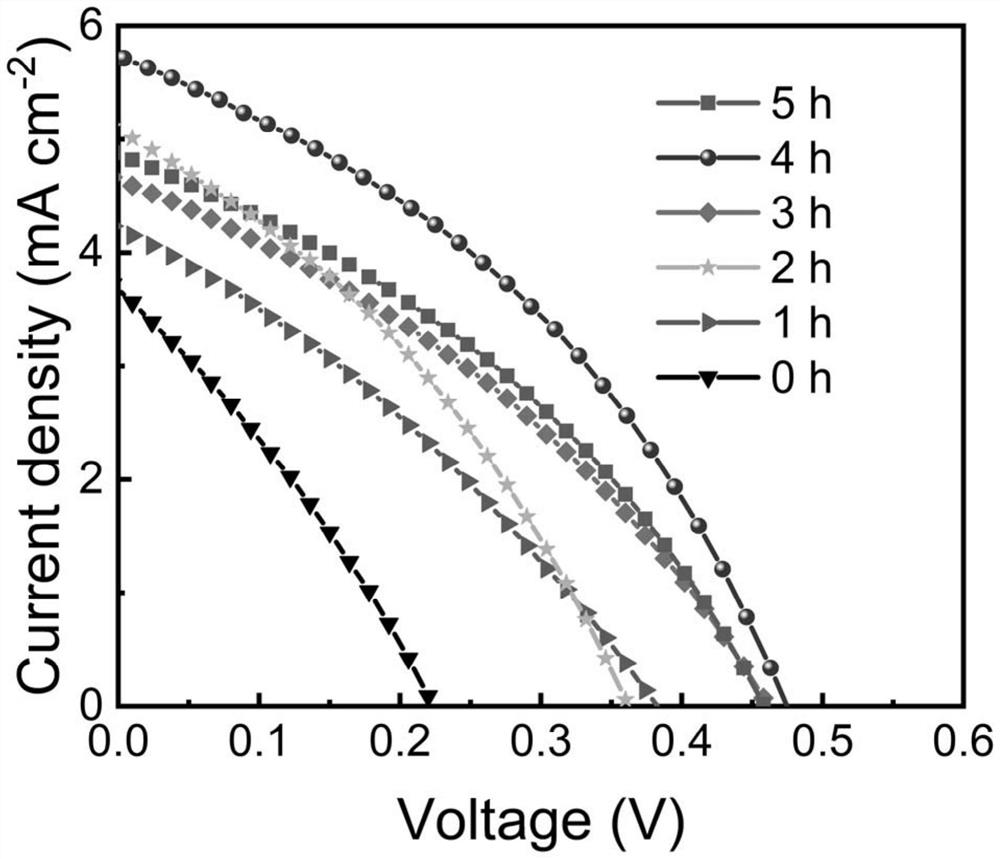

Method for preparing MA3Bi2I9 perovskite solar cell by controlling BiI3 film orientation through solvent evaporation induction

PendingCN114551731AControl evaporation rateImprove surface topographySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellSolvent evaporation

The invention provides a method for preparing an efficient MA3Bi2I9 perovskite solar cell by controlling BiI3 film orientation through solvent evaporation induction, which comprises the following steps of: firstly, spin-coating a DMF (Dimethyl Formamide) precursor solution of BiI3 on a fluorine-doped tin oxide (FTO) substrate deposited with TiO2 to prepare a BiI3 film, and then, putting the prepared BiI3 wet film into a glove box room-temperature closed container; due to the sealing condition in the container, DMF evaporated from the wet film can generate a DMF atmosphere, so that the evaporation rate of the DMF is greatly reduced. By slowing down DMF evaporation, the product with preferred orientation (113) and (300) is successfully prepared; meanwhile, the (003) crystal face of the BiI3 film is weakened. Then, the prepared BiI3 thin film reacts with MAI to form an MBI thin film; the growth of the crystal face of BiI3 (003) is limited, and the crystal face of MBI (006) is also effectively limited, so that compared with a device prepared from an MBI film with preferred orientation of (006), the device is more beneficial to carrier transport.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Vapor deposition material and optical thin film obtained from the same

ActiveCN101636518BControl evaporation rateRealize continuous evaporationVacuum evaporation coatingSputtering coatingNiobiumOptical thin film

The invention relates to a vapor deposition material composed of a two-component oxide of niobium and lanthanum, or a vapor deposition material composed of the two-component oxide and niobium metal and / or lanthanum metal. This vapor deposition material is characterized in that the molar ratio between niobium and lanthanum is from 25:75 to 90:10.

Owner:FUJI TITANIUM IND

A method of drying wood

ActiveCN109405441BReduce drying defectsReduce moisture gradientDrying gas arrangementsDrying solid materialsPulp and paper industryBotany

The invention discloses a fast-growing wood drying method. The method comprises the steps that after to-be-dried wood is pretreated to obtain pretreated wood, the pretreated wood is dried according toordinary benchmark programs for wood drying, wherein the water content of the pretreated wood is 30-90%. The central temperature and surface temperature difference of wood in a wood stack is precisely controlled, the wet bulb depression in a drying room is adjusted, and the wood is dried according to the ordinary benchmark programs for wood drying after the wood is pretreated, so that high-quality dried wood is obtained. By means of the method, the water content gradient in the fast-growing wood drying process is reduced, and thus the treatment quality of the wood in the pretreatment processis guaranteed; then conventional drying is adopted, and compared with direct adoption of conventional drying, the wood drying method greatly improves wood drying efficiency, reduces drying stress, reduces drying defects and improves drying efficiency.

Owner:BEIJING FORESTRY UNIVERSITY

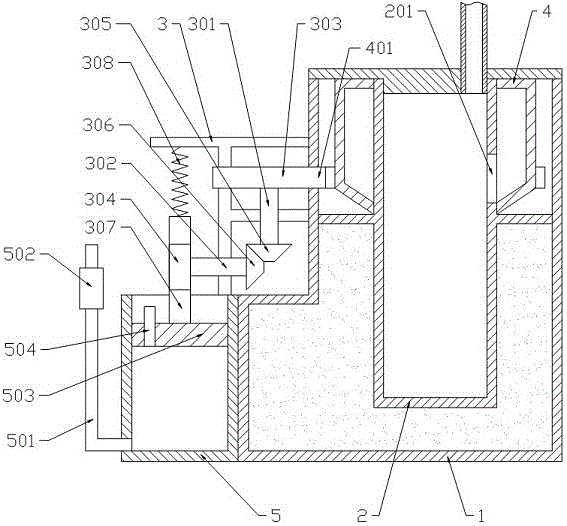

Automatic coal adding heating furnace

InactiveCN106705126AImprove sealingAutomatic coal fillingLighting and heating apparatusStove/ranges for heating waterEvaporationEngineering

The invention relates to the field of heating devices, and discloses an automatic coal adding heating furnace which comprises a furnace body and a hearth. The hearth is located in the furnace body. The heating furnace further comprises a support, a coal storage bin and a water storage barrel. The support is fixed to the furnace body and provided with a gear transmission system. The coal storage bin is in an annular shape, the coal storage bin is coaxially and rotationally connected to the periphery of the hearth, the inner wall of the coal storage bin is provided with an opening, a coaxial outer gear ring is fixed to the outer wall of the coal storage bin, and the outer gear ring is driven by the output end of the gear transmission system. The water storage barrel is fixed to the furnace body. The upper end in the water storage barrel is provided with an opening. A piston is in sliding connection with the interior of the water storage barrel. The piston is connected with the input end of the gear transmission system. The heating furnace further comprises a compressed spring. The lower end of the compressed spring is fixed to the piston, and the upper end of the compressed spring is fixed to the support. The piston is further provided with a pressure release valve. The hearth is provided with a discharge outlet communicating with the coal storage bin. The water storage barrel is further provided with a heat conductive pipe for accelerating water evaporation and a water inlet pipe for water adding. By means of the automatic coal adding heating furnace, coal can be automatically added into the hearth.

Owner:刘开芹

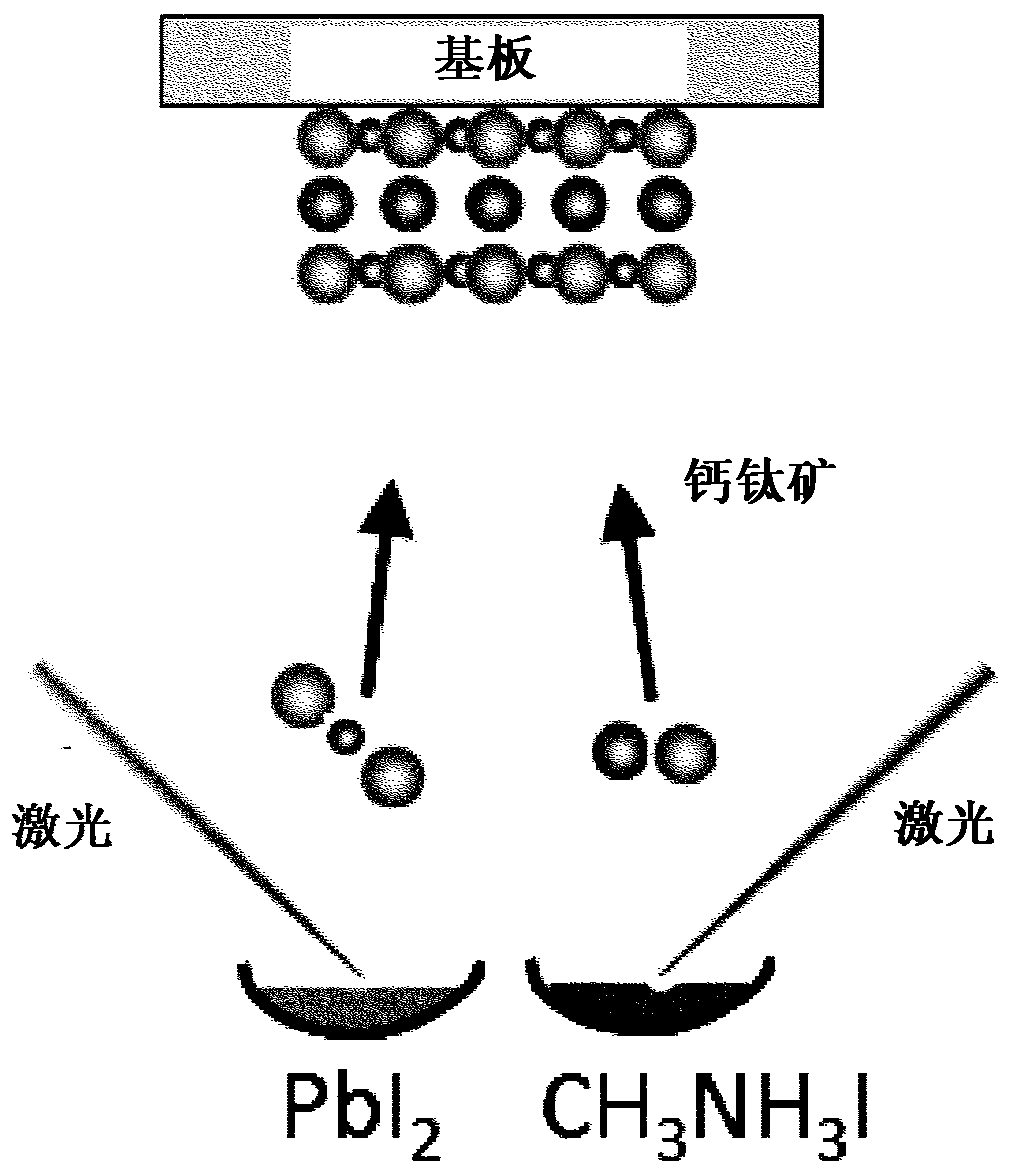

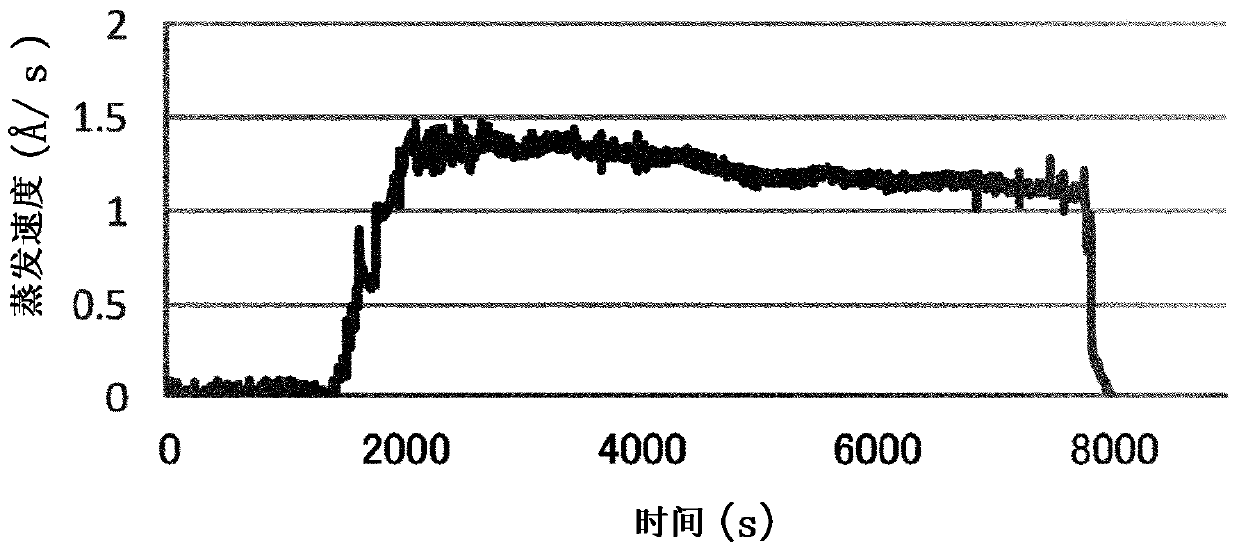

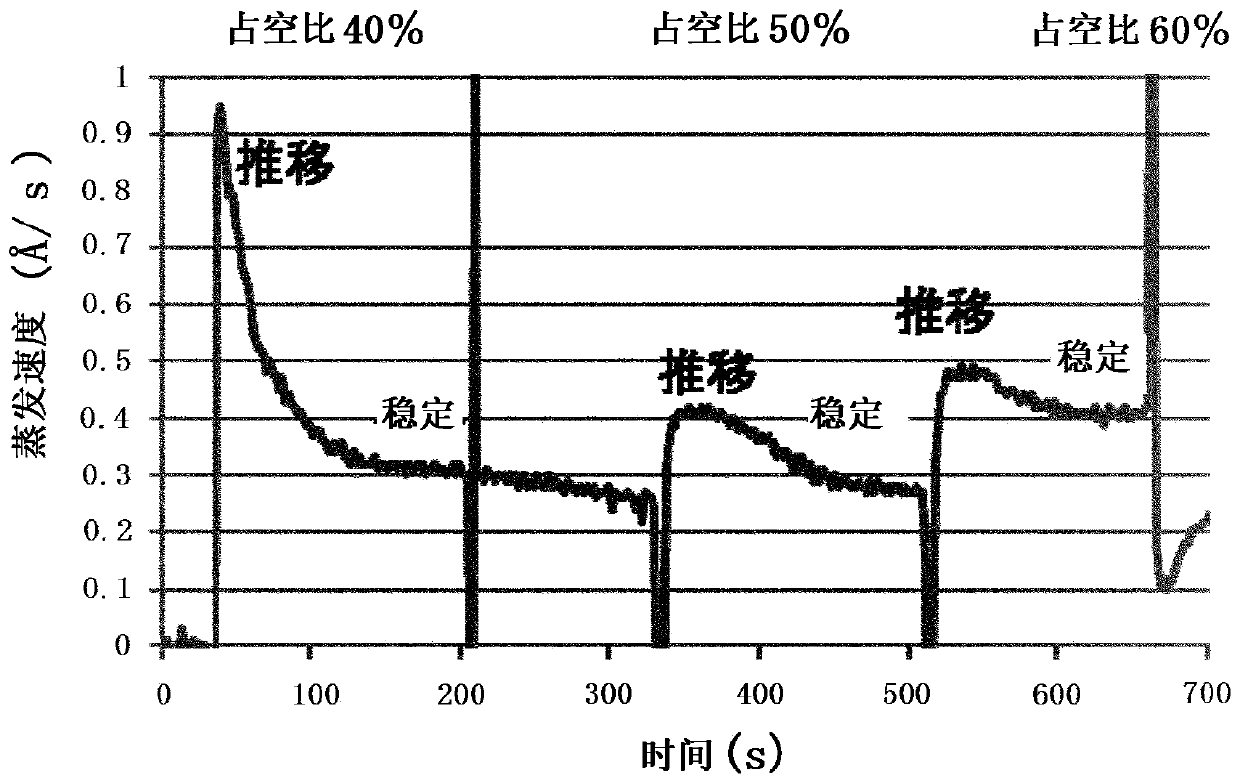

Laser evaporation method and laser evaporation device for organic material film or organic-inorganic composite material film

InactiveCN107109628BReduce gasificationAvoid pollutionElectrolytic capacitorsVacuum evaporation coatingEvaporation (deposition)Laser light

The object of the present invention is to solve the problems in the prior art such as contamination of other raw materials for evaporation due to gasification of organic materials, or loss of control due to uncontrollable film formation speed, and to provide a method that can stably adjust and control the deposition rate. A laser vapor deposition method and a laser vapor deposition device for an organic material with a film speed and an evaporation rate, in the method of carrying out laser vapor deposition of at least one organic material, it is characterized in that the duty ratio of the laser light that vaporizes the organic material is Make adjustments. In addition, it is characterized in that the above-mentioned duty ratio is adjusted based on the evaporation rate of the above-mentioned organic substance and the vapor pressure in the vacuum chamber for vapor deposition.

Owner:NAT INST OF ADVANCED IND SCI & TECH

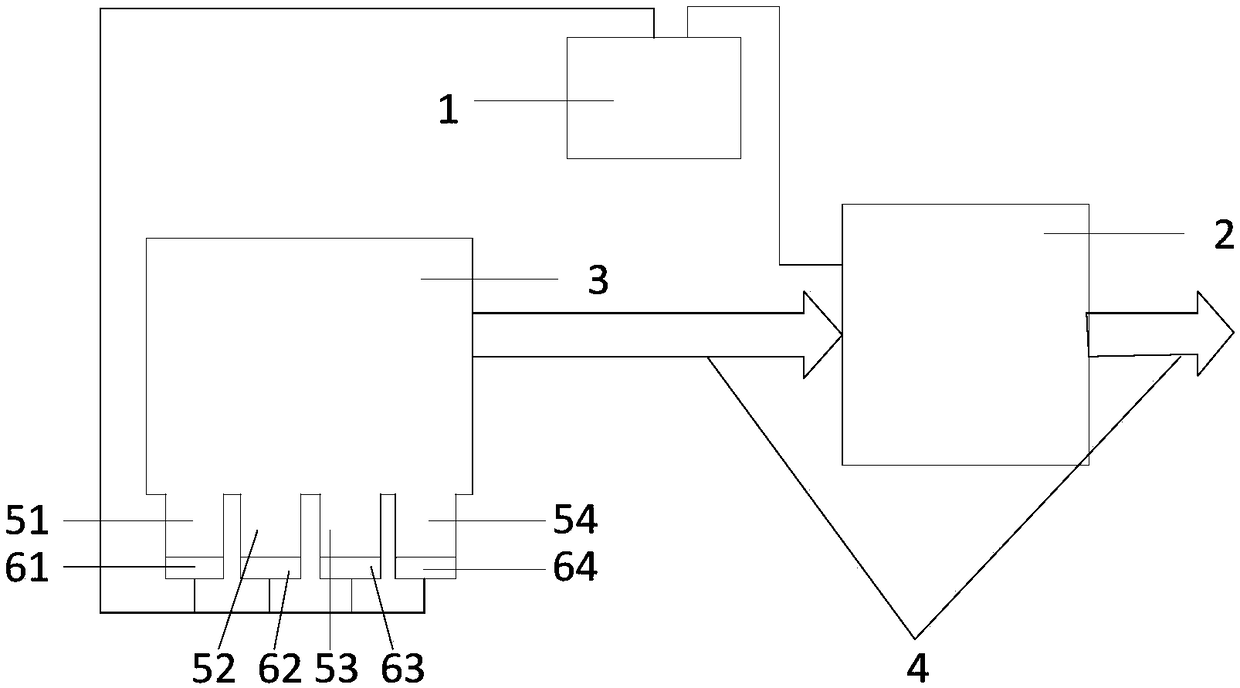

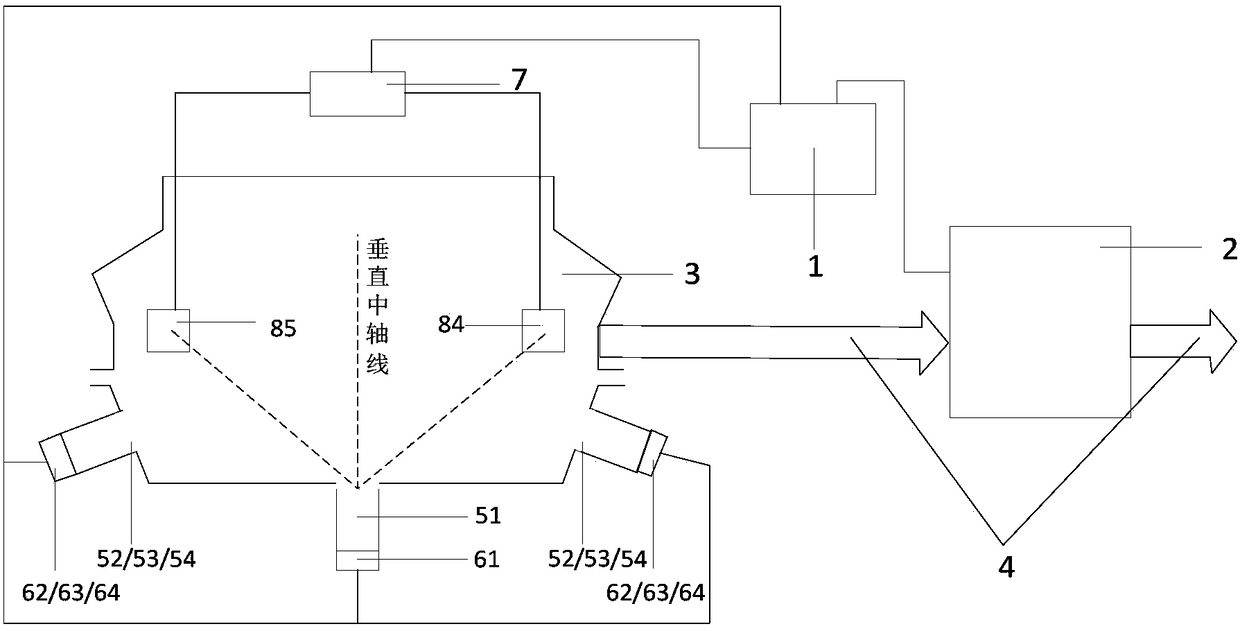

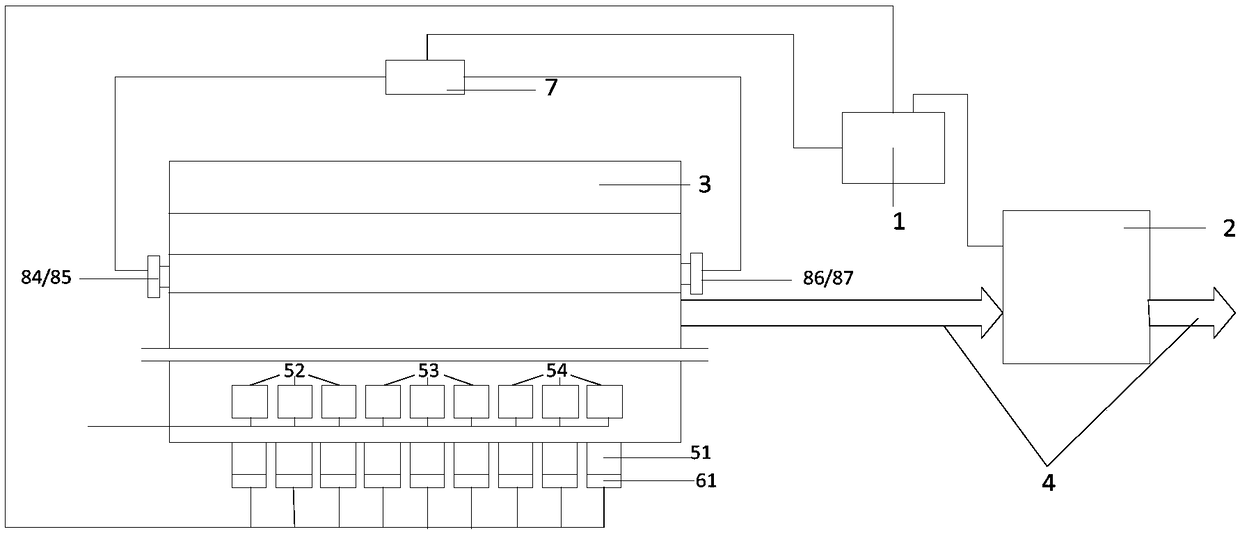

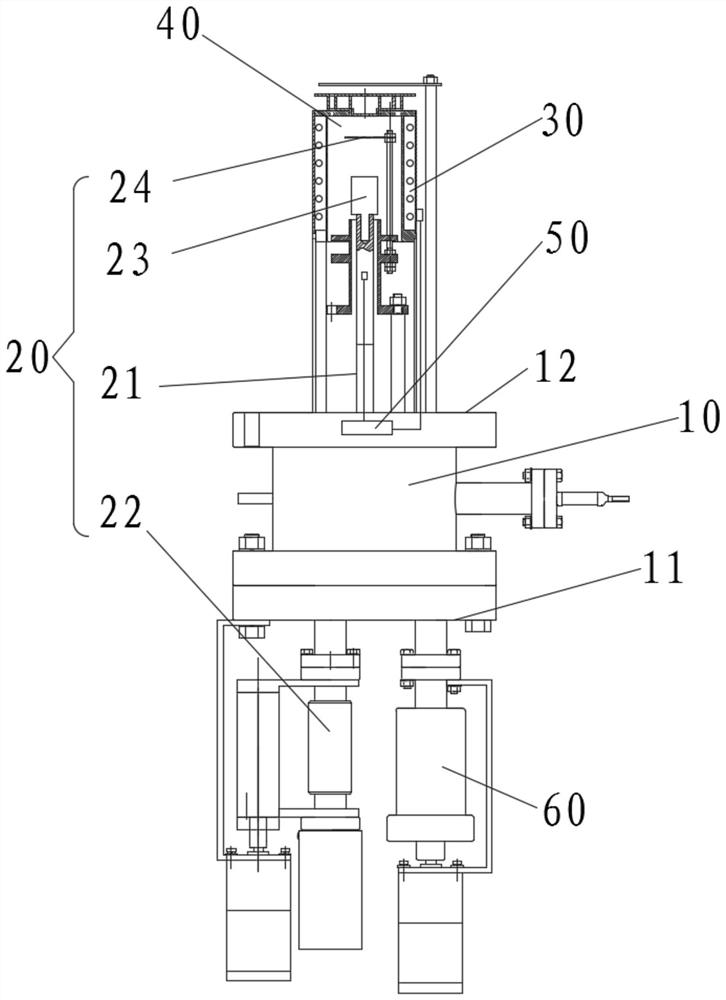

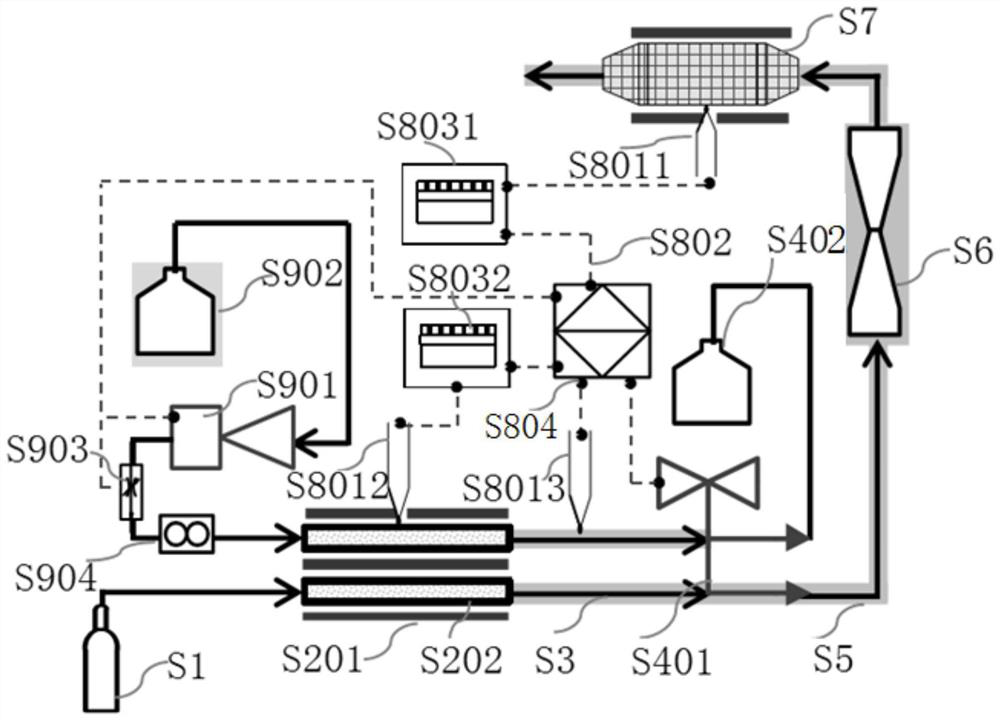

Thin film preparation system

ActiveCN113913755AControl evaporation rateEvaporation stablePolycrystalline material growthVacuum evaporation coatingEvaporation (deposition)Temperature control

The invention provides a thin film preparation system. The thin film preparation system comprises a storage device, an evaporation control device and a thin film deposition device, wherein the storage device is used for storing a to-be-evaporated precursor material; the evaporation control device is located in the storage device and used for controlling the to-be-evaporated precursor material to be evaporated to form precursor molecules in a vacuum environment; and the thin film deposition device communicates with the storage device and is used for receiving the precursor molecules and preparing a thin film by utilizing the precursor molecules in the vacuum environment. The evaporation control device comprises a temperature control device and a control mechanism, wherein the temperature control device is located at the bottom of the storage device and used for evaporating the to-be-evaporated precursor material; and the control mechanism is arranged at the upper part of the storage device and is used for controlling the evaporation rate of the to-be-evaporated precursor material.

Owner:UNIV OF SCI & TECH OF CHINA

Adsorption carrier for vapor deposition material for vapor deposition of antifouling film

ActiveCN103205716BWon't happenGuaranteed uniformityVacuum evaporation coatingSputtering coatingChemical reactionCopper

The invention provides an adsorption carrier for an evaporation material for evaporation of an anti-fouling film. The adsorption carrier is a sintered body of metal powder, and the metal powder is one or a metal mixture of at least two selected from iron, stainless steel, copper and aluminum. The adsorption carrier provided by the invention has the advantages that the adsorption carrier does not contain impurities and can ensure that the impurities can not be produced by melting during the film plating process under high-vacuum and high-temperature conditions, and the adsorption carrier can not perform chemical reaction with the evaporation material which is adsorbed and carried by the adsorption carrier; a sintering raw material with appropriate heat conductivity can be selected according to the demands of film plating equipment, so that the uniformity of film plating is ensured; and the anti-fouling film which is obtained by using the adsorption carrier provided by the invention to perform vacuum evaporation can greatly improve the wear resistance and is better than the anti-fouling film which is obtained by evaporation by using the adsorption carrier in the prior art.

Owner:OPTORUN SHANGHAI CO LTD

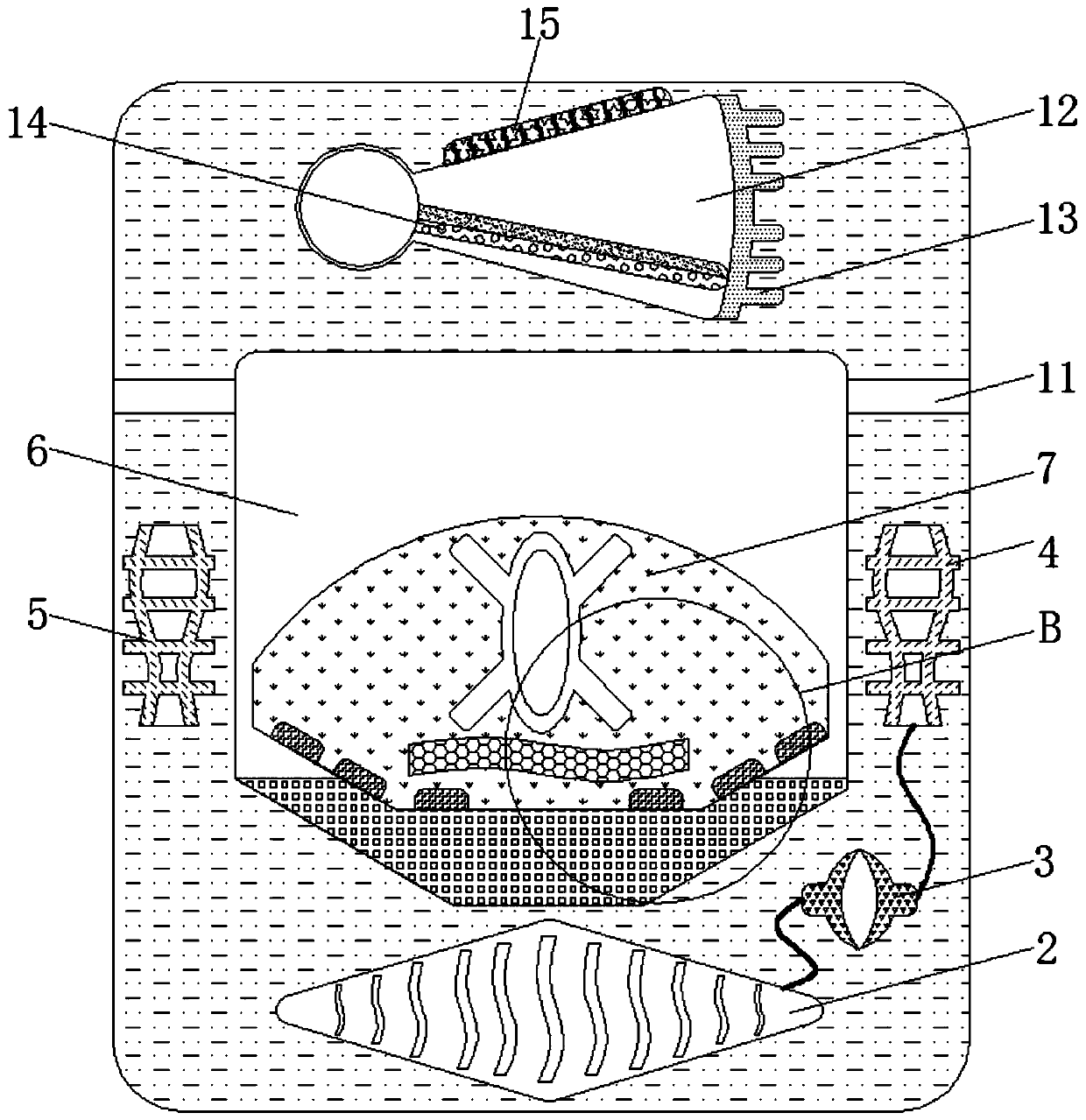

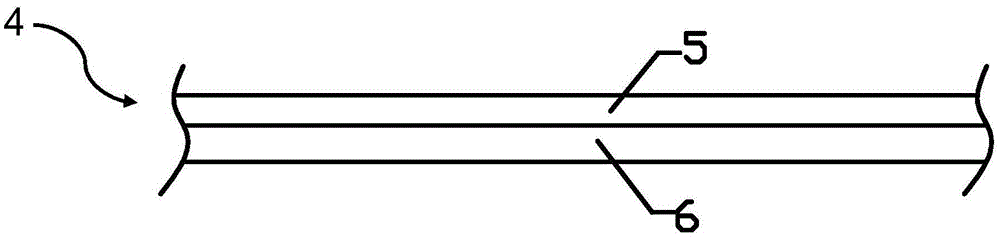

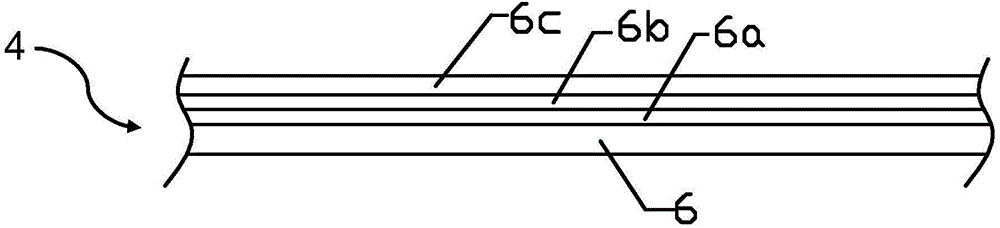

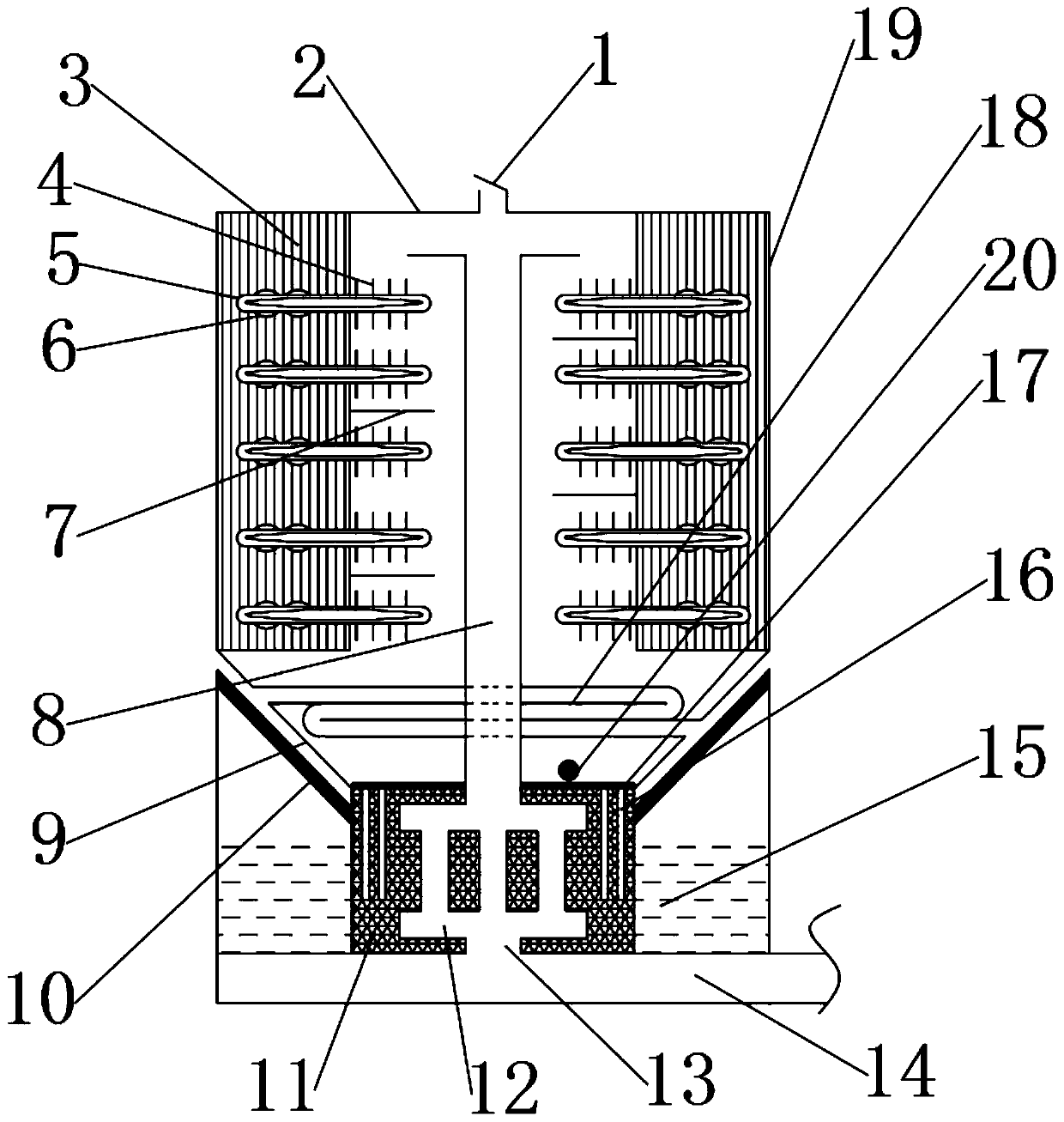

A superconducting magnet liquid helium container including a vacuum chamber

The invention discloses a superconducting magnet liquid helium container comprising a vacuum chamber. The superconducting magnet liquid helium container comprises a liquid helium storage tank and an outer cold screen. The liquid helium storage tank is disposed within the outer cold screen; a vacuum layer is provided between the liquid helium storage tank and the outer cold screen; a main bobbin, a shielding bobbin and the vacuum chamber are provided in the liquid helium storage tank. The superconducting magnet liquid helium container has the advantages that operational safety and stability of magnets can be guaranteed, required usage of the liquid helium is less, the cost is lowered, and liquid helium evaporation is effectively controlled.

Owner:ALLTECH MEDICAL SYST

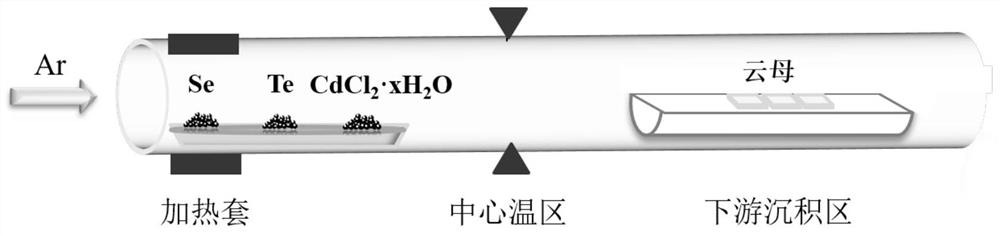

a two-dimensional cd 7 te 7 cl 8 o 17 Crystal material and preparation method thereof

ActiveCN112853490BAvoid destructionAchieving controllable equipmentPolycrystalline material growthFrom chemically reactive gasesSemiconductor materialsCadmium chloride

The invention belongs to the technical field related to nano-semiconductor materials, and discloses a two-dimensional Cd 7 Te 7 Cl 8 o 17 A crystal material and a preparation method thereof, the method comprising the following steps: (1) dividing the reaction zone of a horizontal tube furnace into an upstream low temperature zone, a central temperature zone and a downstream deposition zone, and separating cadmium chloride, tellurium powder and selenium powder Placed in the upstream low temperature area as a precursor; (2) Cadmium chloride, tellurium powder and selenium powder react to generate Cd 7 Te 7 Cl 8 o 17 After crystallizing the material, the Cd 7 Te 7 Cl 8 o 17 The crystalline material is brought into the downstream deposition zone to be deposited on the substrate located in the downstream deposition zone, resulting in two-dimensional Cd 7 Te 7 Cl 8 o 17 crystal material. The present invention uses selenium powder as an oxidant to promote the generation of Cd 7 Te 7 Cl 8 o 17 reaction, to avoid the generation of by-product cadmium telluride, and to realize the controllability of the preparation process. At the same time, the present invention arranges the substrate in the downstream deposition area and keeps a certain distance from the central temperature area, which can avoid the damage of the substrate due to excessive temperature in the central temperature area. end.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of PbTe colloid nanocrystalline self-assembly film

InactiveCN101830446BPrevent oxidationHighly ordered assemblyLiquid surface applicatorsCoatingsEvaporationSolvent

Owner:XI AN JIAOTONG UNIV

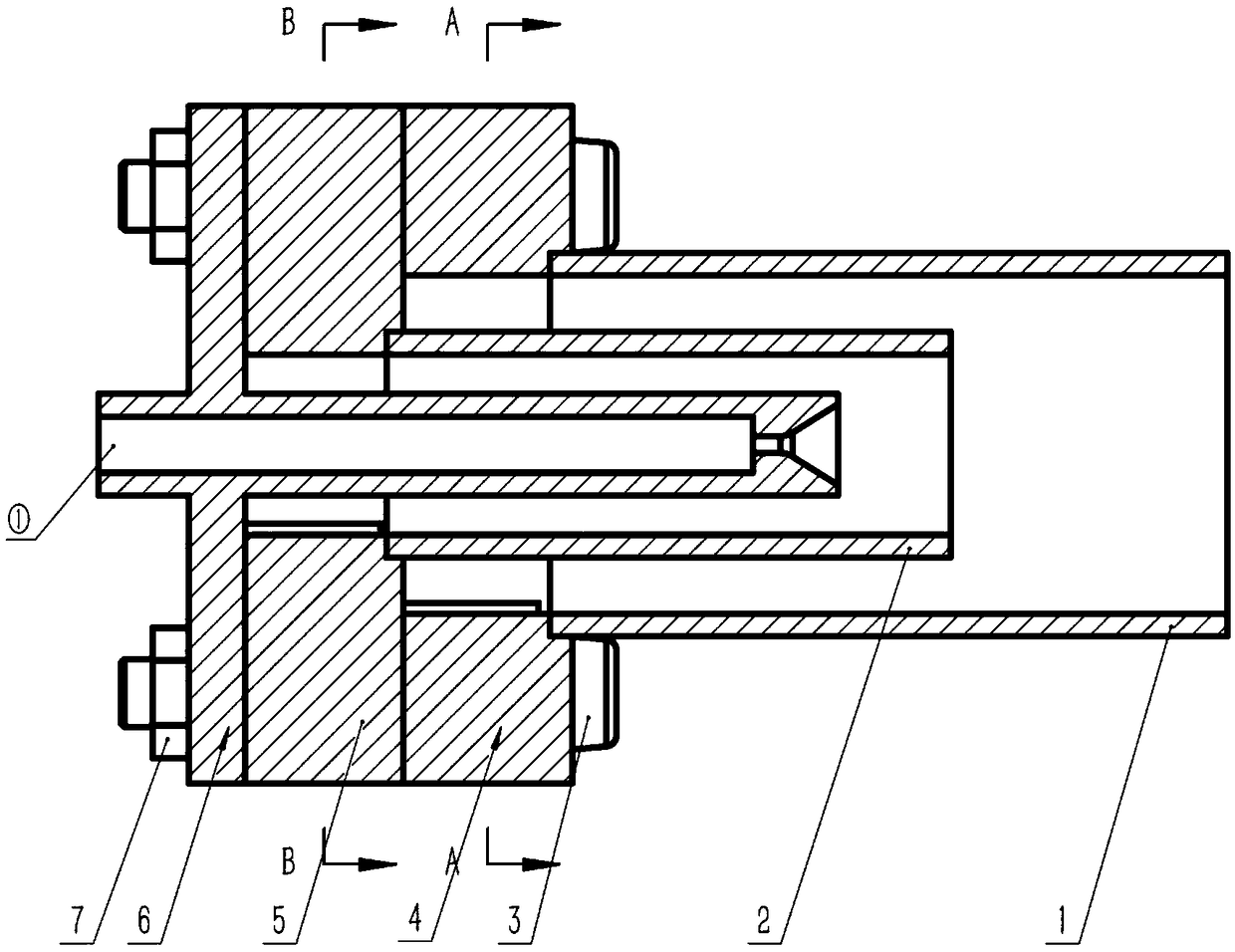

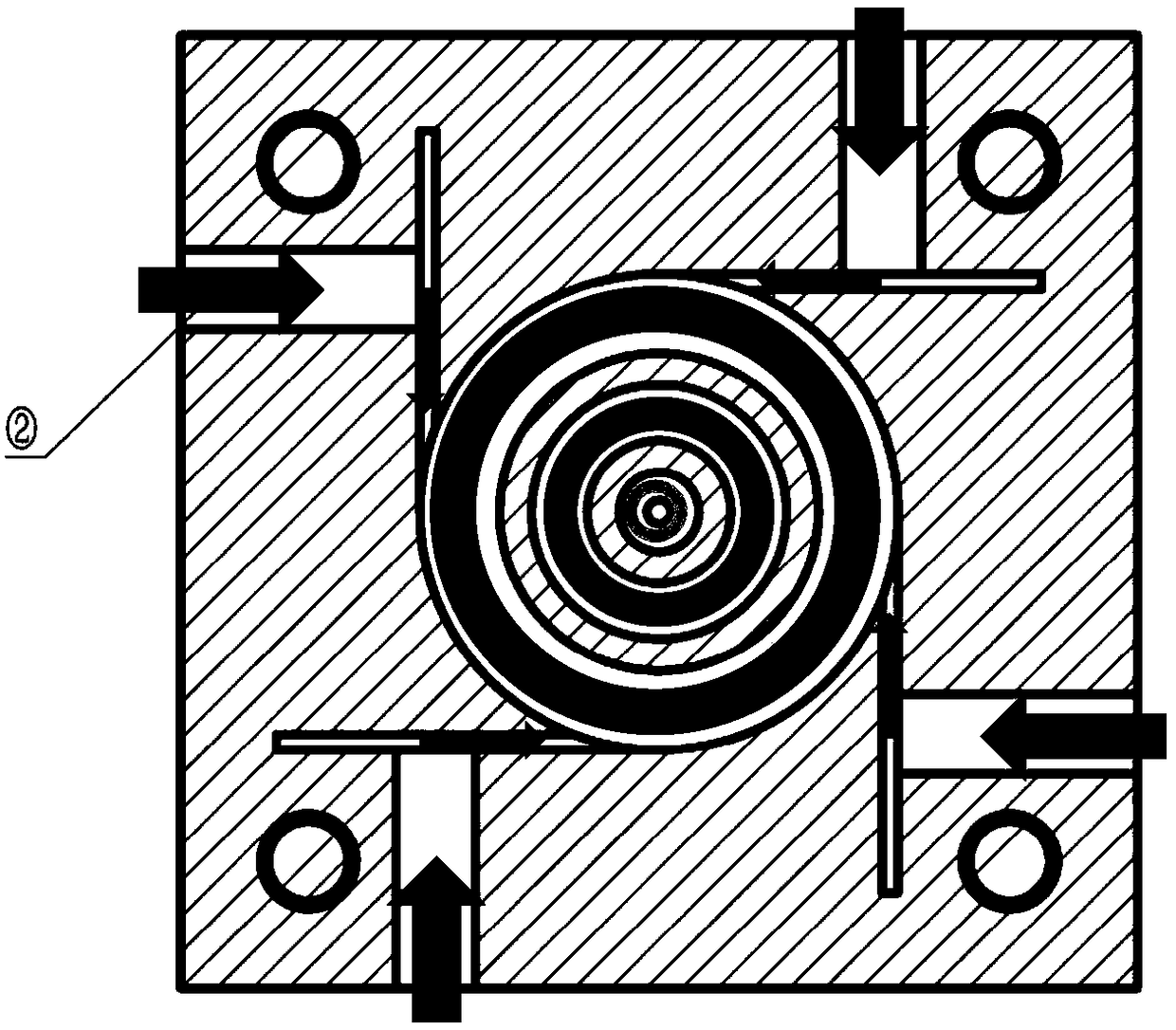

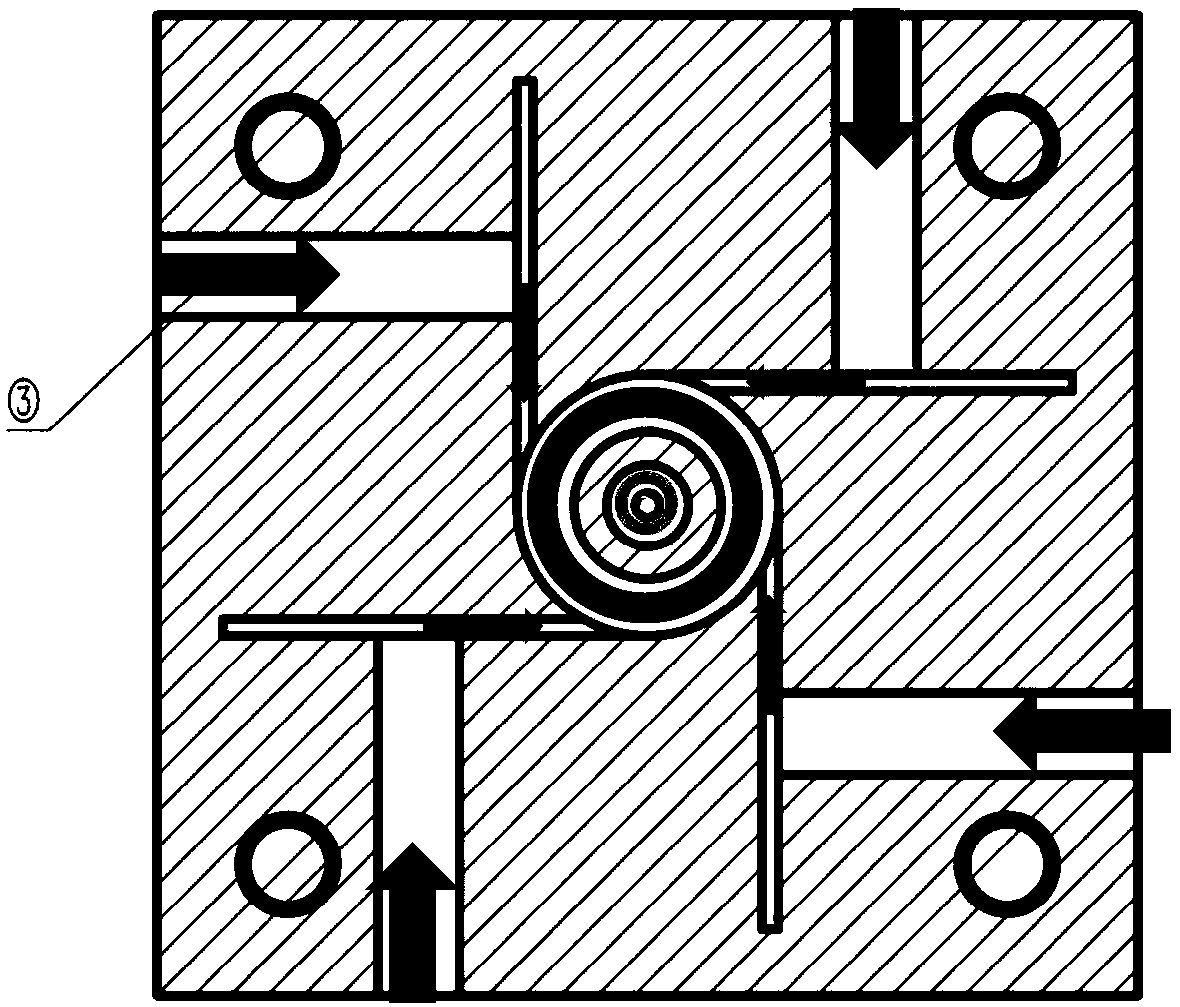

A clean gas-liquid dual-fuel dual-swirl burner

InactiveCN107084390BSimple structureImprove evaporation efficiencyIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberEvaporation

The invention discloses an efficient clean gas-liquid dual-fuel dual-vortex burner, and belongs to the field of burning. The efficient clean gas-liquid dual-fuel dual-vortex burner comprises a large-diameter connecting pipe, a small-diameter connecting pipe, an inner hexagonal screw, a first vortex block, a second vortex block, an axial liquid atomizer and a hexagonal nut. Gas fuel and an oxidizing agent are introduced into a burning chamber from N1 tangential inlets of the first vortex block for mixed burning; air injected coaxially and tangentially into the second vortex block is heated by the high-temperature gas generated during mixed burning; the heat of the heated air is transferred to a coaxial liquid fuel line located in the second vortex block; through the heat transfer with the vortex air, the liquid fuel is boiled and evaporated, and is sufficiently mixed with the preheated air for combustion under the action of the vortex at an outlet of the liquid line, so that steady flame burning is realized and the operating cycle of the burner is extended. The technical problems to be solved by the invention are that the evaporation, atomization and pollutant discharge in the burning process of the liquid fuel are reduced, steady flame burning is achieved and the operation cycle of the burner is extended.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Electronic action ultrahigh vacuum evaporation source

PendingCN114032511ACooling effect controlTemperature controlVacuum evaporation coatingSputtering coatingTemperature controlEngineering

The invention discloses an electronic action ultrahigh vacuum evaporation source which comprises a base, an evaporation assembly, a water-cooling protective sleeve and a temperature control assembly, wherein the evaporation assembly is arranged on the base, the water cooling protective sleeve is arranged on the base and is arranged outside the evaporation assembly in a sleeving manner. The water-cooling protective sleeve and the base form an evaporation inner cavity; and the temperature control assembly is arranged on the base, is electrically connected with the evaporation assembly and the water cooling protective sleeve at the same time, and is used for monitoring and controlling the temperature in the evaporation inner cavity in real time. According to the electronic action ultrahigh vacuum evaporation source, the temperature control assembly is arranged on the base to adjust the temperature in the evaporation process, so that the evaporation rate is controlled, and the evaporation effect is improved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Intelligent eyeshade capable of achieving fumigation by heating medicine and working method of intelligent eyeshade

PendingCN114404268APlay a role in relievingPlay a relaxing roleEye-masksBathing devicesEye drynessPharmacy medicine

The invention belongs to the field of eye nursing, and particularly relates to an intelligent eyeshade achieving fumigation through medicine heating and a working method thereof.The intelligent eyeshade comprises an eyeshade body and an elastic surrounding belt matched with the eyeshade body, the inner side of the eyeshade body is provided with two fumigation grooves matched with the positions of eyes, and the inner sides of the fumigation grooves are provided with fumigation medicine; a heating layer matched with the fumigation medicine is arranged on the inner side of the eyeshade body, a waterproof layer is arranged between the heating layer and the fumigation medicine, and an intelligent control box matched with the heating layer is arranged on the outer side of the eyeshade body. The heating layer, the fumigating groove and the fumigating medicine are integrated on the eyeshade, the tablet carrier containing liquid medicine is heated through the heating layer, medicine steam is generated, a traditional fumigating mode is restored, eye dryness, redness and swelling, dark circles, couperose skin, under-eye puffiness symptoms and eye fatigue are relieved and relaxed, and the eyeshade is small in size, convenient to carry and suitable for popularization and application. The fumigation cost is low.

Owner:杭州甘之草科技有限公司

A controllable evaporative micro burner utilizing waste heat of flue gas

Owner:HEFEI UNIV OF TECH

Casting micro dip-coating continuous production equipment and method of ultrathin membrane polymer complex film

InactiveCN103446895BQuality assuranceControl evaporation rateSemi-permeable membranesComputer control systemBatch processing

The invention discloses curtain coating micro dip coating continuous production equipment and a method of an ultrathin membrane polymer complex film, belonging to the technical field of chemical equipment and process. The technical scheme I is that the production equipment provided by the invention comprises a transmission system, a computer control system, a micro dip coating system, a drying system and a solvent recovery system; The technical scheme II is the curtain coating micro dip coating continuous production method of the ultrathin membrane polymer complex film provided by the invention. The equipment and the method provided by the invention have the advantages that the complex film is continuously automatically produced, the production efficiency is high, and the end product quality is good; the uniform and flawless complex film is produced, the temperature, resistance time and vacuum degree and the like of a vacuum drying oven are controlled, and the quality of the complex film is guaranteed; a solvent is recovered, the manufacturing cost is saved, meanwhile, the environmental pollution is stopped, and when output achieves a certain scale, the costs of the continuous production equipment and the method are lower than the batch processing costs.

Owner:HUBEI LONGFEIXIANG IND GRP CO LTD +1

Production equipment and method for batch casting and micro-dipping of ultrathin polymer composite film

InactiveCN103418251BQuality assuranceControl evaporation rateSemi-permeable membranesComputer control systemTransport system

Owner:HUBEI LONGFEIXIANG IND GRP CO LTD

Flow-controllable and temperature-controllable liquid evaporator

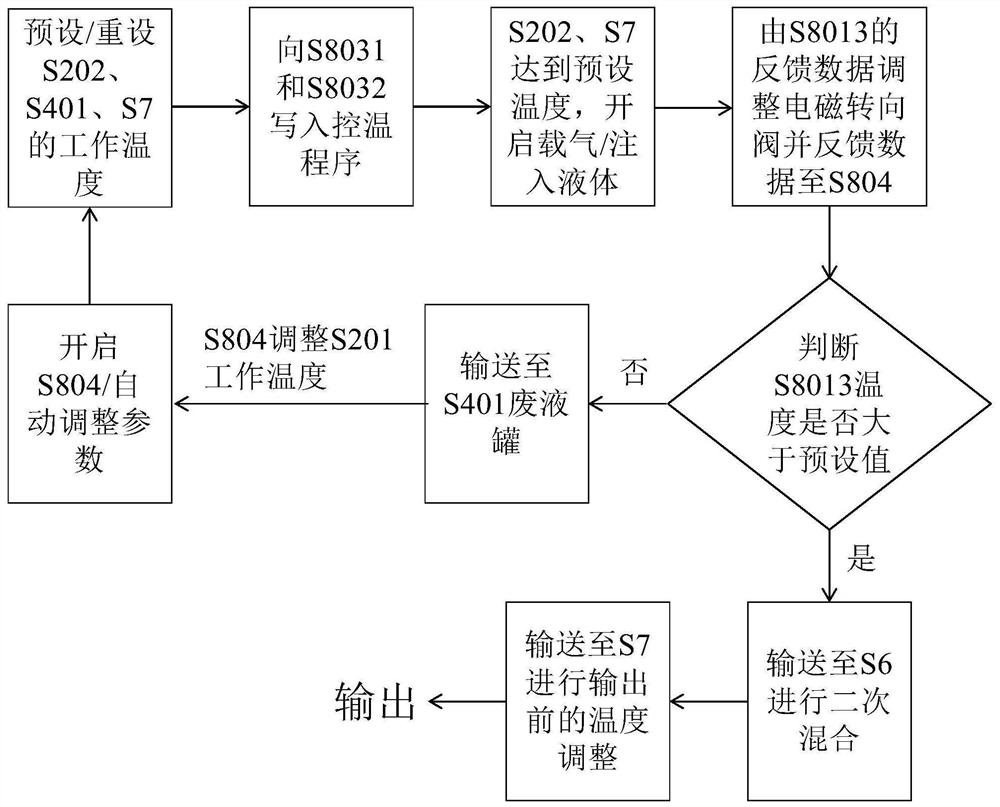

ActiveCN111928224AExtended service lifeEasy to replaceSteam generation heating methodsBoiler controlAutomatic controlControl cell

The invention discloses a flow-controllable and temperature-controllable liquid evaporator. The flow-controllable and temperature-controllable liquid evaporator comprises a liquid evaporation system,a liquid supply and control system, a fluid transmission system, an output gas mixing and temperature adjusting device and a flow velocity and temperature control system, wherein the liquid evaporation system is formed by connecting an evaporator and a temperature controller; the liquid supply and control system is formed by connecting a double-plunger pump, a flow control meter and a water storage chamber; the fluid transmission system is formed by connecting an electromagnetic conversion valve and an insulating layer; the output gas mixing and temperature adjusting device is formed by connecting a Venturi tube and a heat exchanger; and the flow velocity and temperature control system is formed by connecting a logic control unit and a temperature controller. According to the device, the functions of metering, controlling and evaporating input liquid, mixing mixed gas, adjusting temperature and the like are achieved by integrally and automatically controlling all the components; and the device can rapidly evaporate liquid into gas with controllable flow and temperature, can be widely applied to industrial production and laboratory research in the fields of clothing, food, textiles,packaging, medicines, metallurgy and the like, and has the advantages of stable working performance, long service time, energy conservation, environmental protection and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com