Wood drying method

A drying method, wood drying technology, applied in the direction of wood drying, static material dryer, drying solid material, etc., can solve the problems of increasing the relative humidity of the drying environment, reducing the moisture content gradient in the drying process of fast-growing wood, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

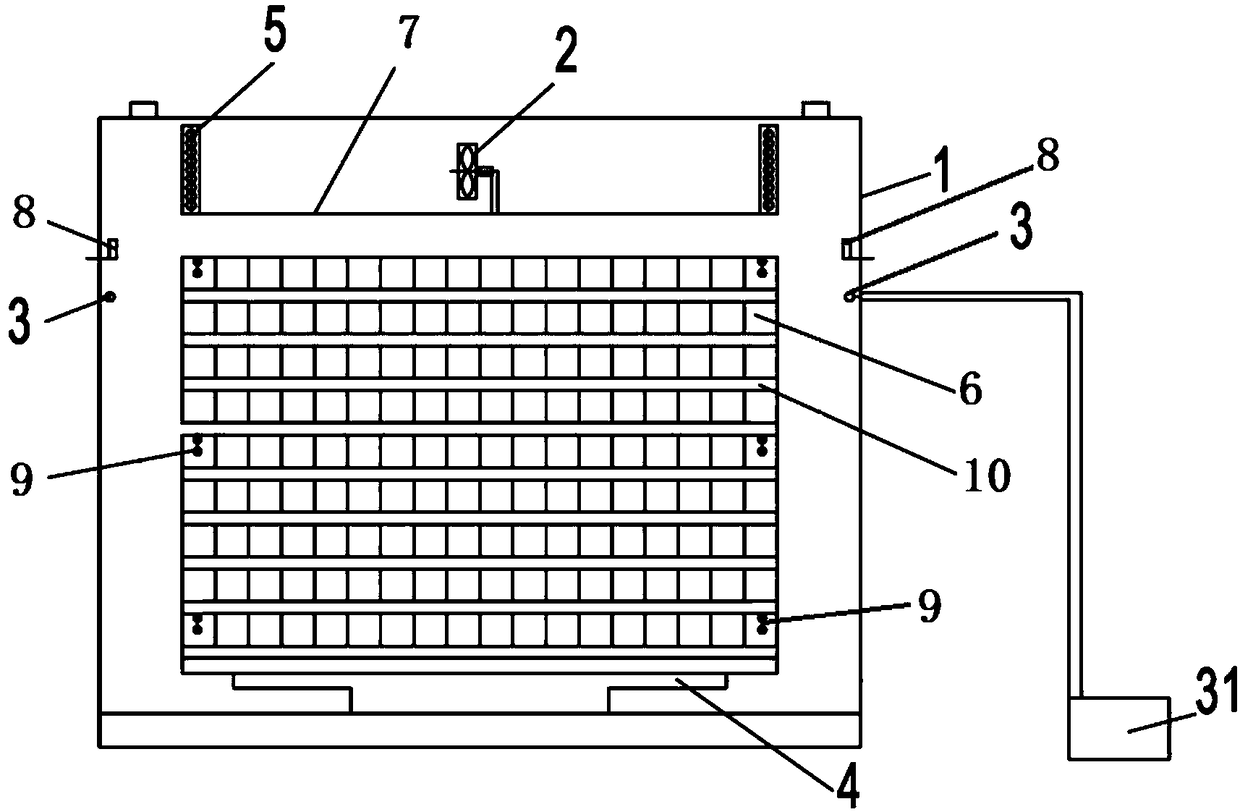

Image

Examples

Embodiment 1

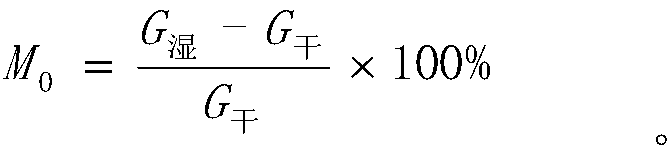

[0094] 1. Determination of the initial moisture content of the wood to be dried (M 0 )

[0095] According to the sampling inspection standard, randomly select a representative wood from the fast-growing eucalyptus wood to be dried, and first weigh its wet weight (G 湿 ), then place the weighed fast-growing wood in an oven with a temperature of (103±2)°C, dry it, and weigh it every 6 hours. When the weight difference between two consecutive weighings is less than 0.02g, it is considered as Dried to a dry state, the weight of the fast-growing wood at this time is the dry weight of the fast-growing wood (G 干 );

[0096] According to the wood moisture content formula (1), calculate the initial moisture content of the wood to be dried (M 0 ):

[0097]

[0098] The initial moisture content M of fast-growing timber eucalyptus wood in the embodiment of the present invention 0 95% (60-200% initial moisture content of wood to be dried is applicable to the present invention);

[...

Embodiment 2

[0146] 1. Determination of the initial moisture content of the wood to be dried (M 0 )

[0147] Same as embodiment 1;

[0148] 2. Palletizing

[0149] Except that 5 temperature sensor groups are arranged at the drying medium inflow end and the outflow end of the pile of materials, all the other are identical with embodiment 1;

[0150] 3. Wood pretreatment

[0151] Except step A) in the pretreatment process: during the pretreatment process, measure the dry and wet bulb temperature T of the drying medium in the drying chamber every 2min (usually 1-3min) 干 and T 湿; Then calculate the relative humidity (Φ) in the drying room according to the formula (3):

[0152] (A1) When Φ≤80%, turn on the steam generator in the drying chamber, spray steam into the drying kiln, and increase the relative humidity in the drying kiln;

[0153] (A2) When Φ≥90%, turn off the steam generator and stop spraying steam, so that the relative humidity in the drying kiln is always higher than 80%, oth...

Embodiment 3

[0166] 1. Determination of the initial moisture content of the wood to be dried (M 0 )

[0167] Same as embodiment 1;

[0168] 2. Palletizing

[0169] Except that 5 temperature sensor groups are arranged at the drying medium inflow end and the outflow end of the pile of materials, all the other are identical with embodiment 1;

[0170] 3. Wood pretreatment

[0171] In addition to the heating stage of pretreatment except step B1) in the pretreatment process, that is, when the medium temperature is lower than 90°C (usually 70-90°C),

[0172] B1-1) When T 表 –T 中 When >5°C (usually 5-8°C), the heater is turned off, waiting for the core temperature of the wood to continue to rise;

[0173] B1-2) When T 表 –T 中 When ≤2°C (usually 2-4°C), turn on the heater and heat up at a heating rate of 10°C / h (usually 5-10°C / h);

[0174] Wherein, in the heating stage, steps B1-1) and B1-2) are carried out alternately until the temperature of the drying medium in the drying chamber reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com