Automatic coal adding heating furnace

A technology for heating stoves and adding coal, which is applied in household stoves/stoves, stoves/stoves with hot water devices, heating methods, etc., can solve problems such as inconvenience and affect people's sleep, and achieve the effect of increasing humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

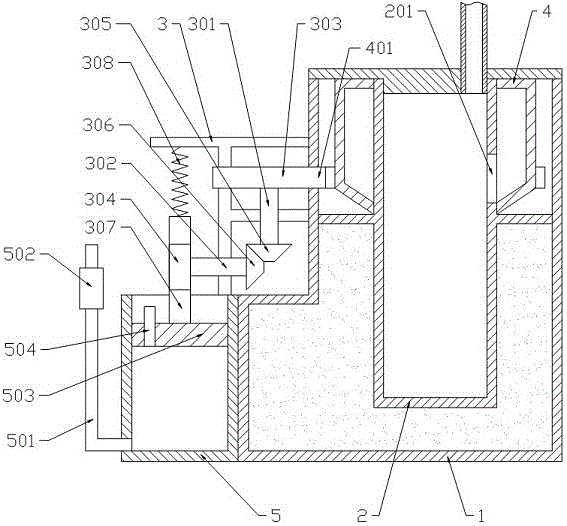

[0017] The reference signs in the drawings of the description include: furnace body 1, furnace 2, support 3, coal storage bin 4, water storage barrel 5, discharge port 201, first rotating shaft 301, second rotating shaft 302, first cylindrical gear 303, Second cylindrical gear 304, first bevel gear 305, second bevel gear 306, rack 307, compression spring 308, outer ring gear 401, water inlet pipe 501, second valve 502, piston 503, pressure relief valve 504.

[0018] The self-filling coal heating furnace of the embodiment is basically as attached figure 1 Shown: including the furnace body 1 and the furnace 2, the furnace 2 is located in the furnace body 1, and also includes a support 3, a coal storage bin 4 and a water storage bucket 5, the support 3 is fixed on the furnace body 1, and the support 3 is rotatably connected with a vertical The first rotating shaft 301 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com