Laser evaporation method and laser evaporation device for organic material film or organic-inorganic composite material film

An organic material, laser evaporation technology, applied in vacuum evaporation coating, metal material coating process, sputtering coating and other directions, can solve the problems of runaway, uncontrollable film formation speed, pollution of other evaporation materials, etc. Achieve stable regulation and prevent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] (Embodiment 1)

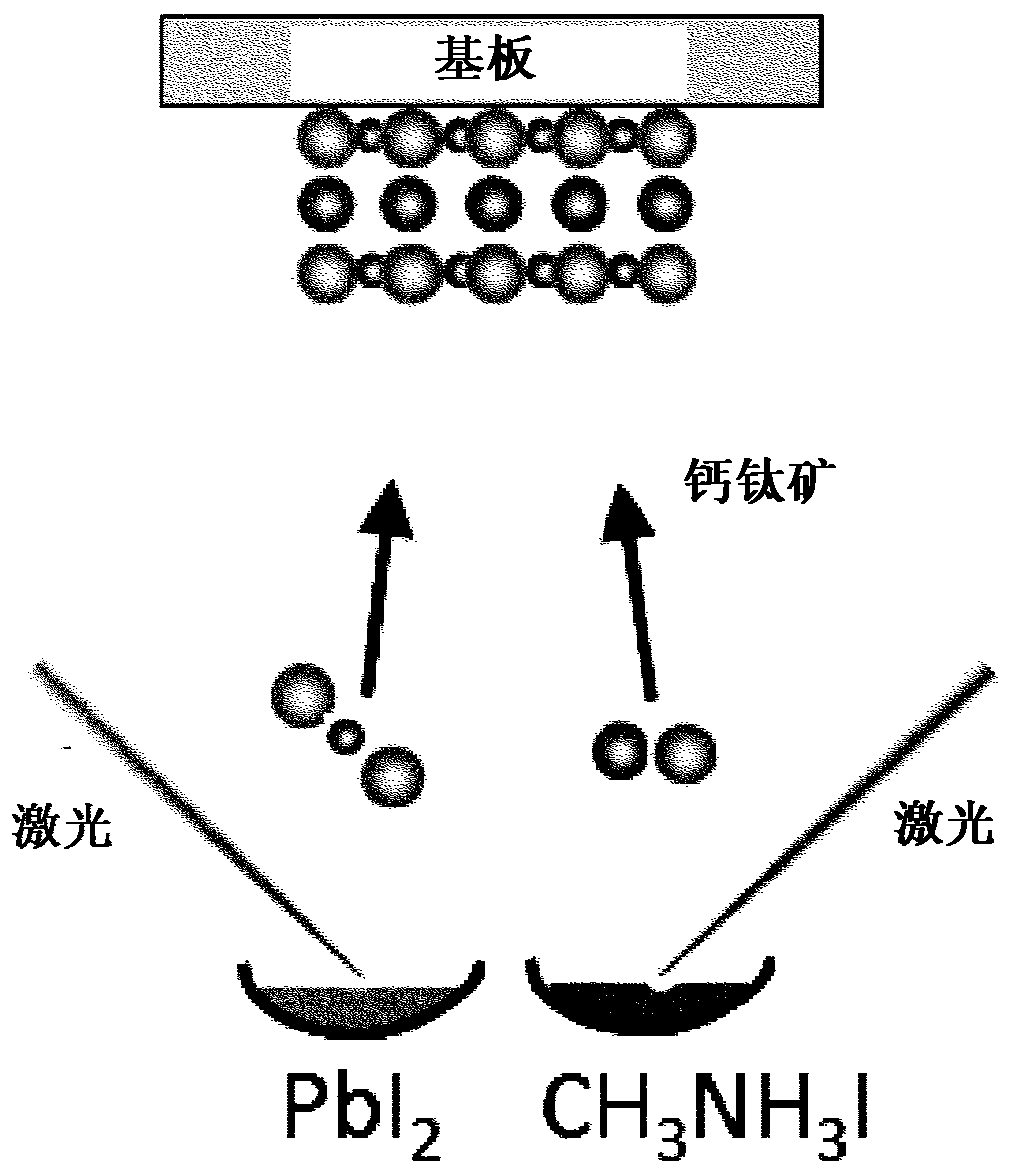

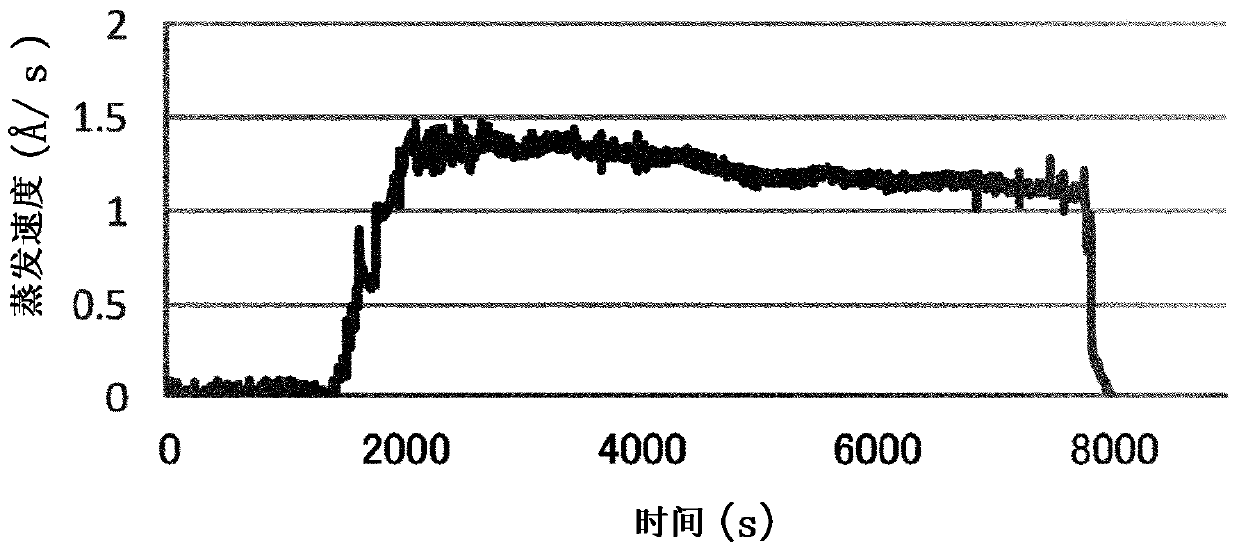

[0080] In the vacuum chamber for evaporation, set PbI 2 and CH 3 NH 3 I as the target, and set for the PbI 2 and the CH 3 NH 3 A quartz vibrator film thickness gauge for measuring the evaporation rate of I (installed near the path of the evaporation flux to measure the film thickness of the vapor-deposited film. The same applies to the following quartz vibrator film thickness gauges). The laser evaporation apparatus was set up as follows: separately for PbI 2 By irradiating continuous laser light with a wavelength of 808nm, CH, which is a material with a high vapor pressure 3 NH 3 I irradiates pulsed laser light with a wavelength of 808 nm and modulated at 10 Hz.

[0081] Make the vacuum degree in the vacuum chamber be 10 -5 After Pa, about PbI 2 side of the laser, making its power up to 1.6W, on the other hand, on the CH 3 NH 3 The pulse amplitude of the I side laser was 17.9 W, the duty ratio was adjusted to 26%, and co-deposition was per...

Embodiment 2

[0083] (Example 2)

[0084] In the vacuum chamber for evaporation, set PbI 2 and CH 3 NH 3 I as the target, and set for the CH 3 NH 3 A quartz vibrator film thickness gauge for measuring the evaporation rate of I, the laser evaporation device is set as follows: for PbI 2 Without laser irradiation, for CH 3 NH 3 I irradiates pulsed laser light with a wavelength of 808 nm and modulated at 10 Hz.

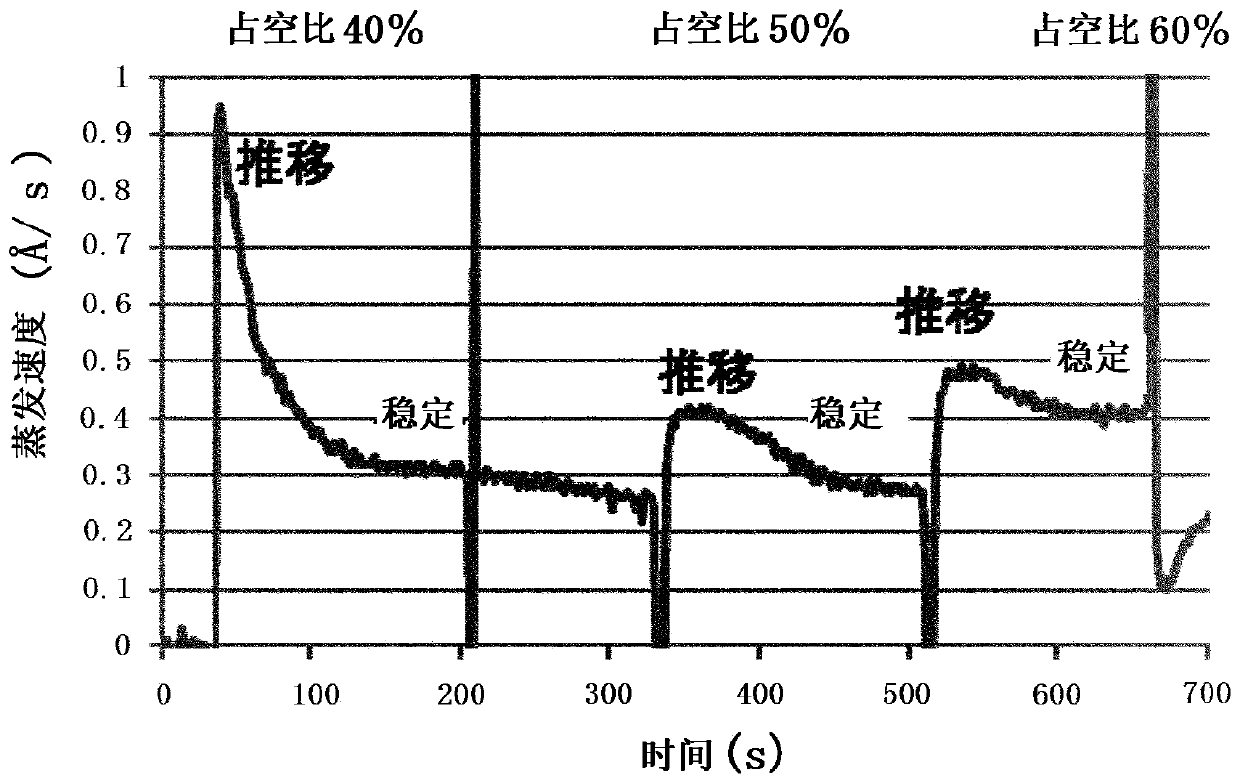

[0085] Make the vacuum degree in the vacuum chamber be 10 -5 After Pa, for CH 3 NH 3 The pulse amplitude of the I-side laser was 17.9 W, and the duty ratio was adjusted to 40, 50%, and 60%, and vapor deposition was performed on the surface of a glass substrate. CH at this time 3 NH 3 The evolution of the evaporation rate of I is shown in image 3 middle. About CH 3 NH 3 For the evaporation rate of I, it can be seen that since the adjustment width of the duty ratio is as large as 10%, fluctuations accompanying the adjustment are observed, but the evaporation rate can be...

Embodiment 3

[0087] (Example 3)

[0088] In the vacuum chamber for evaporation, set PbI 2 and CH 3 NH 3 I as the target, and set for the PbI 2 and the CH 3 NH 3 A quartz vibrator film thickness gauge is used to measure the evaporation rate of I, and the laser evaporation device is set as follows: in PbI 2 and CH 3 NH 3 In the observation of the evaporation rate of I and the vacuum degree in the vacuum chamber, the PbI 2 Irradiate a continuous laser with a wavelength of 808nm and treat CH which is a material with a high vapor pressure 3 NH 3 I irradiates pulsed laser light with a wavelength of 808 nm and modulated at 10 Hz.

[0089] Make the vacuum degree in the vacuum chamber be 10 -5 After Pa, firstly, CH with high vapor pressure 3 NH 3 The amplitude of the laser pulse on the I side is gradually increased to allow the observation of CH 3 NH 3 The evaporation rate of I. Observe CH 3 NH 3 When the evaporation rate of I, gradually increase the duty cycle of the laser to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com