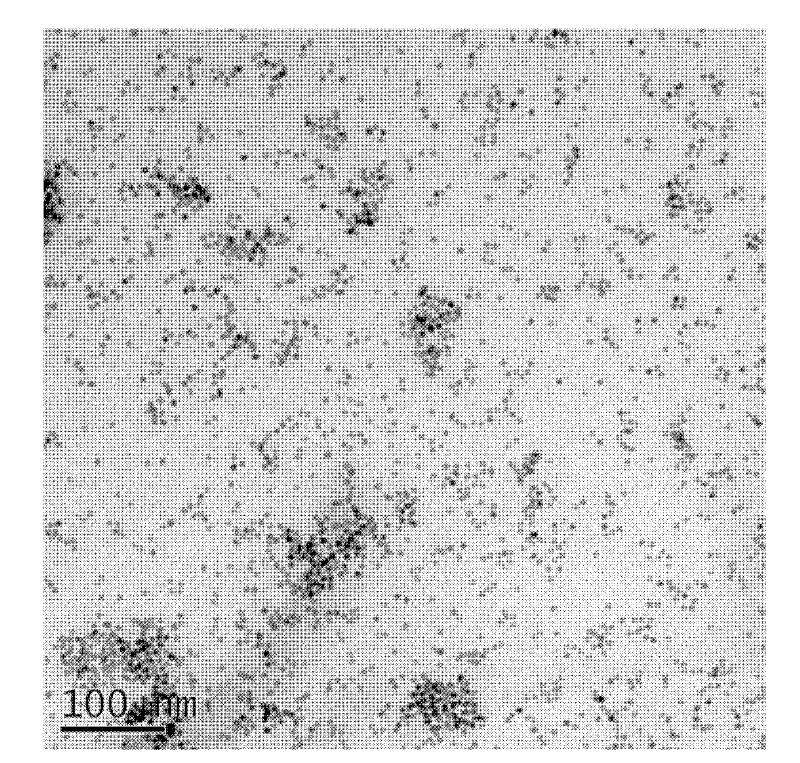

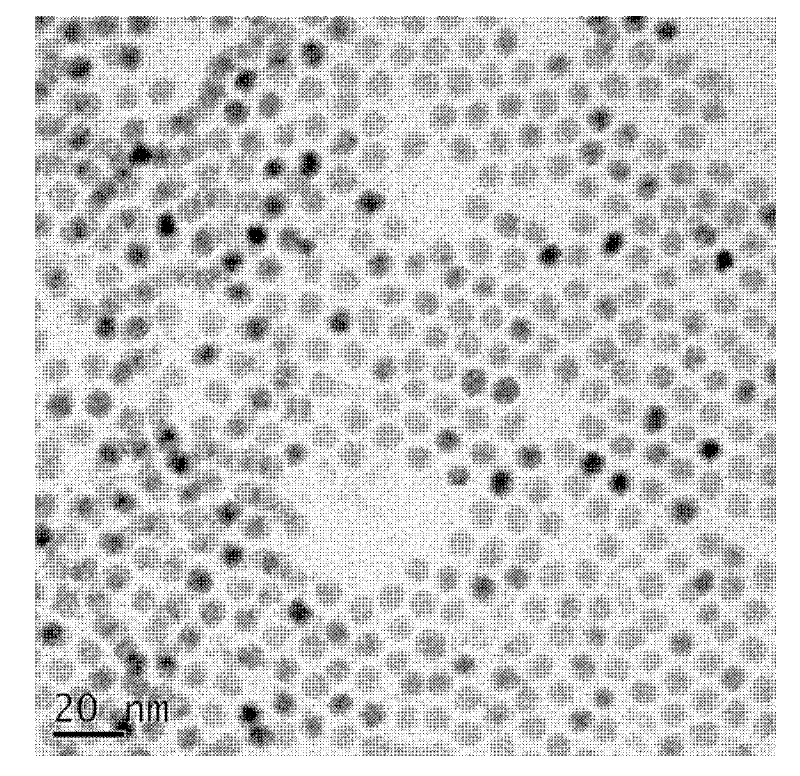

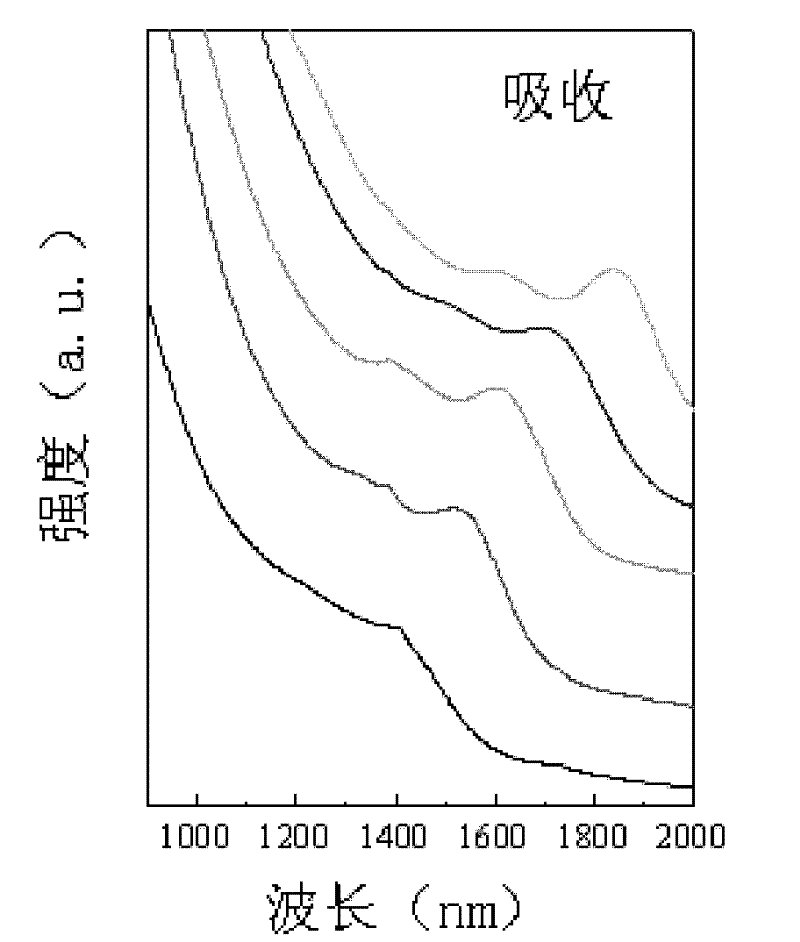

Preparation method of PbTe colloid nanocrystalline self-assembly film

A nanocrystal and self-assembly technology, which is applied to devices, coatings, and binary selenium/tellurium compounds that coat surfaces with liquids. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Under the protection of Ar gas and magnetic stirring, dissolve PbO and oleic acid in octadecene and react at 130°C until PbO disappears to prepare a colorless and transparent lead oleate solution with a lead ion concentration of 0.05mol / l. Wherein PbO: the mol ratio of oleic acid=1: 2.5;

[0023] 2) Under the protection of Ar gas and magnetic stirring, dissolve tellurium powder in trioctylphosphorus, heat in a water bath at 70°C until the black tellurium powder disappears completely, and make trioctyl with a tellurium ion concentration of 0.1mol / l tellurium solution;

[0024] 3) Take the lead oleate solution and heat it to 180°C, then add the trioctyl tellurium solution to the lead oleate solution and react for 5 seconds to obtain a mixed solvent, wherein the lead oleate solution and the trioctyl tellurium solution have a ratio of Pb:Te=2:1 The molar ratio of;

[0025]4) Move the mixed solvent to an oil bath at 150°C for 30 seconds and then place it in a cold water...

Embodiment 2

[0030] 1) Under the protection of Ar gas and magnetic stirring, dissolve PbO and oleic acid in octadecene and react at 130°C until PbO disappears to prepare a colorless and transparent lead oleate solution with a lead ion concentration of 0.05mol / l. Wherein PbO: the mol ratio of oleic acid=1: 2.5;

[0031] 2) Under the protection of Ar gas and magnetic stirring, dissolve tellurium powder in trioctylphosphorus, heat in a water bath at 70°C until the black tellurium powder disappears completely, and make trioctyl with a tellurium ion concentration of 0.1mol / l tellurium solution;

[0032] 3) Take the lead oleate solution and heat it to 180°C, then add the trioctyl tellurium solution to the lead oleate solution and react for 5 seconds to obtain a mixed solvent, wherein the lead oleate solution and the trioctyl tellurium solution have a ratio of Pb:Te=2:1 The molar ratio of;

[0033] 4) Move the mixed solvent to an oil bath at 150°C for 30 seconds and then place it in a cold wate...

Embodiment 3

[0038] 1) Under the protection of Ar gas and magnetic stirring, dissolve PbO and oleic acid in octadecene and react at 150°C until PbO disappears to prepare a colorless and transparent lead oleate solution with a lead ion concentration of 0.1mol / l. Wherein PbO: the mol ratio of oleic acid=1: 4;

[0039] 2) Under the protection of Ar gas and magnetic stirring, dissolve tellurium powder in trioctylphosphorus, heat in a water bath at 60°C until the black tellurium powder disappears completely, and make trioctyl with a tellurium ion concentration of 0.3mol / l tellurium solution;

[0040] 3) Take the lead oleate solution and heat it to 150°C, then add the trioctyl tellurium solution to the lead oleate solution and react for 50s to obtain a mixed solvent, wherein the lead oleate solution and the trioctyl tellurium solution have a ratio of Pb:Te=1:5 The molar ratio of;

[0041] 4) Move the mixed solvent to an oil bath at 100°C for 100 seconds and then place it in a cold water bath t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com