A clean gas-liquid dual-fuel dual-swirl burner

A dual-fuel, double-swirl technology, applied in the field of combustion, can solve the problems of pollutant discharge and short burner operation cycle, and achieve the effects of reducing pollutant discharge, eliminating the risk of flashback, and good flame stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

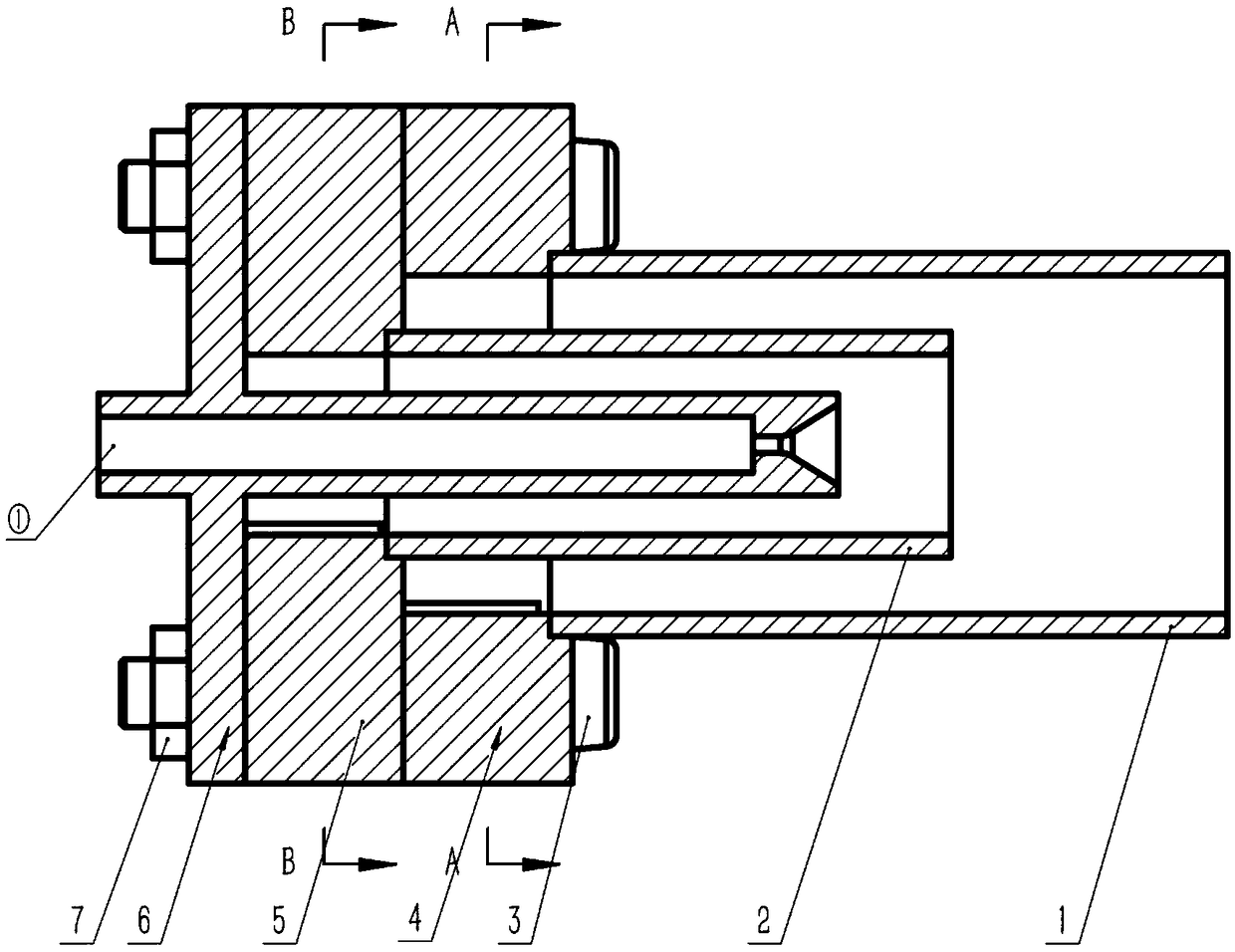

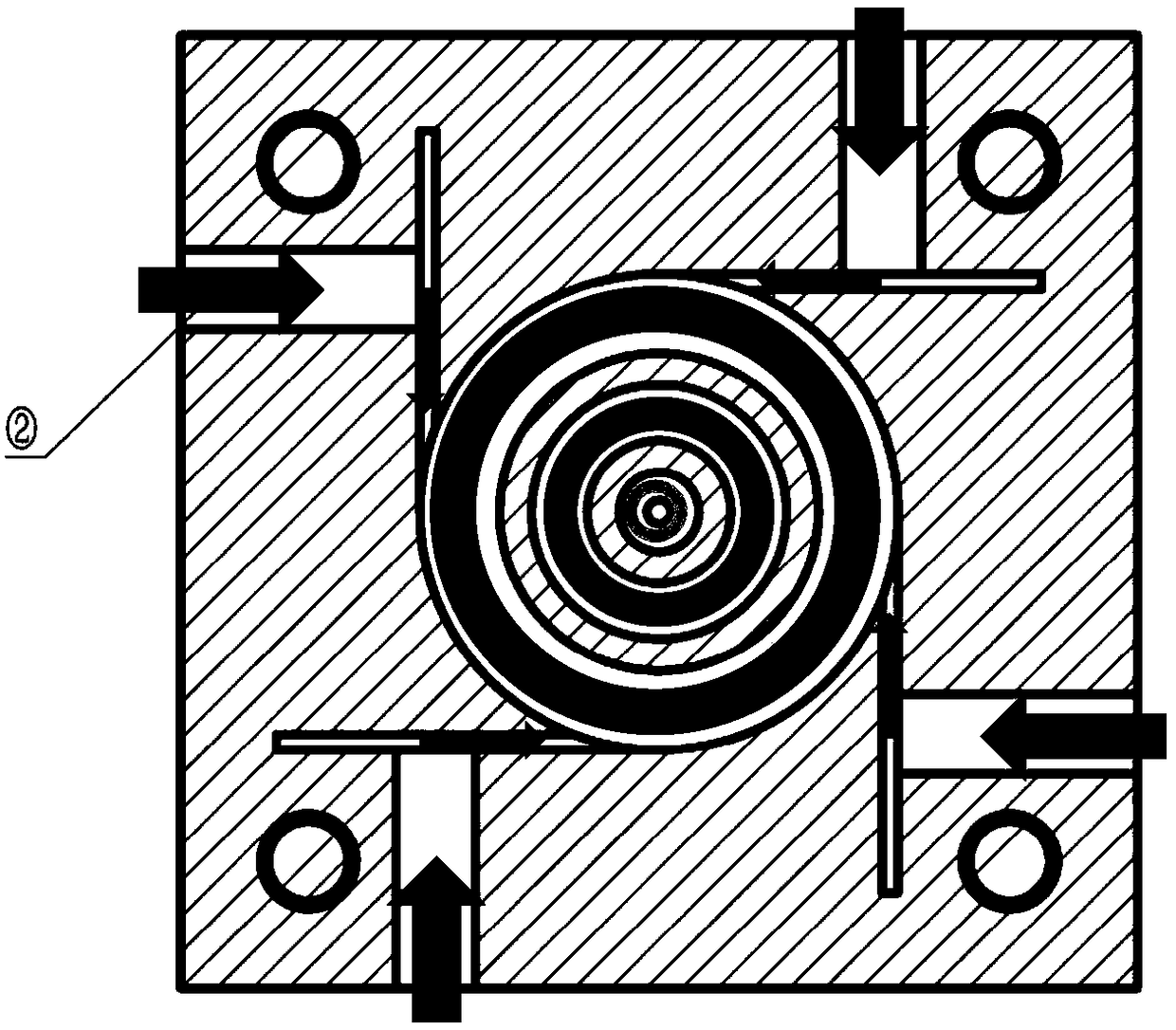

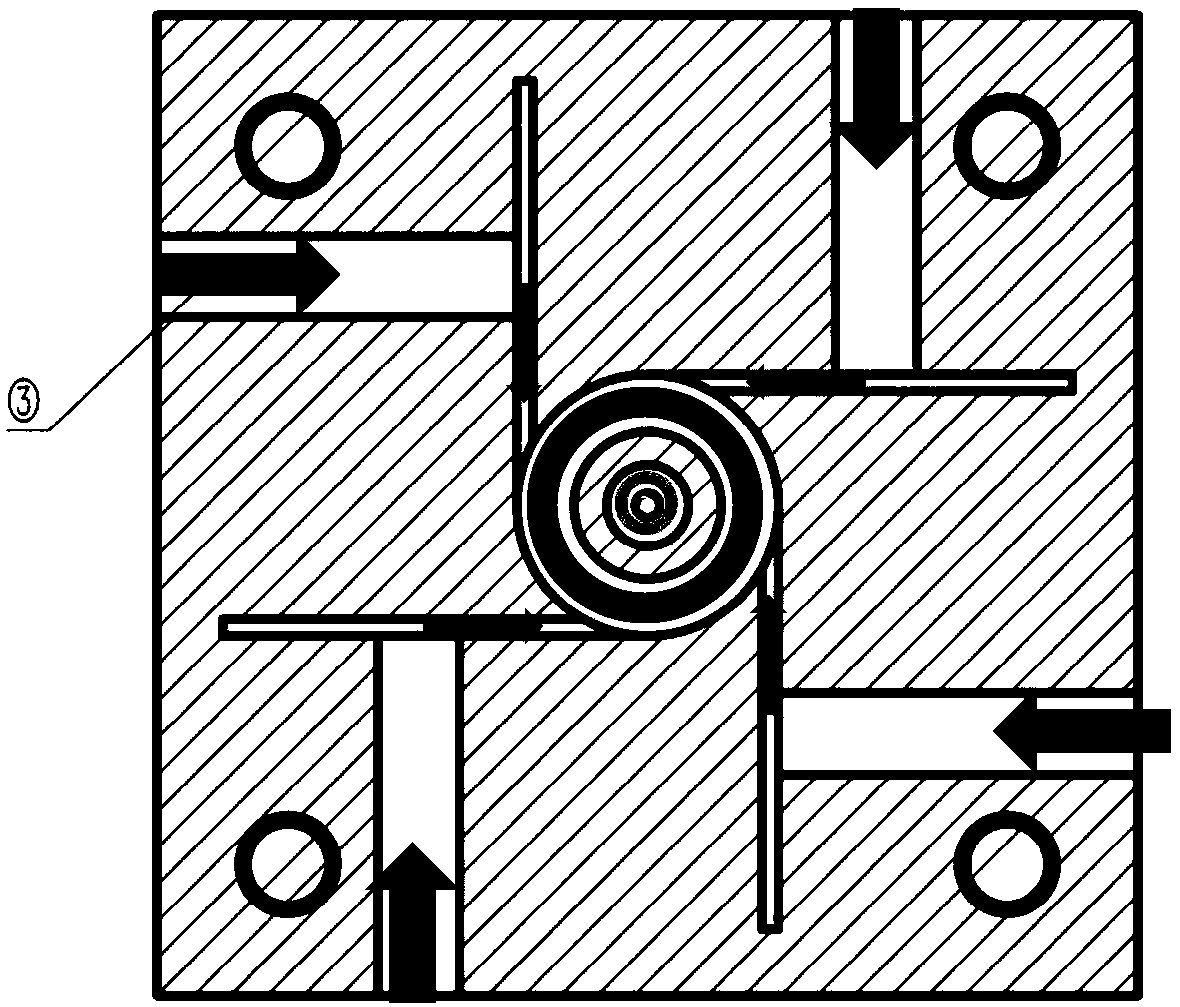

[0024] Such as figure 1 As shown, a high-efficiency and clean gas-liquid dual-fuel dual-swirl burner disclosed in this embodiment includes a large-diameter connecting pipe 1, a small-diameter connecting pipe 2, a hexagon socket head cap screw 3, a first swirl block 4, a second Swirl block 5, axial liquid atomizer 6 and hex nut 7. The diameter of the large-diameter connecting pipe 1 is 30mm, and the diameter of the small-diameter connecting pipe 2 is 15mm. The small-diameter connecting pipe 2 is installed in the groove of the second swirl block 5 . The material of the large-diameter connecting pipe 1 and the small-diameter connecting pipe 2 is quartz glass. Such as image 3 As shown, the second swirl block 5 has four tangential inlets, and has gas inlet holes corresponding to the four tangential inlets. The second swirl block 5 is used to heat the axial liquid atomizer 6, And mixed with the gas evaporated from the axial liquid atomizer 6 for combustion. Install the large-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com