Patents

Literature

56results about How to "Easy heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

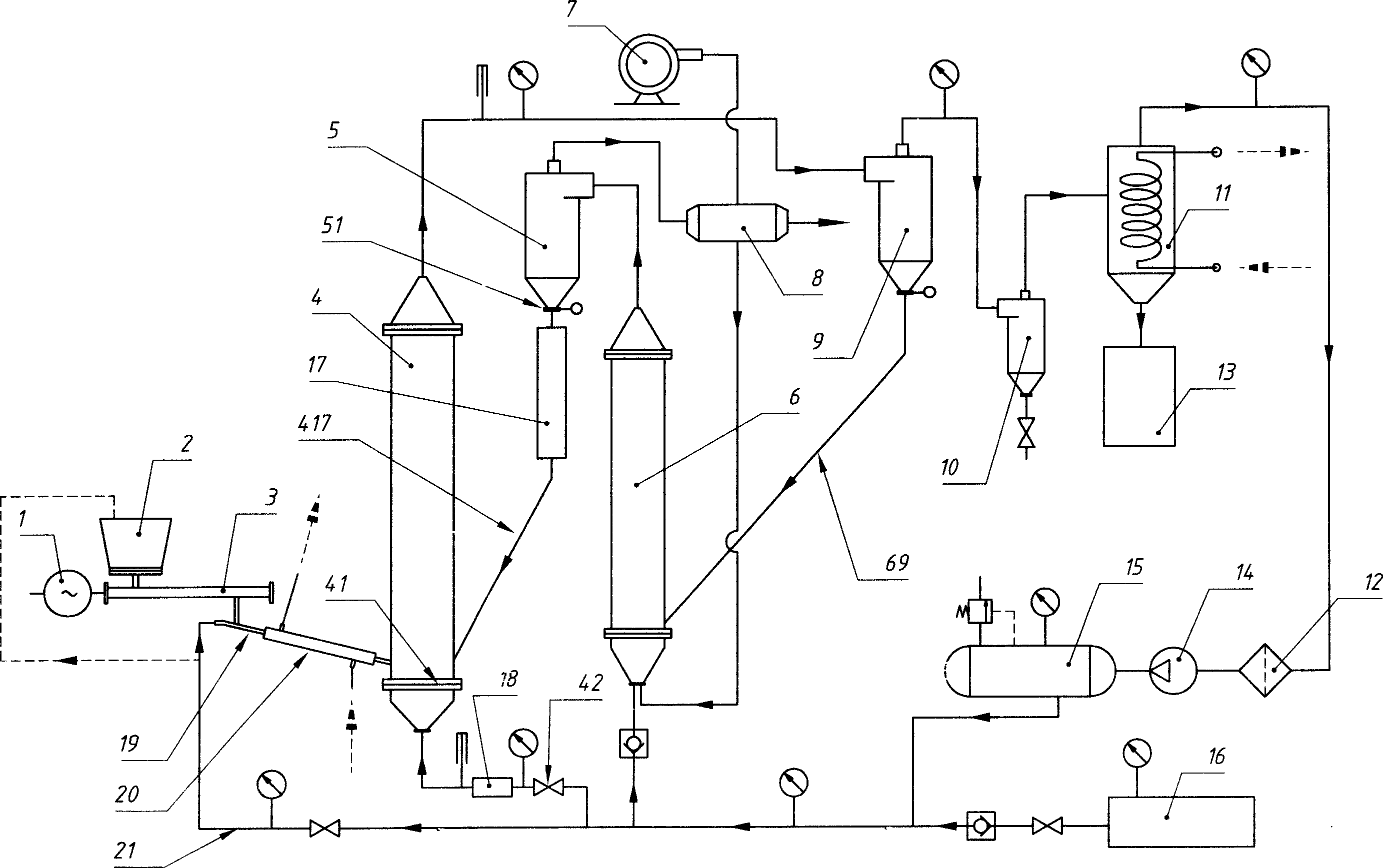

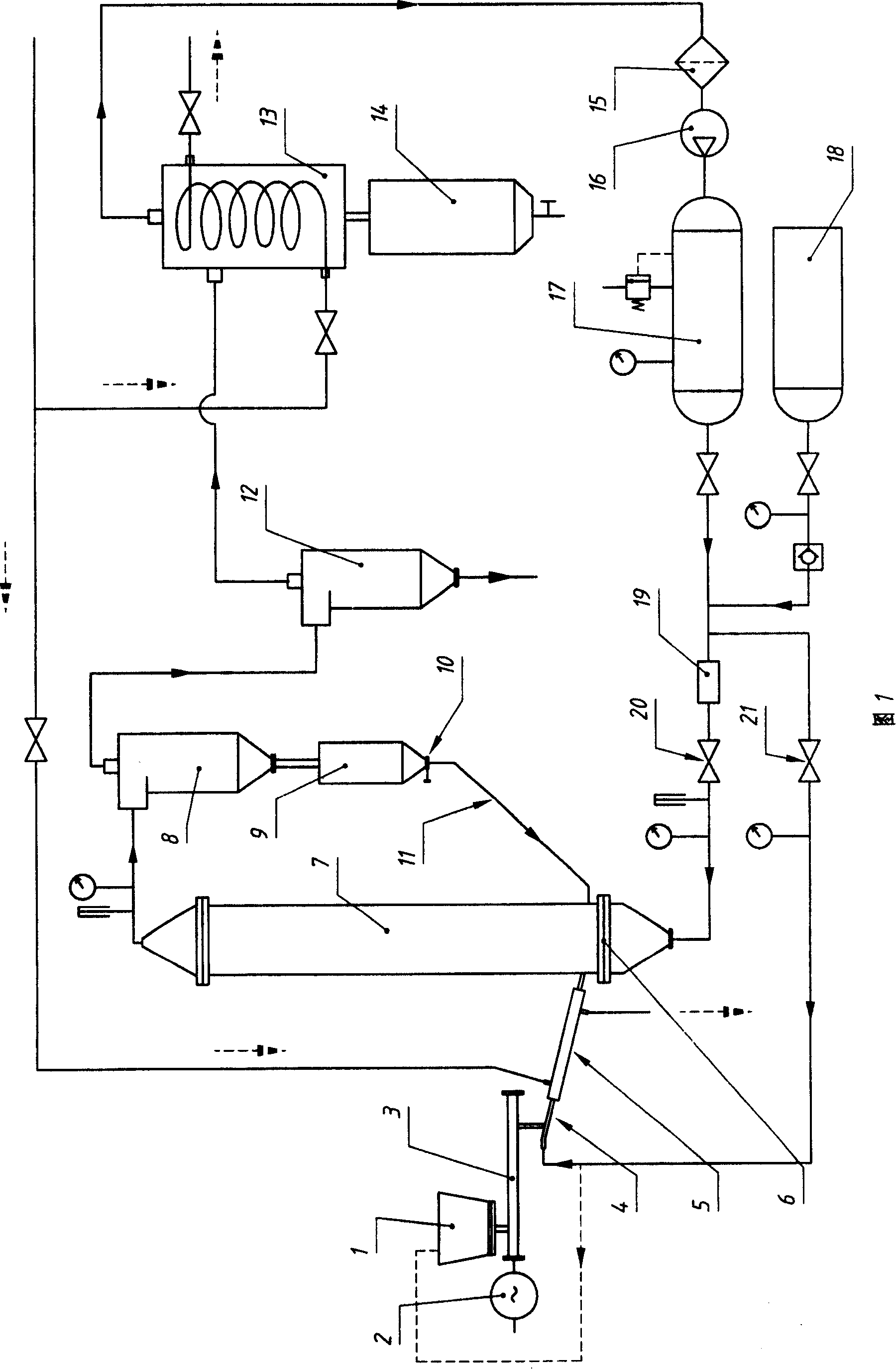

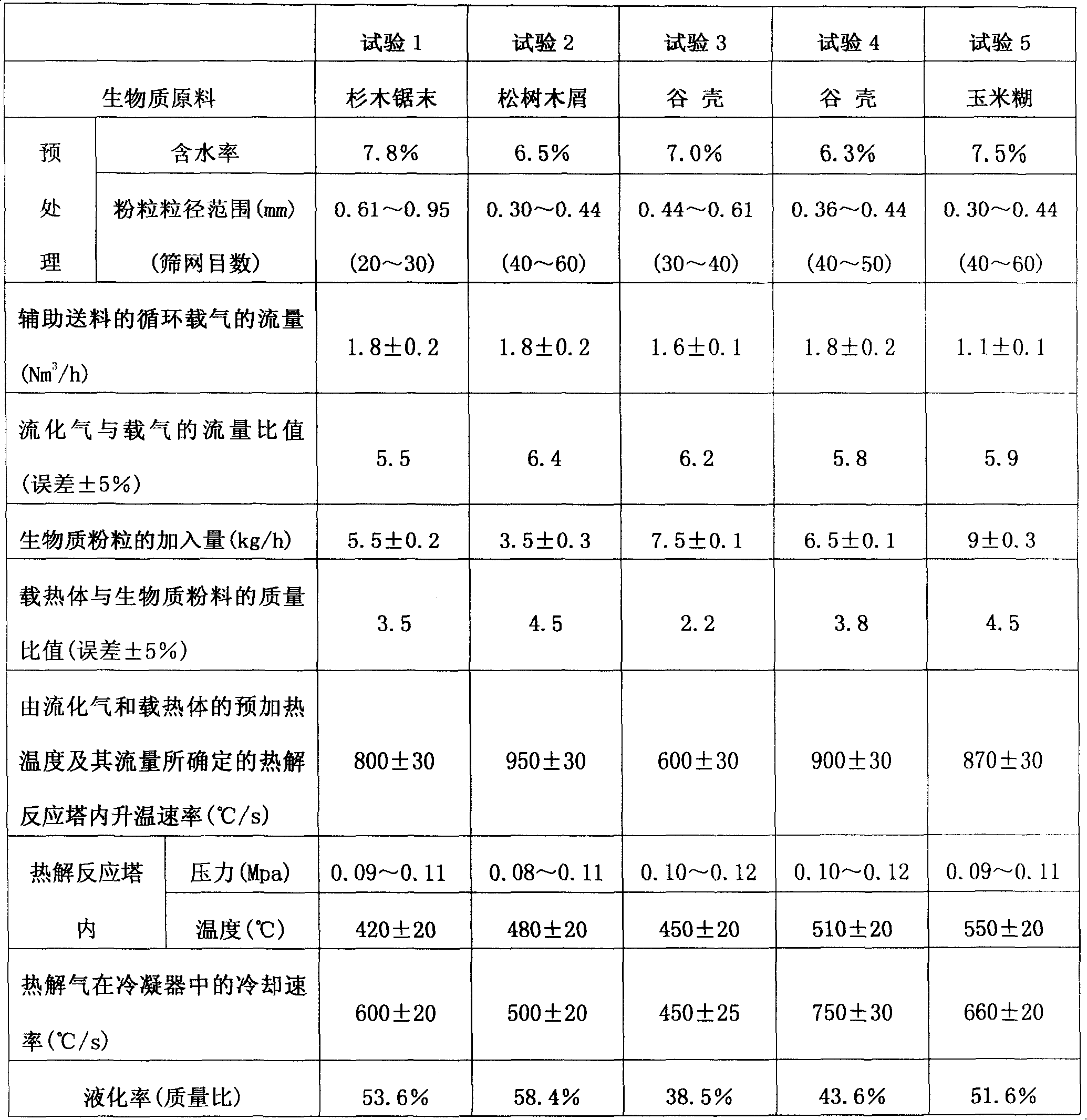

Biomass pyrolysis liquefied technique and double tower apparatus system thereof

InactiveCN1730177AImprove pyrolysis efficiencyWell mixedSolid waste disposalGas phaseProcess engineering

The invention relates to a biomass analgesic liquidation method and its twin-tower set system, the processes of which comprise the following steps: sending biomass to pyrolytic reaction tower and blending it with high-heat fluidized gas to subject biomass to pyrolytic cracking; separating thermal cracking gas with carbon residue and ash content in separator; and condensing thermal cracking gas to biological oil in condenser. In the process, heat-carrying agent is exported from pyrolytic reaction tower along with thermal cracking gas, carbon residue and so on, and carbon residue is used to preheat heat-carrying agent. The invention is special for heat-carrying agent heating tower to burn carbon residue and primary separator to separate heat-carrying agent, carbon residue and other materials. The invention can not only increase circulation rate to ensure uniform and stable temperature field in pyrolytic reaction tower, higher heating rates and shorter detention period of gas phase, but also make use of carbon residue as heat source by using existing apparatus.

Owner:CHONGQING UNIV

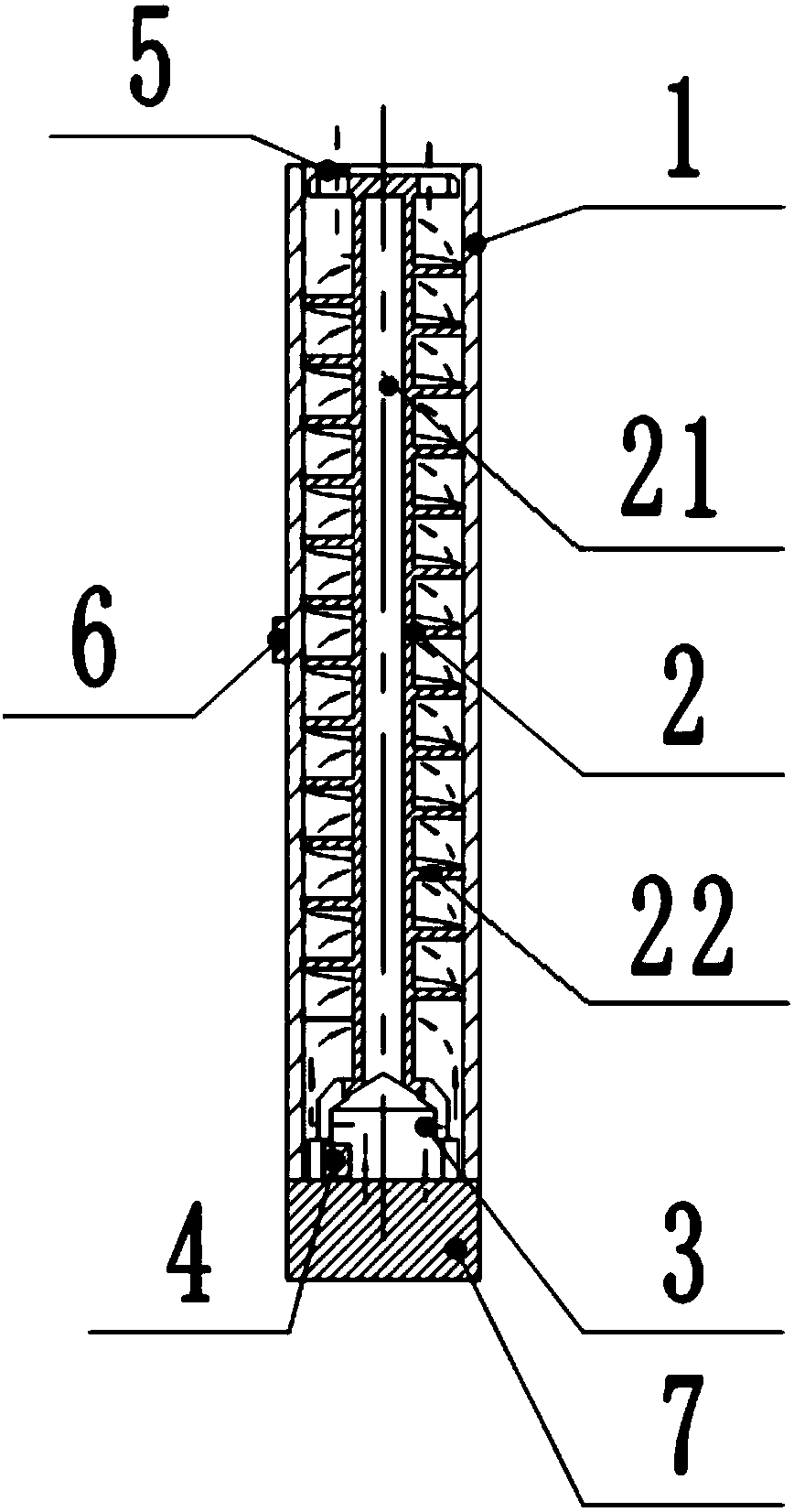

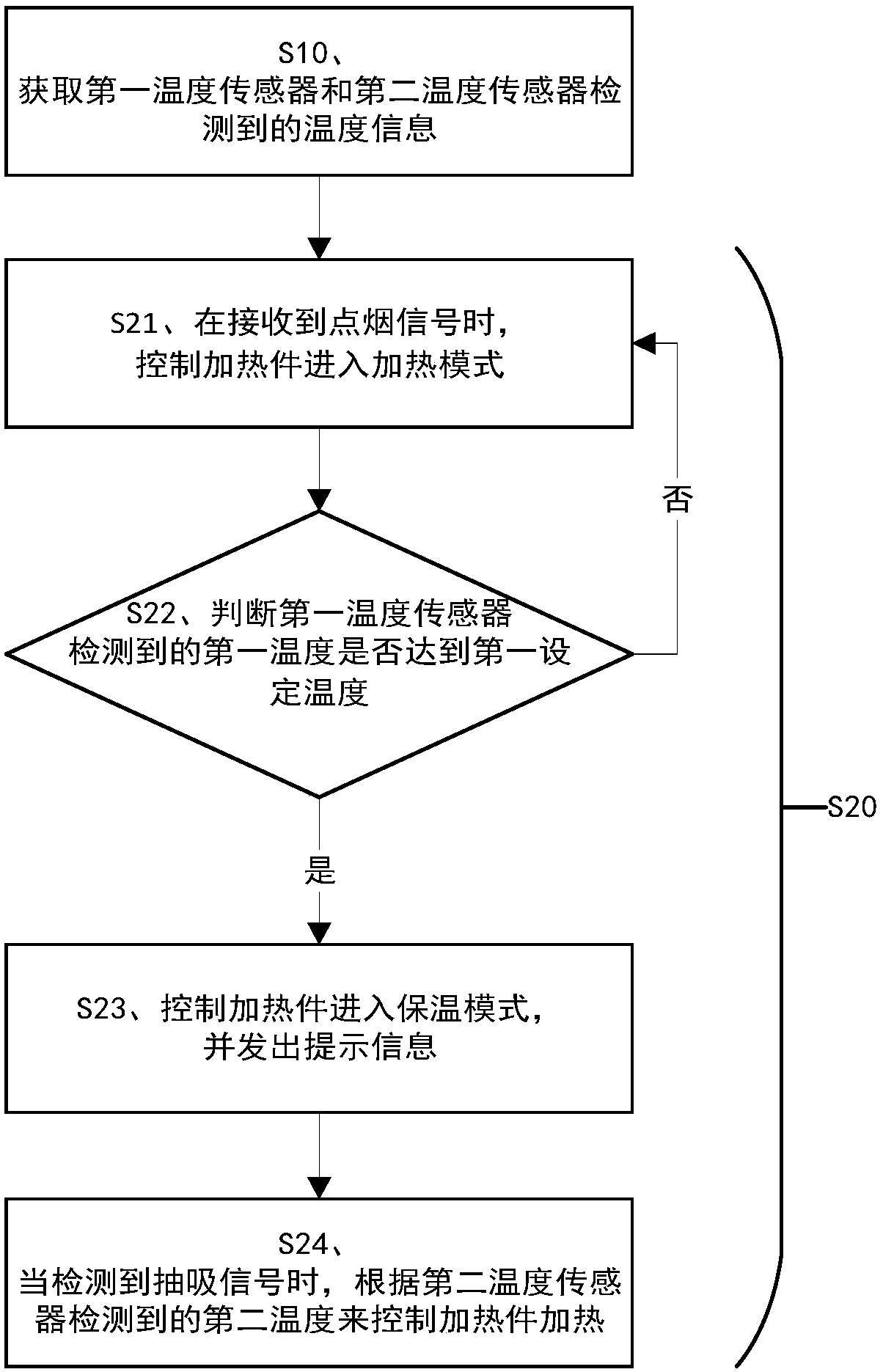

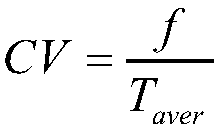

Air flow heating device, heating control method and electronic cigarette

InactiveCN107713016AEasy heating temperatureGood smokeTobacco devicesEngineeringElectronic cigarette

The invention discloses an air flow heating device, which comprises an air path for making air flow pass through, a heating piece for heating air in the air path, and a first temperature sensor, a second temperature sensor, and a control device; the first temperature sensor is used for detecting temperature of the heating piece, and the second temperature sensor is located at an air outlet of theair path and used for detecting temperature of the gas at the air outlet of the air path; the control device is connected to the first temperature sensor, the second temperature sensor and the heatingpiece, and used for receiving the temperature information of the heating piece detected according to the first temperature sensor and air flow temperature information of the air outlet of the air path detected by the second temperature sensor, and accordingly controlling the heating piece. The invention further provides a heating control method and an electronic cigarette. The invention can provide the best heating temperature of cigarettes, thus the cigarettes can reach the best smoke effect.

Owner:CHANGZHOU PATENT ELECTRONICS TECH CO LTD

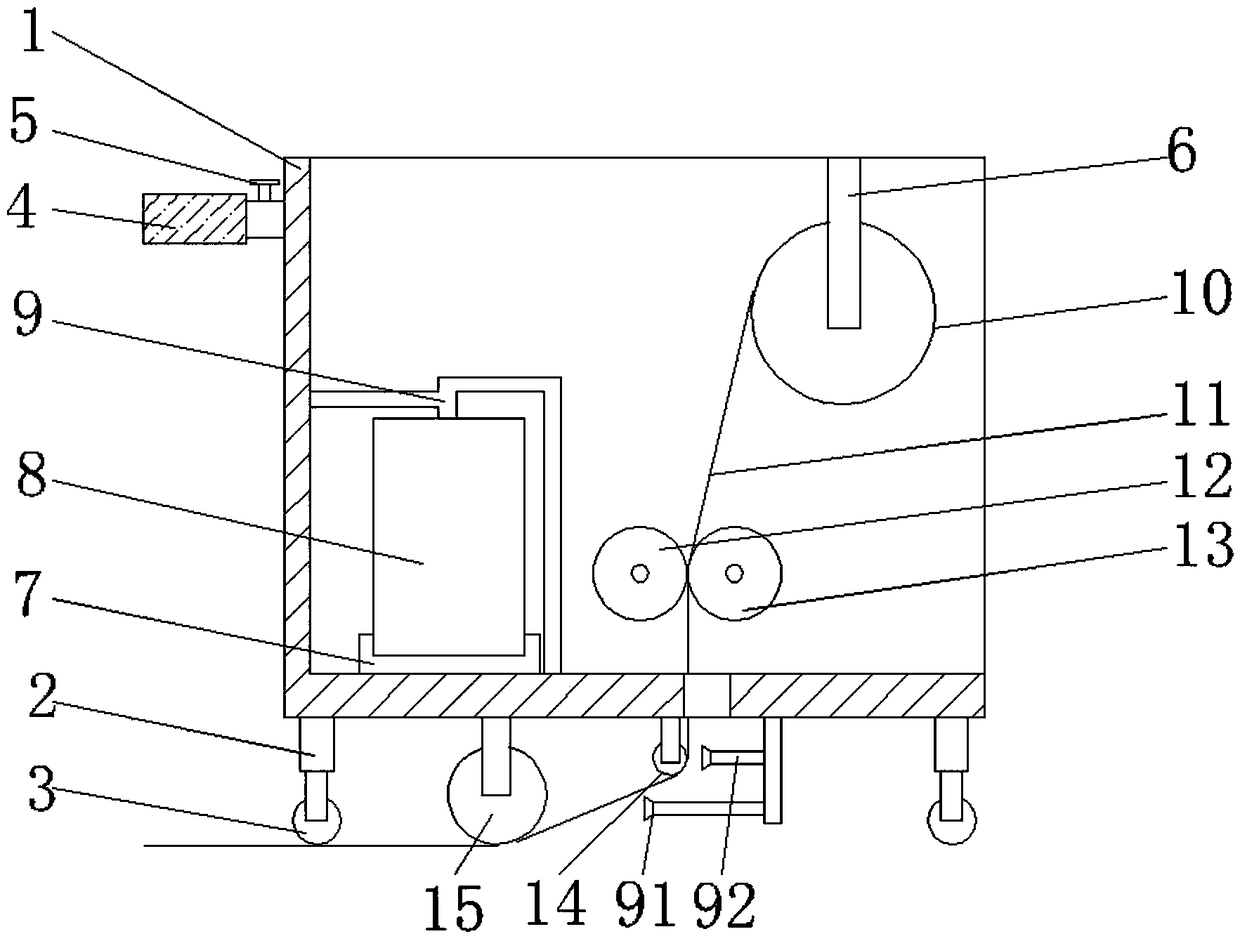

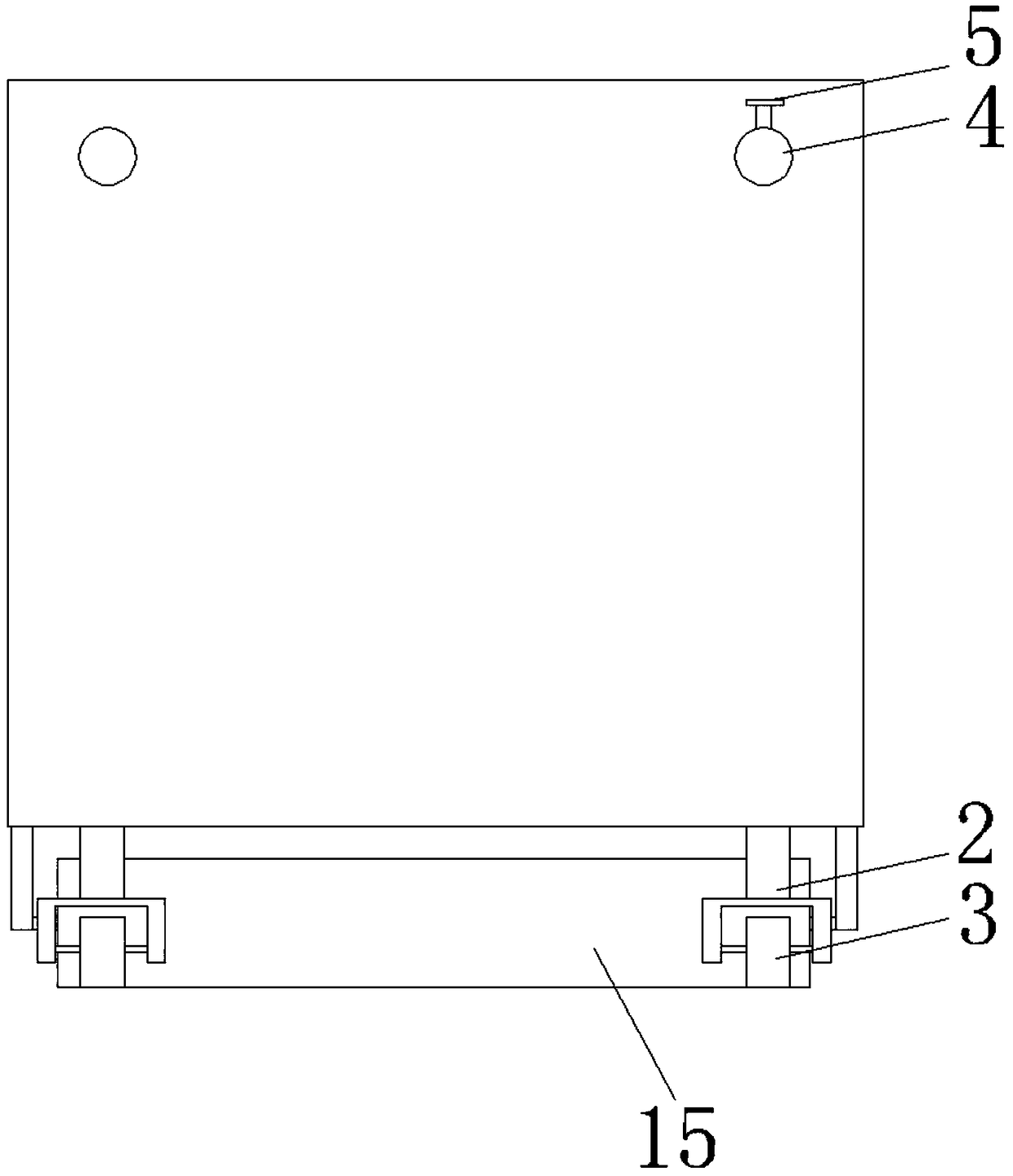

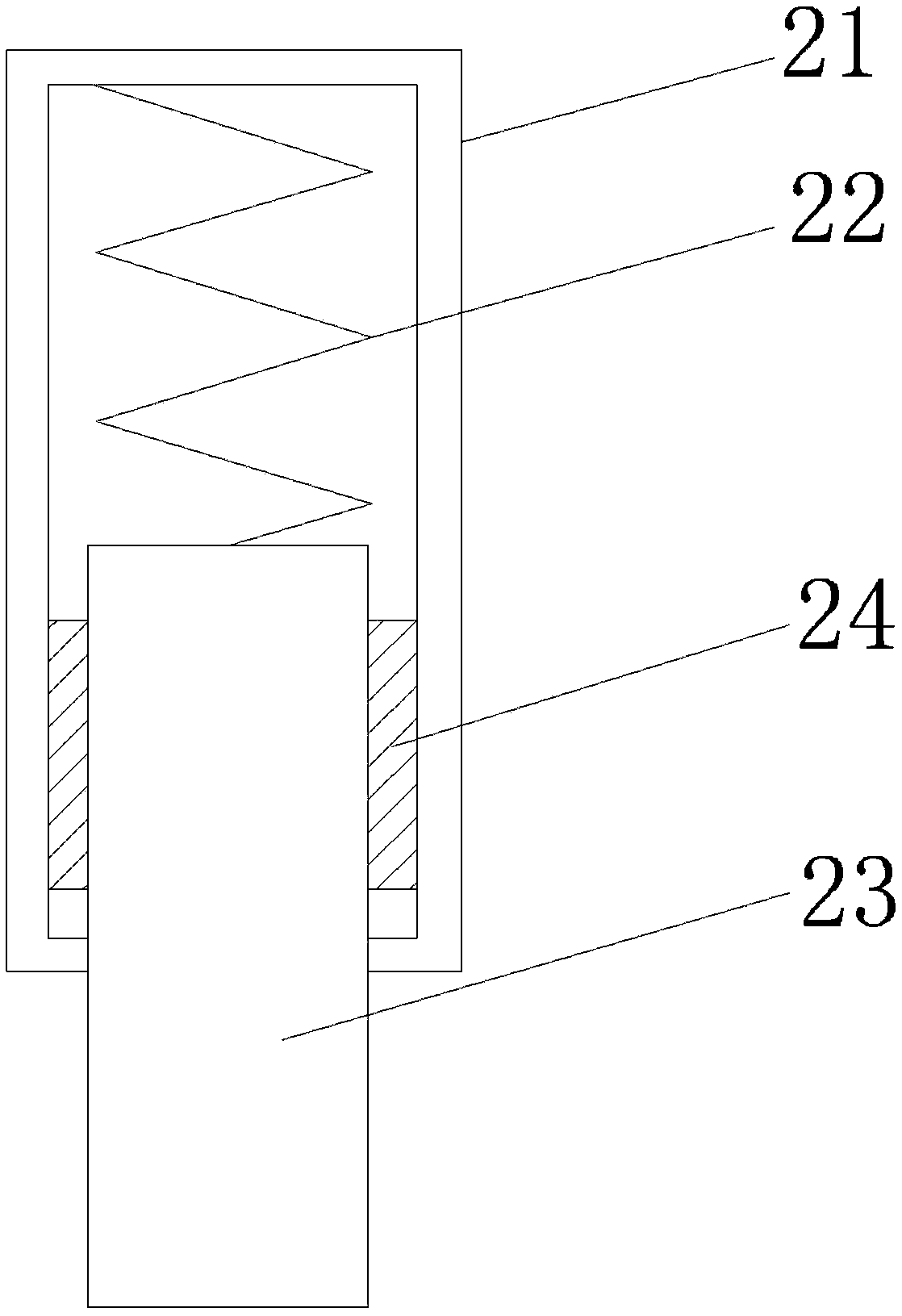

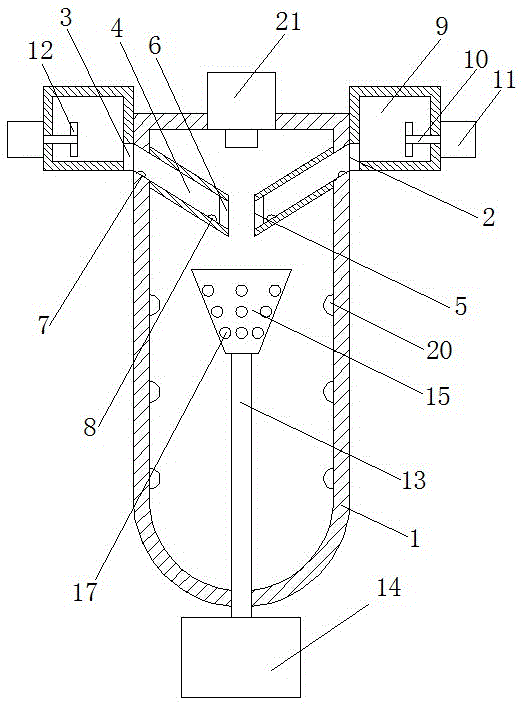

Laying device for waterproof coiled material

The invention discloses a laying device for a waterproof coiled material. The laying device comprises a box body, a heating device and a laying pressing device; damping rods are mounted at the four corners of the bottom end of the box body, sliding wheels are mounted at the bottom ends of the damping rods, a handle is arranged at the upper end of the outer wall of the left side of the box body, and an adjusting valve is arranged on the handle; sliding grooves are symmetrically formed in the front inner wall and the rear inner wall of the box body; the heating device comprises a U-shaped base,a fuel gas tank and a fuel gas pipeline; the U-shaped base is fixed to a bottom plate of the box body, the fuel gas pipeline stretches out of the fuel gas tank, one end of the fuel gas pipeline is connected with the adjusting valve, and the other end of the fuel gas pipeline stretches out of the bottom plate of the box body and is provided with a preheating spraying nozzle and a heating spraying nozzle; and the laying pressing device comprises a first winding roller, the waterproof coiled material, a second winding roller, a third winding roller, a flat-laying roller and a pressing roller. Thelaying device has the advantages that the stability of the laying device is good, the pasting effect of the waterproof coiled material is good, construction manpower is reduced, and the constructionefficiency is improved.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

High-precision tungsten piece preparation method

ActiveCN1621199AImproved uniformity of heatingSmall thickness deviationFurnace typesOther manufacturing equipments/toolsEmulsionSurface roughness

The high precision tungsten plate producing process is especially suitable for producing high precision shielding tungsten plate for CT machine. The production process includes coating the blank tungsten plate with graphite emulsion of 15-20 wt% concentration, rolling after homogeneous heating, electrolytic polishing and pressurizing flattening. The said process is suitable for production of high precision tungsten plate with thickness deviation within 0.01 mm, flatness within 0.005 mm, lower surface roughness and sizes 0.203x146.05x257.05 mm.

Owner:WESTERN METAL MATERIAL

High manganese steel and preparation method thereof

InactiveCN102534405AGuaranteed impact resistanceGuaranteed wear resistanceProcess efficiency improvementQuenching agentsHigh resistanceManganese

The invention discloses high manganese steel, which consists of the following components in percentage by weight: 0.9-1.2 % of C, 11-14 % of Mn, 0.3-0.6 % of Si, 1.5-2.5 % of Cr, less than or equal to 0.04 % of P, less than or equal to 0.04 % of S, and the balance of ferrum. A preparation method for the high manganese steel comprises the following steps of: selecting raw materials; performing smelting, namely preparing molten steel only after the components are ensured to be qualified, and controlling the temperature of the molten steel to be 1,650 DEG C for casting; performing modeling, painting after the modeling is finished, and performing mold assembly and casting; performing cleaning, namely deburring castings, and polishing and checking the castings; performing thermal treatment, namely stacking the cleaned castings in a high-temperature thermal treatment furnace, sealing a furnace door, raising the temperature to 1,100 DEG C, preserving the heat for 4 hours, quickly discharging the castings out of the furnace, and placing the castings into water for quenching; and cleaning the surfaces again, and checking and accepting, warehousing, stacking and classifying the castings. The invention has the advantages that the high manganese steel has high impact resistance and abrasion resistance; and the preparation method is simple, the production cost is low, and the market prospect is good.

Owner:TONGLING ANDONG CAST STEEL

Rolling technology method for ultra-thin ultra-wide steel plate

ActiveCN104148384AAvoid bad deformationEasy heating temperatureTemperature control deviceMetal rolling arrangementsSteel platesManipulator

The invention provides a rolling technology method for an ultra-thin ultra-wide steel plate. The rolling technology method for the ultra-thin ultra-wide steel plate comprises the steps that the soaking temperature of a steel pushing type heating furnace is controlled to range from 1200 DEG C to 1250 DEG C, it is guaranteed that time of a soaking zone is longer than or equal to 60 minutes, and the head and tail temperature difference of a billet is smaller than or equal to 30 DEG C; dog bone rolling is adopted in a rough rolling forming stage and the last pass of a broadening stage; supporting rolls are of a flat roll type and has chamfers in the edges, and the lower roll diameter of a working roll is 2 mm to 5 mm larger than the upper roll diameter of the working roll; the deference of the manipulator centering degree is no larger than 10 mm; the rolling pass of a rough mill is controlled according to the eighth pass to the tenth pass, fine rolling is carried out according to the sixth pass to the eighth pass, reduction of the last three passes is gradually decreased, and the reduction rate of the last three passes is controlled to be 10 % to 15%; two eleven-roll straighteners are used for straightening. According to the rolling technology method for the ultra-thin ultra-wide steel plate, a 2800-mm mill can be used for producing the steel plate with the thickness smaller than 10 mm and the width larger than 2600 mm.

Owner:LIUZHOU IRON & STEEL

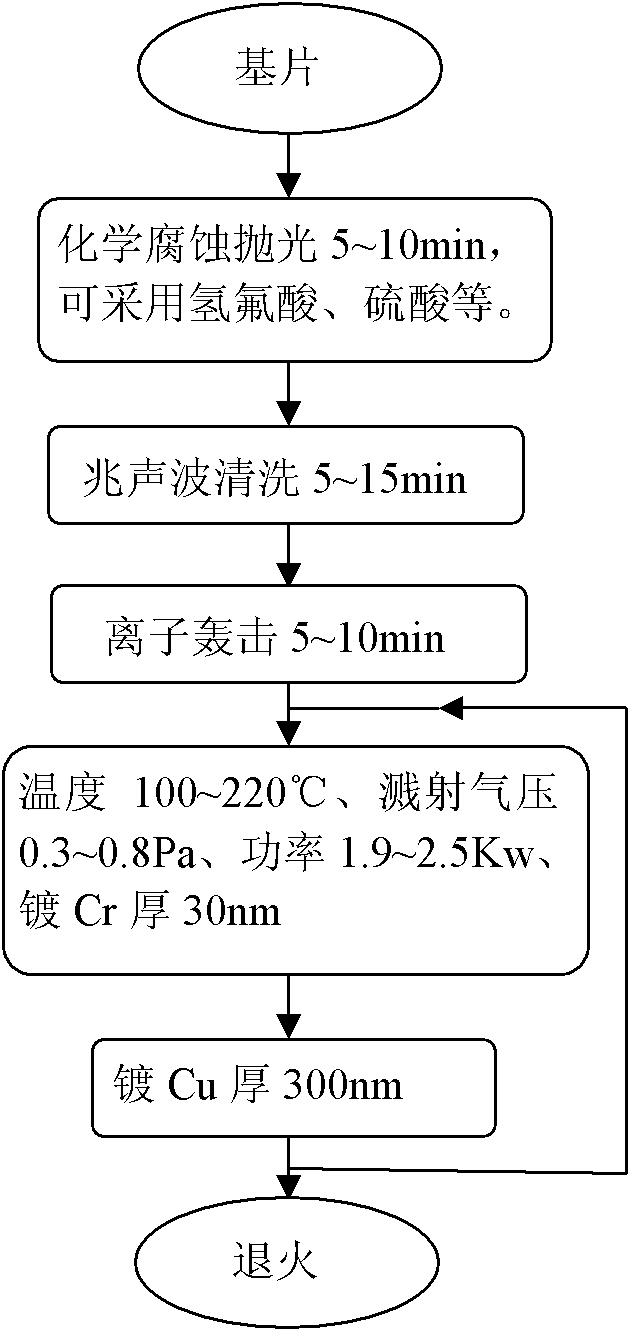

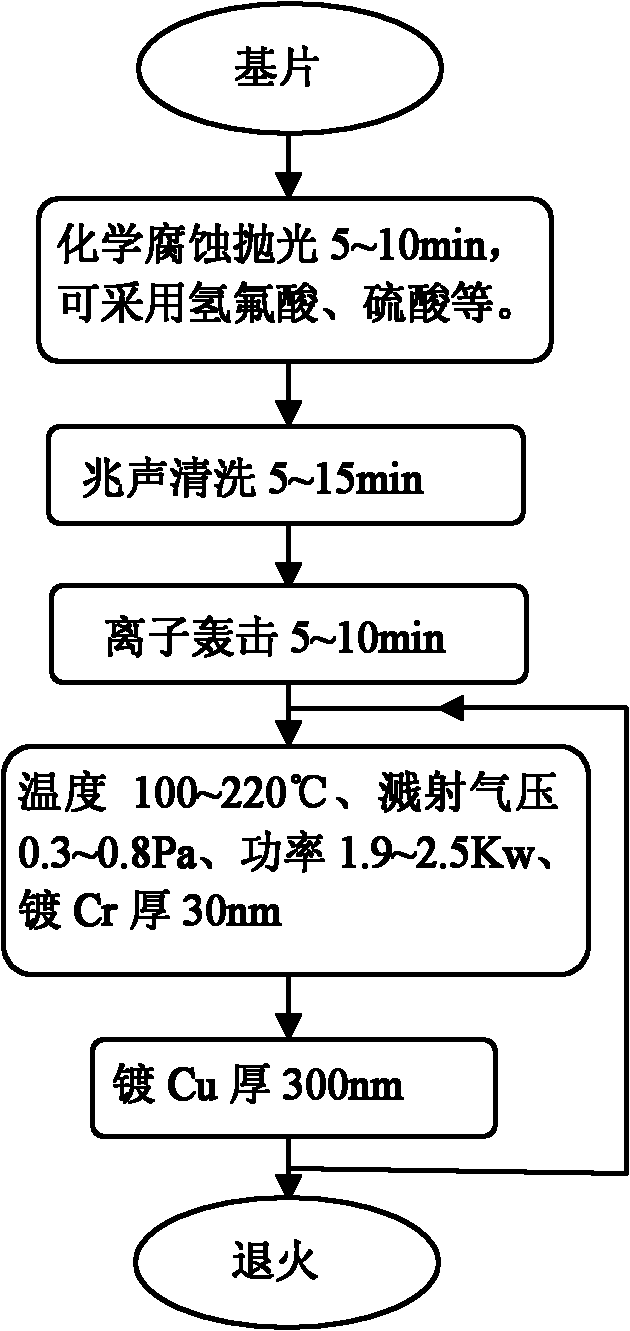

Method for preparing metal mask resistant to corrosion of hydrofluoric acid corrosive liquid

The invention relates to a method for preparing an anticorrosive metal mask, in particular to a method for preparing a metal mask resistant to the corrosion of hydrofluoric acid corrosive liquid. The invention aims to solve the problems of undercut holes, local warping, peeling defects and the like of the conventional corroded mask. The method particularly comprises the following steps of: a, cleaning, namely performing corrosion soaking on a substrate to be coated in hydrofluoric acid and hydrogen peroxide mixed liquid or sulfuric acid and hydrogen peroxide mixed liquid, and performing megasonic cleaning on the substrate; and b, coating, namely (1) performing ion bombardment on Ar on the surface of the substrate; (2) sequentially coating a Cr film and a Cu film on the surface of the substrate under the condition of the temperature of between 100 and 220 DEG C, the sputtering pressure of 0.3 to 0.8 Pa and the sputtering power of 1.9 to 2.5 Kw; and (3) repeating the step (2) to coat the Cr film and the Cu film on the surface of the substrate again to form a double-layered or multilayered Cr / Cu metal mask. The method effectively reduces pinhole undercutting due to fine particles and film layer defects, improves the adhesion of the mask and effectively removes stress.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

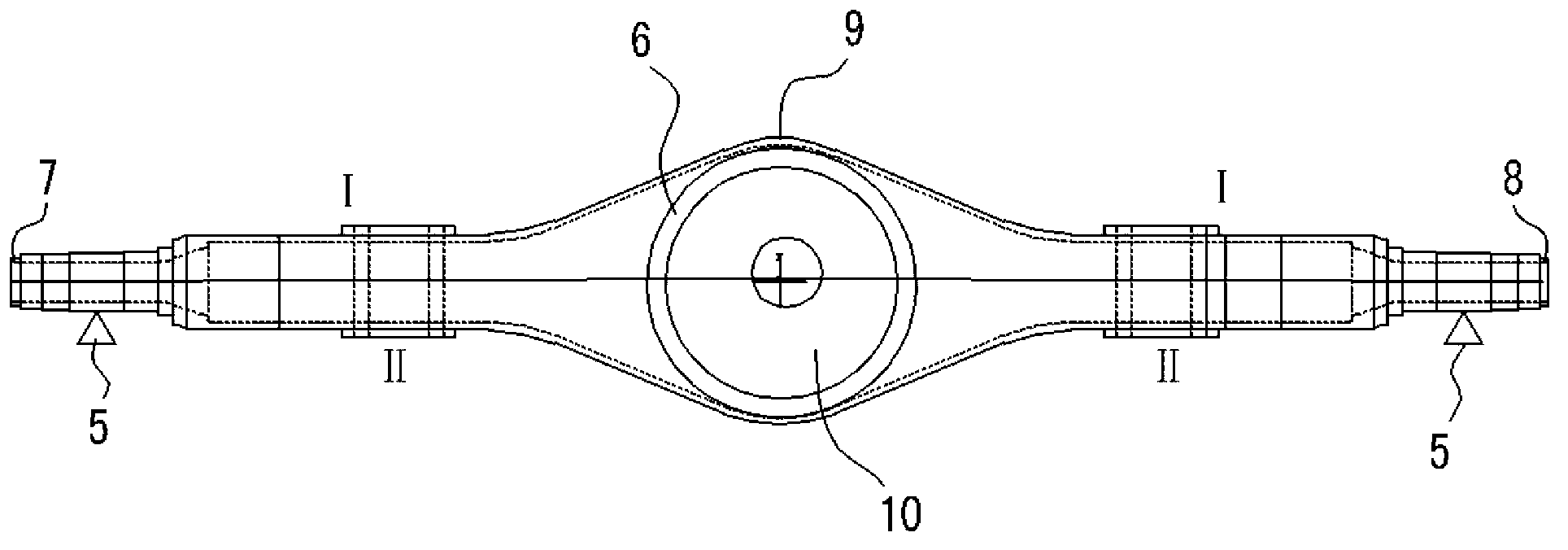

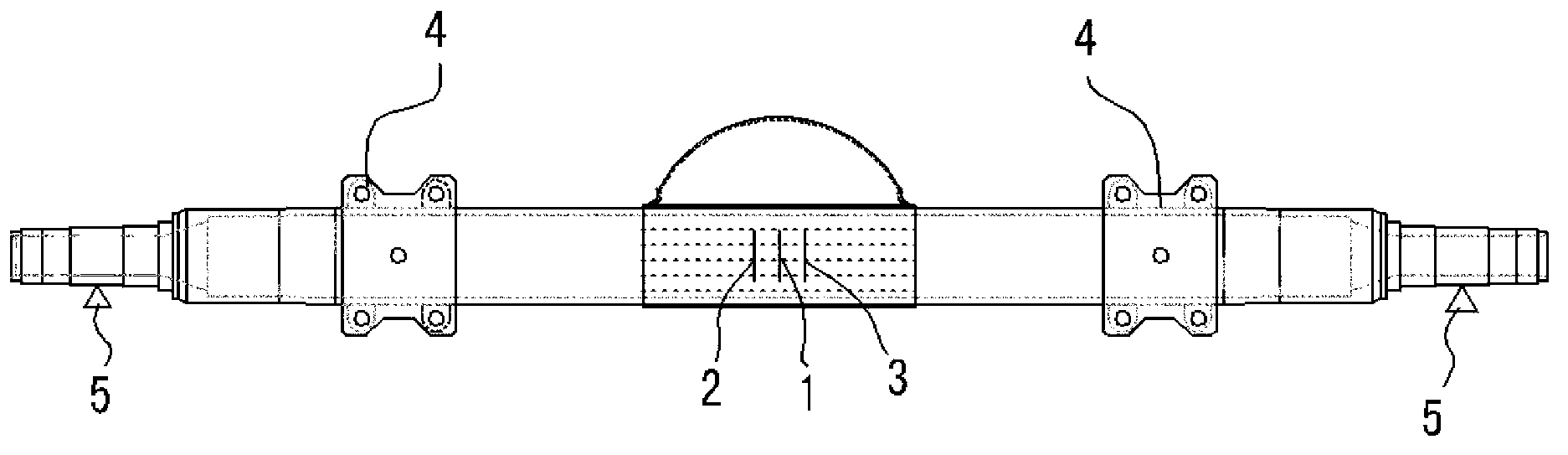

Method for straightening flame of large-deformation automobile drive axle housing

ActiveCN103008402ASimple measurement toolConvenient measuring toolMetal working apparatusFixed bearingEngineering

The invention discloses a method for straightening the flame of a large-deformation automobile drive axle housing. The method is characterized in that a deformed axle housing is put on a detection platform to measure the axle housing deformation; sand is fully filled in an inner cavity of the deformed axle housing, the deformed axle housing is sealed and is then put on a 'V'-shaped piece fixed bearing, the other parts of the deformed axle housing are kept suspended in the air, the back side of a working surface of the deformed axle housing is put upwards, and loading application force points for assisting the straightening are positioned on two end positions, at which an axle housing spring seat assembly is installed; and heating wires which have the same length and width and are symmetrically distributed are marked on the axle housing along the longitudinal direction sequentially, acetylene flame is used to move from one ends to the other ends of the heating wires to heat, after each heating is completed, water is adopted to cool the axle housing, and flame heating and loading force applying are repeatedly carried out until the axle housing deformation reaches the tolerance allowed range of the axle housing design. By the method, the material shaping reserve consumption can be effectively avoided, and accordingly, the reutilization ratio of the large-deformation drive axle housing is increased.

Owner:HEFEI UNIV OF TECH

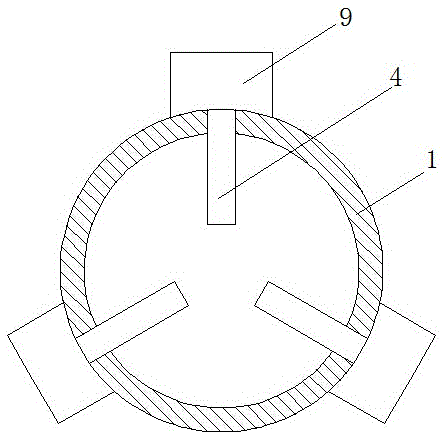

Printing and dyeing raw material mixing equipment based on synchronous mixing treatment

ActiveCN105582842AEasy heating temperatureTo achieve the desired effectRotating receptacle mixersTransportation and packagingEngineeringControl valves

The invention discloses printing and dyeing raw material mixing equipment based on synchronous mixing treatment, which comprises a mixing barrel, wherein three feeding ports extending into the mixing barrel are arranged on the mixing barrel, the three feeding ports are spirally symmetric relatively to the axis of the mixing barrel, and each feeding port is internally provided with a first control valve; and the three feeding ports are respectively connected with a feeding pipe extending toward the axis of the mixing barrel. According to the printing and dyeing raw material mixing equipment adopting the technical scheme, through the arrangement of the three feeding ports in the mixing barrel, three primary color dyes can be fed and mixed synchronously, so that the uniformity of color of the molded dyes is more ideal; according to the printing and dyeing raw material mixing equipment based on synchronous mixing treatment, in the mixing process of printing and dyeing raw materials, three primary color printing and dyeing raw materials can be fed and mixed synchronously, so that the mixing uniformity is obviously improved.

Owner:绍兴中漂印染有限公司

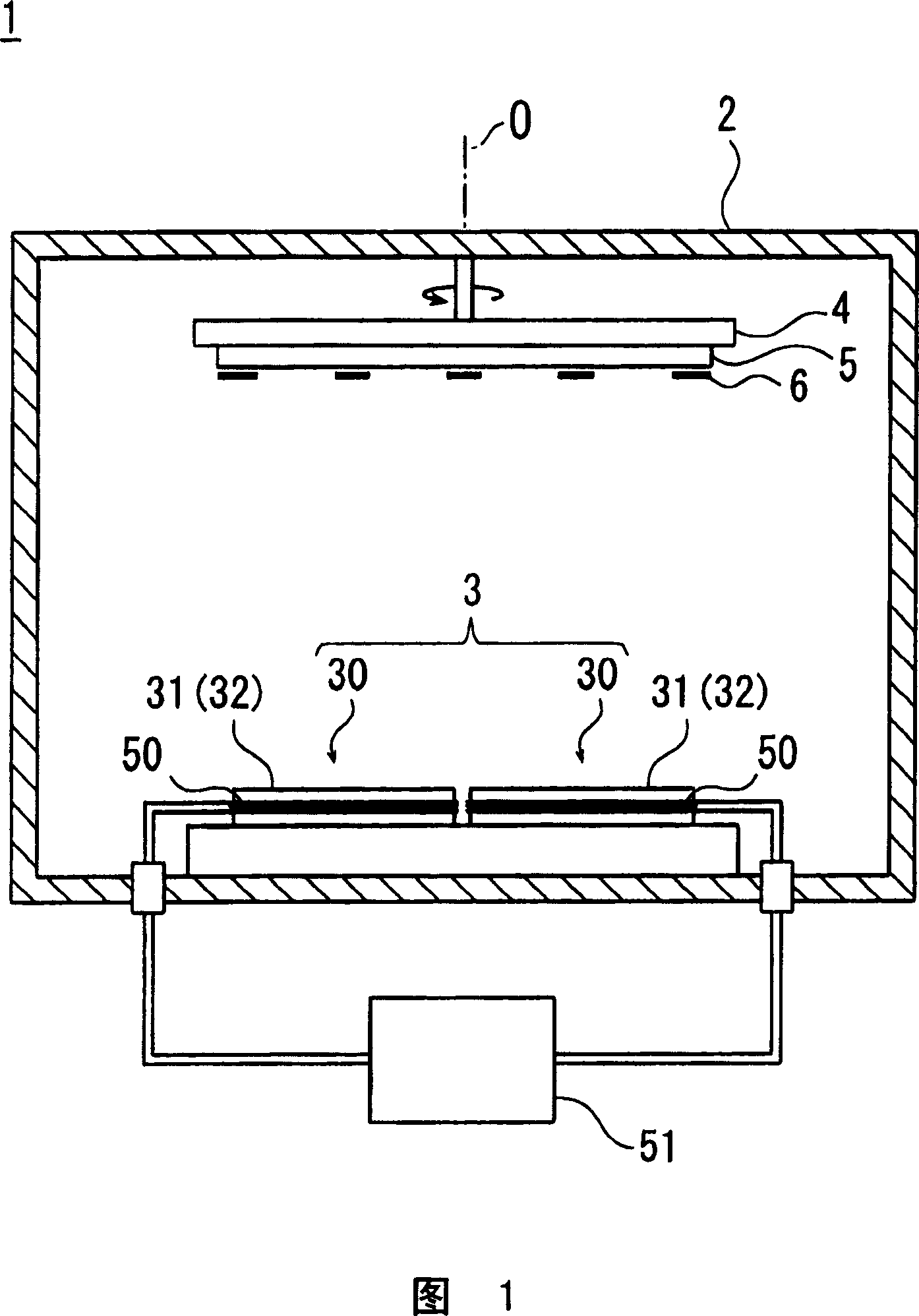

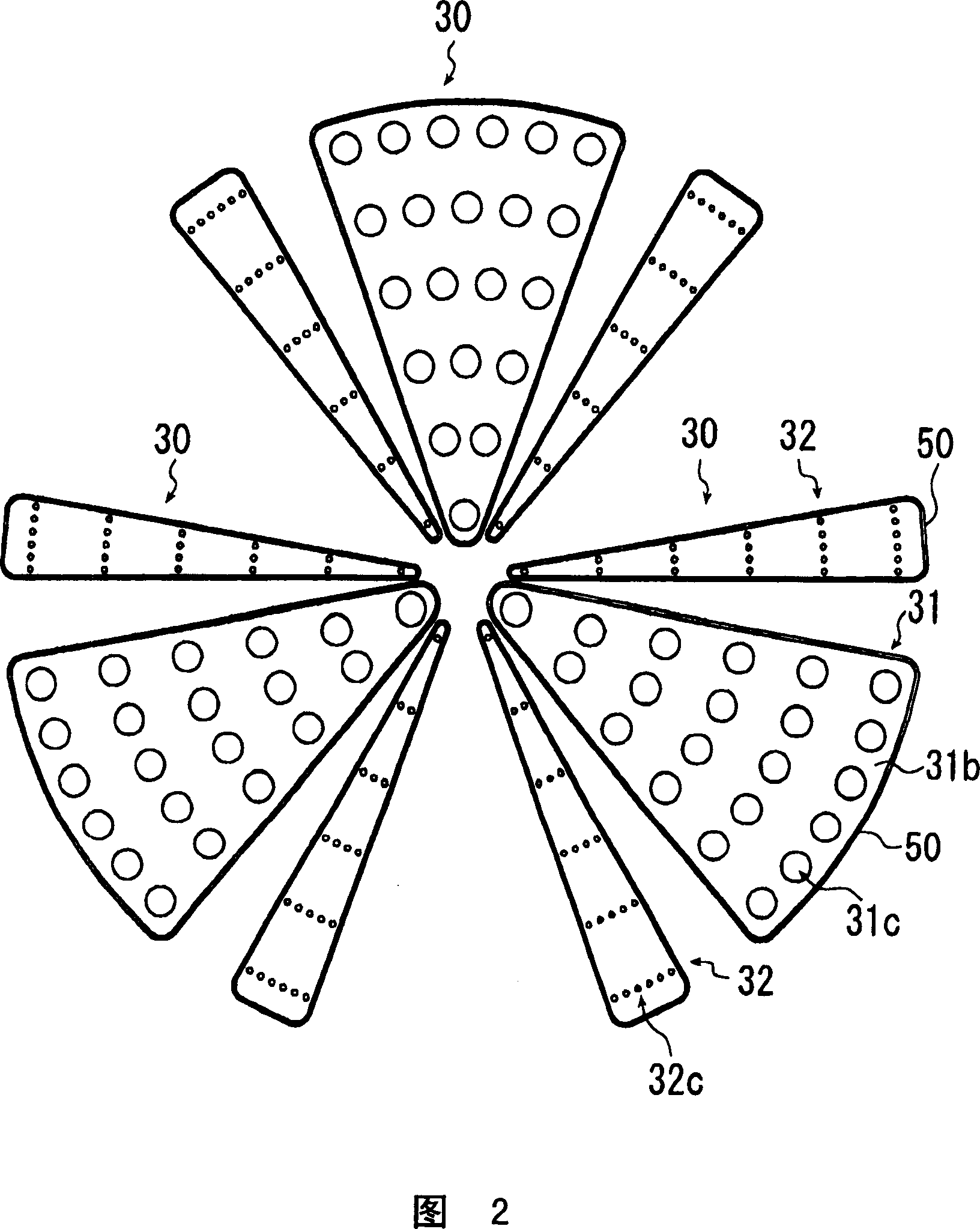

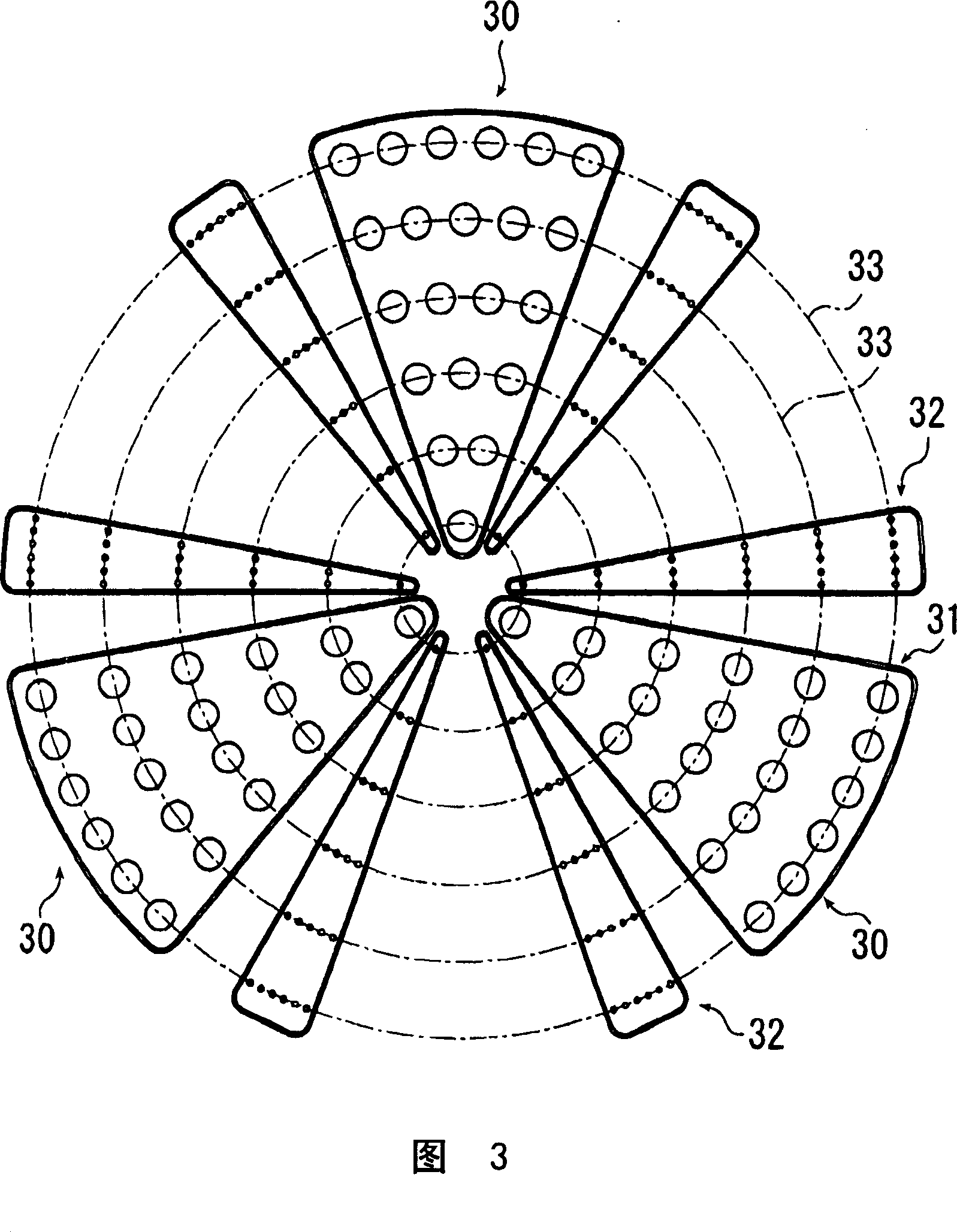

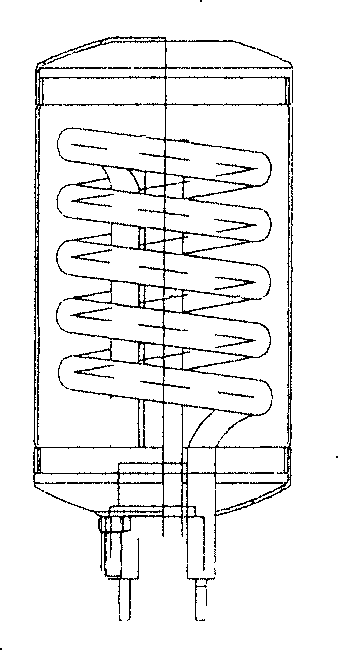

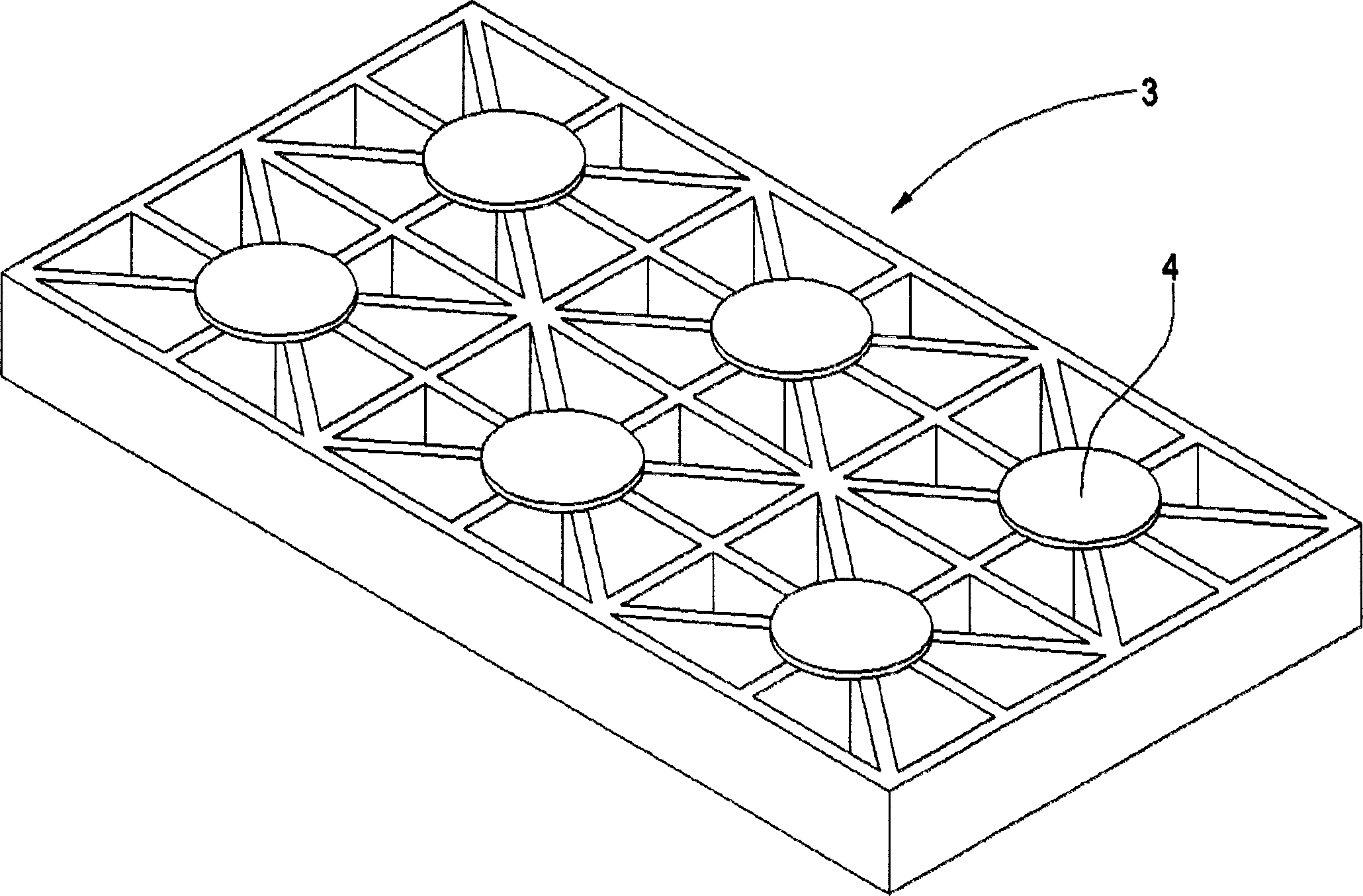

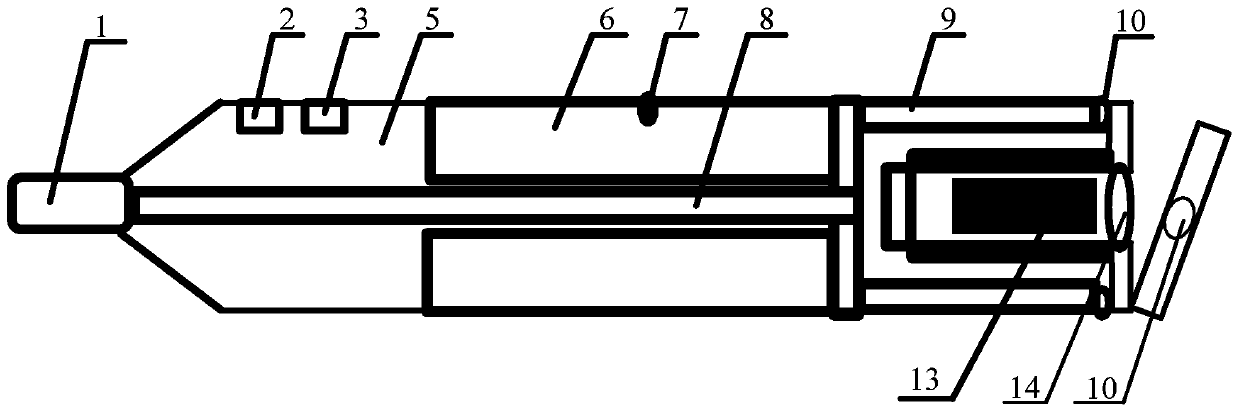

Organic material evaporation source and organic vapor deposition device

InactiveCN1950536AUniform film thickness distributionControl heating temperatureElectroluminescent light sourcesSolid-state devicesVaporizationMembrane thickness

An organic material evaporation source capable of forming a membrane having a uniform membrane thickness distribution with respect to a large-sized substrate and capable of controlling heating temperature and evaporation rate during vapor deposition accurately and with good responsiveness; and an organic vapor deposition device using the source. A vaporization source comprises a vessel main body (31a) having a heating section consisting of a high frequency induction coil (50) and receiving a predetermined organic material, and a lid (31b) having a vaporization port (31c) for the vapor of the organic material to pass therethrough. The arrangement is such that the amount of vapor of the organic material discharged from the vaporization port (31c) in the lid (31b) steadily increases with respect to a two-dimensional position with a predetermined reference position used as a basis.

Owner:ULVAC INC

Medium manganese steel and preparation method thereof

The invention discloses medium manganese steel. The medium manganese steel comprises the following components in percentage by weight: 0.9 to 1.1 percent of carbon (C), 6 to 8 percent of manganese (Mn), 0.3 to 0.6 percent of silicon (Si), 1.0 to 1.2 percent of chromium (Cr), 0.2 to 0.4 percent of percent (MO), less than or equal to 0.04 percent of phosphorus (P), less than or equal to 0.04 percent of sulphur (S), and the balance of Fe. A preparation method comprises the following steps of: selecting raw materials; smelting, and yielding water after ensuring that the components are qualified, wherein the water yielding temperature is controlled at 1,650 DEG C, and casting; molding, coating after molding, assembling molds and casting; removing sand: cleaning cast burrs, and performing polishing inspection; preserving the heat, stacking casts with sand cleaned in a high-temperature heat treatment furnace, sealing a furnace door, raising the temperature, preserving the heat after the temperature is raised to 1,100 DEG C, preserving the heat for 6 hours, quickly discharging the casts, and putting the casts into water for quenching; and cleaning surfaces again, and inspecting, accepting, warehousing, stacking, classifying and warehousing products. The medium manganese steel has the advantages of ensuring high impact resistance and abrasion resistance of manganese steel; having a simple production process, low production cost and a good market prospect.

Owner:TONGLING ANDONG CAST STEEL

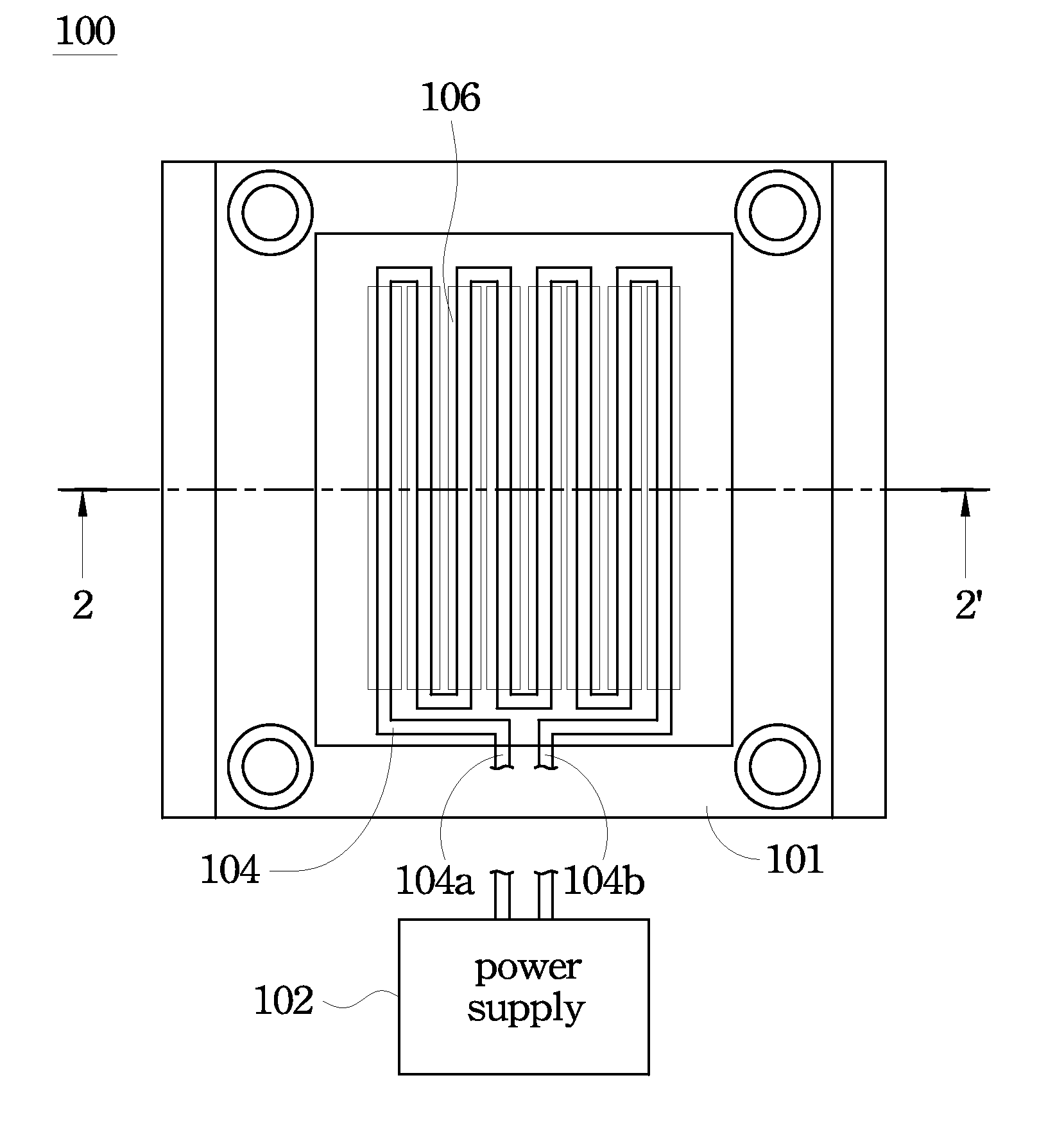

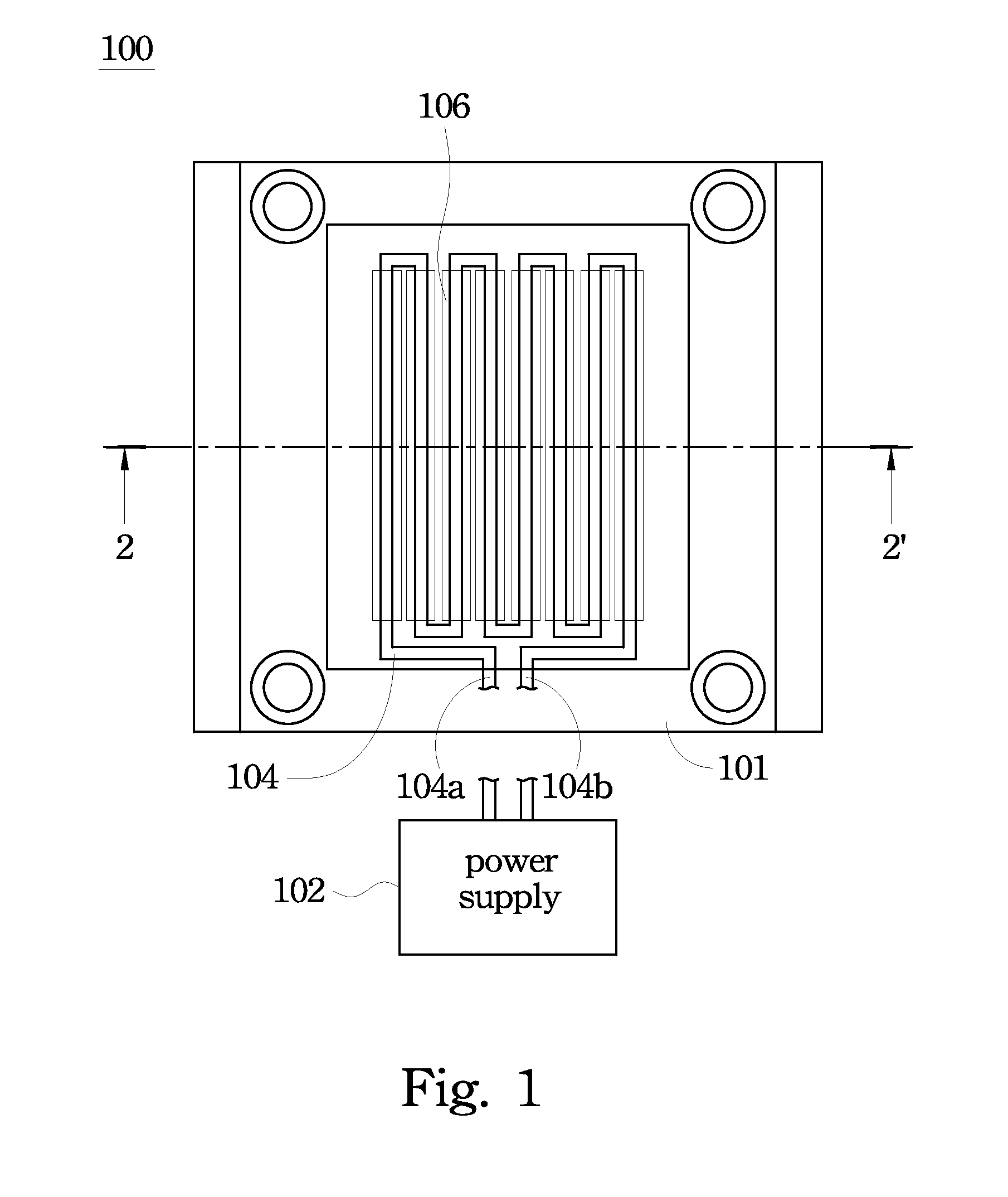

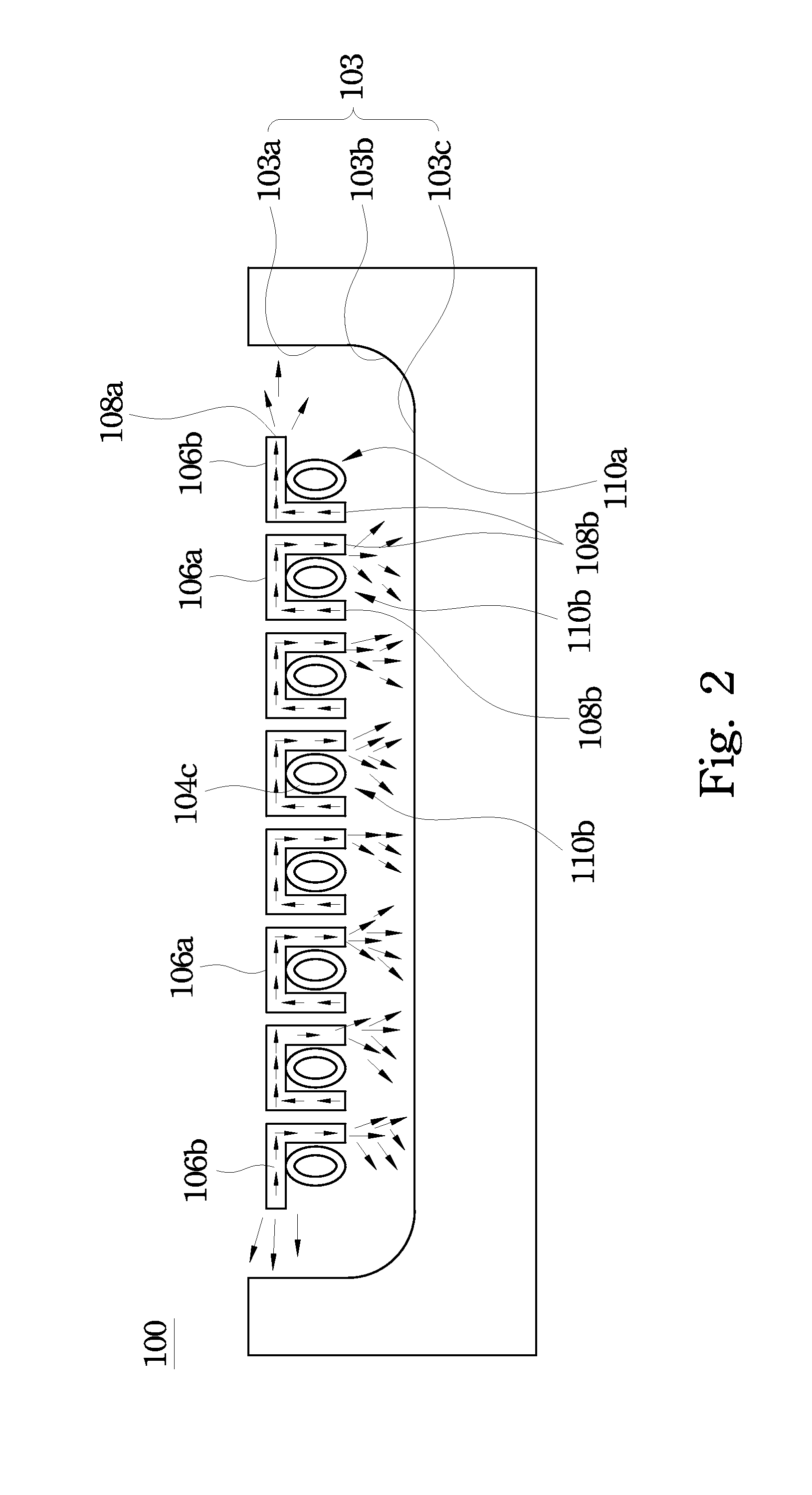

High frequency electromagnetic induction heating device and method for using the same to heat surface of mold

InactiveUS20130015178A1Shorten heating timeEasy heating temperatureCoil arrangementsInduction current sourcesElectricityEm induction

A high frequency electromagnetic induction heating device includes a power supply, a high frequency electromagnetic induction coil and an electromagnetic guide sleeve. The high frequency electromagnetic induction coil has two electrodes which are electrically connected with the power supply. The electromagnetic guide sleeve is disposed around the high frequency electromagnetic induction coil, and has an opening exposing the high frequency electromagnetic induction coil, wherein the opening faces towards a surface to be heated.

Owner:QUANTA COMPUTER INC

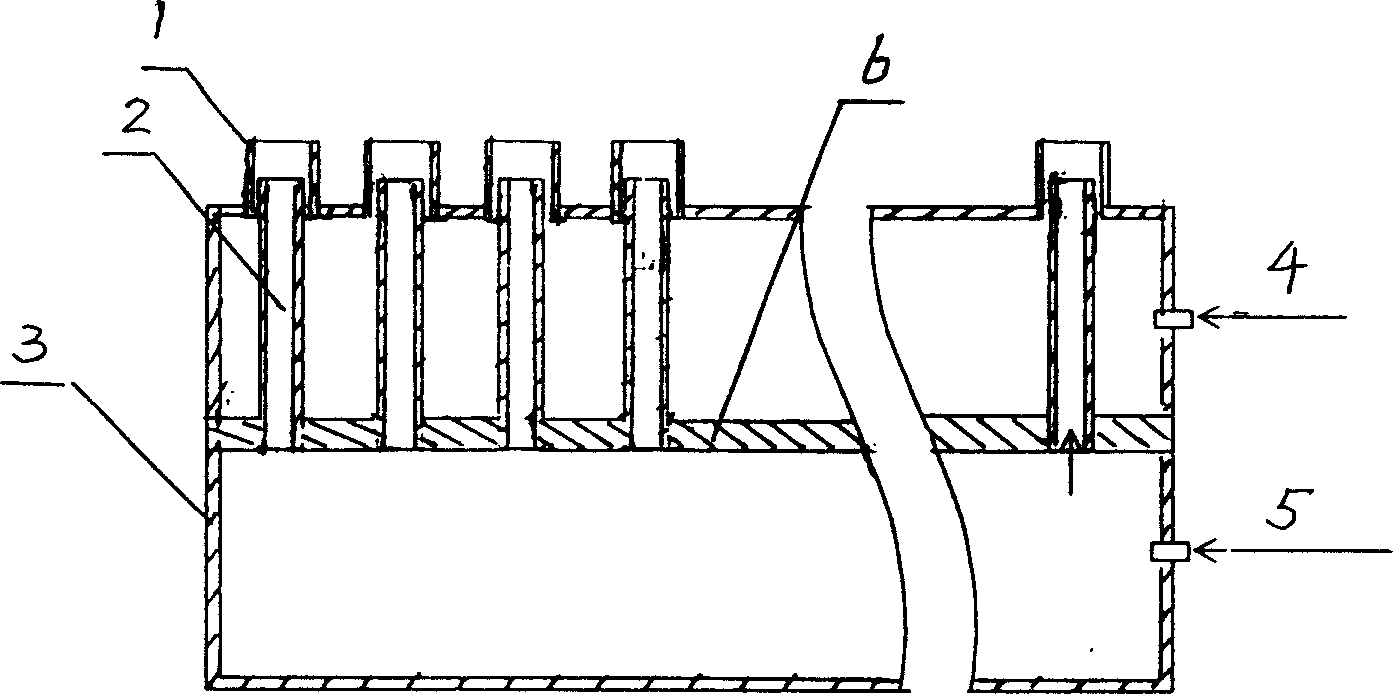

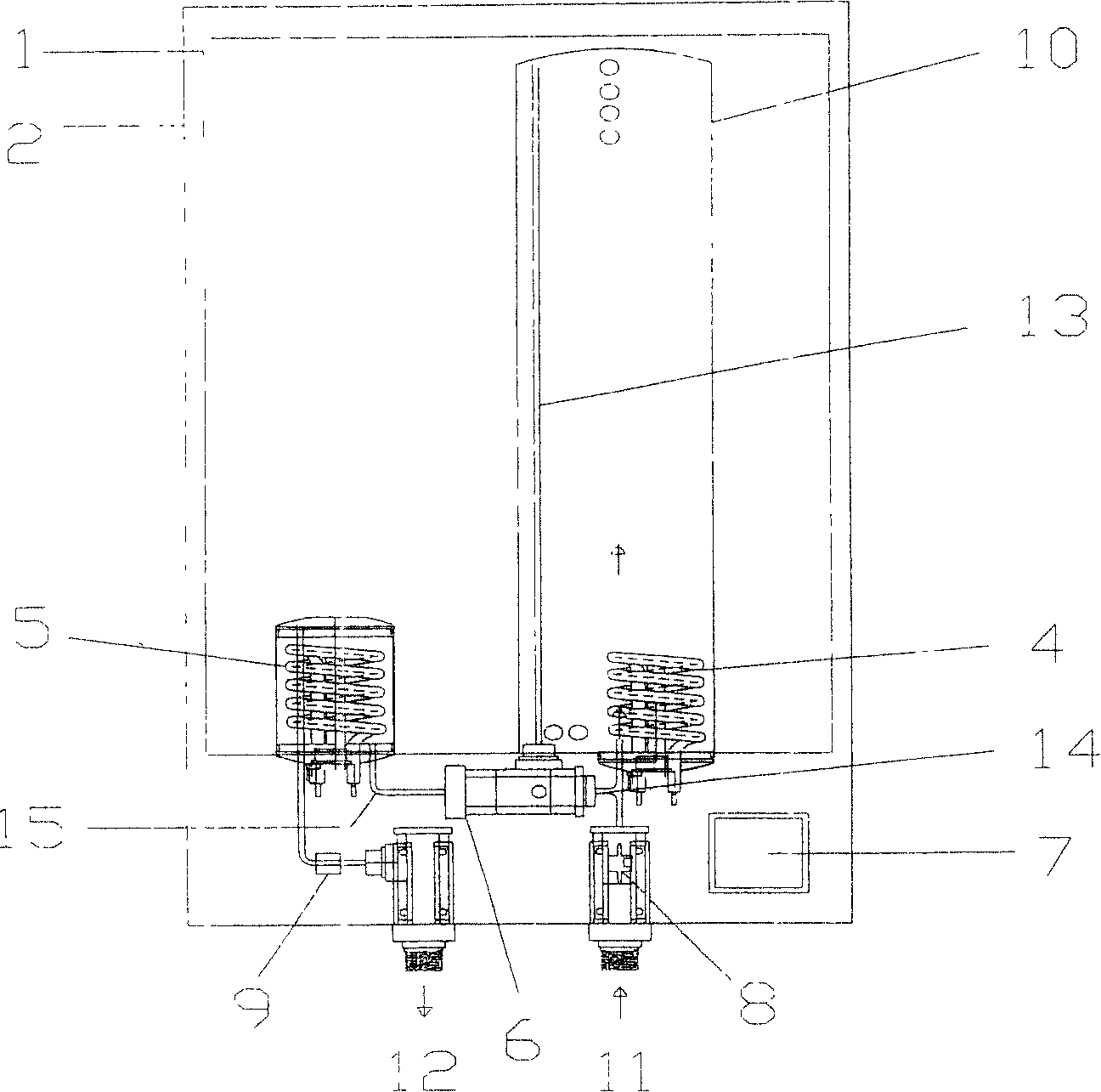

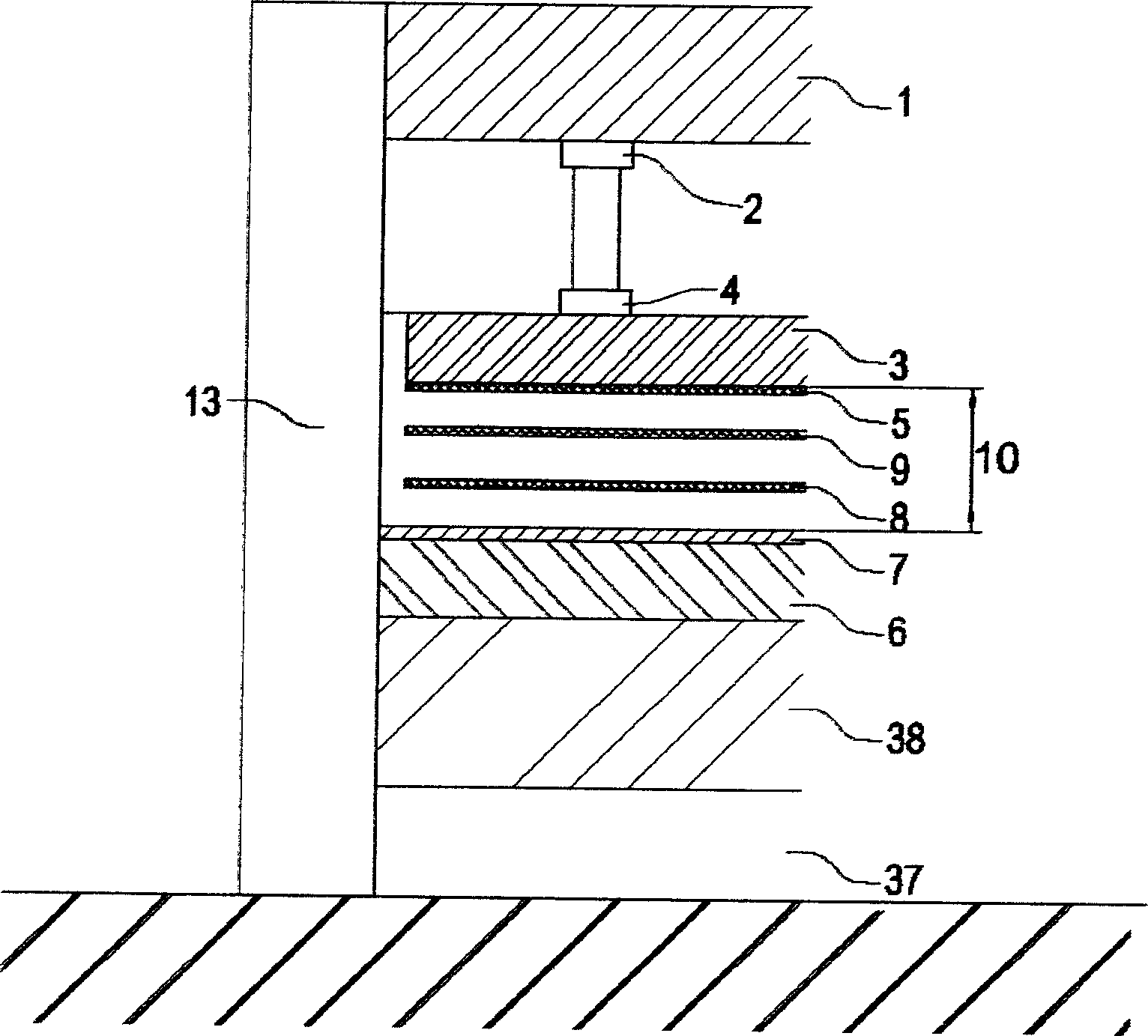

Thermostatic instant heating water storage type electric heater

InactiveCN101162107AEasy heating and temperature controlImprove heating efficiencyWater heatersWater storage tankHeating efficiency

The invention discloses a constant temperature instant heating water storage type electric water heater; the invention is characterized in that a water storage tank(1) is provided inside with a constant temperature heater(5) and a heat radiation collector(10), the heat radiation collector(10) provided inside with a muff heater(4) has a water outlet connected with a mixing temperature limiter(6) of which an water outlet is communicated with the constant temperature heater(5) by an admitting pipe(15); the constant temperature heater(5) is provided with a temperature sensor(9), the muff heater(4) is provided with a water flow sensor(8); an electric thermostatic control device(7) is connected with the temperature sensor(9) and the water flow sensor(8). The mixing temperature limiter(6) can apply the structure or the similar structure disclosed in the Chinese patent of invention (Z1200420047315.3). Because the invention adopts the technical proposal, thereby the guaranteeing that when the present constant temperature supply is started and the present water storage tank is heated, the hot water can continuously be generated, which effectively resolves the defect existing in prior art; because the mixing temperature limiter is applied in the invention, the temperature of the water entering in the constant temperature heater can be accurately adjusted, thereby causing the following heating and the temperature control convenient, improving the heating efficiency and avoiding the loss of the energy resources.

Owner:陈继雄

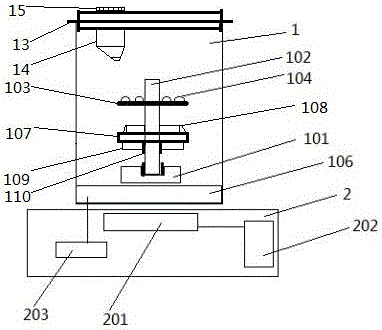

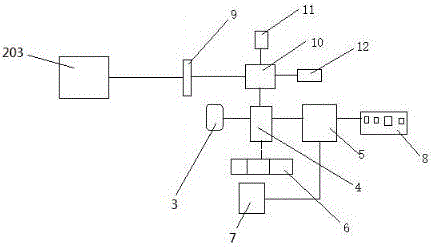

Microwave themal compression machine bench

A hot compressing equipment using a microwave is provided to heat, dry and compress form the compressing object by irradiating a microwave generated from a microwave generator onto a compressing plate to heat the compressing plate, placing a compressing object between the compressing plate and a metallic reflection plate, and compressing the compressing object by the heated compressing plate. In a compressor for applying a pressure to an object placed in a compression chamber to compress the object, a hot compressing equipment using a microwave comprises an irradiation part installed at one side of the compression chamber to irradiate a microwave with a frequency of 300 to 300,000 MHz into the compression chamber such that the microwave heats the object in the compression chamber. The compression chamber has a metallic reflection plate(5) attached to at lest one of inner side faces thereof to reflect the microwave, and at least one compressing plate(8,9) installed on the inner side faces or an inner part thereof in a planar or curved plate-shape to pass through the microwave.

Owner:孙辰豪

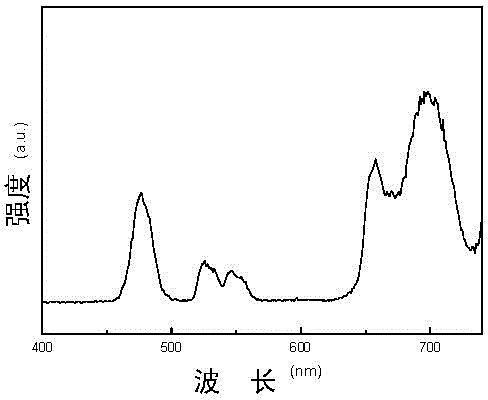

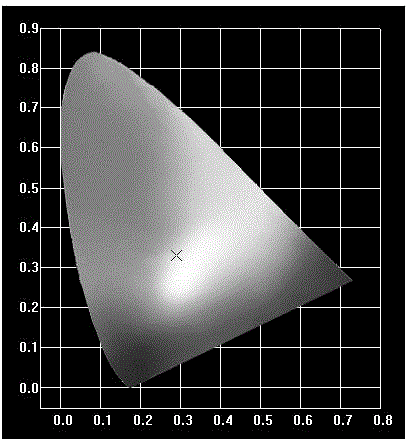

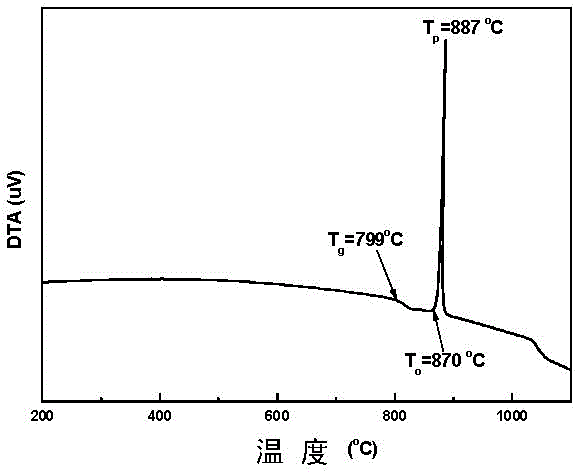

Heavy metal oxide block glass material for up-conversion of white light and method for enhancing illumination intensity of heavy metal oxide block glass material

The invention relates to a heavy metal oxide block glass material for up-conversion of white light and a method for enhancing the illumination intensity of the heavy metal oxide block glass material. The heavy metal oxide block glass material for the up-conversion of the white light consists of the following components in percentage by mass of the glass material: 47wt% to 49wt% of TiO2, 30wt% to 44wt% of La2O3, 3wt% to 4wt% of ZrO2, 0.1wt% to 1.1wt% of Er2O3, 0.3wt% to 6.1wt% of Tm2O3 and 2.7wt% to 11.2wt% of Yb2O3, wherein the sum of the mass percentages of the components is 100%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

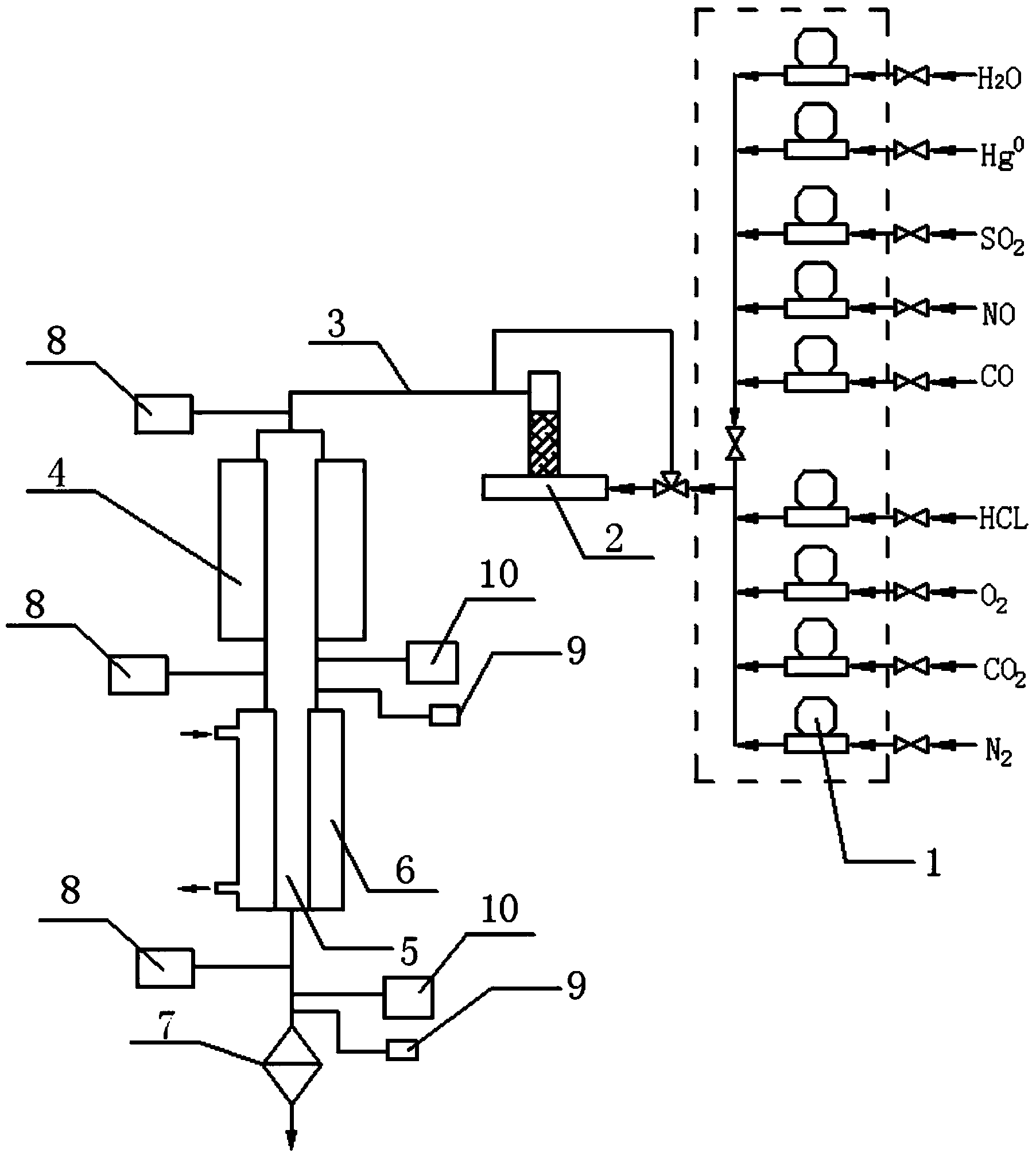

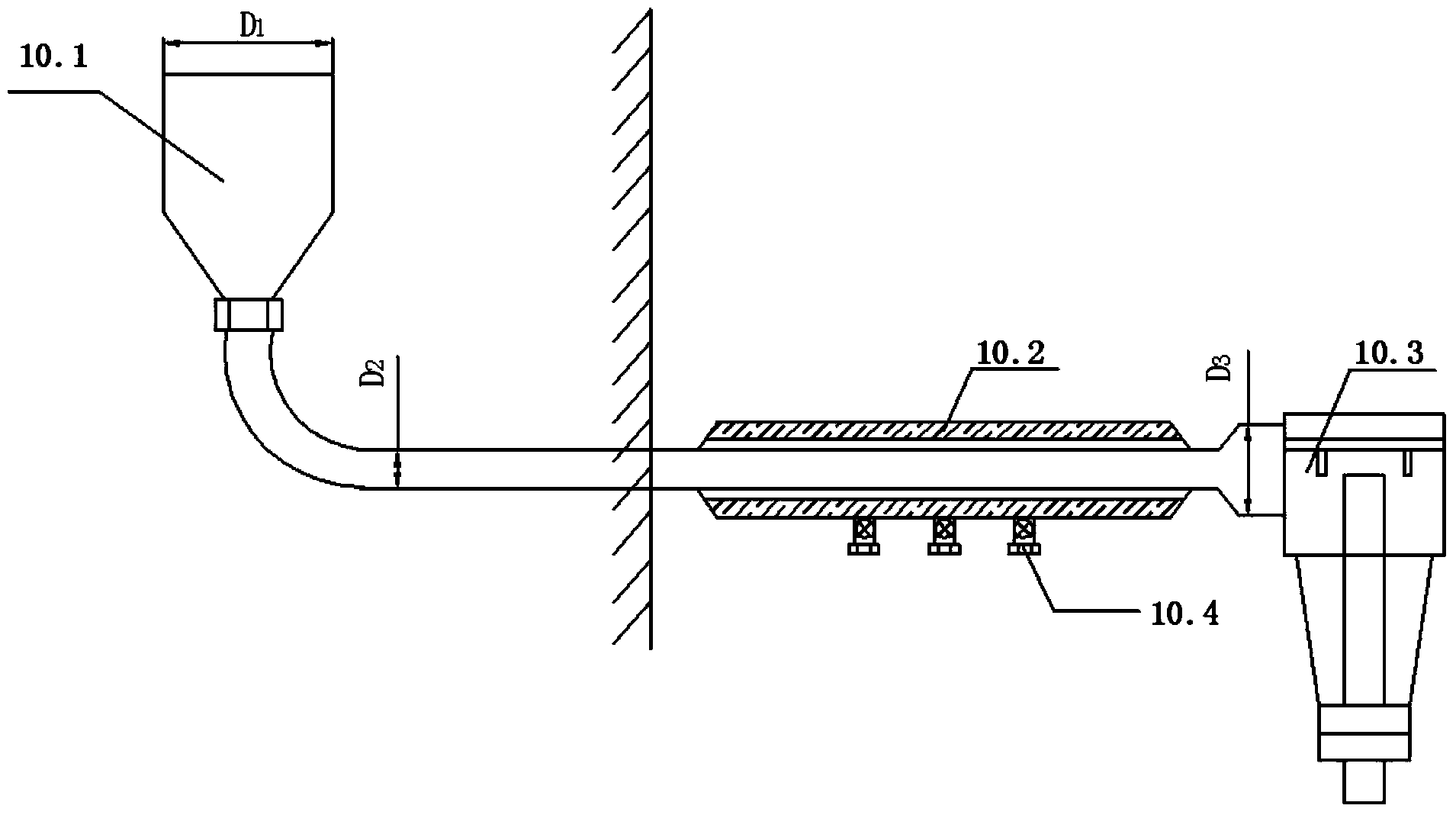

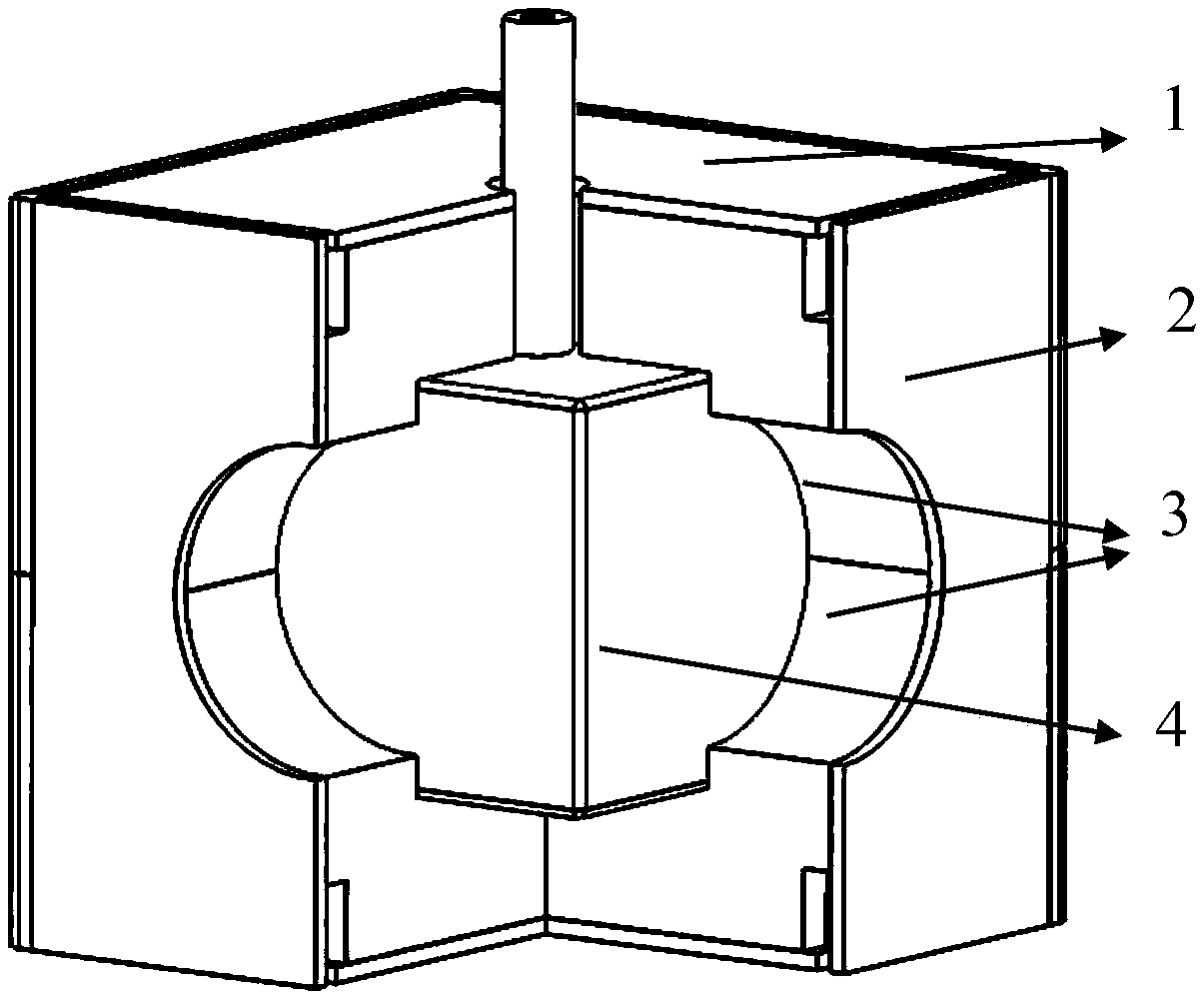

Coal-fired flue gas mercury homogeneous/heterogeneous reaction form transformation mechanism device and method for detecting form of mercury by using same

The invention discloses a coal-fired flue gas mercury homogeneous / heterogeneous reaction form transformation mechanism device and a method for detecting the form of mercury by using the same. The device comprises a feeding device, a cooling device, a dust removal filter and a detecting device, wherein the feeding device comprises a burning device of a drop tube furnace; the cooling device comprises a flue gas water-cooled tube, the flue gas water-cooled tube comprises a quartz tube core and a water-cooled tube which is wrapped outside the quartz tube core and provided with a water inlet and a water outlet, and the upper end of the flue gas water-cooled tube is connected with a lower outlet of the drop tube furnace; the upper end of the dust removal filter is connected with the lower outlet of the flue gas water-cooled tube; the detecting device comprises a temperature detector, a flue gas component detector and a mercury form detector. The device and method disclosed by the invention have the advantages that the influence of fly ash on the form of Hg in the process of sampling can be reduced or avoided, and the mutual switching between homogeneous heterogeneous researches under same experiment setting conditions is realized, thereby facilitating the implementation of comparison experiments, and facilitating the more clear understanding of the effect of particulate matters such as fly ash and the like in the heterogeneous process during Hg oxidation.

Owner:浙江省洁净煤技术研究开发中心

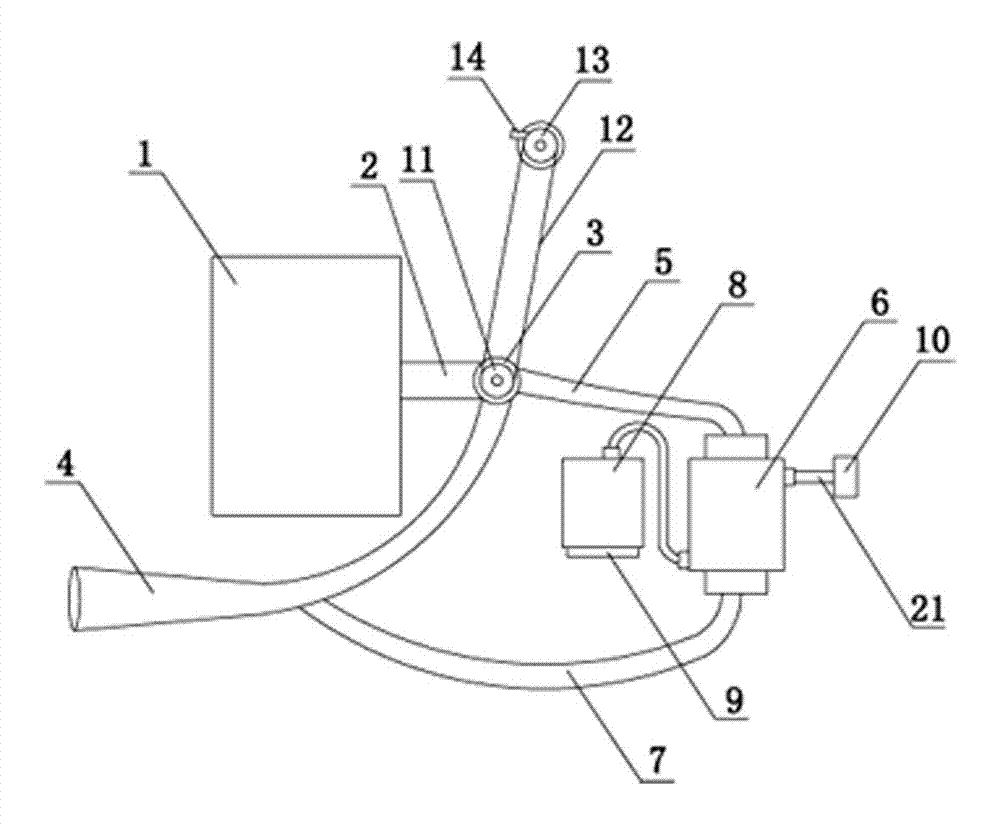

Tail gas warming device of motor bicycle and warming clothing applied to same

InactiveCN102785733AWide applicabilityReduce emission noiseCycle equipmentsEngineeringHeat exchanger

The invention discloses a tail gas warming device of a motor bicycle and warming clothing applied to the same. The tail gas warming device comprises a heat exchanger and a fan. An air outlet of the fan is connected onto an air inlet of the heat exchanger through an air guide pipe, an air outlet of the heat exchanger is connected with an air outlet connector through the air guide pipe, an exhaust front pipe is connected at the position of an engine tail gas outlet of the motor bicycle, the tail end of the exhaust front pipe is connected with one inlet of the three-way flow dividing valve, and the other two outlets of the three-way flow dividing valve are respectively connected onto an exhaust tail pipe and a branch gas tail pipe. The tail end of the branch gas front pipe is connected onto a hot fluid inlet of the heat exchanger, and a branch gas back pipe is connected with a hot fluid outlet of the heat exchanger. An adjusting device used for poking and rotating a valve switch is arranged on the three-way flow dividing valve. The warming temperature of the tail gas warming device can be adjusted simply by the gas flow degree of the three-way flow dividing valve to enable a human body to obtain optimum warming temperature. Therefore, adaptability of the tail gas warming device is expanded, and the tail gas warming device overcomes the shortcoming in the prior art that the warming device is wasted and left unused for most time.

Owner:陈涧忠

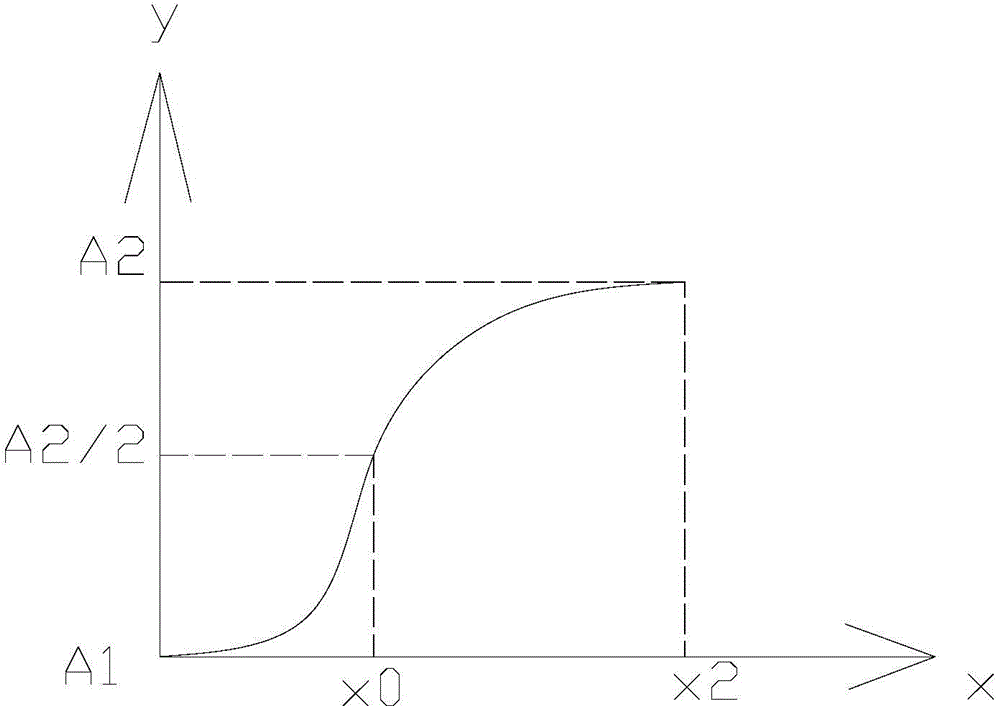

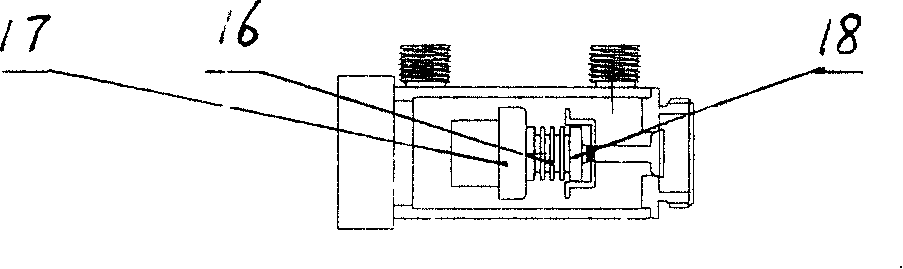

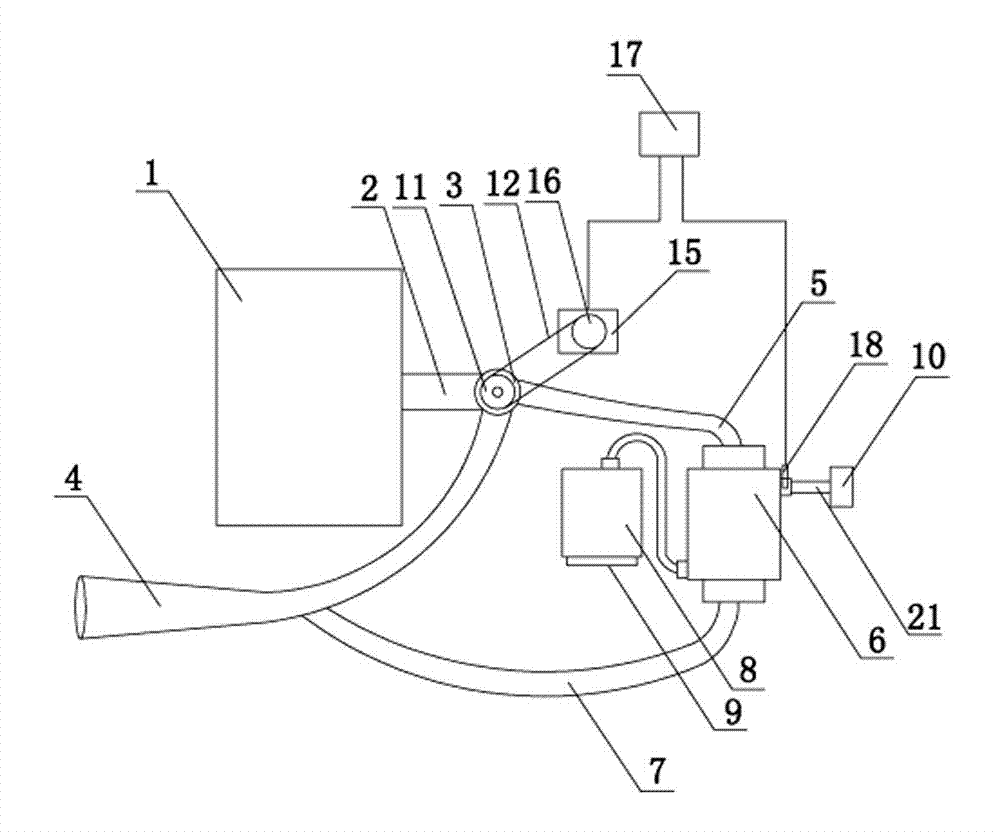

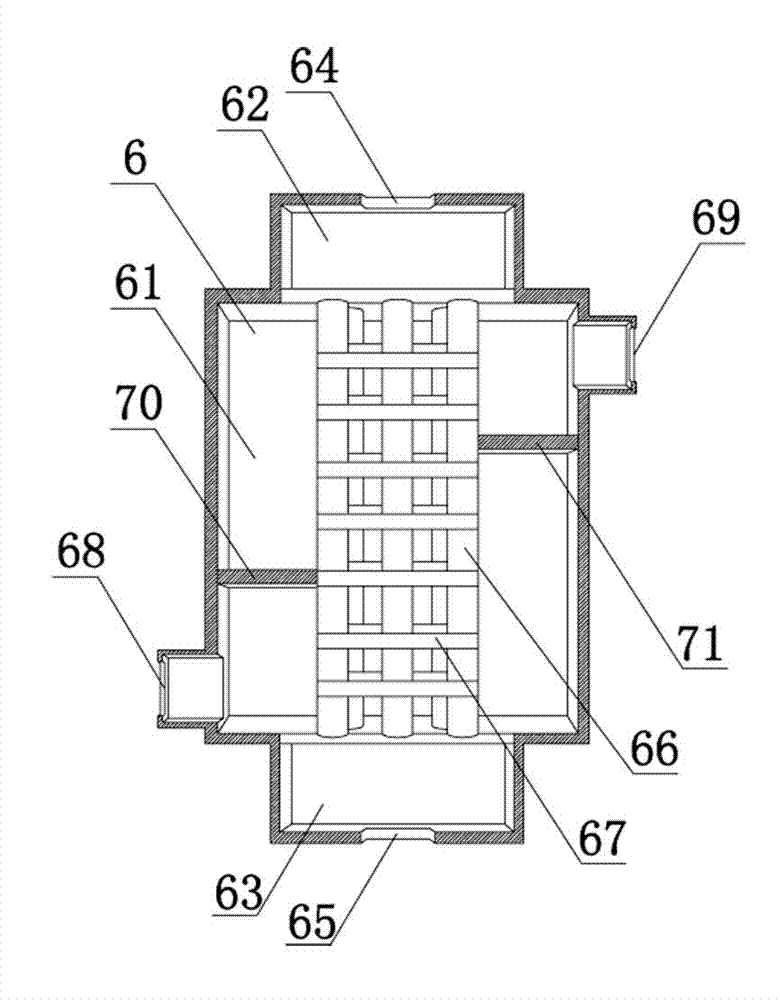

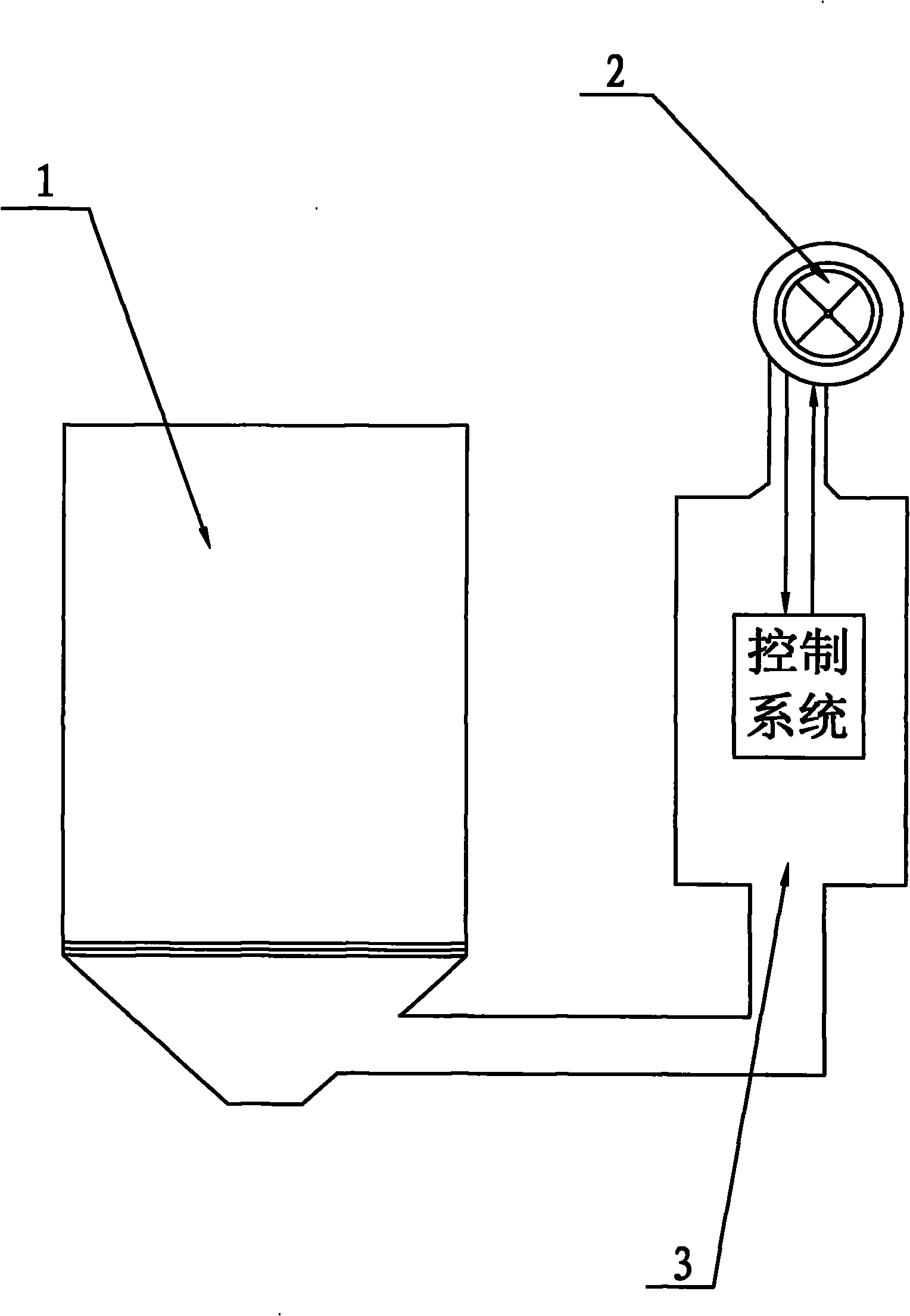

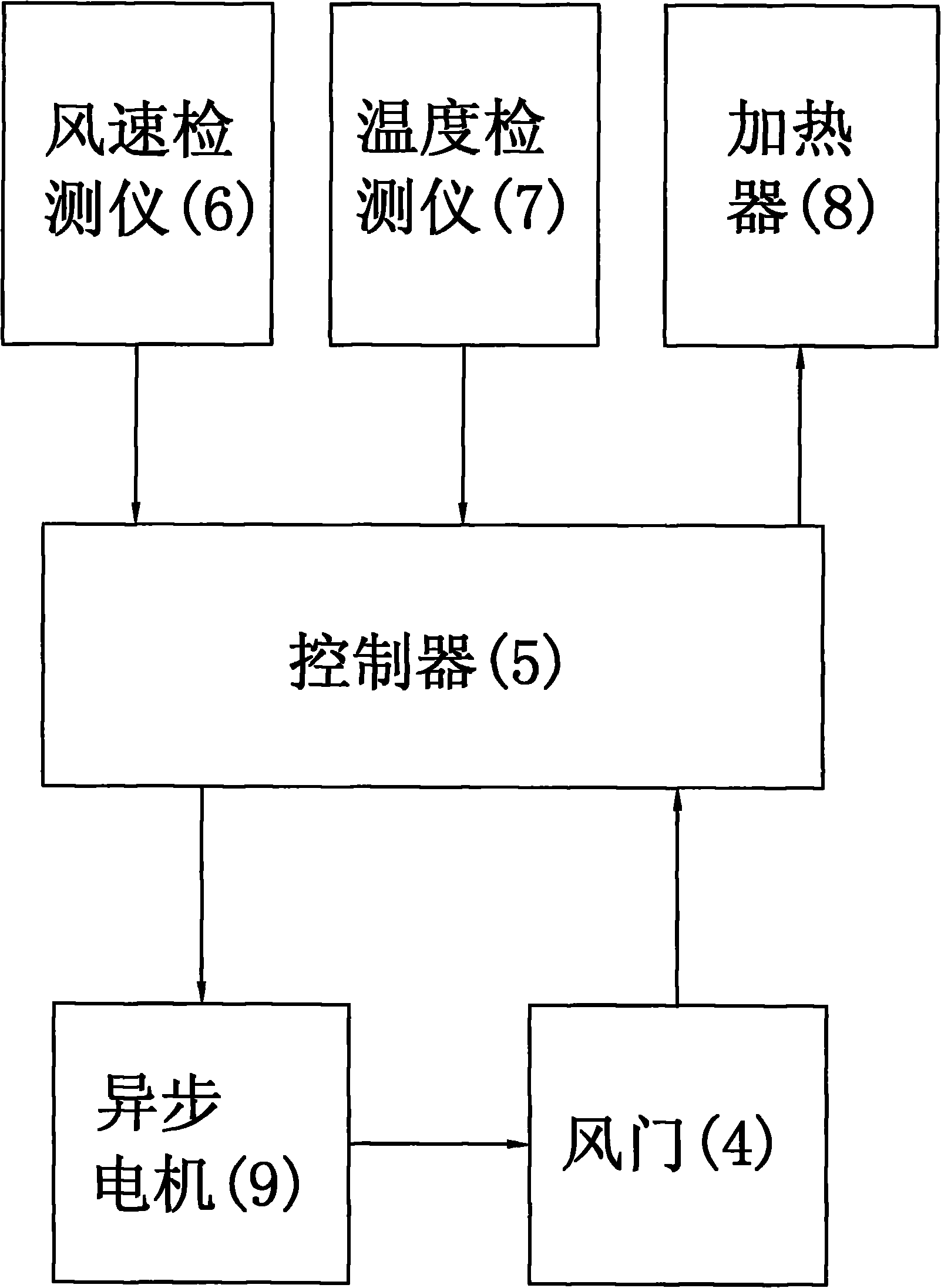

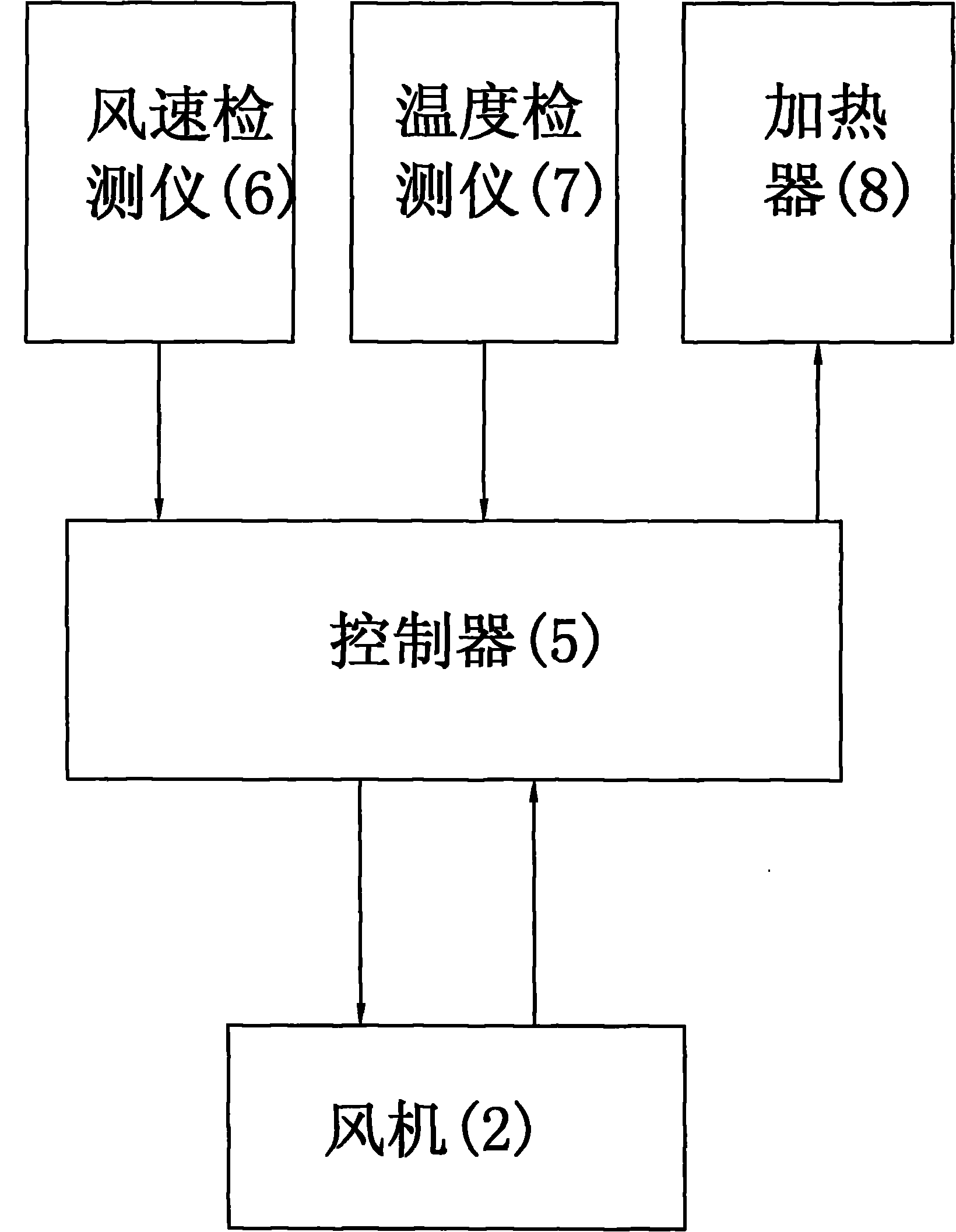

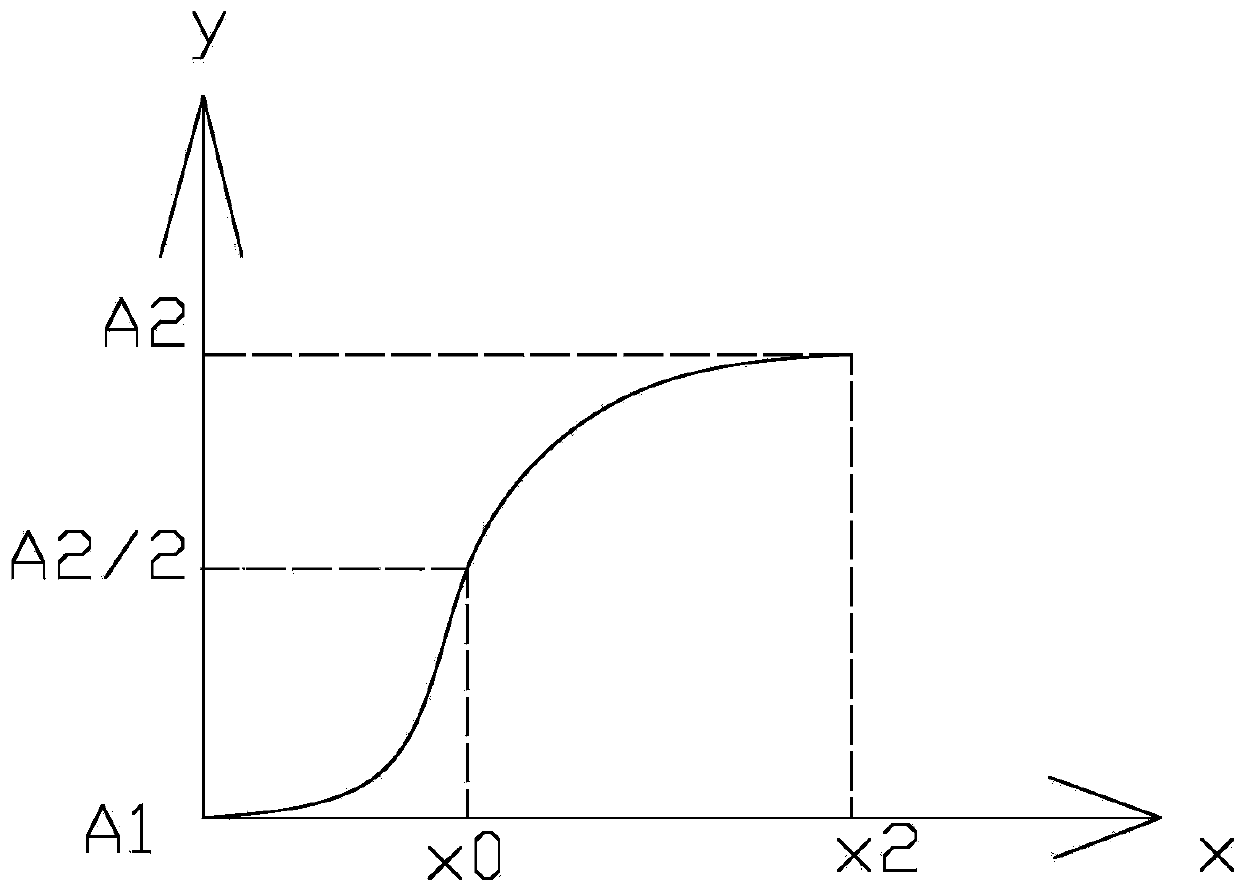

Variable air volume heating method with feedback and device thereof

InactiveCN102072633AEasy heating temperatureGood heating temperatureDrying gas arrangementsVariable air volumeAir volume

The invention discloses a variable air volume heating method with feedback and a device thereof. The variable air volume heating method with feedback is characterized in that comparing the heating temperature and air speed provided practically through a detection device and the heating temperature and air speed required by setting simultaneously; regulating the heating system through a feedback system to achieve the optimum heating temperature; and regulating the air speed through regulating the size of an air gate and / or fan rotation speed. The device implementing the method controls the air gate arranged between the fan and an air pipe through a control system, and regulates the air volume entered into a material bucket through regulating the size of the air gate; or the control system regulates the fan rotation speed to regulate the air volume entered into the material bucket in a unit time, thereby setting the quantity of the air volume entered into the material bucket as required, and reaching the effect of energy conservation and emission reduction.

Owner:黄天宙

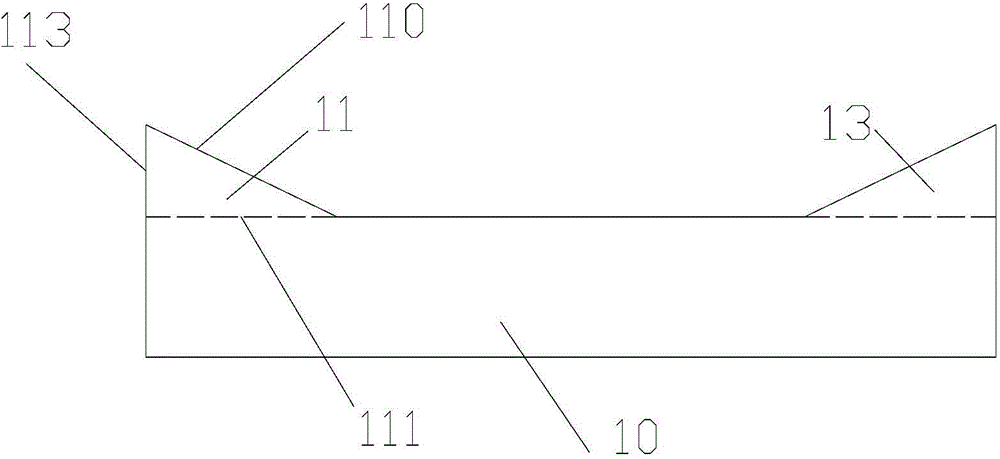

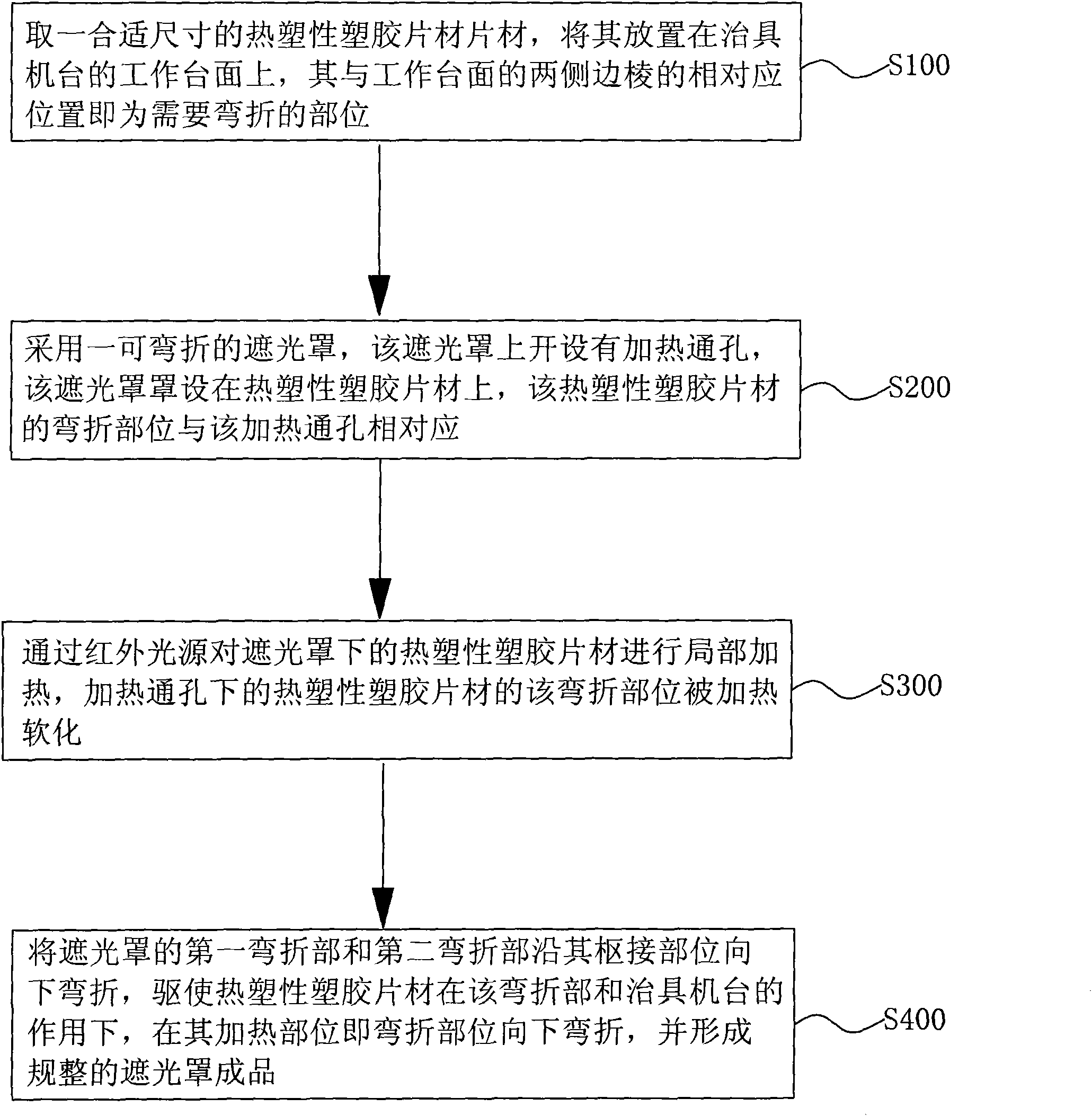

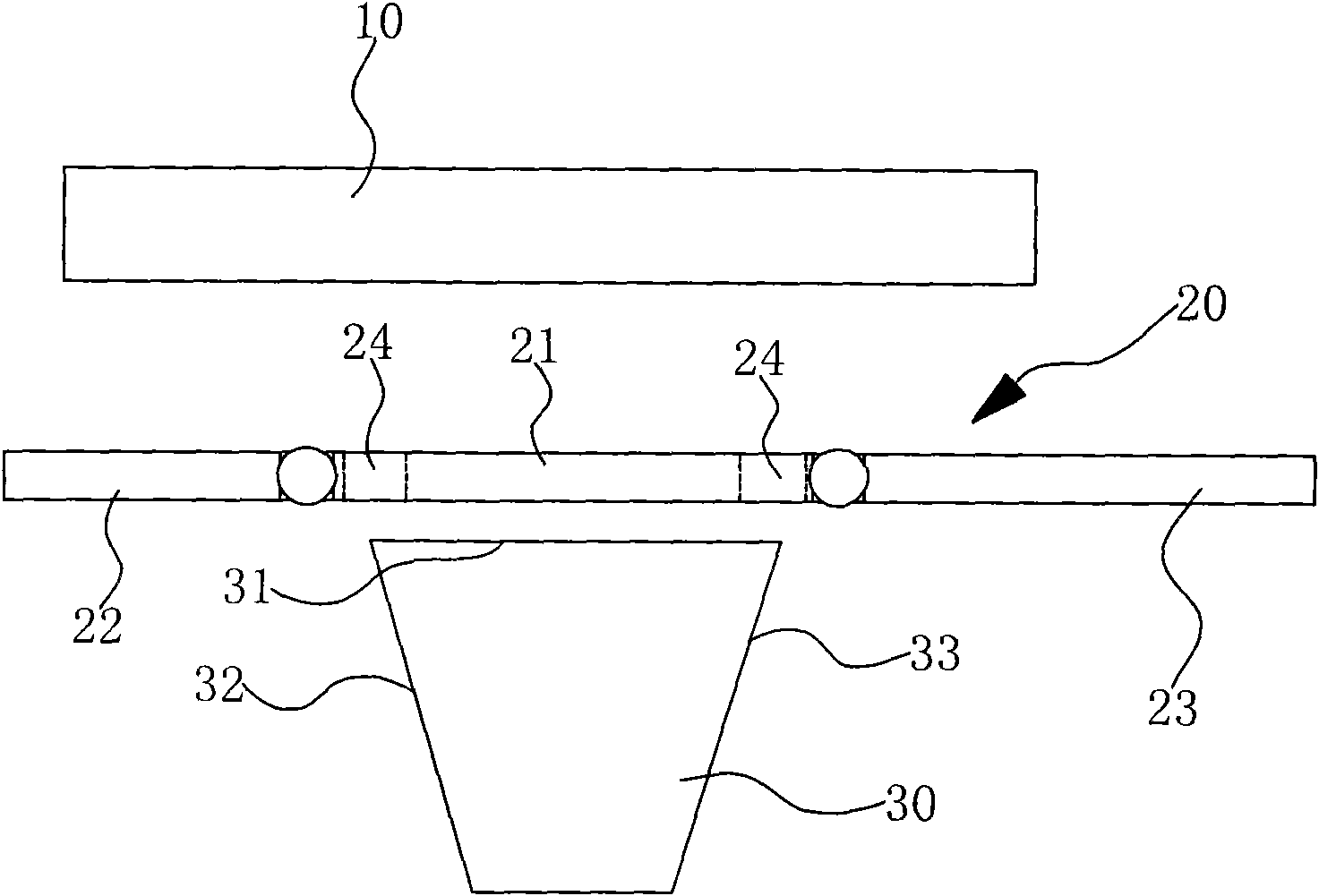

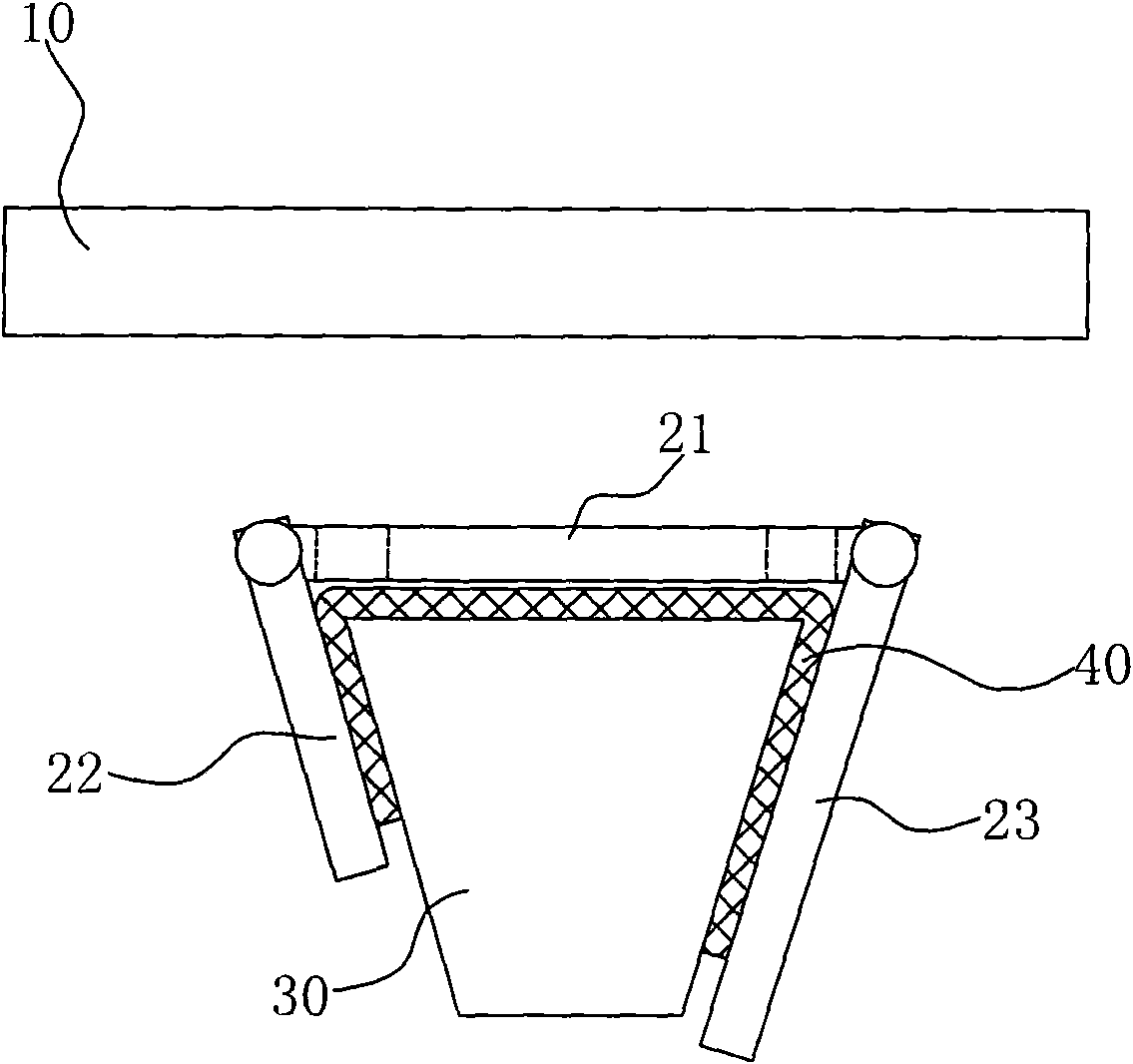

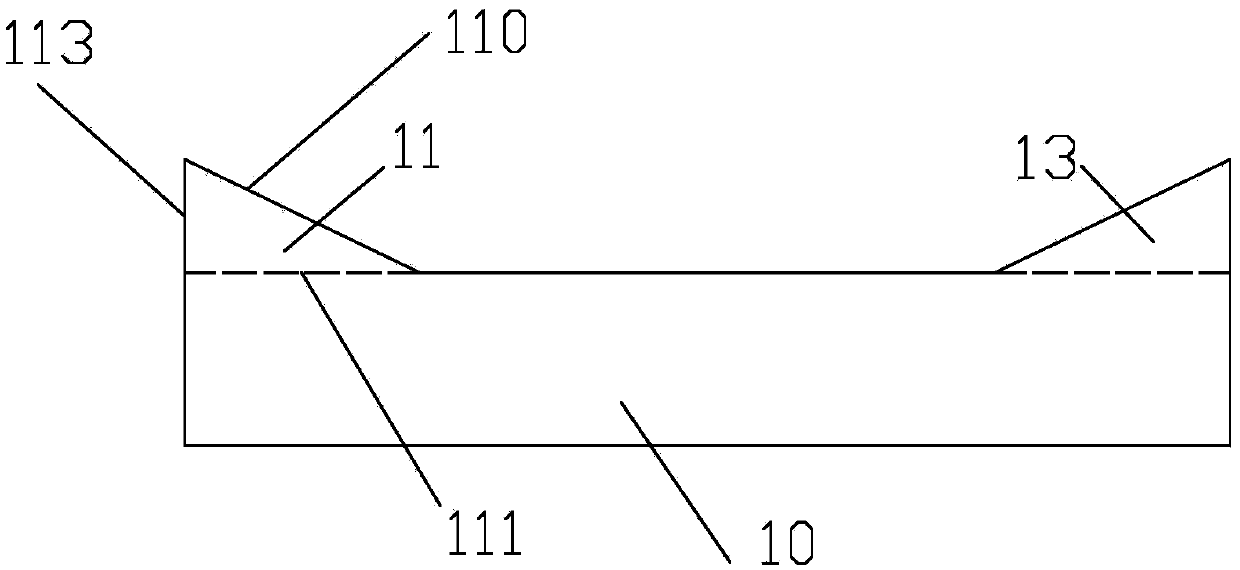

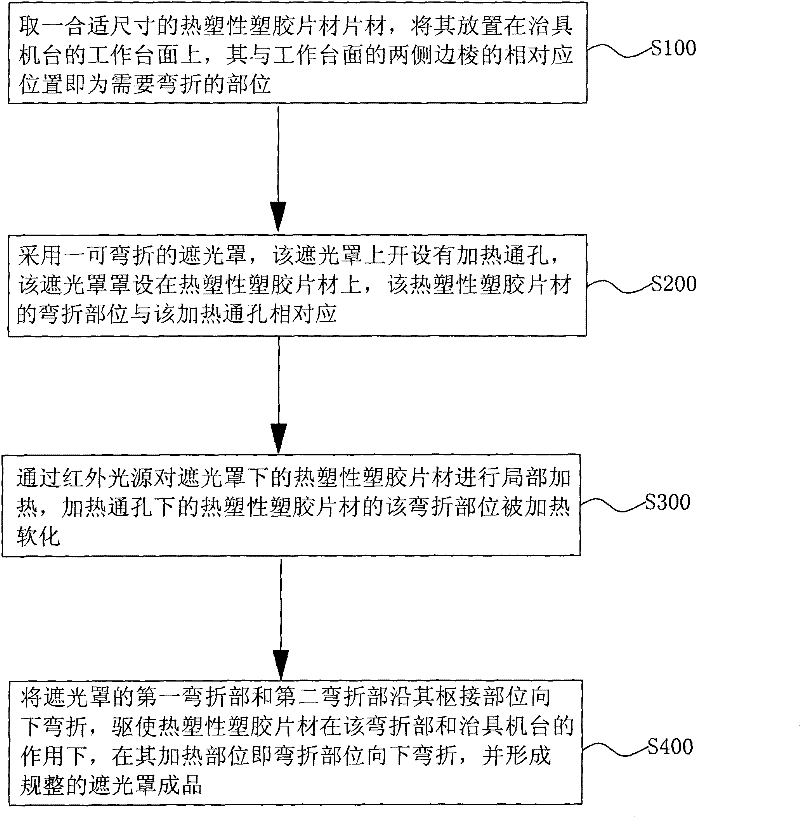

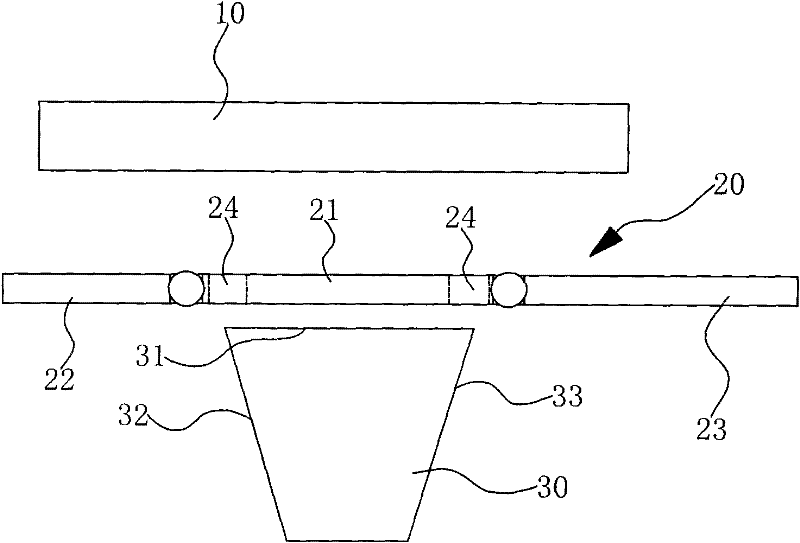

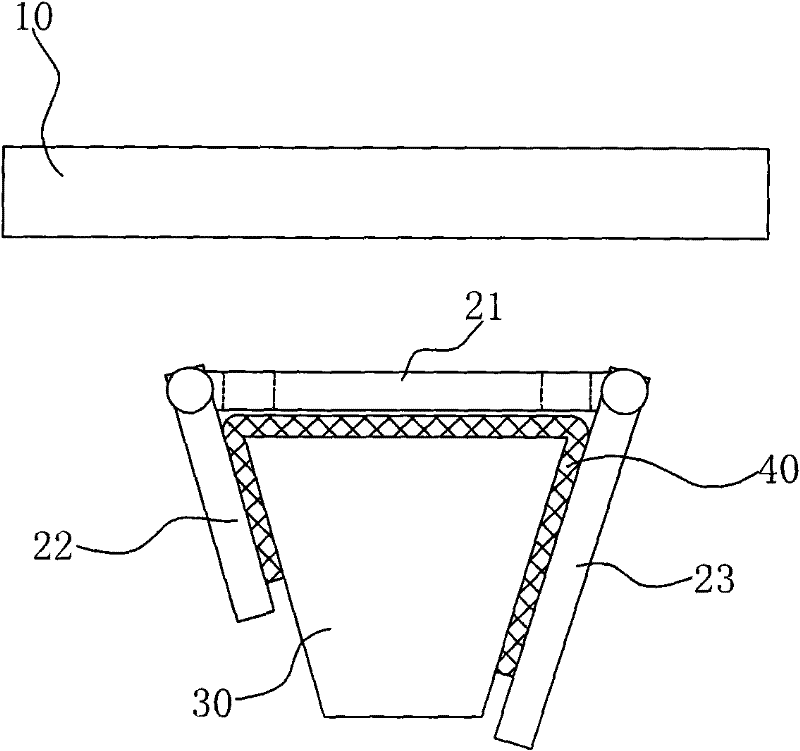

Preparation method and device of reflecting housing of backlight module

InactiveCN101788126AImprove production efficiencyBest mechanical bendingNon-linear opticsReflectorsLens hoodEngineering

The invention relates to preparation method and device of a reflecting housing of a backlight module. The preparation method comprises the following steps of: adopting a bendable sunshade, wherein a heating through hole is arranged on the sunshade, a thermoplastic sheet is placed under the sunshade, and a bending part of the thermoplastic sheet corresponds to the heating through hole; heating and softening the bending part of the thermoplastic sheet positioned at the heating through hole by utilizing light illumination, and bending the sunshade so as to drive the thermoplastic sheet to be bent to form the reflecting housing. The preparation method improves the production efficiency of the reflecting housing, effectively reduces the manufacturing cost of the reflecting housing and realizes high regularity and highly-efficient mechanical manufacturing degree of the reflecting housing. The preparation device realizes the fixed-point softening and the mechanical bending to the bending part of the thermoplastic material by adopting the sunshade, has reasonable design, can effectively shorten the bending and production time and improve the defect that the reflection housing deformation in the preparation process is easy to cause as the surface heating temperature of the thermoplastic material is not controlled appropriately.

Owner:DARWIN PRECISIONS XM

Chiffon cake and preparation method thereof

InactiveCN105994521AIncreased complexityShorten the timeDough treatmentMixing/kneading structural elementsWhole eggEdible oil

The invention relates to a chiffon cake. The chiffon cake is formed by stirring chiffon cake premixed flour, eggs and water, wherein the chiffon cake premixed flour contains the following raw materials: white granulated sugar, wheat flour, wheat starch, an emulsifying agent, baking powder and table salt. A preparation method of the chiffon cake comprises the following steps: adding eggs and water into the chiffon cake premixed flour, uniformly mixing, rapidly mixing for about 5 minutes by adopting a stirring device, then adding edible oil, uniformly stirring, putting into an oven at the temperature of 180 DEG C, and baking for about 45 minutes, so that the chiffon cake with mellow taste can be obtained. Besides, the chiffon cake premixed flour is blended in advance when the chiffon cake is prepared, a powder instant drying technology is adopted after mixing and stirring, moisture of starch can be reduced by 2-4% within 5 seconds, the problems that the baking powder loses efficacy and a product cakes are effectively solved, a whole egg beating method is adopted, the complexity of a chiffon cake separate egg beating method is simplified, the chiffon cake preparation time is shortened, the working efficiency is improved, and the effect of a cake prepared by adopting the separate egg beating method is also realized.

Owner:江苏江南上一道科技股份有限公司

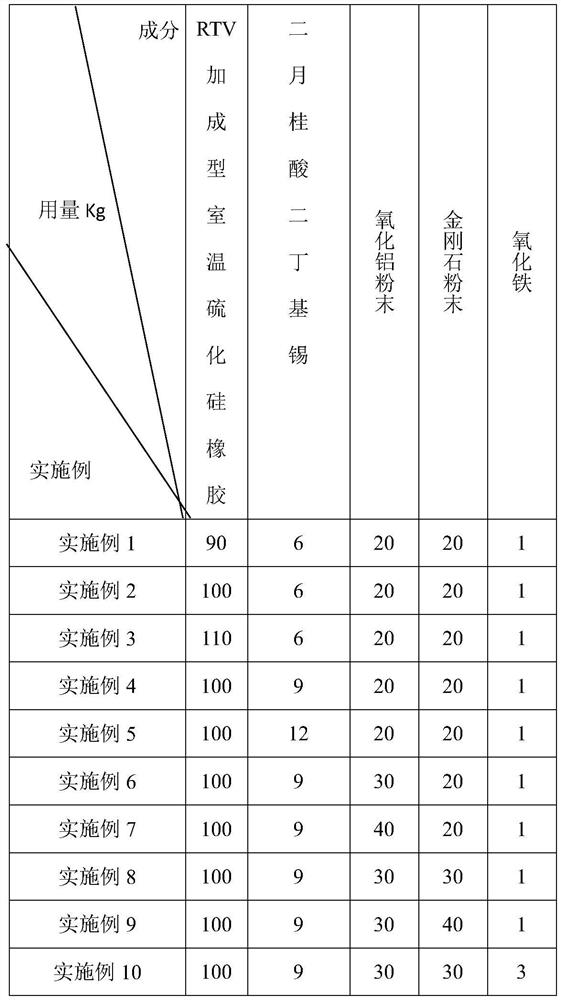

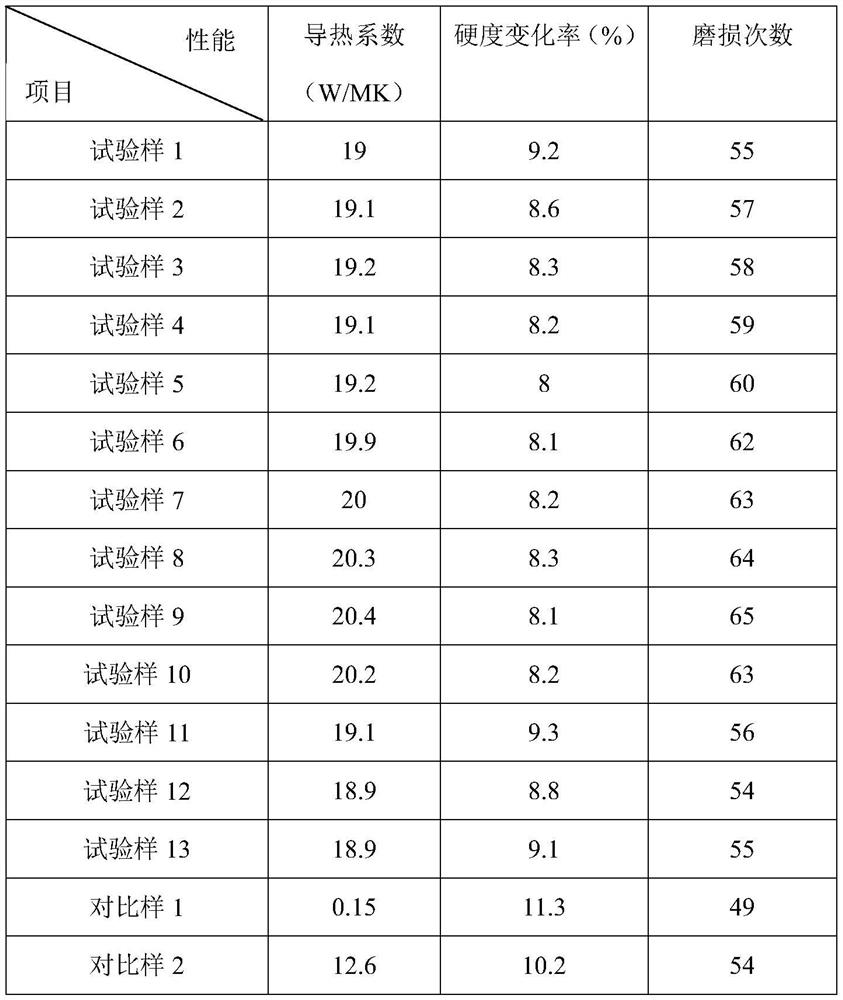

High-thermal-conductivity silica gel embossing roller and preparation method thereof

ActiveCN114211903AEasy to manufactureEasy heating temperatureEmbossing decorationsPolymer scienceSilica gel

The invention relates to the technical field of rubber rollers, and particularly discloses a high-thermal-conductivity silica gel embossing roller and a preparation method thereof. The high-thermal-conductivity silica gel embossing roller sequentially comprises a roller core, a bonding layer and a silica gel layer from inside to outside, the silica gel layer is prepared from the following raw materials: liquid silica gel, a curing agent, a first heat-conducting filler, a second heat-conducting filler and a pigment. The preparation method of the high-thermal-conductivity silica gel embossing roller comprises the following steps: mixing and grinding raw materials of the silica gel layer to prepare composite liquid silica gel; coating the composite liquid silica gel on an original mold with patterns, and curing at room temperature to obtain a silica gel layer; coating a bonding layer on the silica gel layer to obtain a silica gel sleeve; and sleeving the roller core with the silica gel sleeve, and heating to obtain the high-thermal-conductivity silica gel embossing roller. According to the heat-conducting embossing roller, the liquid silica gel and the two heat-conducting materials are compounded, through the synergistic effect of the liquid silica gel, the two heat-conducting materials and the two heat-conducting materials, the heat conductivity of the silica gel embossing roller is improved, and meanwhile the heat-conducting embossing roller has good heat resistance and abrasion resistance.

Owner:SUZHOU RUIGAO NEW MATERIAL CO LTD

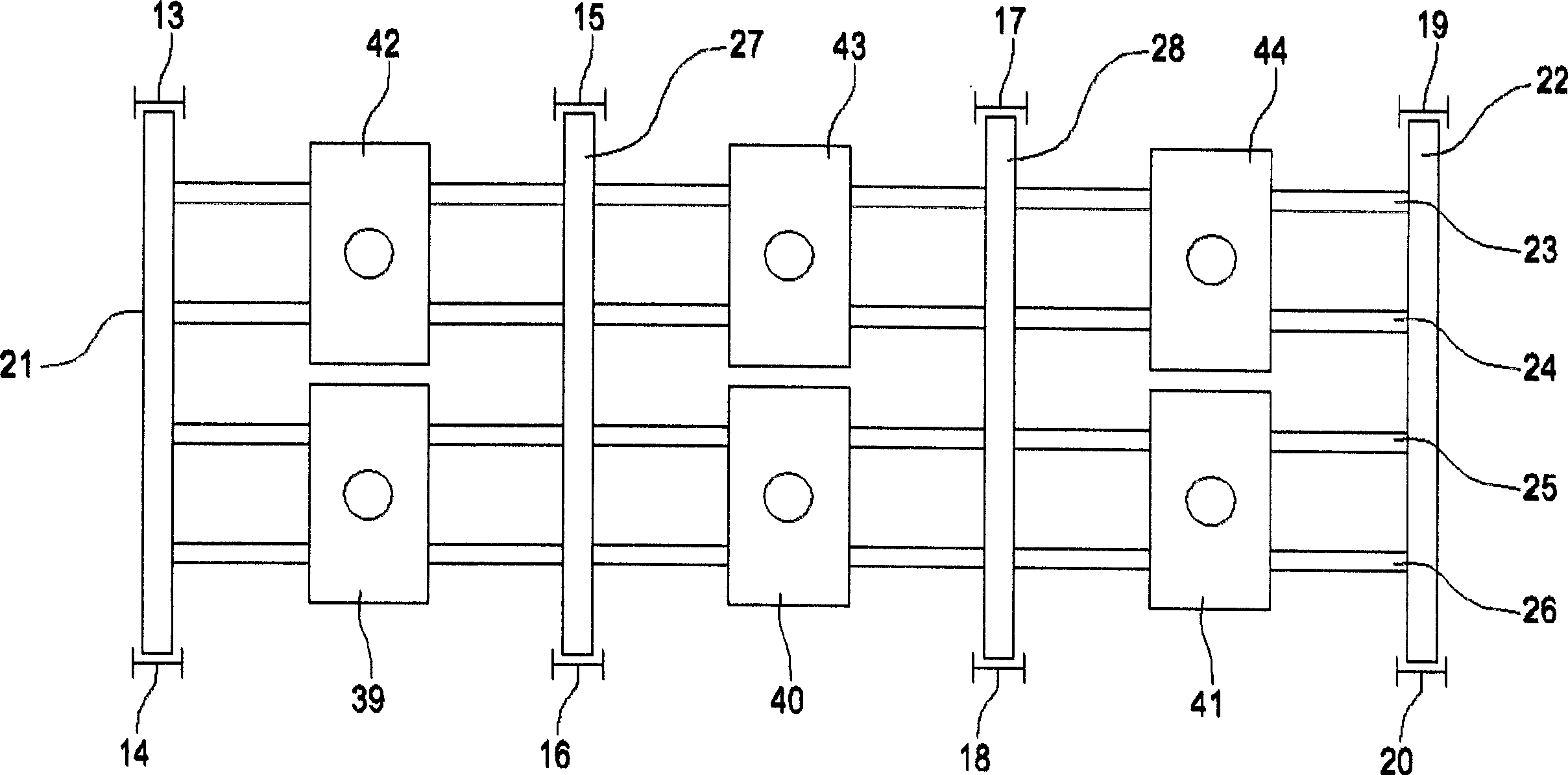

Biomass pyrolysis liquefied technique and apparatus system thereof

InactiveCN100387367CImprove pyrolysis efficiencyWell mixedSolid waste disposalThermodynamicsProcess engineering

The invention relates to a biomass analgesic liquidation method and its twin-tower set system, the processes of which comprise the following steps: sending biomass to pyrolytic reaction tower and blending it with high-heat fluidized gas to subject biomass to pyrolytic cracking; separating thermal cracking gas with carbon residue and ash content in separator; and condensing thermal cracking gas to biological oil in condenser. In the process, heat-carrying agent is exported from pyrolytic reaction tower to recycle in the system along with thermal cracking gas, carbon residue and so on. The invention is special for heat-carrying agent separator to separate heat-carrying agent, carbon residue and other materials and thermal fluid heater to heat separated heat-carrying agent. The invention can not only increase circulation rate in system to ensure uniform and stable temperature field in pyrolytic reaction tower, higher heating rates and shorter detention period of gas phase, but also make use of existing apparatus.

Owner:CHONGQING UNIV

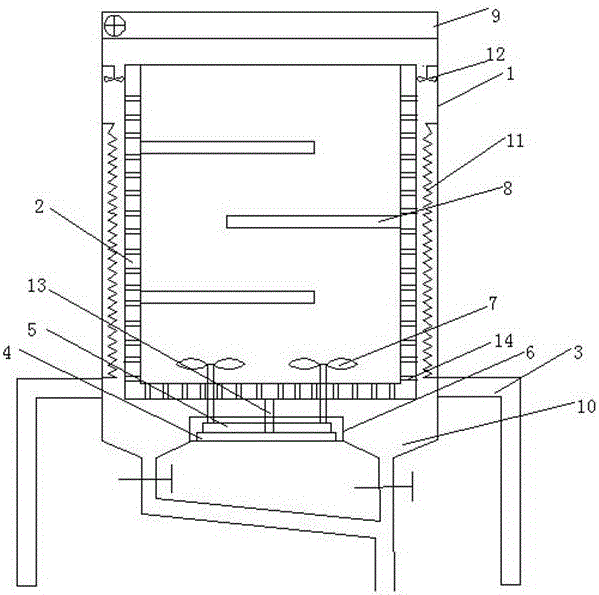

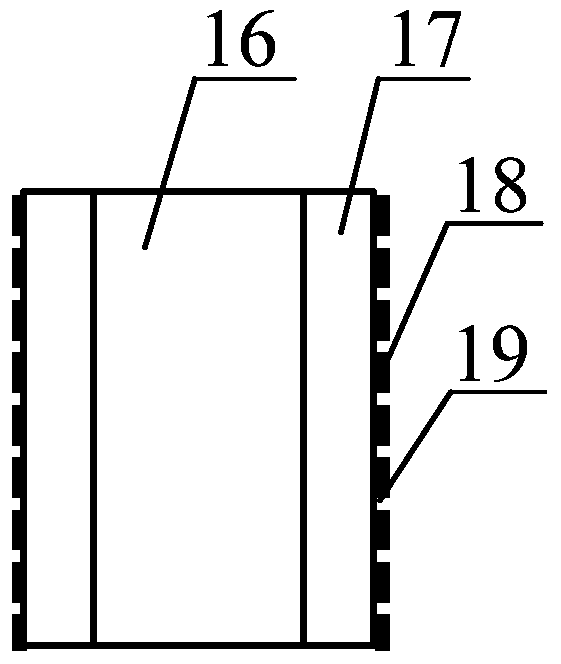

Polyester bottle chip dewatering and drying box

InactiveCN106705620AImprove dehydration rateShorten drying timeDrying gas arrangementsDrying solid materialsPolyesterPulp and paper industry

The invention provides a polyester bottle chip dewatering and drying box. The polyester bottle chip dewatering and drying box comprises a box body, a cylinder, a support, a motor, a transmission case, a protective hood, stirrers and baffles. Draining pipelines are arranged below the two sides of the box body. Electric heating wires are arranged on the middle portions of the inner walls of the two sides of the box body. Fans facing downwards are arranged on the upper portions of the inner walls of the two sides of the box body. The motor is fixedly arranged at the bottom of the box body. The upper portion of the motor is connected with the transmission box. The protective hood is arranged outside the motor and the transmission box. One end of each stirrer is connected with the transmission box, and the other end of each stirrer penetrates through the protective hood and the bottom of the cylinder to stretch into the cylinder. The bottom of the cylinder is connected with an output shaft of the motor through a supporting rod. The inner wall of the cylinder is provided with water outlets leading to the box body, and the baffles. By adoption of the polyester bottle chip dewatering and drying box, the synchronous centrifugal dewatering function and the heating drying function can be achieved, the polyester bottle chip dewatering rate is higher, the drying time is short, and the heating temperature is more uniform; and the polyester bottle chip dewatering and drying box is simple in structure, convenient to operate, reasonable in design and wide in application range and has broad application prospects.

Owner:盐城市华普轻纺机械有限公司

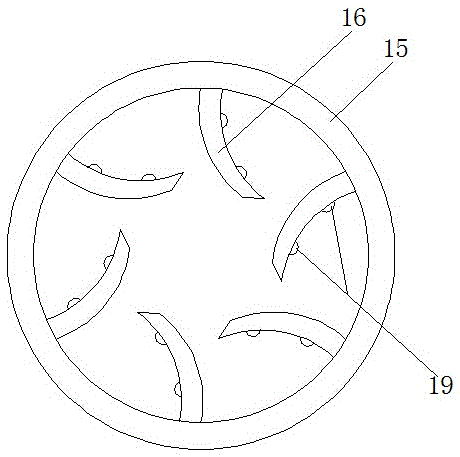

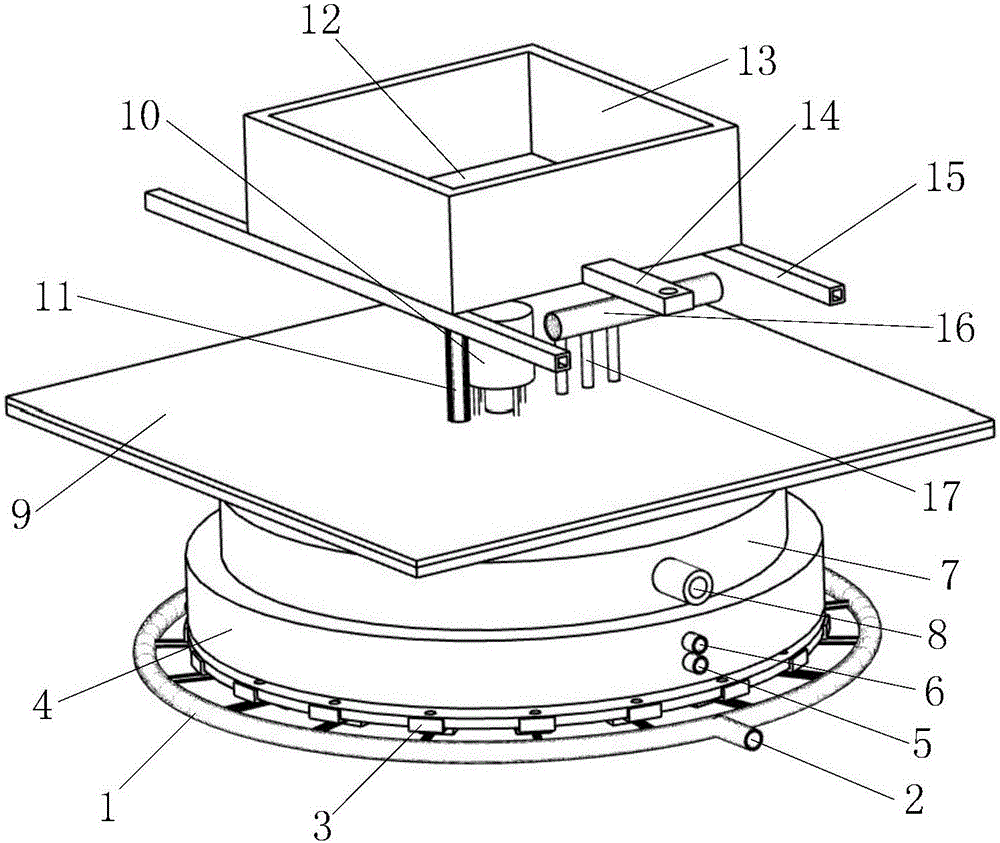

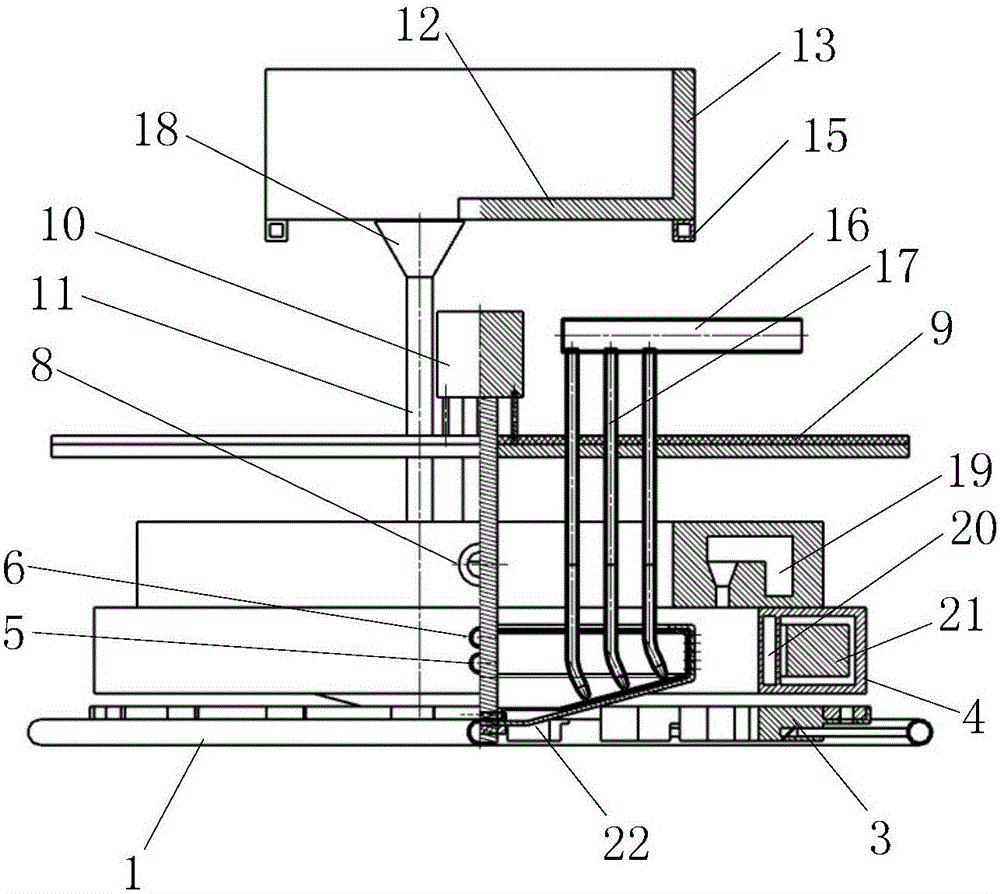

Flame heating and non-tobacco burning type smoking device

ActiveCN104585885AEvenly heatedAvoid unpleasant smellsTobacco devicesTobacco productEnergy consumption

The invention discloses a flame heating and non-tobacco burning type smoking device. The flame heating and non-tobacco burning type smoking device is characterized by comprising a casing and a heating bin body, wherein the interior of the casing is provided with a cavity, the interior of the heating cabin body is provided with a cavity, the heating bin body is detachably connected with the bottom part of the casing, a filtering nozzle is arranged at the top end of the casing, an air flow passage is arranged in the casing and is used for communicating the heating bin body and the filtering nozzle in a sealing way, a tobacco carrier and a flame heating device are arranged in the heating bin body, the tobacco carrier is used for carrying tobacco, the flame heating device is used for heating the tobacco, and an air inlet hole is formed in the heating bin body and is communicated with the internal cavity of the heating bin body. The flame heating and non-tobacco burning type smoking device has the advantages that the structure is simple, and the cost is low; a tobacco product is heated by a flame sprayer, the energy consumption is low, the heating carrier is tobacco filling material, and a food foil layer is arranged on a sleeve, so the tobacco filling material can be uniformly heated, the unpleasant odor of the tobacco filling material caused by sudden overhigh temperature of the heat exchanger is avoided, and the device is suitable for being popularized and applied.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

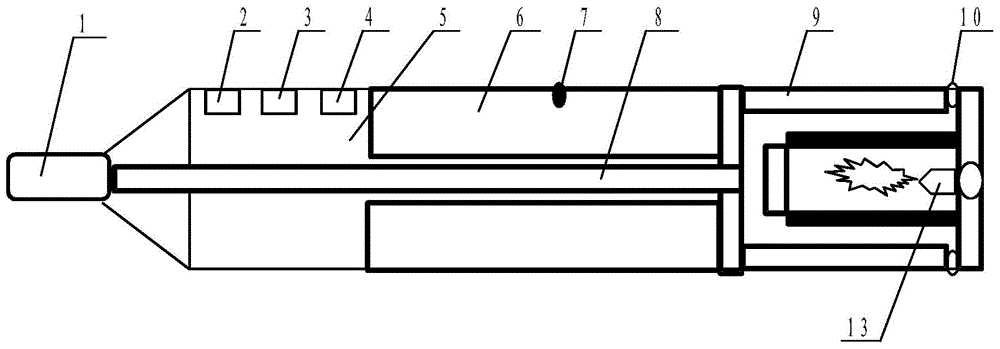

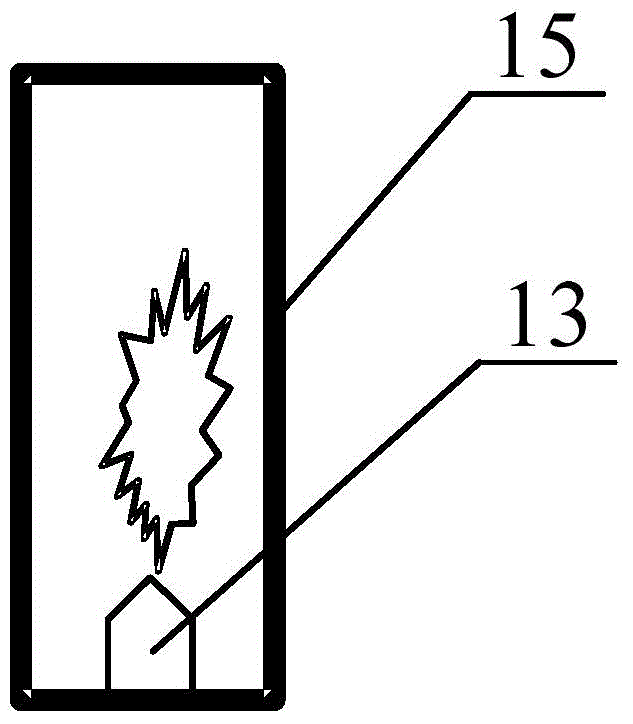

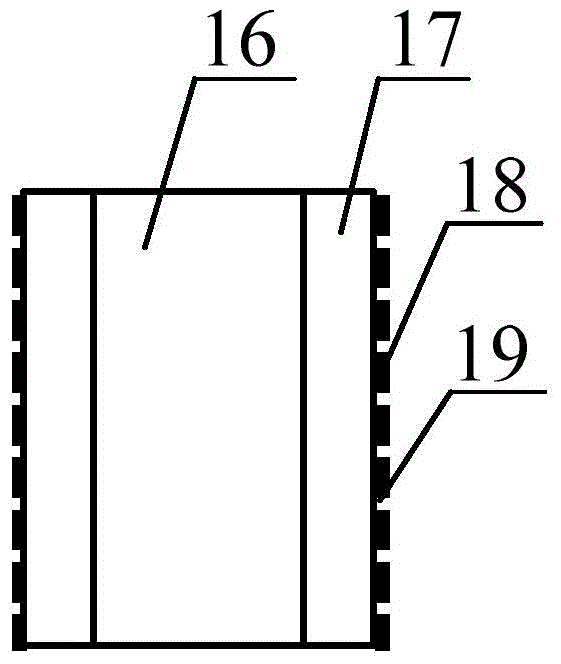

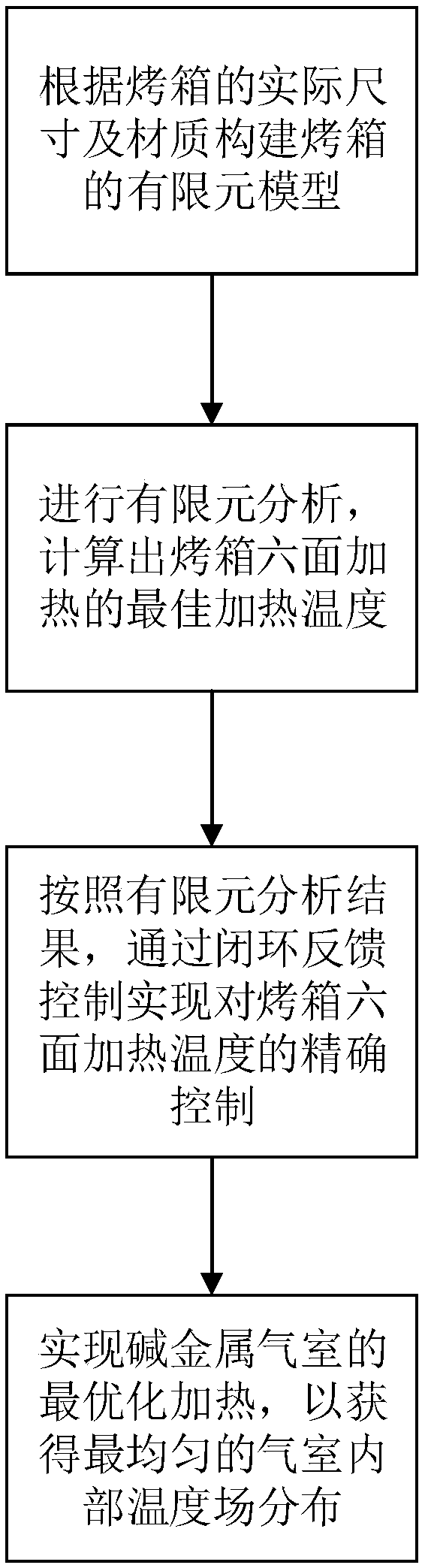

Non-uniform heating method for alkali metal gas chamber based on finite element analysis

InactiveCN109297304AUniform distribution of temperature fieldEasy heating temperatureFurnace typesElectric heating for furnacesAtmospheric airElement analysis

The invention relates to a non-uniform heating method for an alkali metal gas chamber based on finite element analysis. According to the characteristic that the alkali metal gas chamber is unsymmetrical in structure, a finite element analysis method is adopted to calculate the optimum heating temperature of a heating membrane adhered to the outer surface of an oven, and the inner temperature fielddistribution of the alkali metal gas chamber is uniform by applying the heating condition, so that more uniform atomicity density distribution is obtained. According to the method, the uniformity ofthe inner temperature field distribution of the alkali metal gas chamber under the measurement conditions of multiple positions of an atmospheric air chamber can be greatly improved, so that the uniformity in detecting a detection signal is improved. Compared with a hot air heating method, according to the method provided by the invention, the heating efficiency can be greatly improved; and compared with a traditional electrical heating manner, the method provided by the invention can achieve a heating effect with more uniform temperature filed distribution. The heating method can provide a reference for the application of atom magnetometers for measurement of the multiple positions of the atmospheric air chamber in the measurement field of biological magnetic fields.

Owner:BEIHANG UNIV

A suction device for heating non-burning tobacco with charcoal

The invention discloses a suction device for heating non-burning tobacco with charcoal, which is characterized in that it comprises a shell with a cavity inside and a heating chamber with a cavity inside, and the heating chamber is detachably connected to the shell Bottom; the top of the housing is provided with a filter tip, and the inside of the housing is provided with an airflow channel that is airtightly connected to the heating chamber and the filter; the interior of the heating chamber is provided with a tobacco carrier loaded with tobacco and a charcoal heating device for heating tobacco device, the heating chamber body is provided with an air intake hole communicating with the inner cavity of the heating chamber body. In the present invention, the carbon rod is arranged inside the heat exchanger. After the carbon rod is ignited by the igniter, the carbon rod burns to generate heat. The heat is transferred to the sleeve through the heat exchanger and heats the tobacco product, thereby avoiding the direct heating of the carbon heat source that will cause The problem of unpleasant smell and excessive CO release from charcoal combustion is therefore suitable for generalized use.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Heat compensation device and method of glass wool centrifugal machine

ActiveCN105819681ASimple structureImprove the heating effectGlass fibre drawing apparatusCombustion chamberCompensation effect

The invention discloses a heat compensation device of a glass wool centrifugal machine. The heat compensation device comprises a high-pressure gas pipeline and a fuel gas pipeline. The upper portion of the high-pressure gas pipeline is connected with a gas flow cut-off device, a cooling water trough and an electromagnetic heating coil are arranged on the inner side of a power frequency heating device, a mixed combustion chamber is arranged on the upper portion of the power frequency heating device, and the lower side of the fuel gas pipeline is connected with multiple sets of auxiliary combustors. The invention further discloses a heat compensation method of the glass wool centrifugal machine. The heat compensation method comprises the following steps that firstly, equipment is started, and parameters are collected; secondly, heat compensation treatment is carried out. The equipment can be heated or cooled according to the practical situations, and the heat compensation method is more scientific, more reasonable, and good in heat compensation effect.

Owner:HUBEI JIA FU DA ENERGY SAVING TECH CO LTD

Medium manganese steel and preparation method thereof

The invention discloses medium manganese steel. The medium manganese steel comprises the following components in percentage by weight: 0.9 to 1.1 percent of carbon (C), 6 to 8 percent of manganese (Mn), 0.3 to 0.6 percent of silicon (Si), 1.0 to 1.2 percent of chromium (Cr), 0.2 to 0.4 percent of percent (MO), less than or equal to 0.04 percent of phosphorus (P), less than or equal to 0.04 percent of sulphur (S), and the balance of Fe. A preparation method comprises the following steps of: selecting raw materials; smelting, and yielding water after ensuring that the components are qualified, wherein the water yielding temperature is controlled at 1,650 DEG C, and casting; molding, coating after molding, assembling molds and casting; removing sand: cleaning cast burrs, and performing polishing inspection; preserving the heat, stacking casts with sand cleaned in a high-temperature heat treatment furnace, sealing a furnace door, raising the temperature, preserving the heat after the temperature is raised to 1,100 DEG C, preserving the heat for 6 hours, quickly discharging the casts, and putting the casts into water for quenching; and cleaning surfaces again, and inspecting, accepting, warehousing, stacking, classifying and warehousing products. The medium manganese steel has the advantages of ensuring high impact resistance and abrasion resistance of manganese steel; having a simple production process, low production cost and a good market prospect.

Owner:TONGLING ANDONG CAST STEEL

Rolling process method of ultra-thin and ultra-wide steel plate

ActiveCN104148384BAvoid bad deformationEasy heating temperatureTemperature control deviceProfile control deviceReduction rateSheet steel

The invention provides a rolling technology method for an ultra-thin ultra-wide steel plate. The rolling technology method for the ultra-thin ultra-wide steel plate comprises the steps that the soaking temperature of a steel pushing type heating furnace is controlled to range from 1200 DEG C to 1250 DEG C, it is guaranteed that time of a soaking zone is longer than or equal to 60 minutes, and the head and tail temperature difference of a billet is smaller than or equal to 30 DEG C; dog bone rolling is adopted in a rough rolling forming stage and the last pass of a broadening stage; supporting rolls are of a flat roll type and has chamfers in the edges, and the lower roll diameter of a working roll is 2 mm to 5 mm larger than the upper roll diameter of the working roll; the deference of the manipulator centering degree is no larger than 10 mm; the rolling pass of a rough mill is controlled according to the eighth pass to the tenth pass, fine rolling is carried out according to the sixth pass to the eighth pass, reduction of the last three passes is gradually decreased, and the reduction rate of the last three passes is controlled to be 10 % to 15%; two eleven-roll straighteners are used for straightening. According to the rolling technology method for the ultra-thin ultra-wide steel plate, a 2800-mm mill can be used for producing the steel plate with the thickness smaller than 10 mm and the width larger than 2600 mm.

Owner:LIUZHOU IRON & STEEL

Preparation method and device of reflecting housing of backlight module

InactiveCN101788126BImprove production efficiencyBest mechanical bendingNon-linear opticsReflectorsLens hoodEngineering

The invention relates to preparation method and device of a reflecting housing of a backlight module. The preparation method comprises the following steps of: adopting a bendable sunshade, wherein a heating through hole is arranged on the sunshade, a thermoplastic sheet is placed under the sunshade, and a bending part of the thermoplastic sheet corresponds to the heating through hole; heating andsoftening the bending part of the thermoplastic sheet positioned at the heating through hole by utilizing light illumination, and bending the sunshade so as to drive the thermoplastic sheet to be bent to form the reflecting housing. The preparation method improves the production efficiency of the reflecting housing, effectively reduces the manufacturing cost of the reflecting housing and realizeshigh regularity and highly-efficient mechanical manufacturing degree of the reflecting housing. The preparation device realizes the fixed-point softening and the mechanical bending to the bending part of the thermoplastic material by adopting the sunshade, has reasonable design, can effectively shorten the bending and production time and improve the defect that the reflection housing deformation in the preparation process is easy to cause as the surface heating temperature of the thermoplastic material is not controlled appropriately.

Owner:DARWIN PRECISIONS XM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com