Microwave themal compression machine bench

A thermal compressor, microwave technology, used in punching machines, presses, furnace types, etc., can solve problems such as deformation, moisture content deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The microwave thermal compressor table is described in detail below according to an implementation case of the present invention:

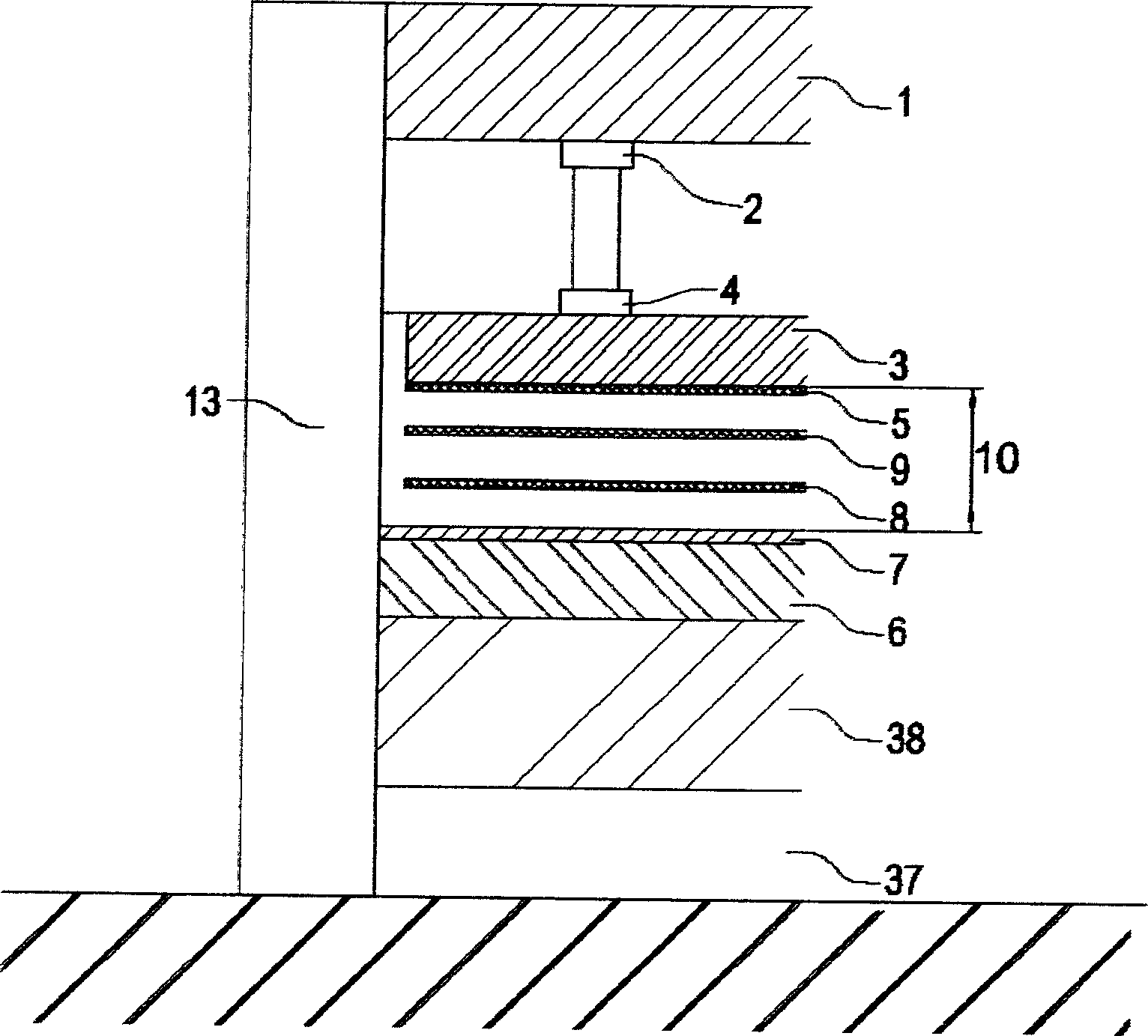

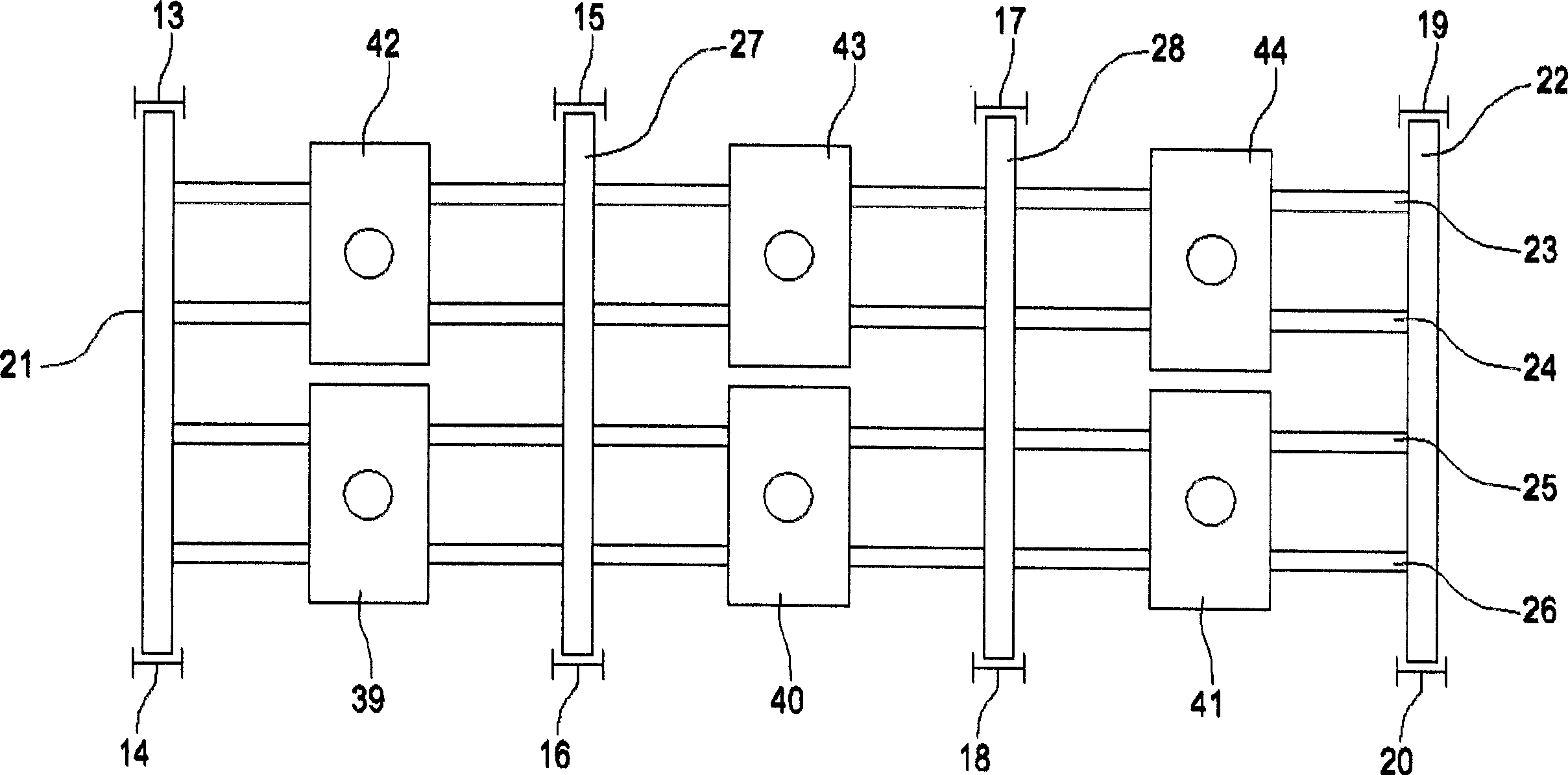

[0060] For the convenience of description, the description of the implementation of the present invention focuses on the fixed lower plate, and the upper plate moves up and down to expand and compress. It has a structure of multi-layer laminated plates, and the pressed object enters and exits from the longitudinal side, and the irradiation part is arranged inside the lower plate. A typical microwave thermal compressor table.

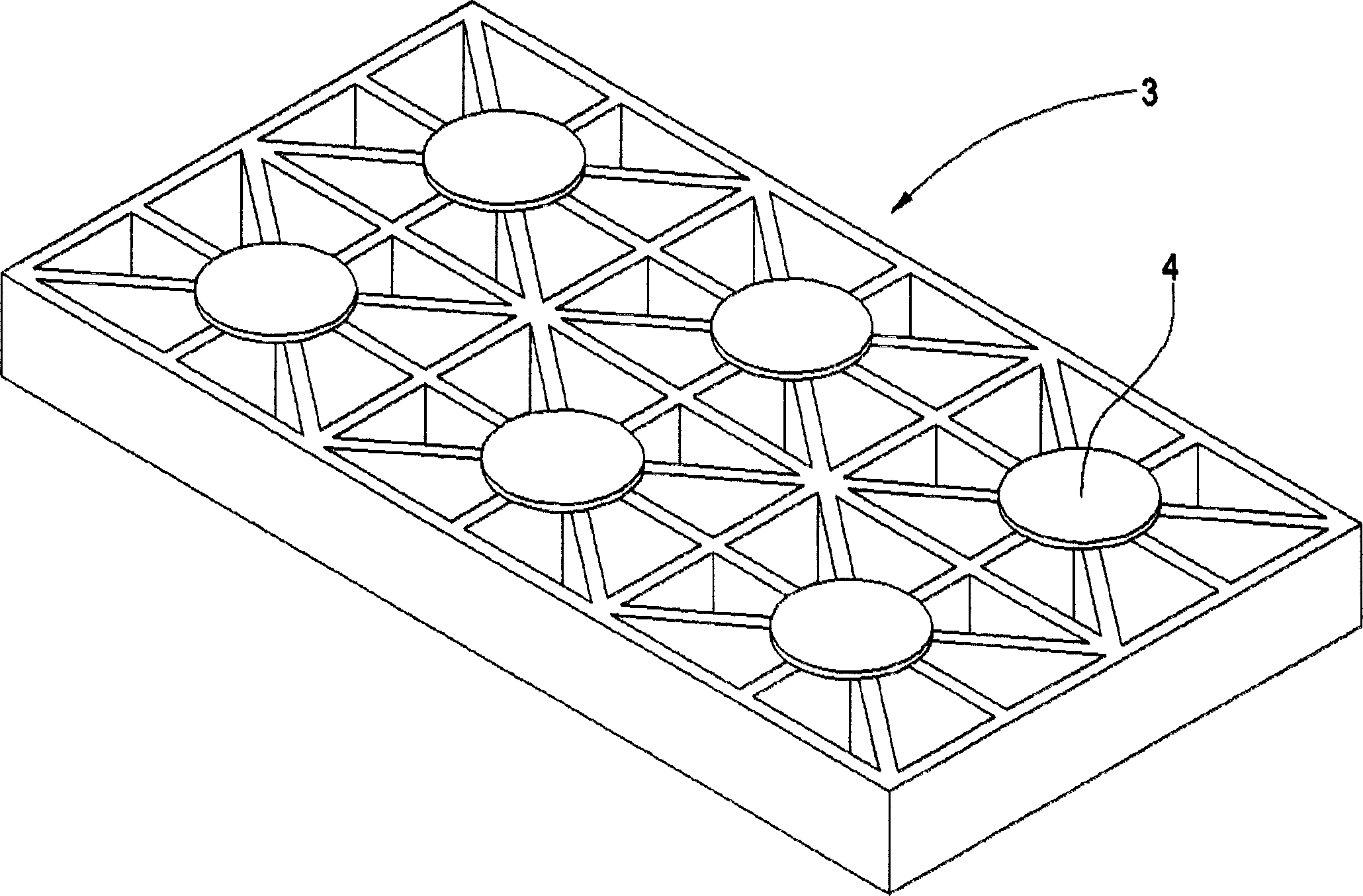

[0061] see Figure 1 to Figure 6 , the compression driving part is composed of six 154.5 metric-ton hydraulic cylinders with a cylinder diameter of 250mm, a plug rod diameter of 180mm, a stroke distance of 360mm, and a pressure of 31.5MPa, which are arranged at the lower end of the upper part 1 of the outer frame. , with a thickness of 30mm marked as a square steel plate 2, and the figure 1 and image 3 Between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com