Coal-fired flue gas mercury homogeneous/heterogeneous reaction form transformation mechanism device and method for detecting form of mercury by using same

A coal-fired flue gas and speciation technology, which is applied in the field of analysis of the influence of coal-fired flue gas components on the oxidation of Hg speciation, can solve problems such as deviation, inability to reflect the contact mode of fly ash and flue gas, and inability to conduct comparative studies of homogeneous reactions. To achieve the effect of avoiding adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

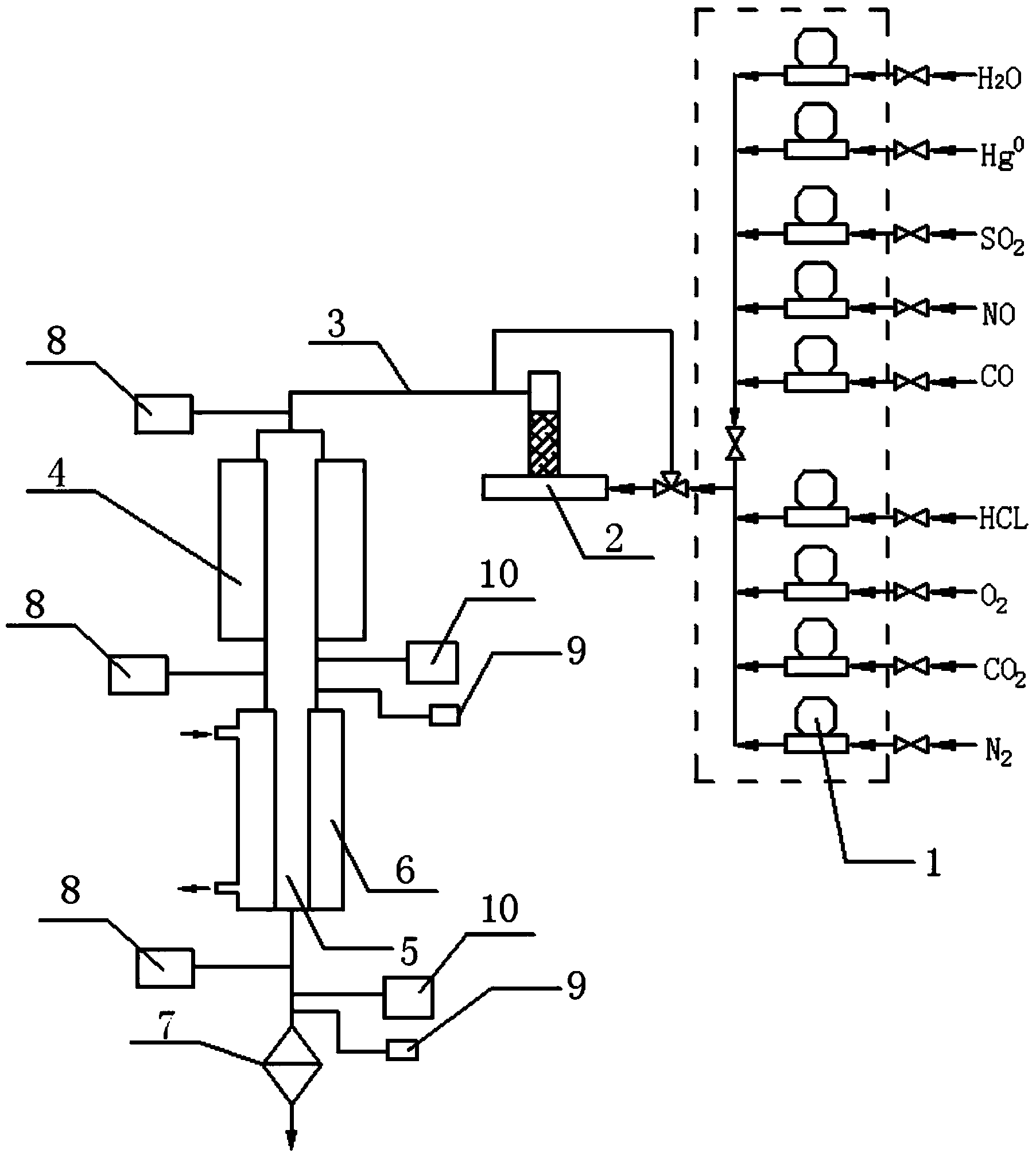

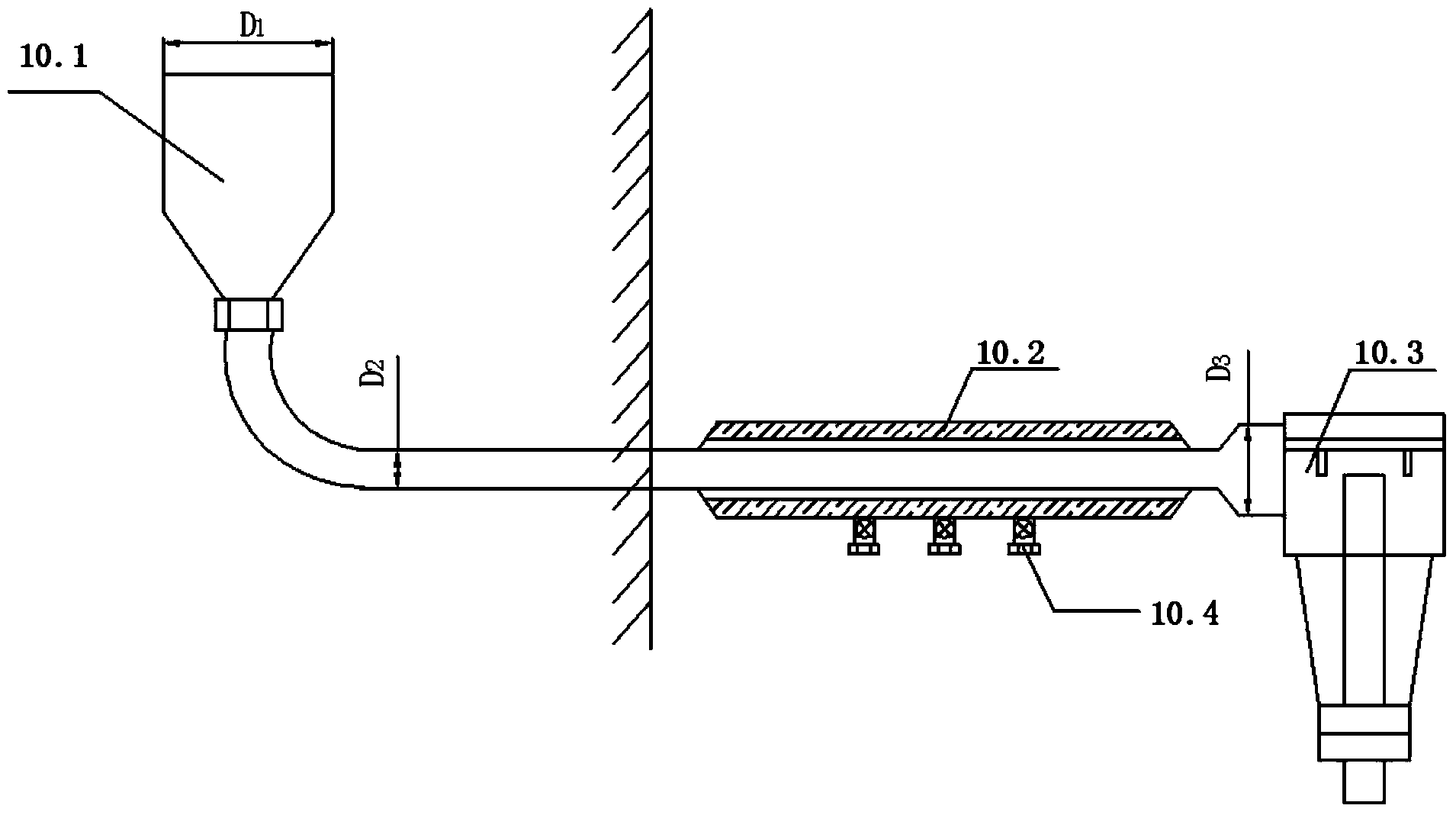

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Heterogeneous reaction (reaction in which both gaseous mercury and particulate mercury exist simultaneously)—combustion experiment of pulverized coal

[0051] 1. The main control parameters during the experiment include: experiment setting and T3 temperature control setting. details as follows

[0052] 1.1. The setting values are shown in Table 1.

[0053] Table 1 Experimental condition settings

[0054]

[0055]

[0056] 1.2. T3 temperature is controlled at 200°C

[0057] 2. The experimental results of mercury speciation analysis are shown in Table 2:

[0058] Table 2 Form content of mercury sampling port

[0059] Sampling port location

[0060] Note: Hg p That is particulate mercury.

Embodiment 2

[0061] Example 2 Heterogeneous Reaction—Simulation of Ash Containing Flue Gas

[0062] 1. The main control parameters during the experiment include: simulated flue gas settings and T1, T2, T3 temperature settings. details as follows

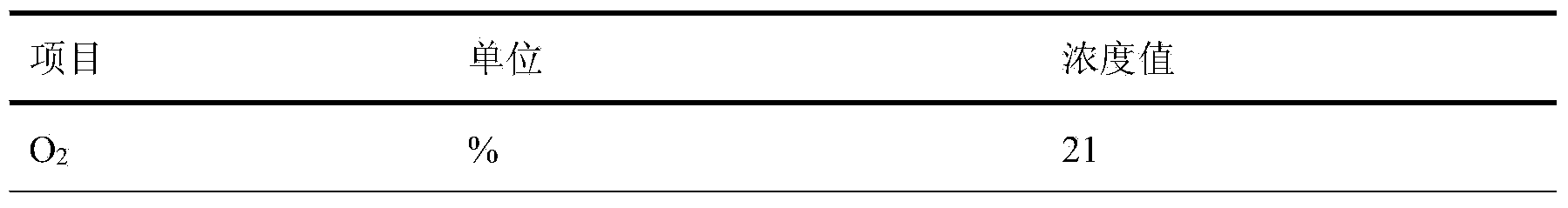

[0063] 1.1. The set value of simulated flue gas concentration is shown in Table 3.

[0064] Table 3 simulated flue gas concentration setting value

[0065]

[0066] 1.2, T1, T2, T3 temperature is controlled at 150°C, 500°C and 200°C respectively

[0067] 2. The experimental results of mercury speciation analysis are shown in Table 4

[0068] Table 4 Form content of mercury sampling port

[0069] Sampling port location

Embodiment 3

[0070] Example 3 Homogeneous reaction (all gaseous mercury) - ashless simulated flue gas

[0071] 1. The main control parameters during the experiment include: simulated flue gas settings and T1, T2, T3 temperature settings. details as follows

[0072] 1.1. The set value of simulated flue gas concentration is shown in Table 5.

[0073] Table 5 simulated flue gas concentration setting value

[0074]

[0075] 1.2, T1, T2, T3 temperatures are controlled at 150°C, 500°C and 200°C respectively;

[0076] 2. The experimental results of mercury speciation analysis are shown in Table 6:

[0077] Table 6 Form content of mercury sampling port

[0078] Sampling port location

[0079] Mercury sampling port 1

[0080] From the above detection results, it can be seen that the detection device and method of the present invention can completely simulate the transformation process of coal-fired flue gas Hg uniformity and heterogeneous reaction form, solve the unfavora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com