Biomass pyrolysis liquefied technique and apparatus system thereof

A technology of biomass pyrolysis and process method, which is applied in the field of biomass regeneration and energy utilization, which can solve the problems of low pyrolysis rate and achieve the effects of shortened gas phase residence time, uniform and stable temperature field, and increased heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

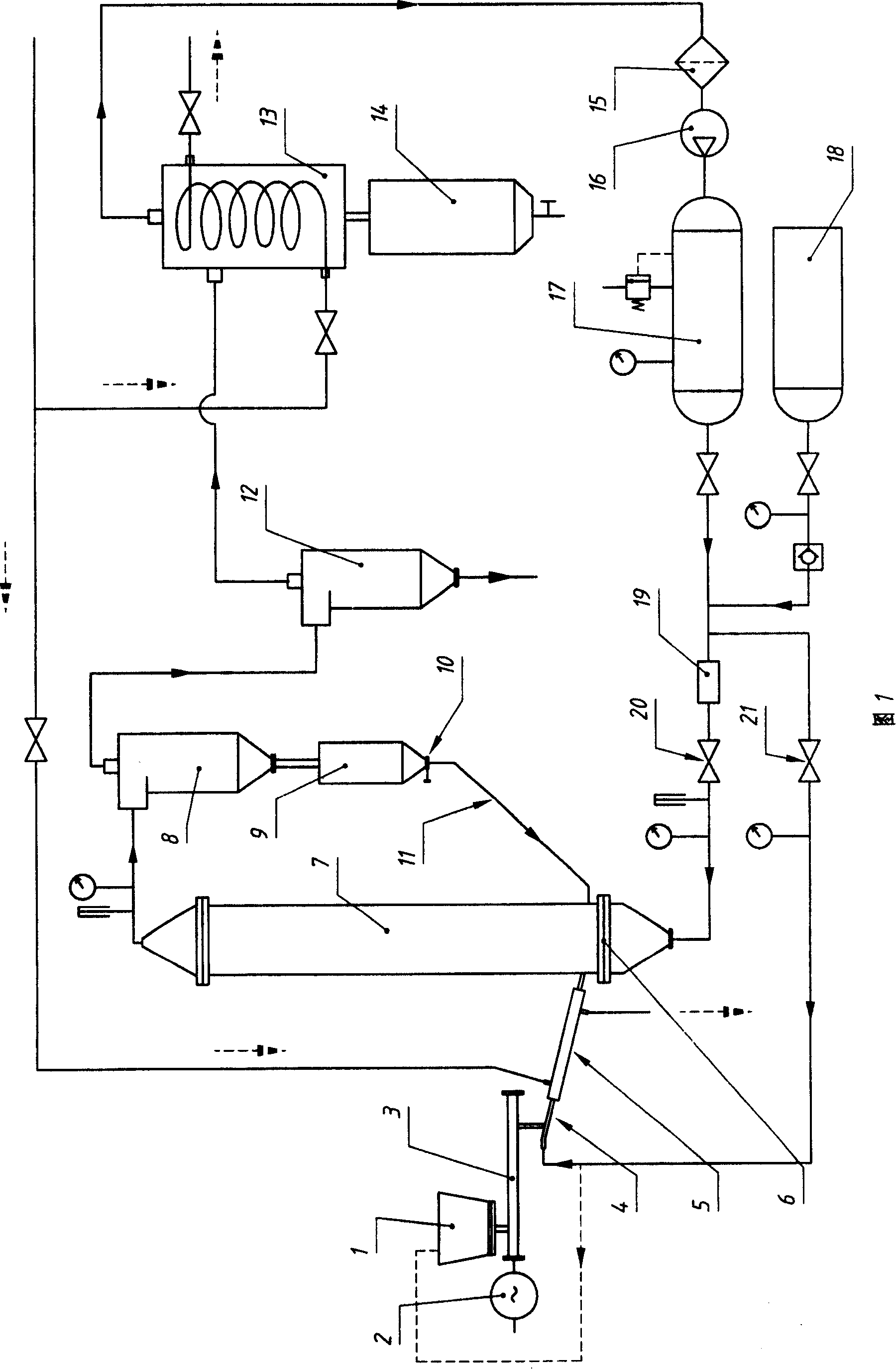

[0036] This example is based on the general description, and is aimed at the further specificity of the way or structure of the heating medium circulation pipe 11 for transporting the heating medium. That is: in the device system of this example, the outlet of the heat carrier heater 9 output heat carrier is higher than the inlet of the pyrolysis reaction tower 7 into the heat carrier, the heat carrier circulation pipe 11 connecting the outlet and the import It is inclined, and the angle between the direction of its inclination and the horizontal plane is greater than 45°. That is to say, in this example, it relies on the gravity of the preheated heating medium itself for transportation. In this way, the operating cost of the system is further saved. Obviously, if each specific device itself and the site allow, the angle between the inclination direction of the heating medium circulation pipe 11 and the horizontal plane can be larger, or the heating medium circulation pipe 11...

Embodiment 2

[0038] This example is based on the general description or Example 1, and is aimed at the further specificity of the way or structure in which carrier gas is used to assist the delivery of biomass powder. That is: in the device system of this example, the feeding mechanism includes a screw conveying device 3 and a feed pipe 4 connecting the outlet of the screw conveying device 3 and the inlet of the pyrolysis reaction tower 7 . The screw conveyor 3 is driven by a variable frequency motor 2 . The carrier gas input pipe connected in the feeding mechanism is connected in the feeding pipe 4 in the structural form of an injector. There is also a branch pipe (drawn with dotted line among the accompanying drawings) at the waist of this carrier gas input pipe, and the outlet of this branch pipe is connected in the charging device 1, and sealing cover is arranged on the feeding port of this charging device 1. That is to say, in this example, the opening adjustment of the heating mediu...

Embodiment 3

[0040] This example is basically the same as Example 2, that is, the feeding mechanism still includes a screw conveying device 3 and a feed pipe 4 connecting the outlet of the screw conveying device 3 and the inlet of the pyrolysis reaction tower 7 . The screw conveyor 3 is driven by a variable frequency motor 2 . The carrier gas input pipe connected in the feeding mechanism is connected in the feeding pipe 4 in the structural form of an injector. The difference is that the dynamic pressure of the carrier gas is greater than the static pressure at the inlet of the pyrolysis reaction tower 7, to allow the carrier gas to carry out auxiliary transportation of the biomass powder in the form of entrainment (because the structural form of the injector belongs to those skilled in the art Clearly, so no partially enlarged cross-sectional view is drawn separately). In other words, when the working condition of the whole system allows the dynamic pressure of the carrier gas to be great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com