High-precision tungsten piece preparation method

A high-precision, tungsten sheet technology, applied to other manufacturing equipment/tools, manufacturing tools, heat treatment equipment, etc., can solve the problems of unsatisfactory demand, production of rough and low-end tungsten plates, etc., and achieve improved heating uniformity and heating uniformity Improved and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

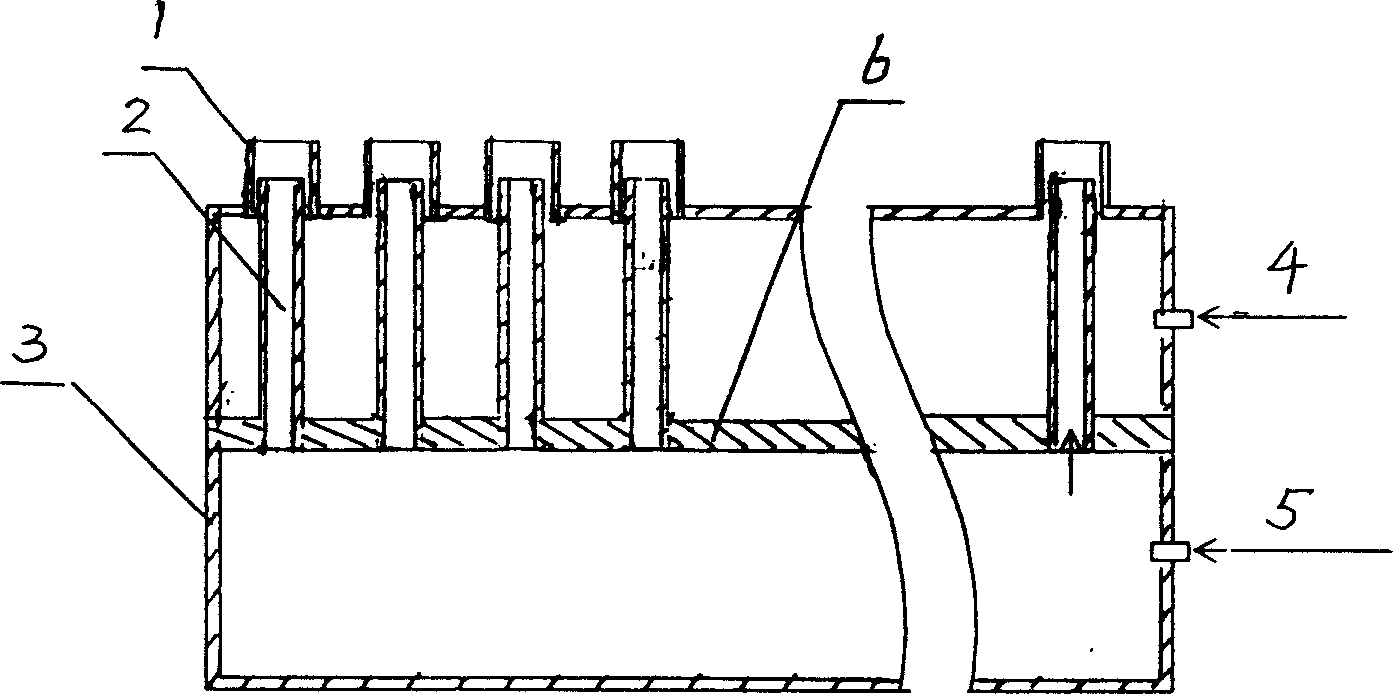

[0013] A method for preparing a high-precision tungsten sheet, including heating, rolling, polishing, and leveling a tungsten blank, characterized in that the tungsten blank is coated with graphite milk with a weight concentration of 15% to 20%, and then The billet is uniformly heated for rolling, and then electropolished and pressure-leveled. The uniform heating of the blank adopts a hydrogen nozzle type heating furnace. The furnace body is a box structure. The box body 3 of the furnace body is divided into upper and lower parts by a horizontal gas separator 6; the side wall of the furnace body under the gas separator There is a compressed air inlet pipe 5 on the top, and a hydrogen inlet pipe 4 on the side wall of the furnace body above the gas baffle; uniformly distributed compressed air injection pipes 2 are vertically fixed on the horizontal partition, and the compressed air pipes pass through the heating furnace vertically The upper box plate of the heating furnace is ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com