Variable air volume heating method with feedback and device thereof

A heating method and variable air volume technology, which is applied to lighting and heating equipment, drying gas arrangement, dryers, etc., can solve problems such as unreasonable air volume supply, large hot air volume, and poor matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

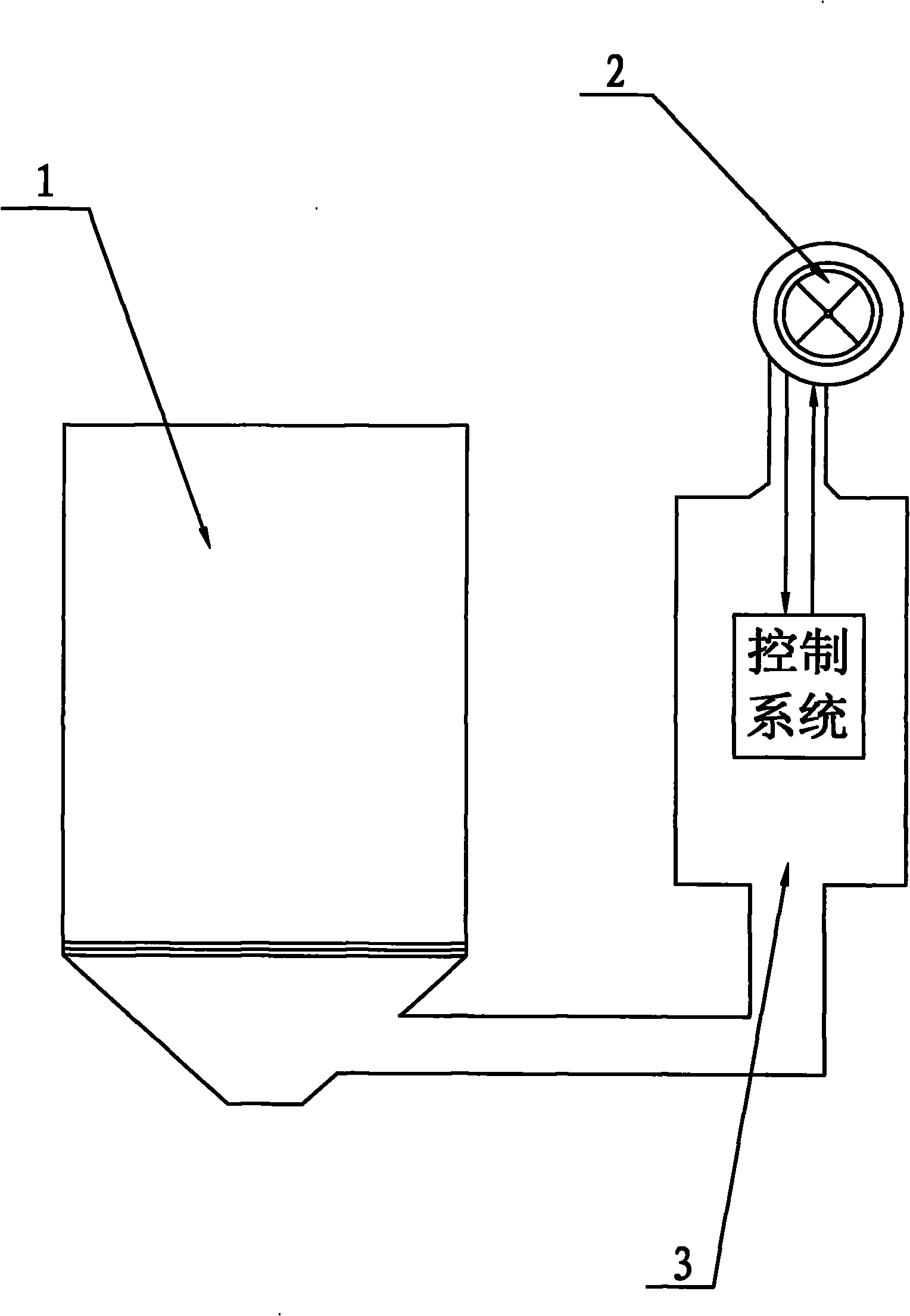

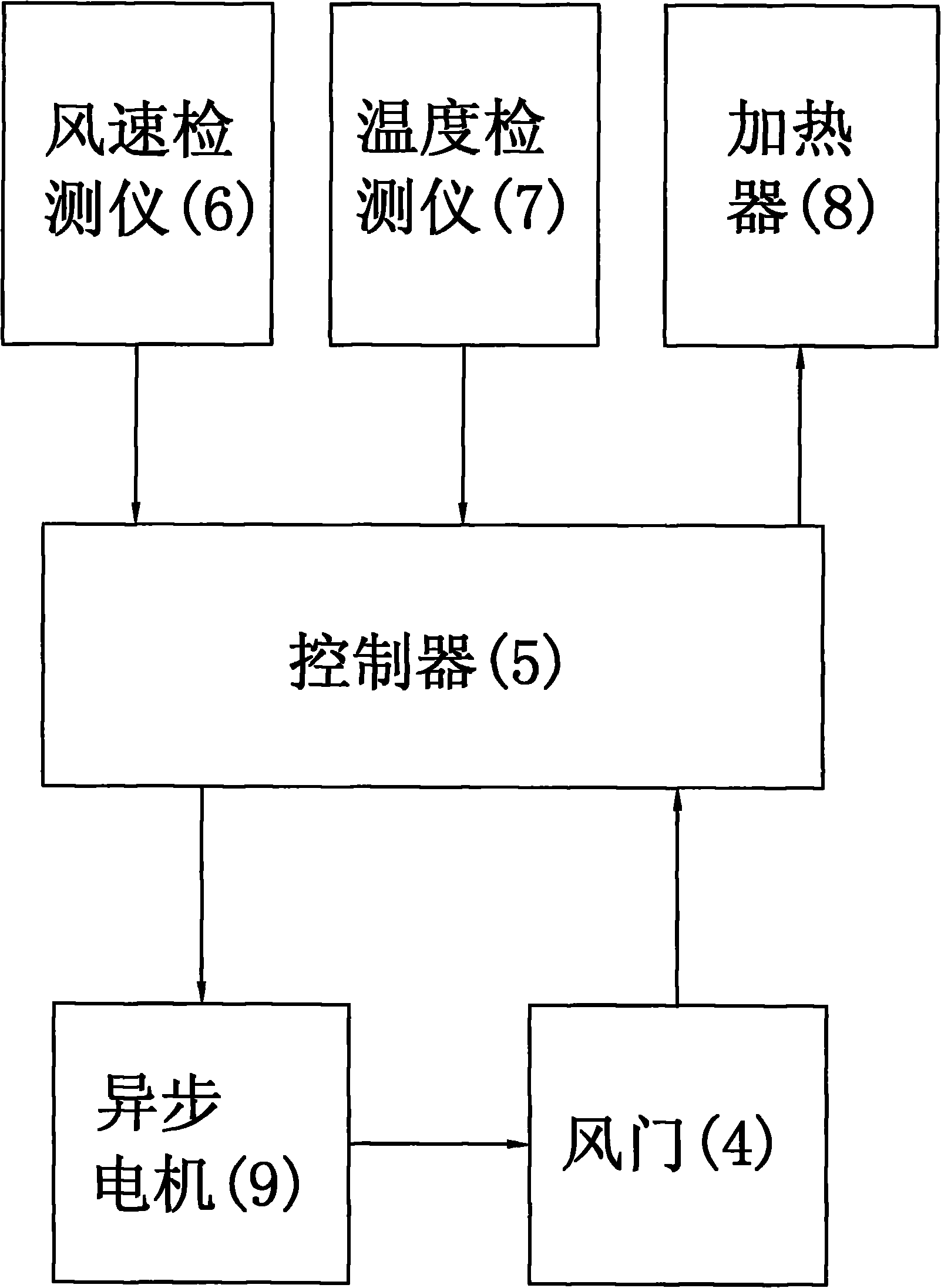

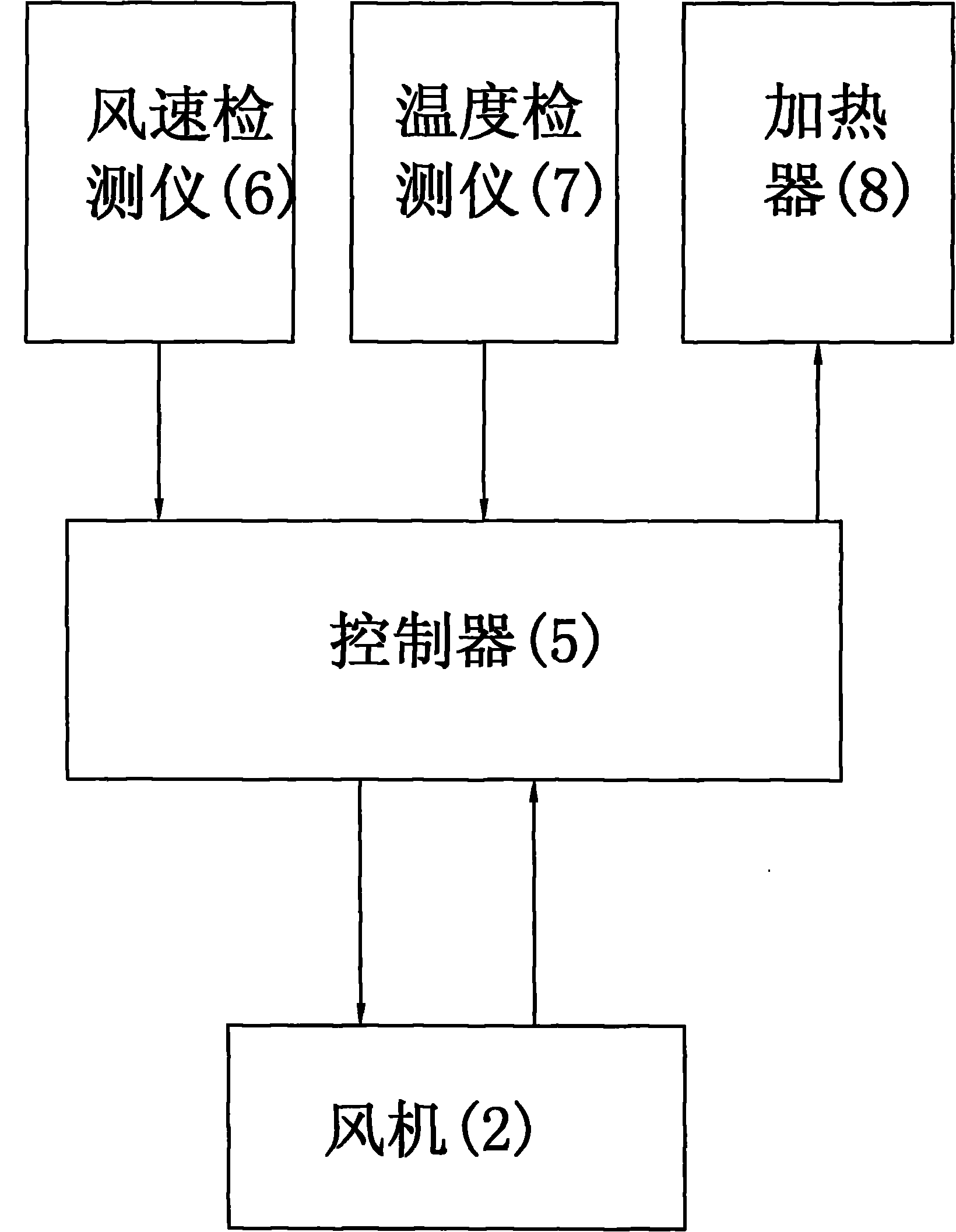

[0021] refer to figure 1 , figure 2 , the present invention is a kind of variable air volume heating method with feedback, is characterized in that, comprises the following steps:

[0022] (1), set the required heating temperature T S and the desired wind speed V S ;

[0023] (2) Detect the actual temperature T in the dryer P and the resulting wind speed V P ;

[0024] (3), respectively compare the required heating temperature T S and the resulting temperature T P , the required wind speed V S and the resulting wind speed V P the size of;

[0025] (4), when the obtained temperature T P Less than the required heating temperature T S When the heat supply is increased, when the resulting temperature T P Not less than the required heating temperature T S When the heat supply is stopped; when the resulting wind speed V P less than the required wind speed V S When the air door opening and / or increase the fan speed; when the obtained wind speed V P equal to the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com