Heavy metal oxide block glass material for up-conversion of white light and method for enhancing illumination intensity of heavy metal oxide block glass material

A technology of heavy metal oxides and glass materials, which is applied in the field of luminescent materials and can solve problems such as the inability to prepare heavy metal oxide glasses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

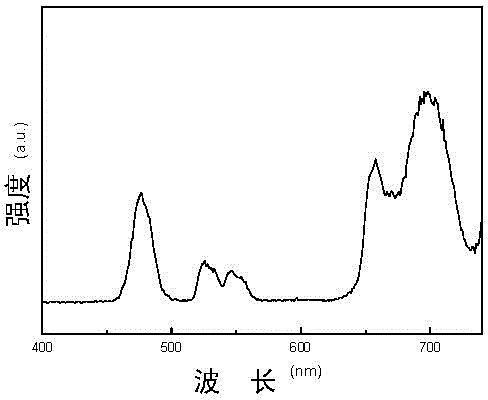

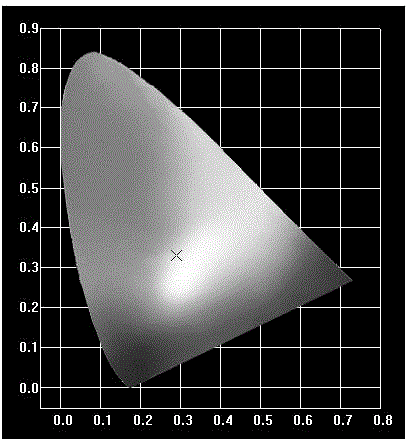

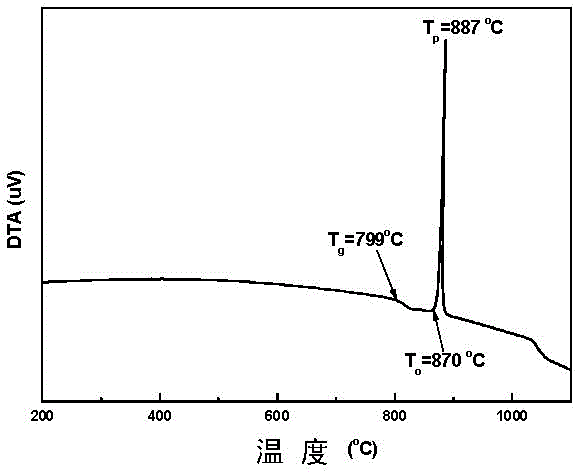

[0046] According to the molecular formula (La 0.757 Er 0.003 T m 0.04 Yb 0.2 )(Zr 0.05 Ti 0.95 ) 2.25 o 6 For batching, weigh six kinds of oxide powders according to the mass ratio, mix them evenly, use alcohol to wet grind twice, then calcinate the mixed powder, the atmosphere is air, cool with the furnace, and then press the powder into a columnar round tablets, the weight of each tablet is 60-80mg, and the pressure is 5-9MPa. Finally, put the wafer into the nozzle of the air-suspension containerless equipment, use laser to melt and solidify the wafer without container, the gas flow is oxygen, and the laser power is 60-90W. After the sample is completely melted into a spherical shape and uniform, quickly Turn off the laser and obtain ellipsoidal or spherical heavy metal oxide glasses. The glass is polished on both sides to obtain a glass disc with a thickness of 1.5 mm, and then the up-conversion fluorescence spectrum of the glass sample is measured under 980 nm cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com