Method for straightening flame of large-deformation automobile drive axle housing

A technology of flame rectification and drive axle housing, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, high cost, limited deformation, etc., achieve simple equipment and measuring tools, and improve reuse rate , The effect of reducing the cost of correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

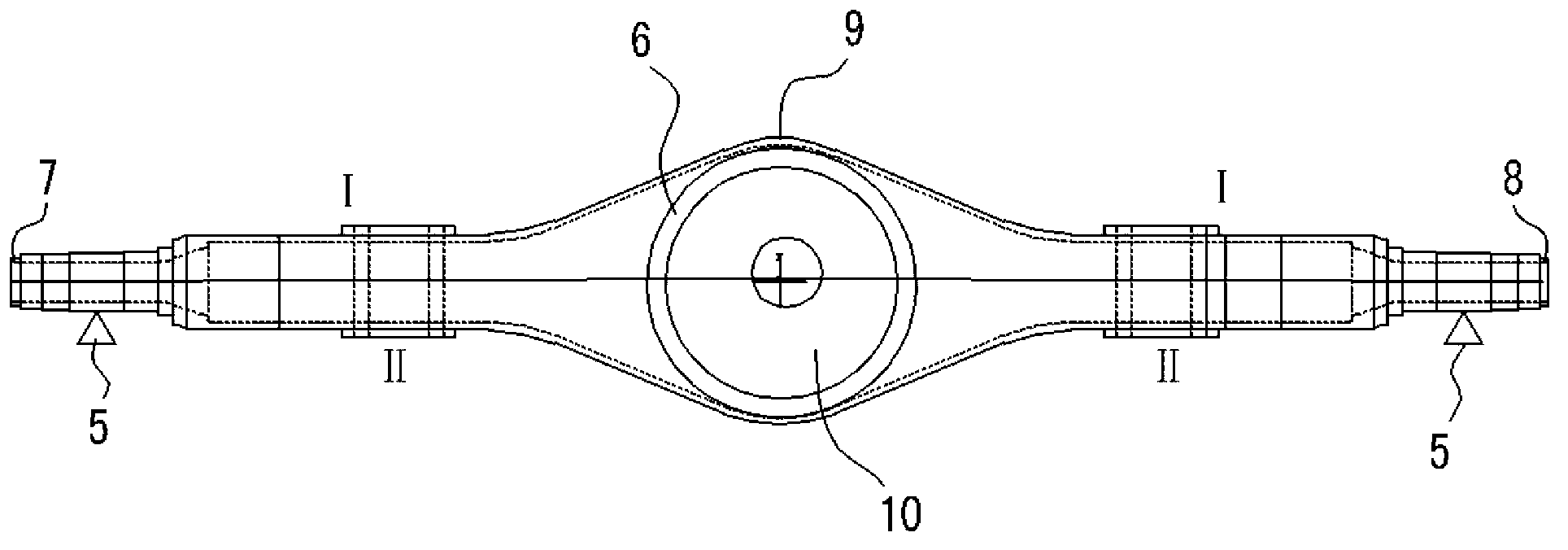

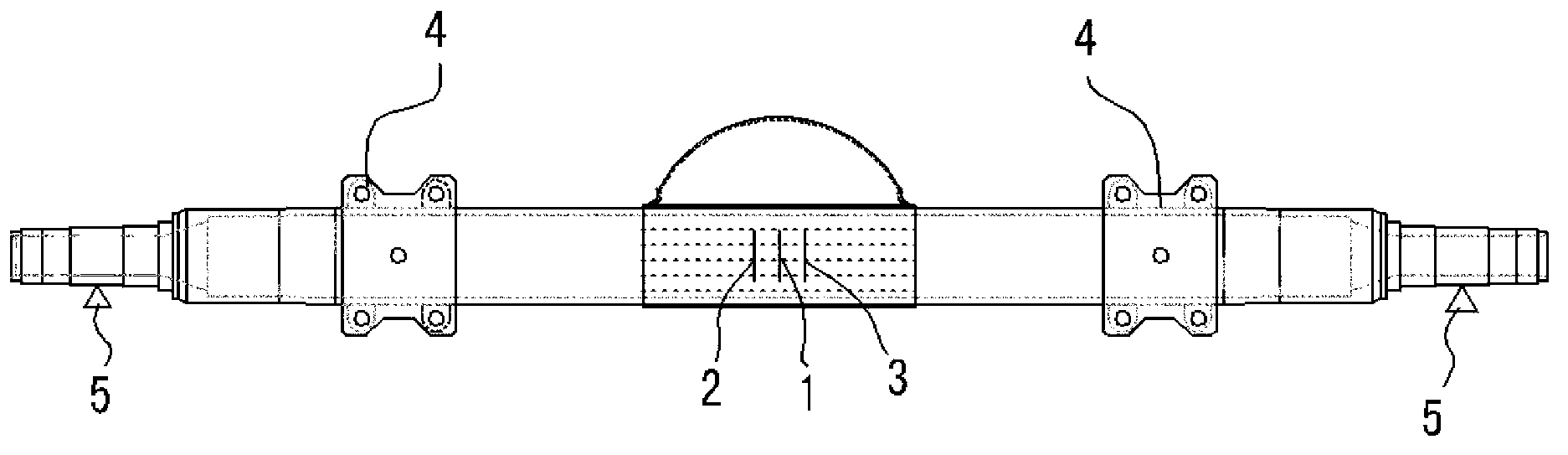

[0027] In the present embodiment, a flame rectification method of a large deformation automobile drive axle housing is carried out according to the following steps:

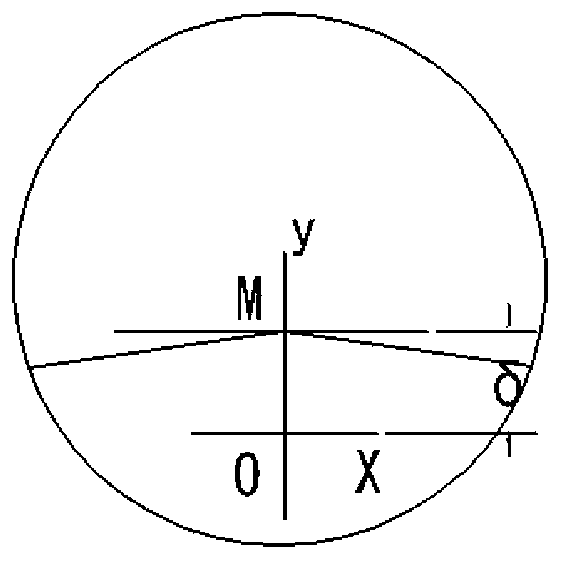

[0028] Step 1: Place the deformed axle housing on the detection platform, measure the distance δ between the center O of the inner circle 6 of the axle housing reinforcement ring and the intersection point M of the centerlines of the two half-shaft casings, and the δ value is the deformation δ value of the axle housing.

[0029] Step 2: Fill the inner cavity of the deformed axle housing with sand with a water content of 4%-8% by weight and a particle size of 0.15mm-1.18mm, and use the inner ring 10 of the reinforcing ring of the deformed axle housing as the main reducer housing The body is sealed, and the left end 7 and the right end 8 of the half-shaft sleeve of the axle housing are sealed with cylindrical wooden plugs respectively; the deformed axle housing is fixed and supported by "V" blocks at the two ends of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com