High-thermal-conductivity silica gel embossing roller and preparation method thereof

An embossing roller, high thermal conductivity technology, applied in the direction of decorative art, embossed decorations, etc., can solve the problems of poor thermal conductivity of embossing rollers, limited development and use, rough appearance texture, etc., to achieve good thermal conductivity and optimize Heating temperature and heating time, and the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

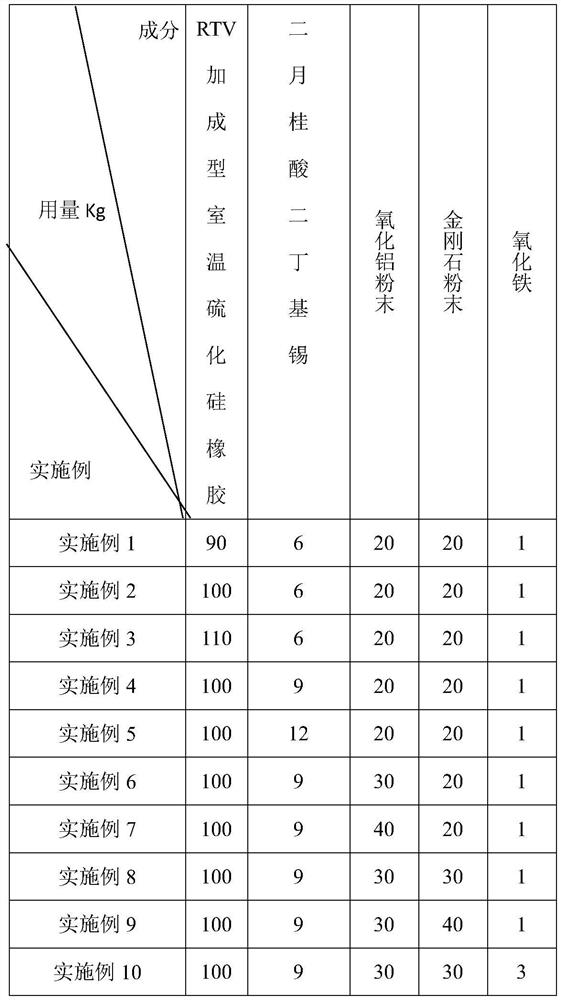

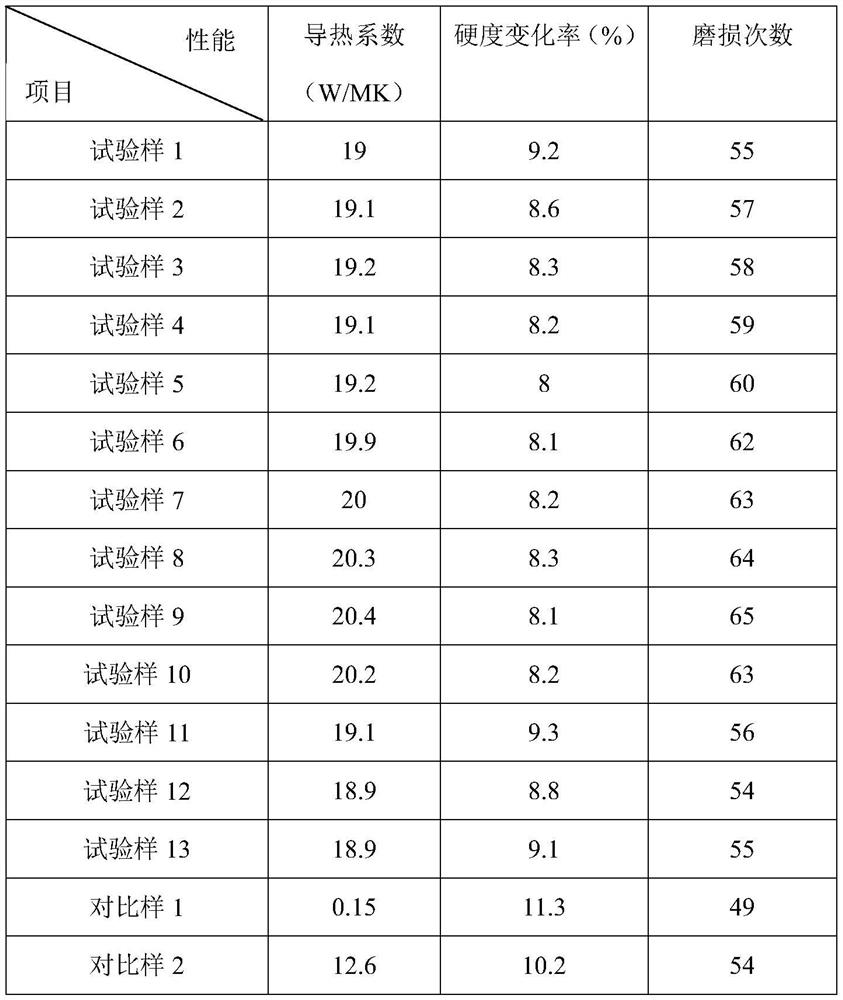

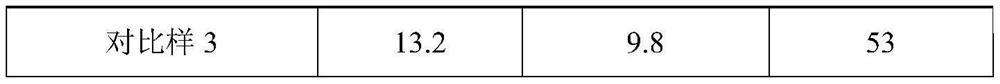

[0040] As shown in Table 1, the main difference between Examples 1-10 is different from the material ratio of the silica gel layer.

[0041] The following explanation is illustrated by Example 1. This example discloses a highly thermally conductive silicon gel roller, which includes a roll core, an adhesive layer, and a silica gel layer bonded together, wherein the roller core is a wall thickness of the surface sandblasting 10 mm. Steel core; the adhesive layer is composed of a single group of compartment temperature, and the thickness is 0.1 mm; the thickness of the silica gel layer is 1 mm, and the silica gel layer is prepared from the following raw materials: RTV addition ventricular temperature vulcanized silicone rubber 100kg, February Tothin 6kg, alumina powder 20kg, diamond powder 20 kg and pigment 1 kg.

[0042] The present embodiment also discloses the preparation method of the above high thermally conductive silica gel compressing roller, and specifically includes the fo...

Embodiment 11

[0049] The present embodiment is substantially the same as that of Example 1, in the case where the thickness of the rigid core is 15 mm, the thickness of the adhesive layer is 0.3 mm, and the thickness of the silica gel is 3 mm.

Embodiment 12

[0051] The present embodiment is substantially the same as that of Example 1, and the difference is that in the raw material composition of the silica gel layer, it is replaced with octoidate dibutyltin with octanoate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com