Non-uniform heating method for alkali metal gas chamber based on finite element analysis

An alkali metal gas chamber and non-uniform heating technology, which is applied in electric furnace heating, lighting and heating equipment, furnace types, etc., can solve problems such as uneven distribution of temperature field, improve the uniformity of temperature field, improve heating efficiency, and optimize Effect of Heating Temperature Conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

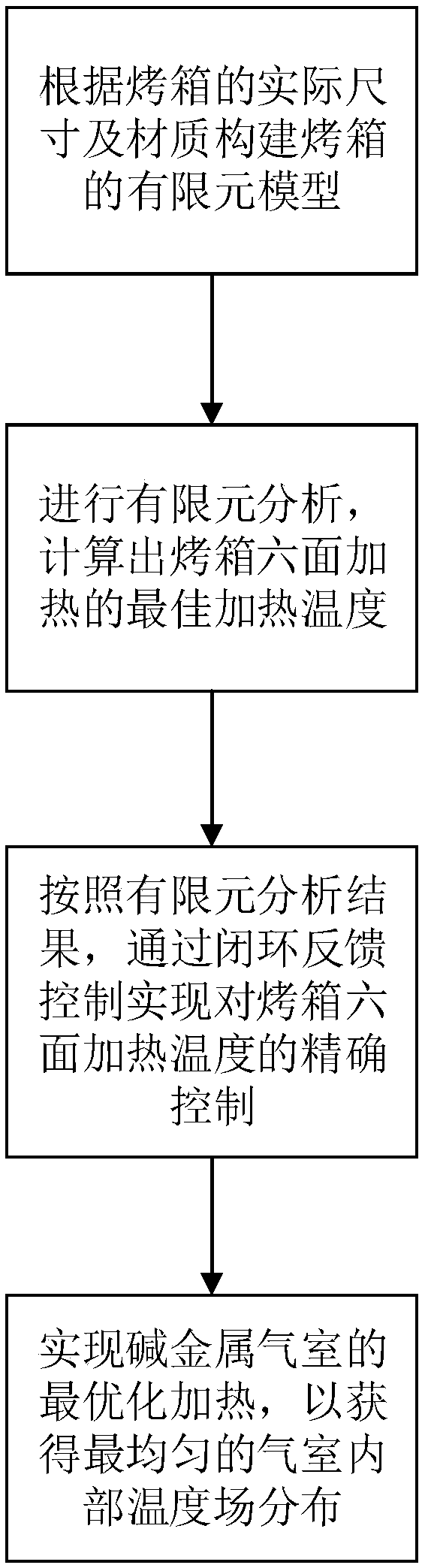

[0028] Such as figure 1 Shown, the specific implementation steps of the present invention are as follows:

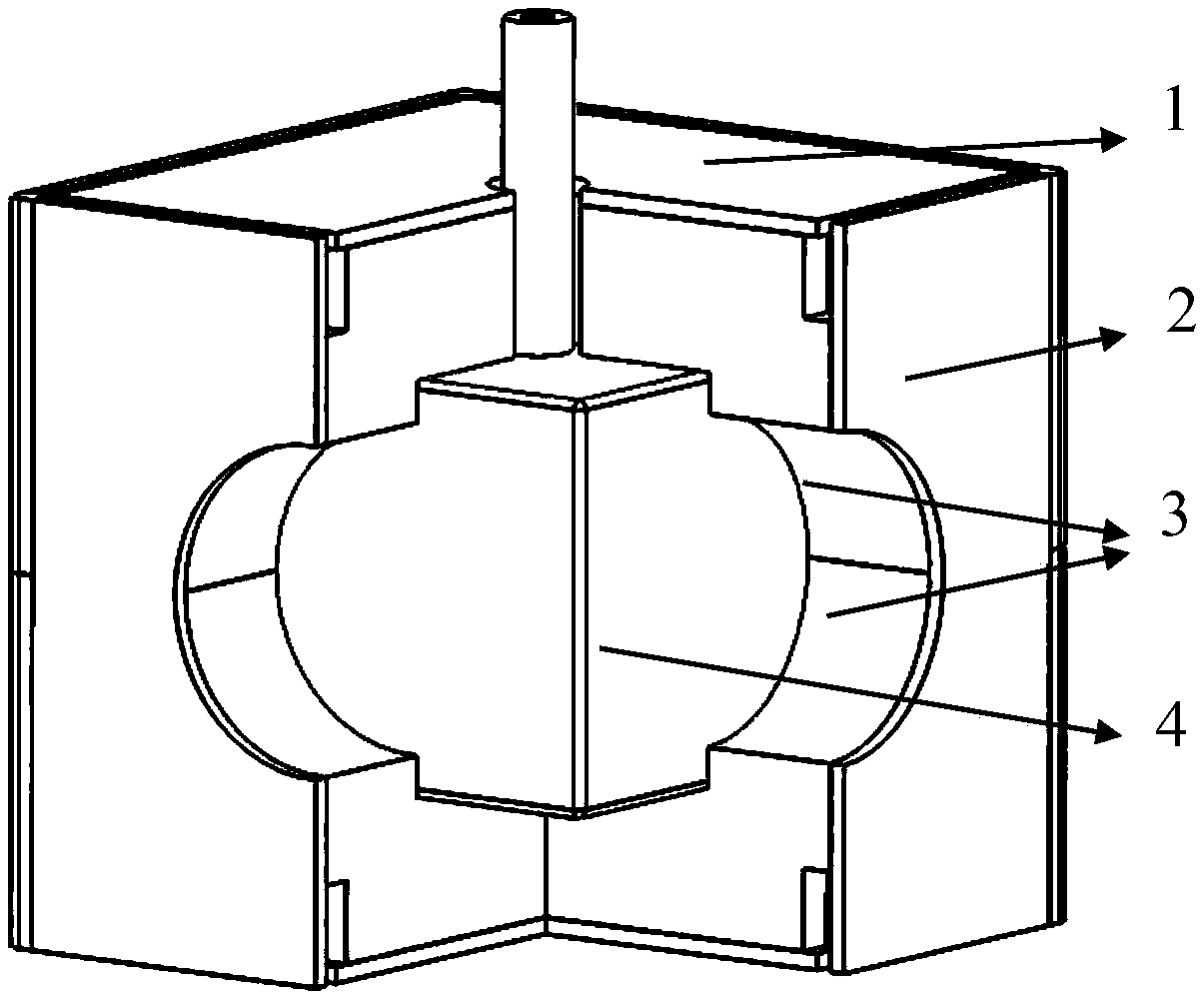

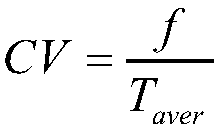

[0029] (1) figure 2 It is a typical alkali metal gas chamber heating structure, its four side structures are similar to a symmetrical structure, and the bottom and upper surface structures are different and asymmetrical. First, according to the actual conditions of the alkali metal gas chamber 4 and its external heating ceramics 3 Build the physical model for its analysis; import the constructed physical model into the finite element analysis software, and determine their respective thermal conductivity and convection according to the material of the alkali metal gas chamber 4, the type of gas inflated in the gas chamber, and the material of the heating ceramic 3 According to these parameters, the thermodynamic parameters of the finite elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com