Method for preparing metal mask resistant to corrosion of hydrofluoric acid corrosive liquid

A metal mask and corrosion solution technology, which is applied in the field of anti-corrosion metal mask preparation, can solve the problems of local warping, mask corrosion drilling holes, peeling, etc., to improve adhesion, reduce pinhole drilling, Enhance the effect of mechanical locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

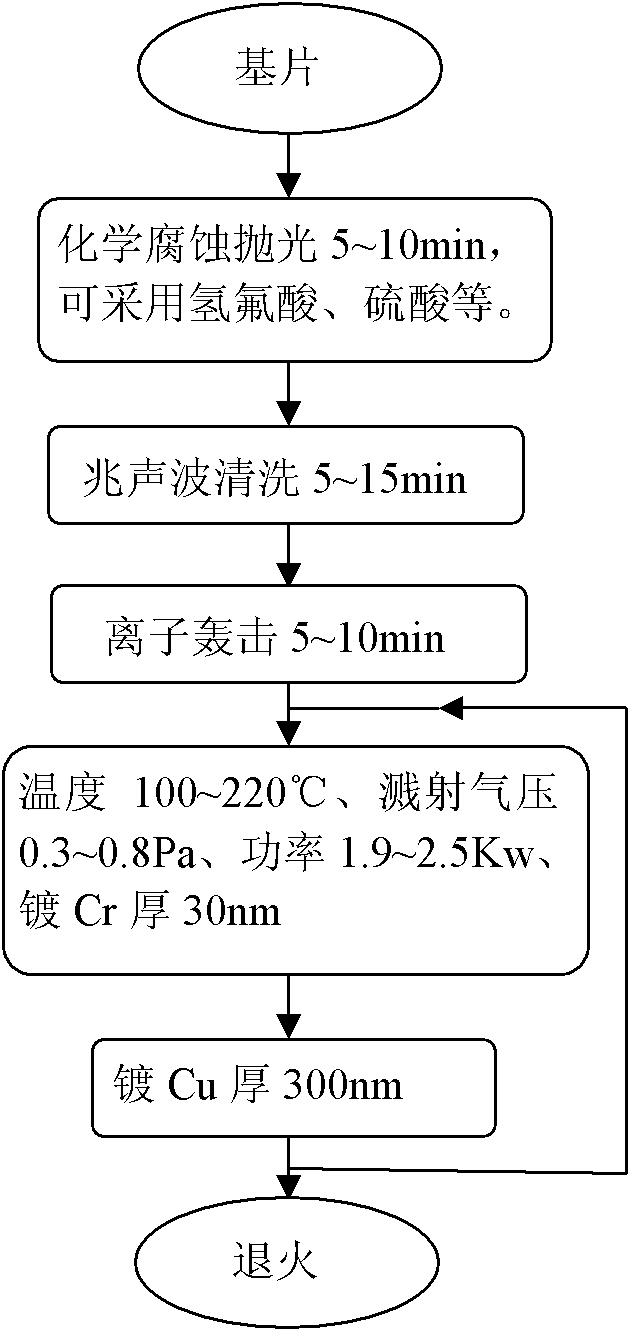

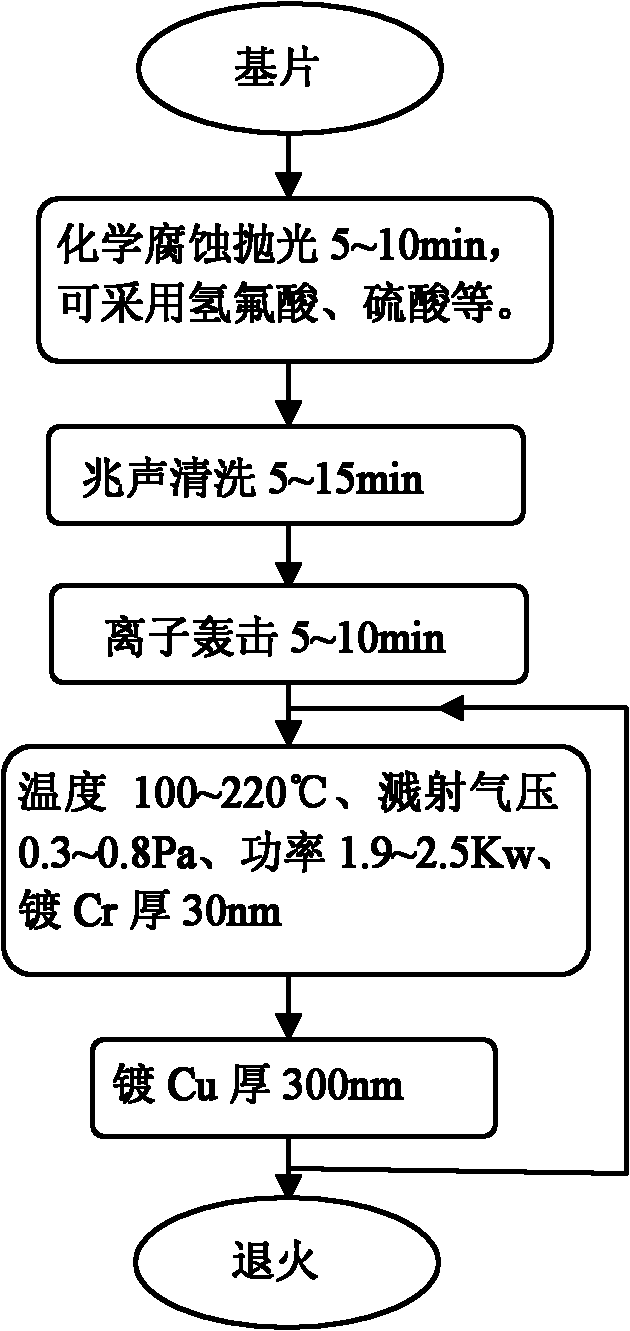

[0035] Processing flow such as figure 1 Shown:

[0036] a. Cleaning: Use hydrofluoric acid hydrogen peroxide mixed solution to corrode and soak the quartz crystal at 60-120°C for 5-10 minutes, then use megasonic cleaning for 5-15 minutes.

[0037] b. Coating: (1) Place the cleaned quartz substrate in a magnetron coating machine, firstly bombard the surface of the substrate with Ar ions for 5-10 minutes, and the ion bombardment power is 70-90w; (2) at a temperature of 100- Under the conditions of 220°C, sputtering pressure of 0.3-0.8Pa, and sputtering power of 1.9-2.5Kw, the surface of the substrate is sequentially plated with a Cr film with a thickness of 30nm and a Cu film with a thickness of 300nm; (3) Repeat step (2) again on the substrate The surface is plated with a Cr film with a thickness of 30nm and a Cu film with a thickness of 300nm to form a double-layer Cr / Cu metal mask. It can also be repeated for more layers of metal masking as needed. The thickness of the fil...

Embodiment 2

[0040] a. Cleaning: put sulfuric acid into the hydrogen peroxide mixture, soak and corrode the 7740 glass substrate at 80-120°C for about 8-10 minutes, then use megasonic cleaning for 5-10 minutes.

[0041] b. Coating: (1) Place the cleaned glass substrate in a magnetron coating machine, and first bombard the surface of the glass substrate with Ar ions for 5-7 minutes, with ion bombardment power of 70-80w; (2) at 100- Under the conditions of 150°C, 0.4-0.8Pa, and 1.9-2.3Kw power conditions, the surface of the substrate is sequentially plated with a Cr film with a thickness of 30nm and a Pt film with a thickness of 300nm; A Cr film and a 300nm Pt film form a double-layer Cr / Pt metal mask.

[0042] c. After naturally cooling to room temperature, take out the substrate and place it in a vacuum annealing furnace for annealing.

Embodiment 3

[0044] a. Cleaning: use sulfuric acid and hydrogen peroxide mixture to soak and corrode the 7740 glass substrate at 100-120°C for 5-7 minutes, then use megasonic cleaning for 5-8 minutes.

[0045]b. Coating: (1) Place the cleaned glass substrate in a magnetron coating machine, and first bombard the surface of the substrate with Ar ions for 5-6 minutes, with ion bombardment power of 70-80w; (2) at 120-150 Under the conditions of ℃, 0.6~0.8Pa, 1.9~2.2Kw power conditions, the surface of the substrate is successively plated with a Cr film with a thickness of 30nm and an Au film with a thickness of 300nm; (3) Repeat step (2) to plate a Cr film with a thickness of 30nm on the substrate surface film and a 300nm Au film to form a double-layer Cr / Au metal mask.

[0046] c. After naturally cooling to room temperature, take out the substrate and place it in a vacuum annealing furnace for annealing.

[0047] The method adopts cleaning measures to remove the surface processing metamorphic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com